The Best Equipment Maintenance Software

A step up from spreadsheets, equipment maintenance software helps extend machinery lifespans. Whether you’re in manufacturing or facilities management, find a platform with asset tracking and preventive maintenance scheduling.

- Offline mode with work order syncing capabilities

- Customizable KPIs

- Strong international support: multi-currency, multilingual, multi-location, etc

- Comprehensive features (spare parts, OEE, depreciation, reporting)

- Unlimited sites, priced per user

- Tailored for manufacturing

- Strong virtual support

- Offers free plan

- Streamlined mobile app allows users to add images/documents

These equipment management solutions cater to industries like manufacturing, healthcare, and construction, helping you reduce maintenance costs and track lifecycles.

| System | Standout Feature | Ideal Industry | Starting Price |

|---|---|---|---|

| Asset Panda | Equipment tagging | Construction | Quote-Based |

| eMaint CMMS | Condition monitoring | Manufacturing | $69/user/month |

| Fiix | Spare parts inventory | Construction | Free |

| FMX | Floorplan mapping | Facilities management | Around $3,000/year |

| FocalPoint | Rental maintenance | Heavy equipment rentals | $9,500 one-time |

| Limble CMMS | Reporting and analytics | Healthcare or manufacturing | Free |

| MaintainX | Work order management | Manufacturing or facilities management | Free |

| MicroMain CMMS | Machine health reporting | Manufacturing | $99/user/month |

| UpKeep | Preventive maintenance scheduling | Manufacturing | $20/user/month |

| Click Maint | Cost-effective | Manufacturing or facilities management | $35/user/month |

- eMaint CMMS: Best Overall

- MicroMain CMMS: Best for Manufacturing

- MaintainX: Best Work Order Management

- UpKeep: Best for Preventive Maintenance

- Limble CMMS: Best for Healthcare

- Fiix: Best for Construction Equipment

- FMX: Best for Facility Management

- Asset Panda: Best for Equipment Tracking

- FocalPoint: Best for Equipment Rentals

- Click Maint: Most Cost-Effective Option

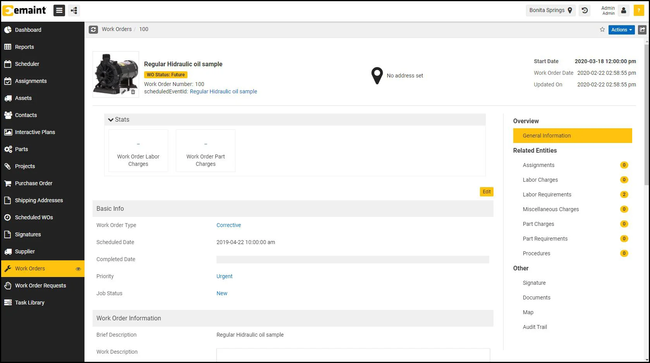

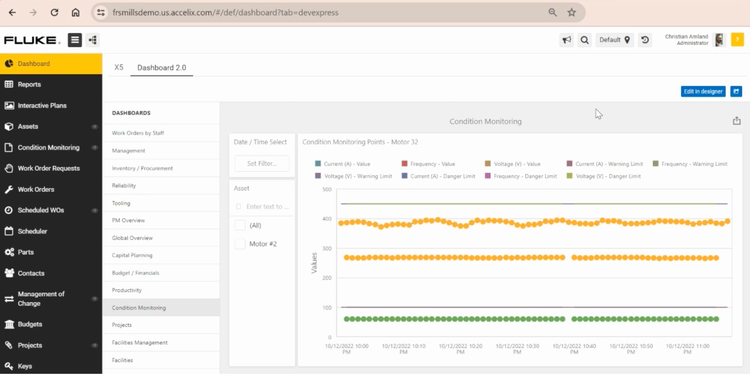

eMaint CMMS - Best Overall

eMaint CMMS offers turnkey, proprietary sensor integrations to help your maintenance teams stay informed about equipment health without manual checks. As part of its product suite, eMaint leverages Fluke’s lineup of 13 different sensor types. These include models like the Azima Accel 310 wireless vibration sensor or the Azima handheld Tro analyzer. These sensors support remote condition monitoring as well.

Once installed, the sensors continuously track machine metrics like:

- Vibration: Measures vibrations in equipment to identify wear and tear or looming failures.

- Power Usage: Monitors electrical consumption to help you pinpoint any anomalies or inefficiencies.

- Temperature: Gauges operating temperatures to prevent equipment from overheating.

Because Fluke owns eMaint, these sensor integrations are built directly into the system, meaning you’ll never have to depend on complicated third-party connections. This is handy if you’re a manufacturer needing fast access to data and early warnings for potential issues. For example, you can set automated alerts and trigger work orders if a vibration metric crosses a danger threshold, saving you from unexpected downtime.

With eMaint’s sensor-based condition monitoring, you can extend the lifespan of your equipment and shift to a predictive maintenance model. However, it can be a bit pricier than other platforms, at $69/user/month. UpKeep starts at $20/user/month, but it lacks eMaint’s proprietary sensor integrations, so setup may be more complicated.

Read our full eMaint CMMS review.

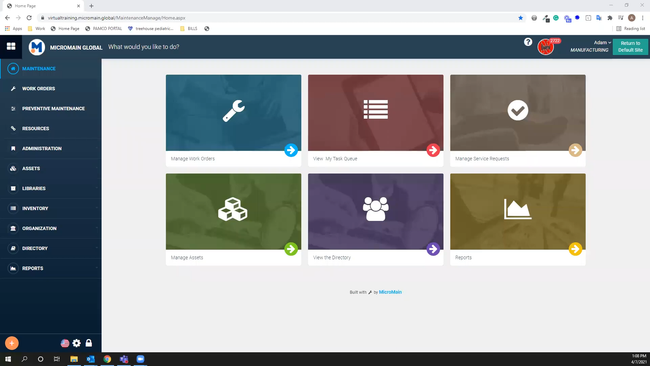

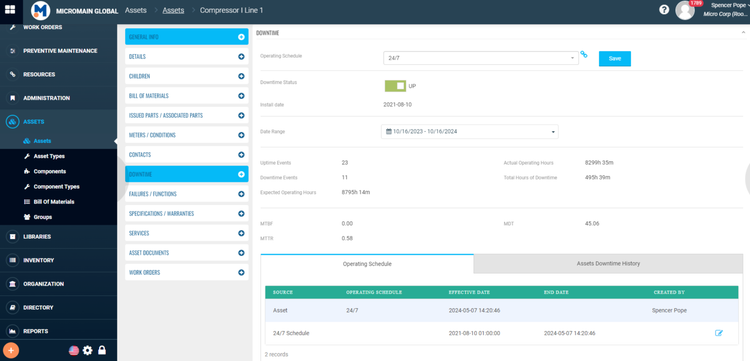

MicroMain CMMS - Best for Manufacturing

MicroMain CMMS allows manufacturers to analyze machine KPIs and performance through its advanced reporting module. Here, you can create several machine metric reports to ensure equipment health and reduce downtime. These include:

- Downtime Events: Track the current status of high-value production machinery and review each downtime event to evaluate root causes.

- Maintenance history: See each machine’s maintenance history to keep a comprehensive record of preventive and corrective work orders.

- Instance comparisons: Compare machinery and other equipment to see which have the most recurring issues to help identify potential replacement opportunities.

Through its detailed reporting, MicroMain also helps manufacturers comply with OSHA regulations. The system stores all heavy equipment maintenance and safety events in a centralized repository. This includes scheduled preventive maintenance or general repairs from requested work orders. Failure to record these can result in failed OSHA audits and hefty fines for safety violations.

MicroMain CMMS is best for multi-site manufacturers managing several high-value machines and pieces of equipment. Its pricing starts at $99/user/month, making it one of the more expensive systems on our list. That said, it’s worth the investment to minimize unexpected production downtimes.

For more info, visit our full MicroMain CMMS review.

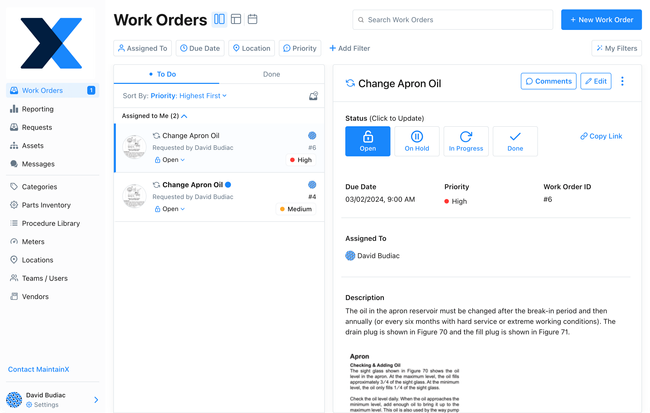

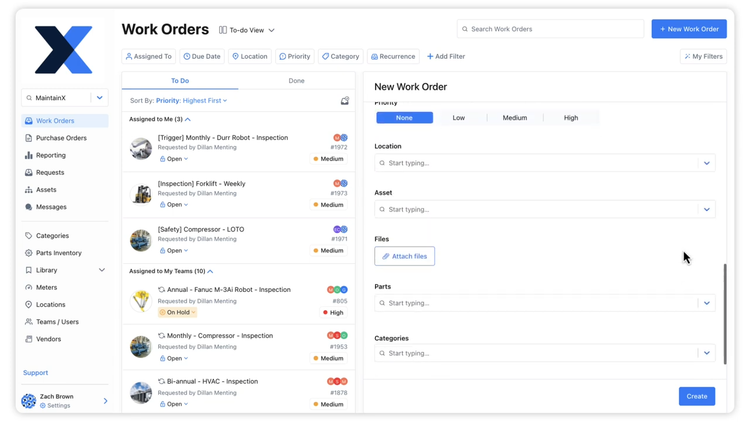

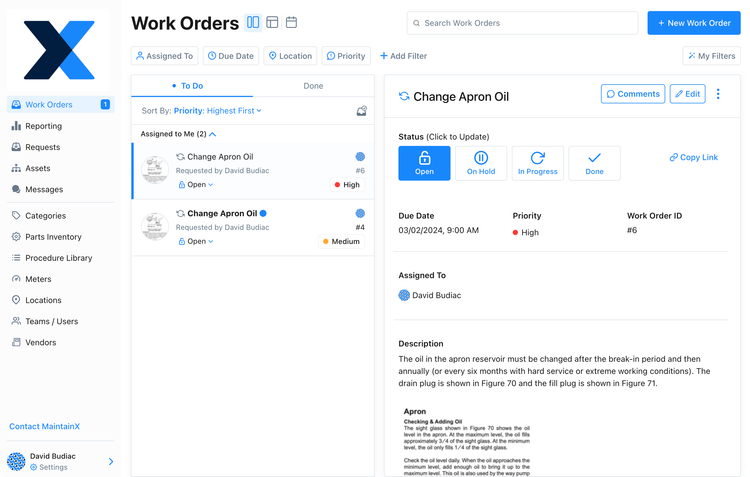

MaintainX - Best Work Order Management

MaintainX offers a streamlined work order management module that simplifies the process for maintenance managers and technicians alike. You can easily create new work orders for routine or spontaneous equipment maintenance. Add procedures, estimated time, and pictures from a centralized screen to make processes more efficient and ensure jobs are done correctly the first time. Plus, you can assign them to a specific asset from your database to keep an accurate maintenance history for each.

Using the information on the work order, technicians can quickly complete equipment maintenance on their mobile devices. Users can go through the attached procedures and checklists to ensure the job is done correctly. Also, if you need to reference equipment maintenance history, you can scan its QR code directly through the app. It even includes an offline mode, so you don’t need an internet or cellular connection to finish a work order.

MaintainX is one of the most affordable systems on the market, making it well-suited for small job shops or single-entity facilities management. Its free plan includes unlimited work orders and requester users so that every employee can submit maintenance needs without increasing the price. However, if you have several assets with procedural maintenance, you’ll want to opt for the Premium plan at $49/user/month.

Read our full MaintainX review.

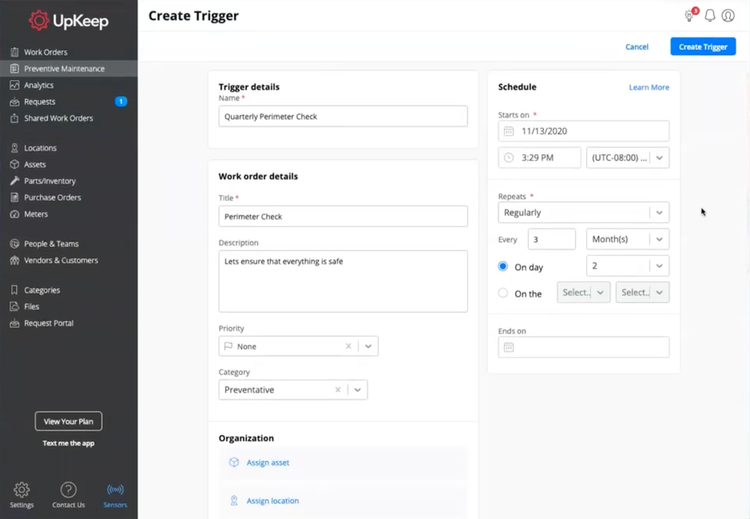

UpKeep - Best for Preventive Maintenance

UpKeep’s automated preventive maintenance scheduler helps you catch equipment faults before they become problematic. The system walks you step by step to generate schedules that cater to various asset types. You can create custom triggers based on several parameters:

- Time: Triggers a work order after a certain number of days, automatically populating into the calendar. This is useful for low-value equipment that degrades at a predictable rate.

- Meter: Configure specific assets to create work orders when certain usage thresholds are met, such as hours of operation for manufacturing machines or miles traveled for fleets.

- Condition: Integrate IoT sensors to monitor conditions and trigger maintenance when anomalies are detected.

For all PMs, you can create a form template with checklist items. These are useful for more involved equipment maintenance jobs, like repairing HVAC systems. Servicing these on a time-based schedule can involve several steps, like air filter cleaning, refrigerant checking, and motor lubrication. UpKeep’s straightforward checklists can be attached to each PM, ensuring the technician follows each step. It can be a great tool in your equipment maintenance management workflow.

Pricing starts at $20/user/month for the Lite plan. However, you’ll have to upgrade to the Starter plan at $45/user/month for full access to preventive maintenance scheduling.

See our UpKeep review.

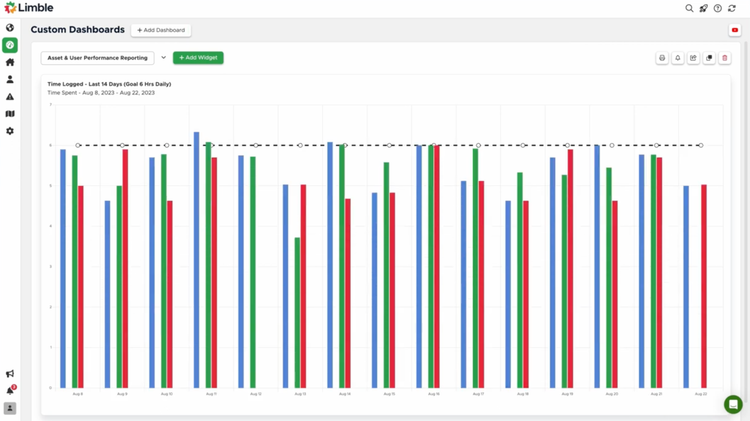

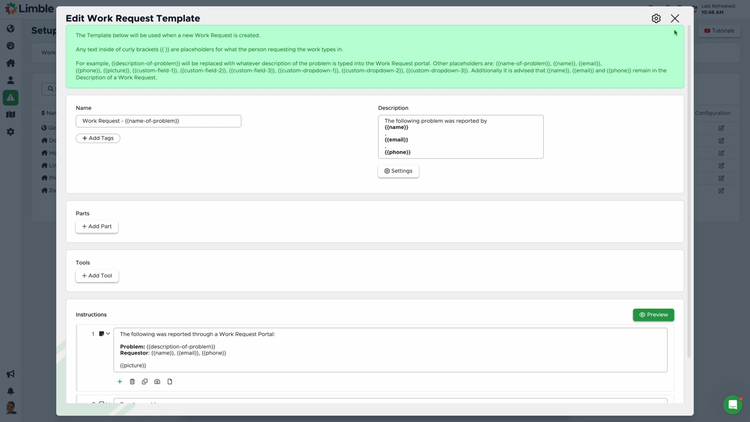

Limble CMMS - Best for Healthcare

Limble CMMS’s custom dashboard and reporting tool helps healthcare organizations reduce maintenance costs and analyze metrics. You can customize the dashboards to view specific data across any period. For example, you can see each user’s weekly hours logged to see if they’re reaching their goals. From there, drill into their task history to identify areas of inefficiency. This helps you adjust the expected time for certain pieces of equipment or better optimize workflows to reduce future costs.

Additionally, Limble CMMS helps you stay compliant with The Joint Commission (TJC) audits. The system centralizes all medical equipment work orders and preventive maintenance documentation. Within each work order, you can customize checklists with all relevant information on each piece of equipment. This helps your technicians inspect and repair medical devices to follow TJC codes and ensure regulations are met for patient safety.

Limble CMMS is a great option for healthcare organizations to stay audit-ready and reduce maintenance costs. However, if you’re a single-site clinic with limited equipment, this system may be too extensive. While it does offer a free plan, it’s very limiting, and custom dashboard reporting is only available in the $28/user/month Standard plan.

For more info, read our full Limble CMMS review.

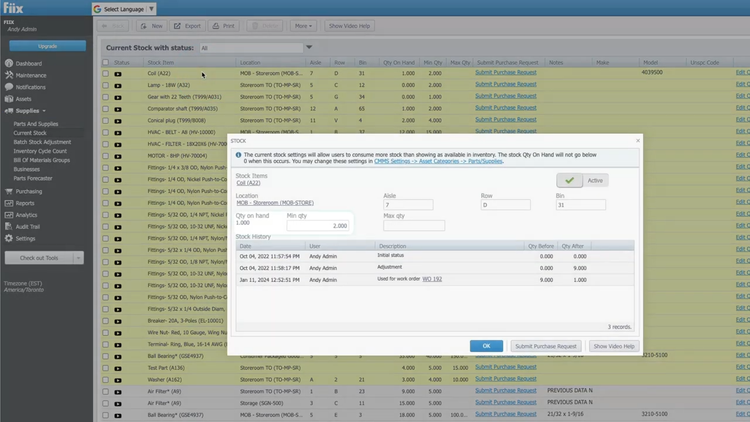

Fiix - Best for Construction Equipment

Fiix’s inventory management module is highly useful for construction companies performing maintenance on their heavy equipment. The software automatically adjusts the stock count when you consume parts on a work order, eliminating manual processes. This ensures inventory levels are always accurate when creating new tasks.

You can also set stock minimums that automatically notify you when you meet the threshold. That way, you can immediately generate a purchase order for the part to stay replenished. This is crucial for high-volume heavy equipment parts, like oils, fuel filters, and tires, as running out of supplies can result in longer downtimes and lost revenue. Once parts are reordered, link receipts to assets and work orders to track the total cost of inventory.

Further, the global search function lets you quickly reference spare parts from your computer or mobile device. Fiix supports multiple entities, so search results show the current location so you can plan accordingly, consolidating your data into one construction equipment maintenance software. You can also search by supplier or vendor for consumption levels and lead times. The software even connects to your existing ERP or inventory management system for two-way data sync.

Fiix offers a free plan that includes its spare parts inventory tool, though it lacks purchasing and RFQ functionality. That’s only available in the $75/user/month Professional plan, making it best suited for companies with higher inventory volumes and multiple entities. Also, the interface is a bit outdated, as the line items and module headings are all grayscale. Other systems like MaintainX and UpKeep have a more modern feel. Still, it’s a solid choice for construction equipment maintenance software.

See our Fiix review.

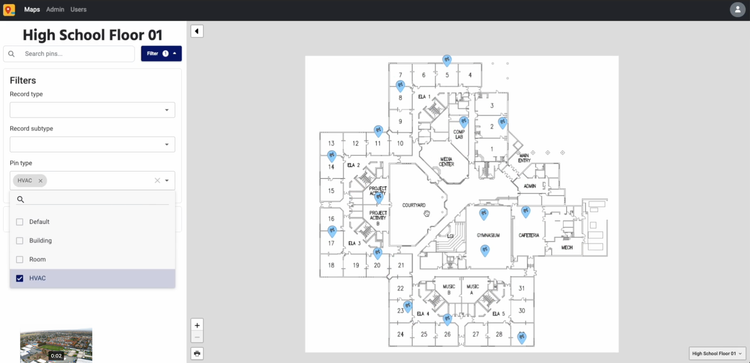

FMX - Best for Facility Management

FMX’s interactive floor mapping is a strong tool for industries managing equipment dispersed throughout multiple facilities, like governments, educational institutions, or even property managers. Upload floorplans or choose between satellite, roadmap, or terrain imagery to create maps. These options give you a holistic view of your facilities and show which maintenance work orders have been assigned to them.

Drill down into a specific facility to view equipment on a floorplan. Accurately tag different assets like HVAC systems, generators, and water heaters. Click into each, and the system displays active work orders or previous maintenance records. Because it can be viewed on mobile devices, it provides technicians with an accurate facility layout to track down equipment faster when performing maintenance, streamlining the process.

Education institutions and government agencies can benefit greatly from FMX’s floorplan mapping. That said, it’s best for organizations managing several facilities, as single-entity companies may find the floorplanning tool excessive. Pricing starts at $3,000/year, depending on your user and facility count.

Get more info on FMX.

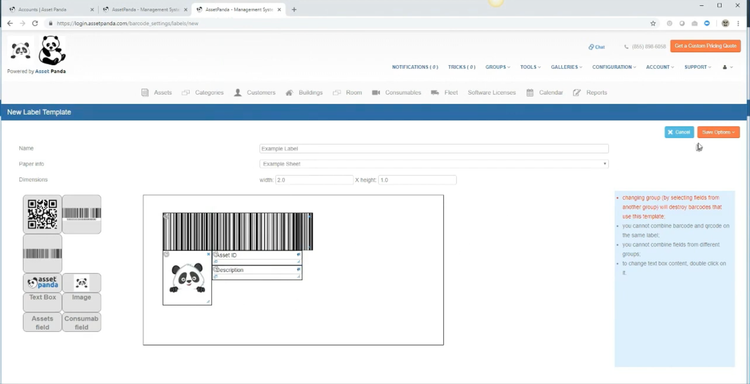

Asset Panda - Best for Equipment Tracking

Asset Panda helps track and perform maintenance on mobile equipment with its asset tagging tools. The system lets you create customized barcodes or QR codes for your high-value equipment of all sizes, whether it’s forklifts in your warehouses or laptops in the office. Simply choose the asset you want to tag and create a customized label to print. Add your logo, company name, asset ID, or description to give it a personalized feel. This way, you can check it in and out or create work orders just by scanning the code.

You can scan the tags using the Asset Panda mobile app, so you don’t need additional hardware like barcode scanners. After you scan, it immediately opens all the equipment’s information, like the last maintenance date, model number, and last scanned location. You can also create work orders that auto-assign to equipment to track its lifecycle history.

The equipment tagging system can benefit construction or healthcare industries with tens or hundreds of tools and devices requiring maintenance. Unfortunately, Asset Panda doesn’t list their prices publicly. They use an asset-based pricing model, so the cost depends on the amount you need to track. Because of this, the system is best for small to midsize businesses, as the cost can add up with a higher equipment volume.

Visit our Asset Panda page for more info.

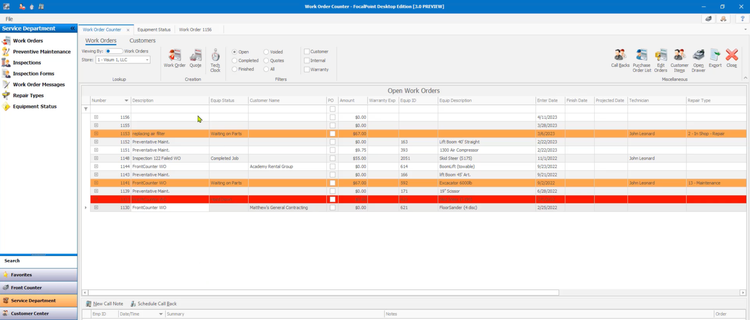

FocalPoint - Best for Equipment Rentals

FocalPoint combines equipment rental tracking and maintenance within its customer work order module. This allows you to perform maintenance and repairs for internal or customer equipment. You can categorize them into several types, including:

- Preventive maintenance: Schedule time-based preventive maintenance work orders to catch equipment faults before they cause problems.

- Failed inspection: Created from failed customer inspections from rentals. These can be assigned as “customer” jobs so that all costs can be accurately billed to the customer.

- Front counter: These are generated from the front counter when repairing customer equipment as a service. This helps differentiate between internal and external maintenance.

FocalPoint’s work order module integrates its front counter rental system. The system uses one centralized database for your equipment, so you can view an item’s maintenance history before checking it out. This is especially useful for heavy equipment, as operational or environmental damage can happen when renting items like excavators or bulldozers. From there, you can quickly draw up the contract and assign the corresponding inspection form.

Compared to other systems on the list, FocalPoint has a unique pricing structure. You can purchase the software outright for $9,500. Alternatively, monthly financing options are available through the developer, and the system can be installed via the cloud or on-premise.

See more on our FocalPoint page.

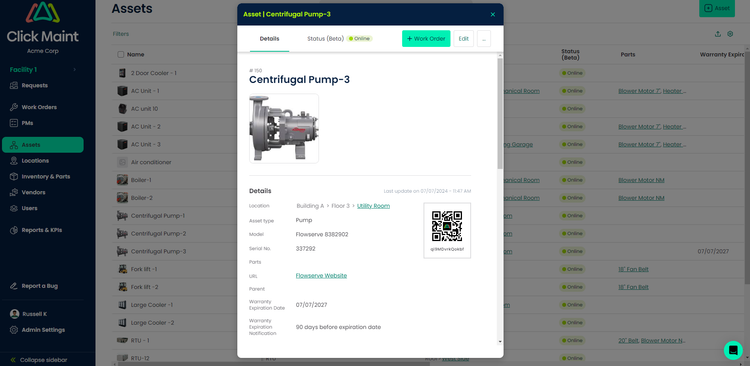

Click Maint - Most Cost-Effective Option

Click Maint is one of the more affordable CMMS tools on the market. Starting at $35/month, the price includes access to its equipment maintenance management module. While some platforms lock this functionality behind higher-tier plans, Click Maint provides full access for smaller teams upgrading from spreadsheets or clunky legacy systems.

The equipment maintenance module makes it easy to manage preventive and reactive work. You can submit a request either through the desktop or mobile app simply by scanning the equipment’s QR. That request becomes a work order with details like asset type, location, priority level, and assigned technician. From there, your techs can start a built-in timer and log the time and parts used. They can even dictate notes using voice-to-text.

Preventive maintenance is just as simple. You can set recurring work orders using usage-based or calendar-based schedules, with attached procedures and checklists. Click Maint then tracks progress so you know when each is coming due. For $35 a month, you’re getting more than basic task lists. While we wouldn’t recommend it for large global enterprises, it’s ideal for smaller companies with up to 100 employees.

Check out our Click Maint product page for more details.

Other Systems We Like

Eptura Asset is a good option for mid to large-sized businesses managing several facilities. It includes digital floorplanning and asset lifecycle management tools to streamline equipment maintenance.

Another capable system is eWorkOrders, with its straightforward UI and wide feature set. It offers more advanced tools like predictive maintenance and GIS mapping for utility companies and large manufacturers.

Systems We Don’t Recommend

Hippo CMMS is a system commonly featured on other equipment maintenance pages, despite it being discontinued in 2019. While some businesses still use it, it’s no longer sold or supported. MaintainX or Click Maint are good alternatives with similar functionalities and prices.

What is Equipment Maintenance Software?

Equipment maintenance software is a type of maintenance management software designed to help you manage, monitor, and maintain equipment and assets. It shares many features with CMMS software but focuses more on equipment management, like heavy machinery and construction tools. It aims to automate task management and scheduling while lowering costs and keeping a detailed maintenance record.

Key Features

| Key Feature | Description | Benefit |

|---|---|---|

| Preventive Maintenance | Create preventive maintenance schedules that automatically trigger work orders based on usage time or meters. | Ensures equipment maintenance is routinely performed on time to prevent unexpected failures and downtimes. |

| Work Order Management | Create maintenance tasks and assign them to your team. | Organizes all equipment maintenance tasks and prioritizes them for streamlined processes. |

| Asset Management | Maintain a record of all equipment and asset information, including location and maintenance history. | Stay audit-ready by easily referencing past maintenance on equipment and ensuring it’s safe to use. |

| Inventory Management | Manage spare parts inventory and attach them to work orders to ensure availability during maintenance. | Optimizes your stock levels to prevent stockouts or overstock. |

| Predictive Maintenance | Uses IoT sensors and analytics to monitor equipment and predict potential failures. | Prevent breakdowns before they occur and get real-time alerts on potential issues to reduce downtime. |

| Mobile App | Create and fill out work orders and reference equipment information from your mobile device. | Allows maintenance crews to receive updates on new tasks and complete work from anywhere, even without a connection. |

| Reporting and Analytics | Create reports on maintenance data like downtime statuses and average cost. | Lets you drill into your data and gain insights into machine health and maintenance crew performance. |

How to Choose Software

| Industry | Recommended Systems | Key Features |

|---|---|---|

| Manufacturing | MicroMain CMMS, eMaint CMMS, UpKeep | Preventive maintenance scheduling, downtime analytics, condition monitoring |

| Facilities management | FMX, MaintainX | Floor mapping, work order management |

| Healthcare | Limble CMMS, eMaint CMMS | Compliance reporting, detailed maintenance documentation |

| Construction | Fiix, Limble CMMS | Spare parts inventory tracking, mobile app |

| Equipment Rentals | FocalPoint | Integrated maintenance and front counter rental system |

Pricing

Pricing for equipment maintenance software varies, but most platforms range between $16-$200/month. This heavily depends on your desired features, equipment amount, and user count. There are some systems, like MaintainX and Fiix, that offer free plans, but they’re extremely limited in functionality and are only recommended for startups. Here are some broad yearly ranges you can expect to pay based on your company size:

- Low-Tier: $3,000-$10,000 per year

- Mid-Tier: $10,000-$30,000 per year

- High-Tier: $30,000-$80,000 per year

- Enterprise: $80,000+ per year

Most systems offer per-user pricing in tiered packages that increase in price with the number of features offered. A good option for small businesses is MaintainX. Its Essentials package starts at $16/user/month, but only includes three work orders and attached procedures. For unlimited, the Premium package costs $49/user/month.

| System | Free Plan | Starting Price | Free Trial for Paid Plans |

|---|---|---|---|

| Asset Panda | ❌ | Quote-Based | 14-day |

| eMaint CMMS | ❌ | $69/user/month | No |

| Fiix | ✅ | $45/user/month | No |

| FMX | ❌ | Around $3,000/year | No |

| FocalPoint | ❌ | $9,500 (one-time) | No |

| Limble CMMS | ✅ | $28/user/month | No |

| MaintainX | ✅ | $16/user/month | 30-day |

| MicroMain CMMS | ❌ | $99/user/month | Yes, non-explicit duration |

| UpKeep | ❌ | $20/user/month | 7-day |