Maintenance Connection

1 Review 5/5 ★ ★ ★ ★ ★A CMMS and EAM software that helps manage work orders, track assets, and schedule preventive maintenance tasks.

Product Overview

Maintenance Connection is a cloud-based Computerized Maintenance Management System (CMMS) that offers extensive functionality for managing the lifecycle of a company’s assets. It includes work order management, asset management, preventive/predictive maintenance, inventory management, and calibration management. The software is designed to enhance preventative maintenance and improve uptime to increases productivity and reduce stock outs.

Maintenance Connection’s inventory management capabilities include features like barcode generation and stock level notifications. The software also has over 150 prebuilt reports and customization options.

Pros

- Plans include automatic monthly software upgrades

- Offers a wide variety of customizations

- Forms Manager allows hiding fields, designating required fields, etc. in each module

Cons

- Mobile app is not as comprehensive as desktop version

- Customizing menus may require vendor assistance

- Potentially high costs for very large organizations

Target Market

Medium to large-sized companies with work environments where managing a large volume of assets and work orders is critical.Video Overview

Key Features

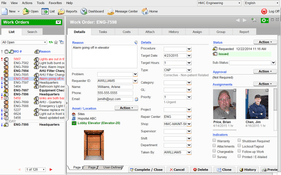

- Work order tracking

- Preventive maintenance

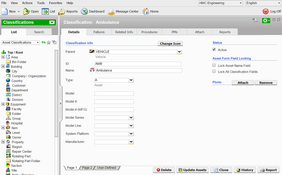

- Asset management

- Asset tracking

- Built-in maintenance procedure libraries

- Inventory management

- Purchasing

- Maintenance scheduling

- Service requests

- Report writer

Dashboard

The Dashboard gives users an overview of how the organization is running by showing KPIs such as backlog hours, mean time between failures (MTTR), and response times. The dashboard also allows users to quickly view reports that have been previously defined in the report writer.

Regulatory Compliance

Helps companies comply with regulations like FDA 21 CFR Part 11 and ISO 27001 with features like:

- Automatic audit trail logs

- Procedure verification

- Digital signatures

- Employee records

Pricing Details

For cloud-based deployment:

- Professional Plan: Starts at $110/user/year with a minimum of 3 users, or $1,325/user/year.

- Mobile Add-on: $58/user/month, or $700/year

- Enterprise Plan: Requires custom quote

On-premise deployment of the Professional plan is $216 per month per named user, and the native app is $86 per month. Paying annually results in a price of $2,600 per year, and the app is $1,040 per year.

Product Overview

Developer Overview

Related Products

User Reviews of Maintenance Connection

Write a ReviewWe became completely paperless

We are the waste water department and have 130,000+ assets that includes all linear assets and manholes and things like that. We have 150-200 employees and we do 1,000 work orders a day. We have a lot of crews out there in the streets.

We’ve been using Maintenance Connection since 2007. Before that we were using Hyper PM and paper. It was a very paper based system.

We took the process and looked at it and thought “how can we follow the approvals how can we follow tha tasks list and manage items in our warehouse?”

We became completely paperless. We can pick parts we want to order, it goes to the management for approval, goes to the warehouse to let them know it’s ready and needs to be fulfilled via the message center and notifications. It notifies management once it’s been shipped and it’s all electronic.