Discrete manufacturing software helps manufacturers manage supply chains, track inventory, and automate scheduling processes. Using our in-depth review methodology, we’ve put together our best picks for discrete manufacturing software:

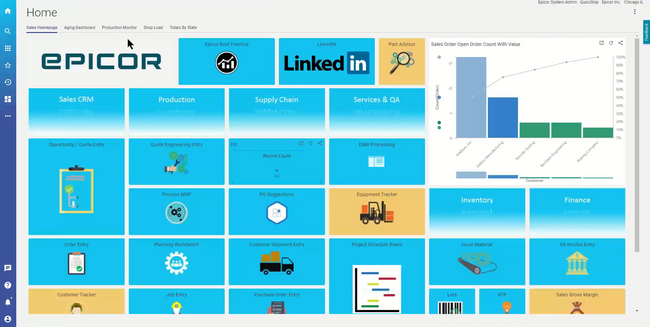

1 Epicor Kinetic - Best Overall

Why We Chose It: Epicor Kinetic is a single, end-to-end software solution for manufacturing businesses. The Kinetic platform is available on-premise or through cloud hosting, each offering a modular approach. Choose from a wide selection of automation capabilities focused on reducing costs, streamlining processes, and improving responsiveness across your business.

One of the key strengths of Epicor Kinetic is its deep functionality in discrete manufacturing, which is complemented by a sophisticated product configurator. This is ideal for businesses dealing with custom or complex products. It also supports order management and financial processes, including general ledger and configurable accounting, which are essential for any manufacturing enterprise.

Read our full Epicor Kinetic review.

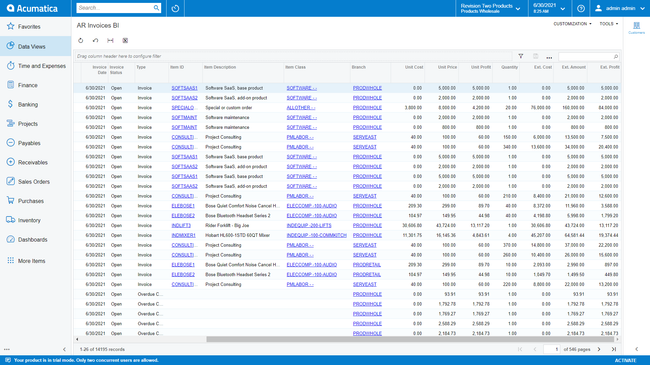

2 Acumatica Cloud ERP - Best Cloud-Based ERP

Why We Chose It: Acumatica Cloud ERP utilizes leading-edge technology, best-in-class business functionality, and customer-friendly business practices to deliver unparalleled value to small and midmarket manufacturing organizations.

A series of integrated workflows span the full suite of business management applications, from financials, project accounting, and inventory management to CRM. The specialized Manufacturing Edition includes bill of material, MP, APS, estimates, and more. Acumatica is built on a future-proof platform for scalability, ease of use, and rapid integrations.

Read our full Acumatica review.

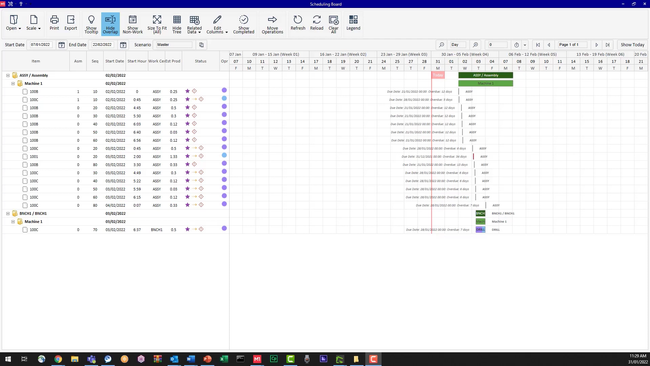

3 ECI M1 - Best Mid-Market Option

Why We Chose It: ECI M1 is an enterprise resource planning (ERP) solution made for manufacturers. This software is capable of integrating and automating jobs ranging from basic quoting all the way through to final invoicing. A business system designed for small-to-medium manufacturers, M1 serves job shops, custom, mixed-mode, and make-to-order manufacturers.

After our review, we determined ECI M1’s main strength lies in its multi-warehouse inventory control, scheduling, and detailed cost and labor tracking modules, which are efficient and beneficial for managing complex manufacturing processes.

Read our full ECI M1 review.

4 Oracle Manufacturing Cloud - Best Enterprise Option

Why We Chose It: Oracle Manufacturing Cloud excels as the top-tier solution for large enterprises due to its automated, insightful, and seamlessly connected platform. This software stands out for its analytics and reporting tools, designed for large-scale manufacturers. As organizations scale, they can count on Oracle’s reputation for handling complex workflows and vast amounts of data with ease.

This competence, combined with a cloud-hosted deployment, means teams across global units can access essential data in real time, ensuring efficient communication and operation. Catering to both large enterprises and organizations with intricate manufacturing processes, Oracle Manufacturing Cloud is an invaluable tool.

5 Striven - Best Integrated System

Why We Chose It: Striven offers an array of features including accounting, CRM, project management, HR, and inventory management, all integrated into a single cloud-based platform. During our review, we found Striven’s user interface, while feature-rich, maintains user-friendliness, though still requires a slight learning curve due to its complexity. An open API and integration options facilitate improved productivity and collaboration, a key benefit for manufacturers transitioning from simpler systems like Excel spreadsheets.

In terms of pricing, Striven offers a reasonable structure, starting at $35 per user per month for the Standard plan and $70 per user per month for the Enterprise plan. For businesses in the discrete manufacturing sector, especially those small to medium-sized and transitioning from simpler systems, Striven offers a cost-effective, customizable, and comprehensive ERP solution.

Read our full Striven review.

6 MRPeasy - Best for Small Businesses

Why We Chose It: MRPeasy appeals to start-ups and small to medium enterprises due to its intuitive interface. The software ensures quick adoption even for businesses unfamiliar with advanced ERP systems. The user-centric design ensures rapid deployment and immediate productivity benefits.

With competitive pricing, it provides an accessible entry point for smaller businesses wanting to ditch spreadsheets and upgrade to a more structured system.

7 xTuple ERP - Best Open Source Solution

Why We Chose It: xTuple ERP is an open-source solution that allows for extensive customization and development by users, catering to those who wish to tailor their ERP to fit their specific needs perfectly.

The ability to modify and improve upon the existing system means businesses can mold xTuple ERP to address their unique challenges, ensuring an optimal fit. Plus, with its integrated design that connects various systems into one platform, it serves as a robust tool for holistic business management.

Read our full xTuple review.

8 Aptean Industrial Manufacturing ERP - Best for Enterprises

Why We Chose It: Aptean Industrial Manufacturing ERP is tailored for mid to enterprise-level discrete production operations, including job shops and mixed-mode manufacturers. We found it stands out for its in-depth functionality and adaptability, catering to diverse engineering requirements, product configurations, and the need for comprehensive inventory and production management.

The main strengths of Aptean are its multi-warehouse support, customizable reporting, and product configurator and scheduling features. These functionalities are crucial for businesses needing precise and efficient control over their manufacturing processes. The software is particularly praised for its fully integrated nature, significantly improving job function integration and inventory management. The inventory management modules, in particular, offer immediate benefits through real-time reports and controls.

What is Discrete Manufacturing Software?

Discrete manufacturing software streamlines the manufacturing process by managing supply chains, reducing waste with lean manufacturing techniques, tracking inventory in real-time, and better scheduling production runs. It integrates various aspects of the manufacturing process, like inventory management, supply chain operations, order processing, and production scheduling, into one platform. This software often incorporates features for quality control, product lifecycle management, and detailed reporting.

Many companies find a full manufacturing ERP system works best for managing these business processes, while some smaller businesses get by with solutions that can be integrated with existing accounting systems. Yet there are times when having a dedicated software to manage the complexities of discrete manufacturing is necessary. Companies with automated shop floors should consider discrete manufacturing software with manufacturing execution system (MES) capabilities.

Discrete vs. Process Manufacturing: What’s the Difference

- Discrete manufacturing is the production and assembly of distinct individual products that can be counted. The individual units are often made up of a number of parts and components to be assembled or even created by the manufacturer. The manufacturers use a bill of materials for instructions on product assembly. Different types of discrete manufacturing include made-to-order, engineer-to-order, and made-to-stock. Industries like job shops, apparel and textile manufacturers, and medical device manufacturers use discrete manufacturing.

- Process manufacturing uses recipes and formulas to create products that can be packaged as individual units. The final product usually cannot be broken back down to the original ingredients, because irreversible chemical reactions occur during manufacturing. Industries including food and beverage, chemical, and pharmaceutical use process manufacturing. Check out our list of the best process manufacturing software if that’s what you need.

Discrete Manufacturing Software Functionality

| Feature | Functionality |

|---|---|

| MRP | Streamline the manufacturing process with production planning, inventory control, scheduling, material requirement calculation, labor/machine workload coordination, and purchase planning. |

| Manufacturing Inventory Management | Track current stock levels of products and purchased materials. |

| Bill of Material | Provide instructions on required materials and assemblies to manufacture a product. |

| Work Order Management | Outline work that has to be completed and provides instructions on how the work needs to be done. Includes scheduling management, rules-based approval management, change orders, and reporting. |

| Job Costing | Assign costs to materials, labor, and equipment needed to manufacture a product to improve cost control and profitability. |

| Manufacturing Accounting | Handle budgeting, financial reporting, and tracking expenses, accounts payable, and accounts receivable. |

| Supply Chain Management | Coordinate raw materials, vendors, purchase orders, warehouse management, and distribution. |

| MES | Streamline manufacturing operations with shop-floor control, master production scheduling, order prioritization, traceability, workload projections, rules-based routing, and job tracking. |

| Production Planning and Scheduling | Calculate estimates of the material and labor inputs you need to manufacture a product. Usually used for make-to-order, custom products, as well as large amounts of limited runs of products. |

| Quality Control | Reduce the risk of defects and improve customer satisfaction with features including risk analysis, workflow management, monitoring and reporting, compliance control, parts non-conformance, corrective action management, quality objectives, and approval management. |

Best Discrete Manufacturing Software Benefits

Choosing the right discrete manufacturing software can shorten order cycles and improve operational efficiency to make your business run smoothly, along with other benefits:

- Improved communication with enterprise-wide visibility. Integrated discrete manufacturing software gives you and your staff the ability to see everything from back-office to manufacturing floor operations. You can synchronize manufacturing controls with sales and purchasing, so you can plan production runs, order the right amount of inventory, and meet delivery dates.

- Reduced order fulfillment errors. Discrete manufacturing software keeps you organized with features including a bill of materials, production planning and scheduling, supply chain management, work order management, and inventory management. You’ll have detailed records of current stock levels, materials you have on hand, information on materials needed to complete a project, and any other critical information you need to ensure products are made correctly and finished on time.

- Improved delivery cycle times. Production planning and scheduling through discrete manufacturing software tracks production deadlines and automates reporting on your current projects. You’ll have insight into whether or not a project is running behind, so you can make corrections to avoid delays.

- Lowered order processing and delivery costs. Improved warehouse management and logistics from discrete manufacturing software save you money on order processing and delivery costs.

- Reduced machine downtime with preventative maintenance. Some discrete manufacturing software solutions have preventative maintenance scheduling capabilities, so you know when to perform critical maintenance work on your machinery. Keeping up-to-date on preventative maintenance will reduce machine downtime and prevent unexpected issues from arising.

- ** Remain compliant with regulations.** Ensure your raw materials and products meet the requirements for conflict minerals legislation, Restriction of Hazardous Substances (RoHS), and Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH).

- Anticipate customer demand. Supply chain management modules include demand planning, so you can use data from things like social media, your warehouse, and even the weather to get a sense of what customers might be ordering in the future.

What Does Your Business Need?

- Small to medium-sized discrete manufacturing businesses. Small to midsize discrete manufacturers should look for software that offers supply chain management to keep track of raw materials, vendors, and purchase orders. You should seek a module-based solution to add functionalities as you grow to include features like customer relationship management (CRM). The discrete manufacturing software solution needs to easily integrate if you’re planning to keep an existing system like QuickBooks (see below).

- Large discrete manufacturing businesses. Large enterprise discrete manufacturing companies should look for a customizable discrete manufacturing ERP system that features MES and MRP to improve workflow management, quality management, and production planning.

Trends In Discrete Manufacturing Software

- Lean manufacturing. More discrete manufacturing ERP software solutions have been adding lean manufacturing features to help businesses cut down on wasted time and resources. The thought is that these lean manufacturing functionalities will implement a more lean manufacturing philosophy to the company which is to reduce waste without sacrificing productivity. These functionalities include real-time ordering of low-stock materials and workflow management.

- Decreased labor force. According to an Advanced Technology Services article “Top 10 Manufacturing Trends for 20249”, it’s critical for manufacturers to “identify ways to increase efficiency and support the workforce.”

- Technology use and the Internet of Things (IoT). More manufacturers are investing in specialized technology to grow their business and get ahead of the competition. According to a Markets and Markets report, the manufacturing market is expected to reach $87.9 billion by 2027.

- Cloud software. Cloud4C study found supply chain executives are reconsidering the importance of cloud-based software after the pandemic, more than any other industry. Cloud software is popular among discrete manufacturers due to the ability to see real-time data from any computer or mobile device, allowing engineers, technicians, and staff to see important orders and customer information from anywhere.

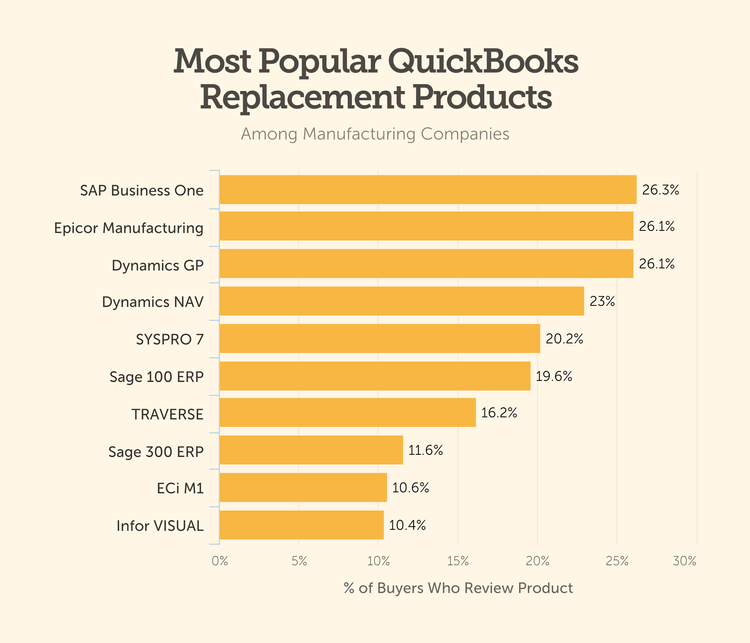

Can QuickBooks be Used as Discrete Manufacturing Software?

QuickBooks Enterprise, one of the most popular accounting software products on the market, is used by some small discrete manufacturers to manage basic inventory, sales orders, and purchasing. However, can it be used as a discrete manufacturing solution? It depends.

Some third-party add-on software solutions are designed for small to medium-sized manufacturing companies. For example, Acctivate is a system designed for growing small to mid-sized discrete manufacturers that features a bill of materials for made-to-stock and made-to-order products, workflow management, barcoding, traceability, order fulfillment, and mobile warehouse management.

Medium and large businesses often outgrow QuickBooks. Some of the functionalities QuickBooks can’t handle (either at all or efficiently enough) include material requirements planning, engineering, production management, and equipment maintenance scheduling.