The Best CMMS Software

We’ve tested the most popular CMMS solutions for all business needs, whether you’re looking to optimize machine maintenance for manufacturing or simply need an affordable work order management system.

- Integrates easily with its Fluke sensors

- Offers real-time condition monitoring

- Alerts for potential machine breakdowns

- Audit-ready document storage

- Safety checklists

- Detailed maintenance reports

- Interactive floor mapping

- Space management

- Accurate inventory stock locations

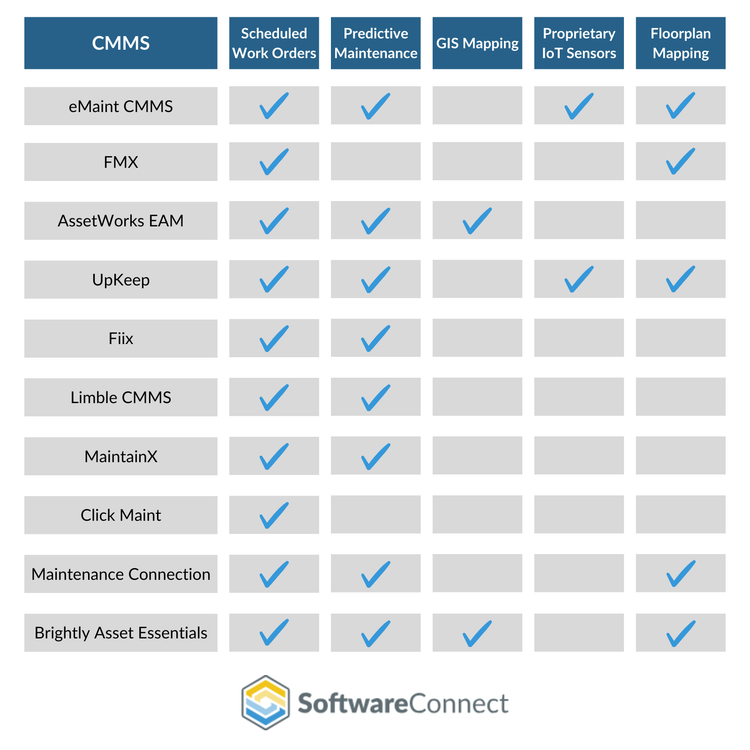

In this guide, we’ve ranked the top CMMS software based on their support of different industries, such as manufacturing and public utilities, and features like mobile and on-premise deployment.

Whether you need a simple free CMMS program for streamlined work order management or an enterprise solution for multi-site asset tracking, these systems have their own strengths to fit your business needs.

- eMaint: Best Sensor Integration

- FMX: Best for Facility Management

- UpKeep: Best for Manufacturing

- Brightly Asset Essentials: Best for Public Utilities

- Fiix: Best AI-Driven Predictive Analytics

- MaintainX and Click Maint: Most Affordable

- AssetWorks EAM: Best EAM System

- Limble CMMS: Best Mobile CMMS

- Maintenance Connection: Best On-Premise Option

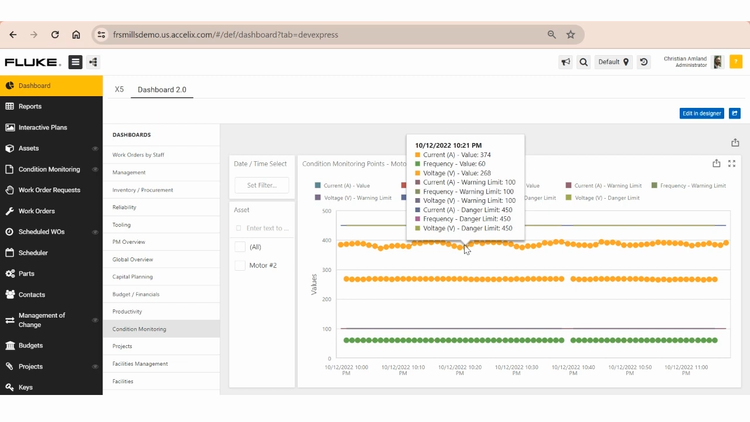

eMaint - Best Sensor Integration

eMaint CMMS easily integrates with its own proprietary Fluke sensors for advanced machine monitoring. Manufacturers that need sensor monitoring can drastically reduce their setup process with eMaint because it already has built-in support for a large range of their Fluke sensors. Because of this, it doesn’t require as many custom integrations as using third-party sensors would.

The Fluke sensors detect machine conditions by monitoring metrics such as voltage, temperature, and vibration. Data is sent straight from the sensor to your eMaint dashboard and plotted into graphs for quick analysis. You can even hover over the data points for individual values and danger limits for different conditions.

Through these sensors, you can identify acceptable thresholds for your assets and create limits to how high or low metrics can fluctuate. The system lets you set alarms when the data passes these limits and indicates a possible failure. This triggers an eMaint work order that allows you to respond quickly to the problem and prevent further damage.

eMaint’s condition monitoring module is available in its Professional plan, which starts at $85/user/month for three or more users. The plan comes with several other advanced features, including interactive image mapping and automated workflows. Because of this, eMaint is a great option for mid to large companies in manufacturing, oil and energy, and even healthcare.

Read our full eMaint review to learn more.

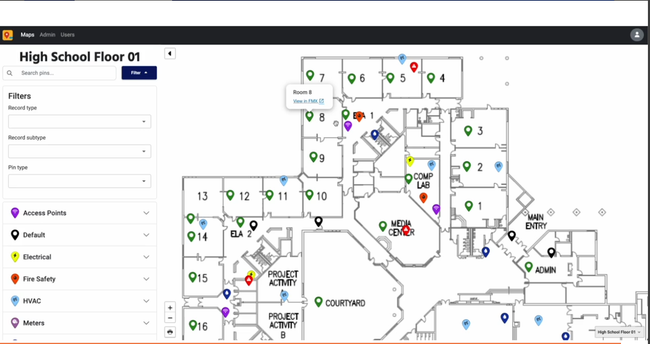

FMX - Best for Facility Management

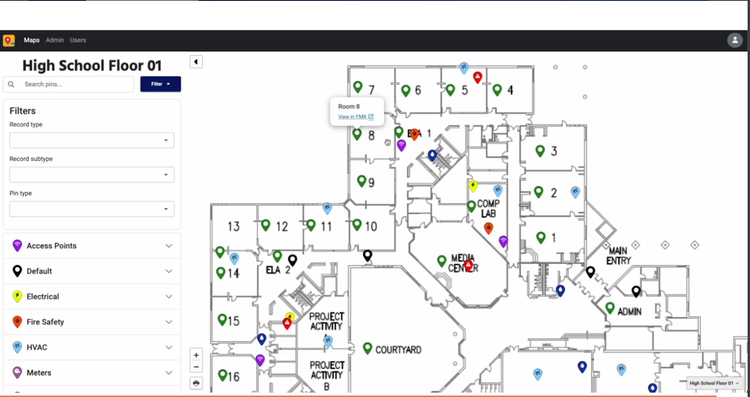

FMX offers an interactive mapping tool that helps you record the physical location of your equipment, resources, utilities, and inventory for each facility. Users can upload floor plans for accurate mapping to ensure fixed assets are properly documented. You can even drill down to specific high-value equipment, like HVAC or electrical, to help specialized technicians view only what they need. Because it’s synced with FMX’s work order and preventive maintenance modules, each asset includes links to documentation and maintenance notes.

The interactive mapping tool also lets you categorize different inventory types. Each grouping can be plotted on the map and searched to show accurate stock locations. This helps employees efficiently find spare parts or general supplies in a warehouse or supply room. The pins can easily be dragged and dropped when inventory is moved, which updates in real-time.

Another plus is the space management feature, especially for education and government facilities. Energy usage data can be integrated into the floor plans to visualize consumption across different sections of the building. This can help identify problematic machines that consume too much energy or even uncover underlying power grid or electrical wiring issues.

FMX works best for mid to large-sized organizations that manage multiple facilities. Because interactive mapping is an add-on module to the core facilities management system, the cost may be too steep for organizations managing only one facility.

Read our FMX product page to learn more.

UpKeep - Best for Manufacturing

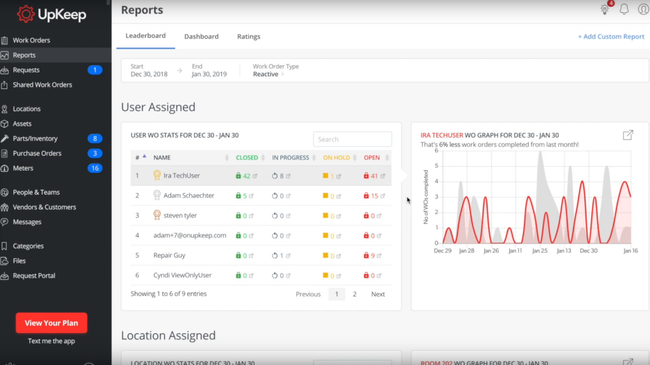

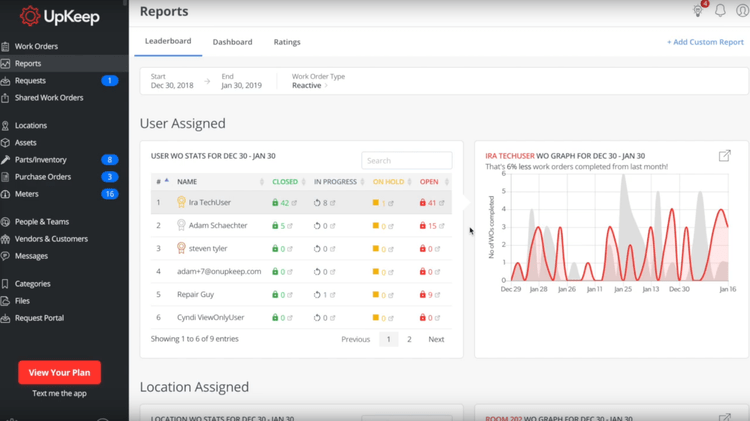

UpKeep helps manufacturers adhere to safety protocols. Its advanced reporting module allows for all maintenance work orders and safety-related incidents to be filed to stay compliant with OSHA, FDA, and GMP regulations. They can be organized in a central repository for easy reference and exported in PDF format. This helps keep a detailed audit trail to avoid hefty GMP violation fines for lack of documentation.

Within the reports module, work orders can be organized by the assigned user. This allows you to ensure each technician is maintaining safety standards during maintenance. This way, all safety incidents they work on can be tracked to hold them accountable for missed safety checks.

UpKeep also includes safety-related information and checklists on every work order to help crews stay safe and compliant. These instructions can be built into inspections as well, and every step must be followed and logged to ensure they are followed.

UpKeep is best for small to midsize manufacturers, with prices starting as low as $20/user/month. That said, the advanced reporting module isn’t available until the Professional plan, which requires a custom quote. Also, if you’re a multi-site or more complex manufacturer, you’ll likely need a more advanced system like eMaint or MicroMain.

Learn more about UpKeep in our full review.

Brightly Asset Essentials - Best for Public Utilities

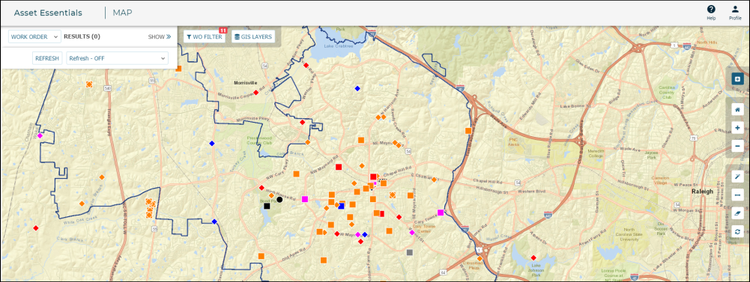

Brightly Asset Essentials integrates with Esri ArcGIS to provide GIS mapping capabilities for public utilities companies. This is especially useful for visualizing assets across large geographic areas in real-time. With precise geospatial information, the interactive map lets you view different infrastructures, like power grids, water lines, and other utilities.

You can filter the map by work orders and sort by date, priority, or site to view details. The system also offers custom map layers that are specific to your business. Data can include weather, traffic, or utility grids, making it easier to asses different variables before you choose which work order to approve or start.

Brightly Asset Essentials’ GIS integration works in tandem with its outage management module. It enables fast response times by pinpointing exact outage locations. When these occur, work orders are automatically generated so you can allocate the correct resources efficiently.

Additionally, the GIS mapping tool is available on mobile devices. Technicians can use street view to help them find assets faster and view work order details to perform maintenance optimally. It even offers an offline mode so that work can be done without an internet or cellular connection.

Fiix - Best AI-Driven Predictive Analytics

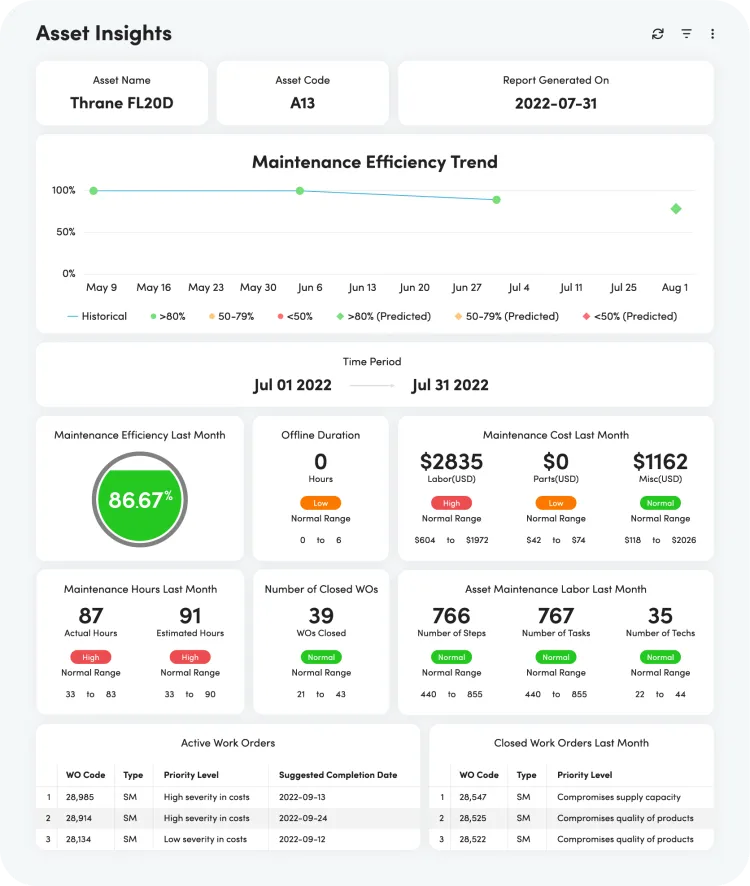

Fiix’s Foresight tool is one of the stronger AI-based features we’ve seen on the market. The feature analyzes each work order in your system and spots patterns and anomalies in asset performance or maintenance requests. You’re able to predict delays by viewing high-risk work orders and ranking them on priority to ensure you get to those first.

The asset insights dashboard gives you a straightforward and organized view of advanced asset metrics and data. It shows the total maintenance cost for the past month and ranks it high, medium, or low compared to previous months so you can monitor unusually high spending. It even graphs a maintenance efficiency trend based on monthly preventive maintenance percentages.

Fiix Foresight also includes a parts forecaster to help plan which parts you’ll need for upcoming maintenance and reduce stockouts. Unfortunately, you can only choose up to 25 parts to track, which can be limiting for companies handling high volumes. Still, the forecaster can be useful for managing the most volatile parts that require constant monitoring. The Fiix Foresight tool is available on the Professional plan, which starts at $75/user/month.

Read our full Fiix review.

MaintainX and Click Maint - Most Affordable

Depending on your business’s needs, both MaintainX and Click Maint can be used to streamline your maintenance processes at a low cost.

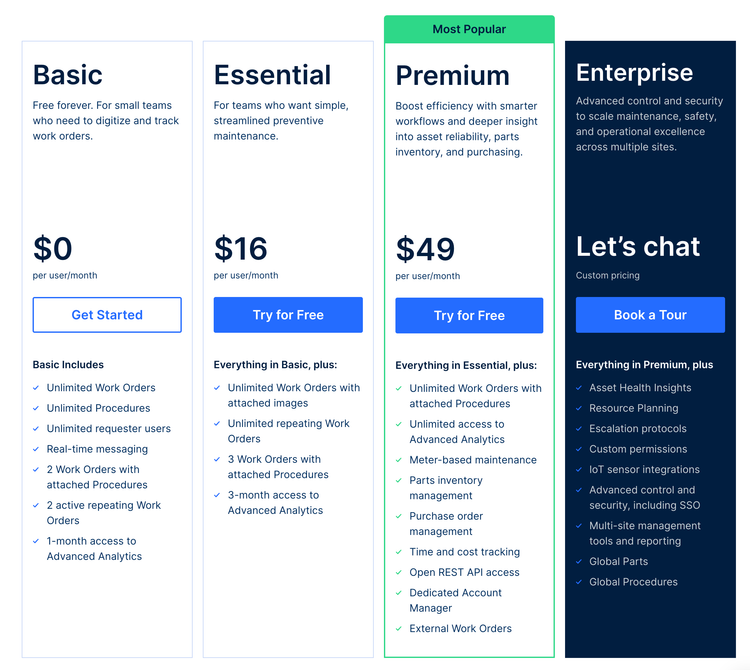

MaintainX offers a capable forever-free plan. It includes unlimited work orders, assets, and requester users, making it an effective option for small businesses that need simple work order management tools. The only caveat is that it only allows two work orders with attached procedures per month. This means that scheduled maintenance with recurring standard procedures will have to be manually generated each time instead of attaching a standardized procedure to it for simplicity. For unlimited procedures, you will need to purchase the Premium plan for $49/user/month, which is still a low price compared to other leading CMMS systems like eMaint CMMS and UpKeep.

Read our full MaintainX review.

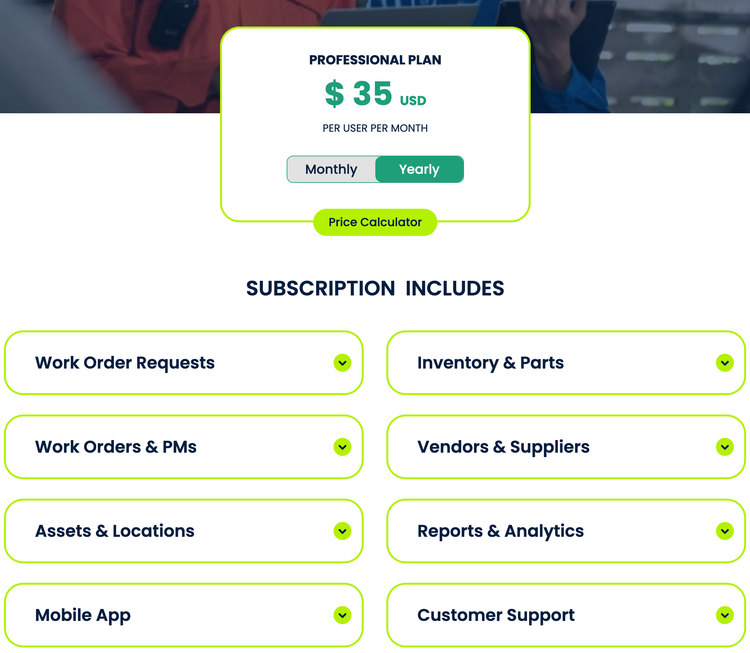

Unlike MaintainX, Click Maint does not offer a free plan. However, it does offer unlimited procedural work order requests on its lowest Professional plan, starting at $35/user/month. It also includes some advanced features, such as KPI report dashboards, preventive maintenance scheduling, and parts inventory management. This makes Click Maint a strong option for businesses that deal with several recurring work orders a month.

Learn more about Click Maint in our review.

AssetWorks EAM - Best EAM System

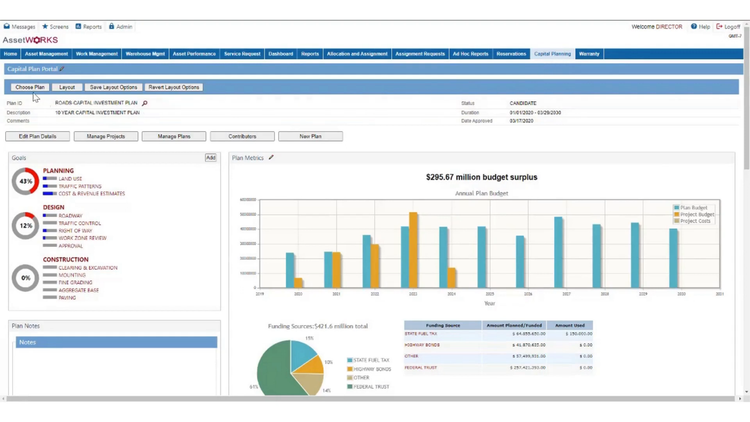

AssetWorks EAM’s capital planning feature is effective for managing high-value projects and their budgets. On the dashboard, you can track the annual budget plan compared to individual project budgets and costs. Plans can be set as far out as 30 years to allow budgeting for multi-year projects like new infrastructure construction or advanced machine engineering.

Each project within the capital plan tool has different sections to manage them, including:

- Real-time tracking of the percentage of budget used: Visualize the money already spent on the project vs. the remaining balance.

- Schedule: Projects are assigned a start and end date and can be broken down into different phases.

- Work Orders: Track real-time spending on each task and expensive repairs or maintenance.

- Approvals: Allows different tasks and work orders within a project to be approved individually.

Additionally, AssetWorks’s capital planning module works directly with its asset performance feature. High-value assets that require unexpected or costly maintenance are factored into the overall budget. Plans can also be adjusted for scenarios like sudden replacements or failed inspections.

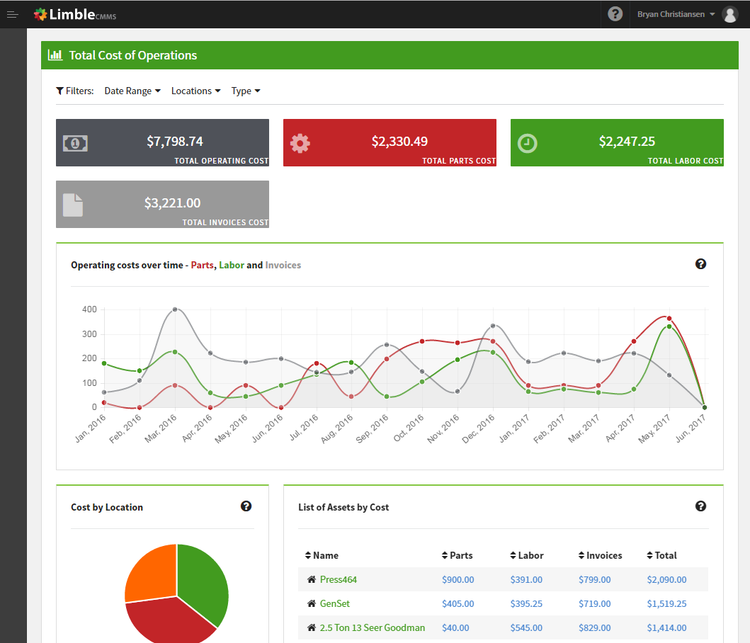

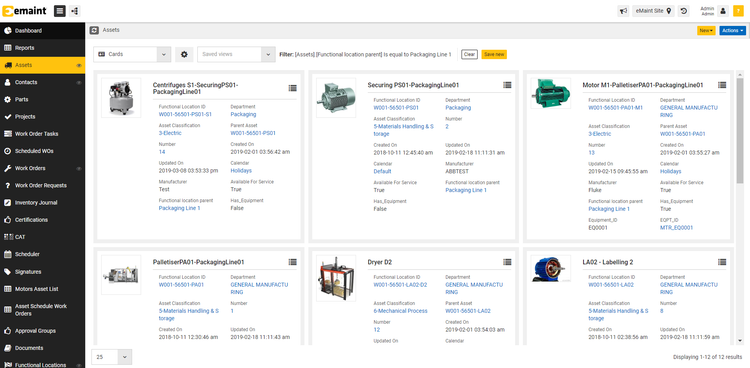

Limble CMMS - Best Mobile CMMS

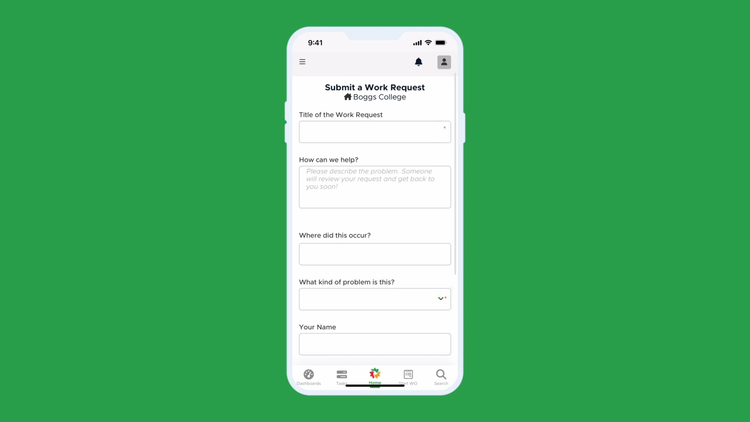

Limble CMMS is a mobile-first platform that streamlines maintenance management for field workers and is available for iOS and Android devices. Tasks follow a streamlined system that makes inspections and maintenance simple. You view the instructions and details for the task, complete the required work, and log the time after. This ensures workers are well-informed and can reference important information while on the job.

The mobile work order request system lets you efficiently request a work order from anywhere. You can configure the work order to your exact needs, upload pictures, and track the status of reports with automated updates. This eliminates the need for inefficient ticketing systems and relying on stationary desktop computers.

Finally, Limble CMMS’s app has an offline mode, allowing crews to work in dead zones. When offline mode is enabled, tasks can still be completed normally, as all the information and updates are stored locally on the device until an internet connection is restored.

Although Limble has strong mobile work order features, some users report limited flexibility in scheduling recurring tasks. Rotating shifts cannot be automatically programmed, so managers must manually assign a technician each time.

Read more in our Limble CMMS review.

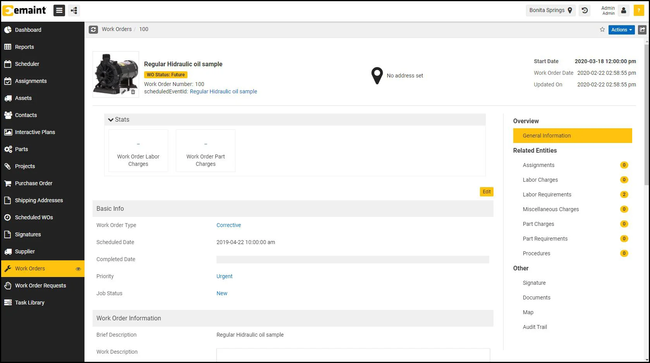

Maintenance Connection - Best On-Premise Option

Maintenance Connection offers a strong on-premise option for industries that require extra security, such as the defense and aerospace sector and healthcare. The system has several user security features that help safeguard sensitive information. It offers customizable authorization access for assignments and approvals, access groups, and role definitions for visibility levels.

The on-premise deployment will give your company more control over its data security. This can help your company comply with security standards such as 21 CFR Part 11. The system even maintains an audit trail of all user actions, providing accountability for all employees.

Maintenance Connection is designed to handle a high volume of work orders across many locations. This is especially important for enterprise-level defense agencies and national healthcare providers with over 500 employees. Because of this, smaller companies will want to look elsewhere.

Read our Maintenance Connection page to learn more.

Other Systems We Like

Equips is a good option for maintenance providers and facilities management. It offers an easy-to-use platform with work order management, asset tracking, and reporting. The features streamline workflows and reduce overall maintenance costs.

MicroMain CMMS is a great option for mid to large-sized manufacturers. You can schedule preventive maintenance and even integrate IoT sensors for advanced machine performance monitoring and predictive capabilities. The manufacturing focus helps multi-site operations reduce downtimes and ensure smooth production.

Systems We Don’t Recommend

While still used by many businesses today, Hippo CMMS was acquired by iOFFICE in 2019 and is no longer supported. Its replacement, Eptura Asset (formerly ManagerPlus), is unfortunately more expensive than Hippo was with the same functionality.

What is a CMMS?

A computerized maintenance management system (CMMS) is software designed to streamline and automate maintenance management tasks at minimal expense. It centralizes data, enabling users to track work orders, manage assets, and schedule preventive maintenance efficiently.

Commonly referred to as maintenance management software or maintenance tracking software, a CMMS helps organizations reduce equipment/machine downtime, extend asset lifespans, and improve efficiency by providing real-time insights and automated workflows.

Common Challenges

These are the most common challenges CMMS programs can help your business overcome:

- High maintenance costs: Maintenance costs rise with unplanned maintenance and an unorganized work order system.

- Disorganized work order system: Clunky ticketing systems or manual work order requests can cause delays, miscommunication, and maintenance errors.

- Compliance issues: Facilities and utilities must adhere to compliance standards to avoid fines and keep infrastructure up to code.

- Reactive maintenance: Reacting to machine maintenance problems can lead to costly repairs vs preventive and predictive maintenance, which catch issues before they get worse or happen at all.

- Asset tracking: Accurately tracking asset health and location helps lengthen asset life and provides insights for repairs and maintenance.

- Communication: Inaccurate or non-descript work orders lead to frustration and delays for maintenance crews.

- Resource allocation: Use historical data to allocate the correct number of resources for maintenance tasks to stay under budget and improve budget accuracy.

- Unplanned downtime: Frequent equipment failures and breakdowns lead to unplanned downtime, resulting in lost productivity and increased operational costs.

Key Features and Benefits

The common CMMS features used in maintenance programs by facility managers include:

- Asset management: Stores information on assets such as frequency of use, costs, maintenance cycles, and specifications.

- Equipment inventory: Tracks information on equipment used in maintenance and repair operations, usually including tools and parts.

- Preventive maintenance: Creates schedules, tracks procedures, and sets maintenance routines to prevent unplanned breakdowns.

- Predictive maintenance: Scans equipment data for performance trends and uses condition-based monitoring to alert the appropriate staff of any potential issues.

- Work order management: Efficiently creates a trackable document identifying what work needs to be done and how it should be accomplished.

- Reporting and analytics: Records key maintenance data to create visual graphs and charts on customizable dashboards.

- Compliance and safety: Keeps you audit-ready by keeping records of work orders, tasks, and compliance documentation.

- Mobile accessibility: Includes a mobile app for maintenance teams to view and approve work orders and log time.

- Performance tracking: Analyze the success of maintenance teams through reporting on metrics like maintenance completion percentage and average downtime length.

Higher-costing CMMS and EAM systems will include advanced features, including:

- IoT integration: The system integrates with IoT sensors to record and monitor machine and vehicle diagnostics like temperature, fuel consumption, and vibration.

- GIS mapping: Uses geographic maps to visualize the locations of assets and infrastructure.

How to Choose the Right CMMS for Your Business

CMMS software can cater to different types of industries and needs, so it’s important to choose one that fits your priorities.

| Industry or Priority | Recommended Systems | Key Features |

|---|---|---|

| Manufacturing | UpKeep, MicroMain, eMaint | Safety and compliance, predictive and preventive maintenance, spare parts inventory |

| Facility Management | FMX, FMS:Workplace, Maintenance Care | Floor mapping, space management |

| Public utilities | Brightly Asset Essentials, Fiix, eMaint | GIS Mapping, asset tracking, Compliance |

| Affordability | MaintainX, Click Maint, Limble CMMS | Free versions, low-cost paid plans, work order management |

| EAM | AssetWorks EAM, Maintenance Connection, Brightly Asset Essentials | Asset lifecycle management, GIS mapping, capital planning |

| On-premise | Maintenance Connection, Fiix | Control over data, visibility roles, offline access |

Pricing Guide

The pricing for CMMS programs varies, as there are many systems that offer free plans, such as MaintainX and Limble CMMS. However, these are often limited in functionality and are only for startups and small businesses that need basic work order management tools.

Paid plans can range from $30-$500/user/month for cloud-based systems, depending on your desired features. Usually, products will offer tiered pricing options, with the cost increasing with the number of features offered. Here’s a breakdown of the expected yearly cost based on your company size:

Low-Tier

- Company Size: 1-25 employees

- Cost Per User Per Month: $30-$80

- Average Yearly Cost: $1,000-$10,000 per year

- Product Examples: UpKeep, Limble CMMS, MaintainX, Click Maint

Mid-Tier

- Company Size: 25-100 employees

- Cost Per User Per Month: $50-$150

- Average Yearly Cost: $10,000-$50,000 per year

- Product Examples: eMaint, Fiix, Equips, MicroMain, Upkeep (Enterprise), MicroMain

High-Tier

- Company Size: 100-500 employees

- Cost Per User Per Month: $150-$250

- Average Yearly Cost: $50,000-$200,000 per year

- Product Examples: Eptura Asset, MicroMain (Enterprise), eMaint (Enterprise)

Enterprise

- Company Size: 500+ employees

- Cost Per User Per Month: $200 - $500+

- Average Yearly Cost: $200,000+ per year

- Product Examples: IBM Maximo, SAP EAM, Infor EAM

For on-premise deployment, there will be a high initial investment cost for licensing, implementation, and training. These costs can total between $1,500 and $20,000, depending on your business size and complexity of the CMMS. While most systems only offer cloud-based options, on-premise is still valuable for large companies emphasizing total control over their data or require offline access for their technicians.

Frequently Asked Questions

How is a CMMS different from an EAM system?

Both systems are similar in approach, as they help manage assets and improve maintenance workflows. The main difference is that CMMS is more maintenance-focused, while EAM systems are designed for high-value assets and managing their entire lifecycles. These can include heavy machinery, complex medical equipment, or utility infrastructure, such as power grids and water treatment plants.

Read more: CMMS vs. EAM: What’s the Difference?