The Best Preventive Maintenance Software

We’ve evaluated the top preventive maintenance software for companies of all sizes. Whether you’re a large manufacturer needing condition monitoring or a small facility manager requiring basic work order management, we’ll help you optimize your maintenance operations.

- Condition monitoring with real time data

- Proprietary sensor integration

- Sends warning alerts to catch possible faults

- Affordable pricing plan

- Centralized dashboard for easy navigation

- Track asset work order history

- Create time or meter triggers on PMs

- Upload manuals and add checklists

- IoT sensor integration ready

Preventive maintenance software is a tool used to schedule and track maintenance tasks to prevent equipment failure and ensure operational efficiency. Here’s a rundown of our top picks based on user reviews and our internal review process.

| System | Standout Feature | Free Plan | Starting Price (for paid plans) |

|---|---|---|---|

| Click Maint | Work order management | ❌ | $35/user/month |

| eMaint | Condition monitoring | ❌ | $69/user/month |

| Fiix | Spare parts inventory management | ✅ | $45/user/month |

| Fleetio | Vehicle service reminders | ❌ | $4/vehicle/month |

| MaintainX | Mobile app | ✅ | $16/user/month |

| UpKeep | Automated maintenance scheduling | ❌ | $20/user/month |

| Limble CMMS | Asset Management. | ✅ | $33/user/month |

- eMaint: Best for Manufacturing

- Click Maint: Best for Work Order Management

- UpKeep: Best for Automated Maintenance Scheduling

- Fleetio: Best for Transportation & Logistics

- MaintainX: Best Mobile Functionality

- Fiix: Best for Spare Parts Management

- Limble CMMS: Best for Asset Management

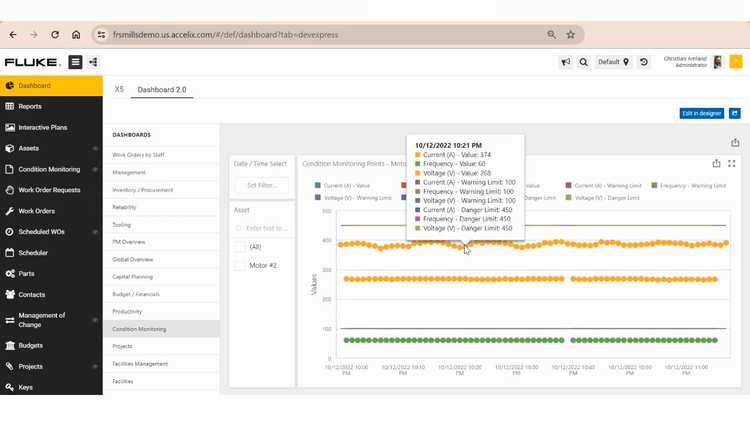

eMaint - Best for Manufacturing

eMaint’s condition monitoring module allows manufacturers to analyze real time machine performance data. This takes preventive maintenance a step further, as instead of scheduling work orders for certain times or meter readings, you can use live data. Set thresholds for temperature, vibration, and voltage readings and receive alerts when the machine exceeds them. This lets you anticipate costly failures before they occur and keep production lines running smoothly.

The system offers its own proprietary Fluke sensors that directly integrate with the condition monitoring system. Popular devices include the Azima Accel 310 wireless vibration sensor and the Azima handheld Trio analyzer. This eliminates searching for third-party sensors and conducting a lengthy integration process like most other systems require.

eMaint’s condition monitoring module is only included in the Professional plan at $85/user/month. Along with extra fees for the sensors, this price is only suitable for large companies with high-cost critical production equipment. Smaller manufacturers requiring a simpler preventive maintenance solution may find Click Maint or MaintainX more suitable.

Learn more about eMaint in our full review.

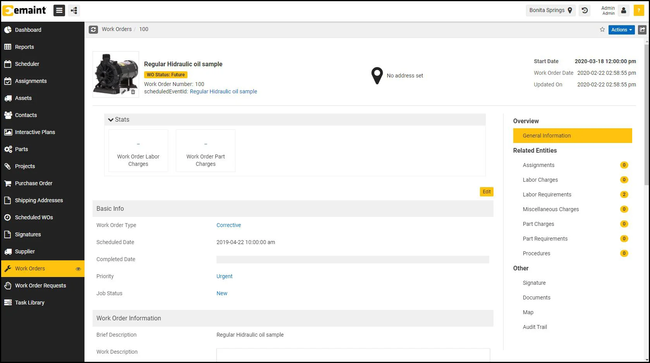

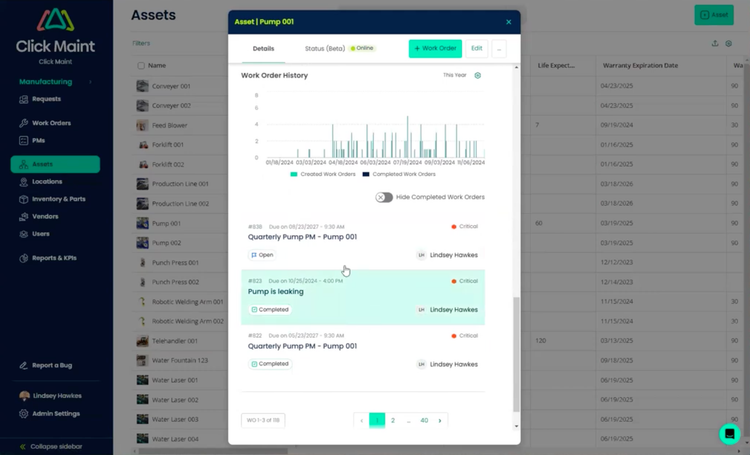

Click Maint - Best for Work Order Management

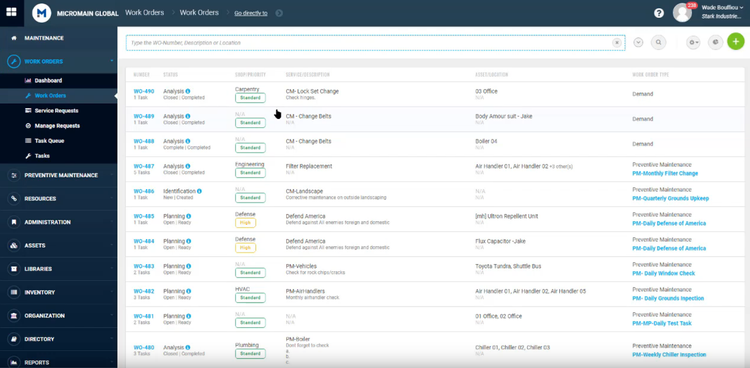

Click Maint’s streamlined work order management module helps businesses across several industries optimize their preventive maintenance processes. You can easily create work orders from the desktop or mobile app, associating them with assets and locations. When you complete and assign orders, technicians will be automatically notified through their email and/or their mobile device, so nothing slips through the cracks.

The module also has a central dashboard of all active work orders. These can be filtered by assigned date, type, or priority, allowing you to manage critical vs. non-critical tasks for a more optimized workflow. You can also switch to a calendar view if you have more time-sensitive deadlines, like repairing critical medical equipment for a hospital. Easily drag and drop work orders to reschedule and ensure technicians are not overbooked.

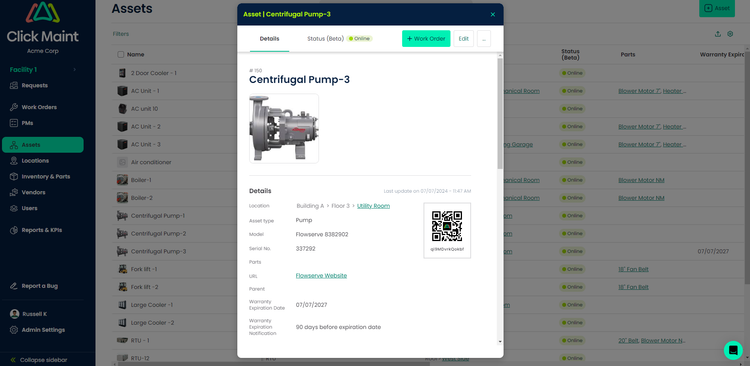

The work order system syncs with the asset module, so you can track all maintenance assigned to equipment individually. When you drill down into an HVAC machine or pump, it displays all current and completed work orders in a list view for easy reference. It also shows a bar chart of created vs. completed WOs across a period, whether by year, month, or week. This helps you identify any maintenance that was never completed or detect possible trends in unexpected failure occurrences.

Click Maint is one of the market’s most affordable preventive maintenance systems, ideal for budget-conscious businesses. It offers a straightforward $35/user/month billed yearly plan that includes all functionalities, including unlimited work orders, PMs, spare parts inventory, and asset management.

View our full Click Maint Review.

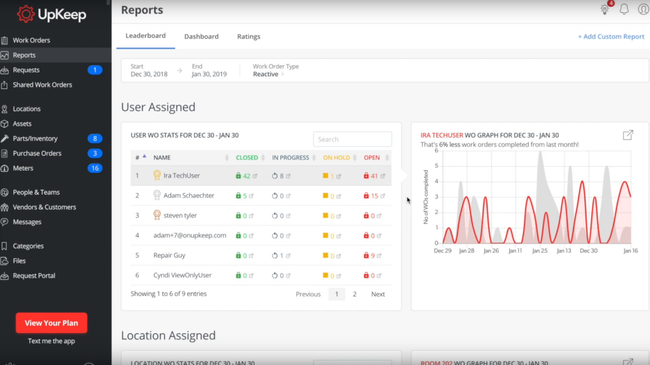

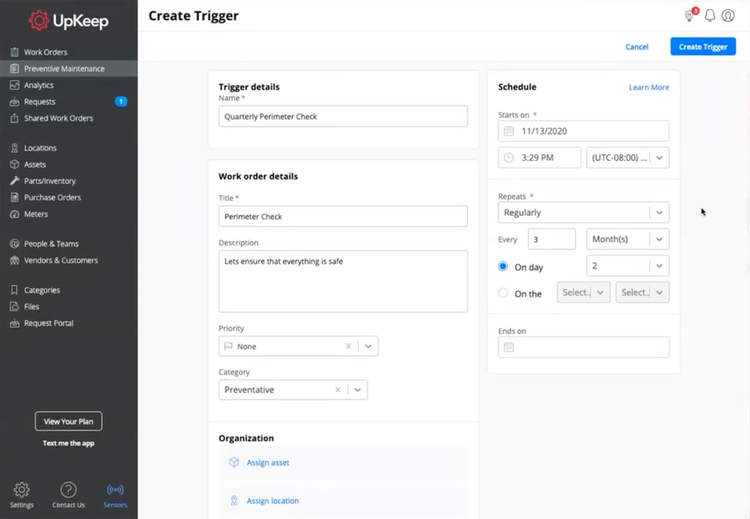

UpKeep - Best for Automated Maintenance Scheduling

UpKeep lets you schedule preventive maintenance work orders automatically by creating custom triggers. These can be time-based, which works well for equipment with more predictable degradation over time, such as facility air conditioning units. If you’re a manufacturer, you can set up meter-based triggers to schedule maintenance after a certain number of production cycles or hours of operation. Once these thresholds are met, you’re instantly alerted, and the corresponding work orders are added to the calendar, minimizing manual processes.

For industries like utilities or oil and gas managing complex assets, UpKeep’s PM templates allow you to upload manuals and checklists. This streamlines routine maintenance or safety inspections, making all equipment information available without leaving the work order. Once completed, the system logs all PMs for complete history visibility.

UpKeep’s pricing starts at $20/user/month for the Lite plan, though it only includes limited preventive maintenance capabilities. Businesses are better off opting for the Starter plan at $45/user/month as it includes full PM scheduling and meter readings functionality.

Visit our UpKeep review for more info.

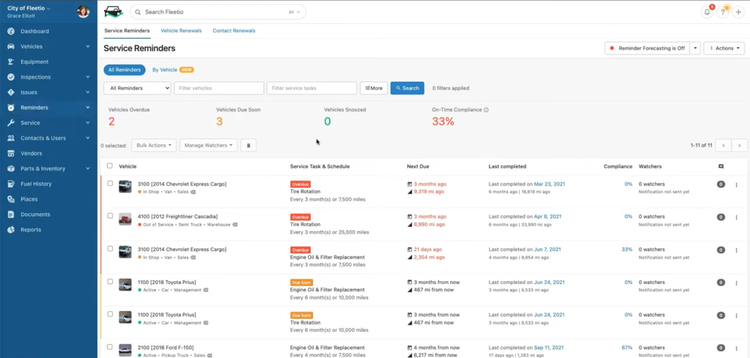

Fleetio - Best for Transportation & Logistics

Fleetio offers a service reminders module to help you organize vehicle preventive maintenance schedules. When you import your vehicles onto the system, it will automatically populate the original equipment manufacturer (OEM) recommended schedules for each. These plans created by the vehicle manufacturer include several items like oil changes, filter replacements, and tire rotation, among other inspection elements. This helps you instantly plan maintenance for your entire fleet and immediately streamline operations.

The system compiles these reminders into a list view that organizes tasks by due date. At the top, you can see how many services are overdue or due soon and your on-time percentage. If vehicles are late, the screen shows the last completed date and how many miles are over the threshold. This gives your maintenance team a clear picture of what needs to be done and if vehicles need to be grounded because of safety concerns, like extremely low oil.

The platform also lets you create customized vehicle preventive maintenance schedules if you don’t want to follow OEM guidelines, or simply require more configurations for your usage patterns. For example, say your fleet operates in harsh weather environments, and you need more frequent maintenance. You can edit the service reminder to lower the time or primary meter threshold.

Fleetio’s most popular Professional plan has an average starting price of $7/vehicle/month when billed annually. However, you will most likely require vehicle diagnostics sensors to capture real time data, which will incur additional costs.

Get more pricing and product details for Fleetio.

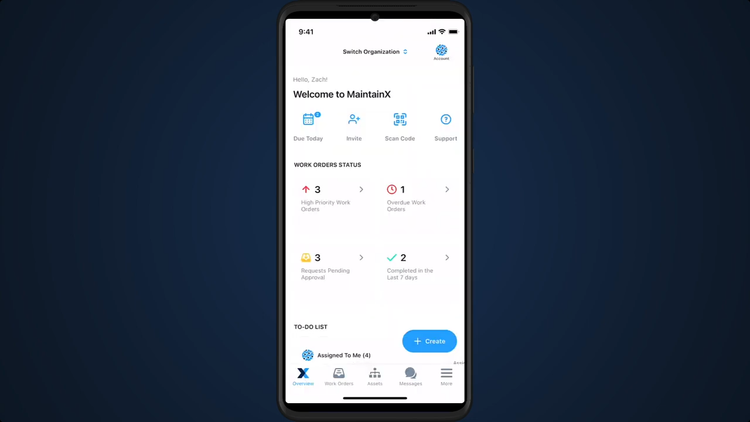

MaintainX - Best Mobile Functionality

MaintainX’s mobile app helps technicians and maintenance managers alike streamline operations. While most preventive maintenance systems include this, MaintainX is one of the easiest to navigate. It features tabs at the bottom for work orders, assets, and messages, so each section is always one click away. This lets you communicate with team members during an ongoing work order without losing progress.

Additionally, the home screen lets you check statuses and schedules without navigating anywhere. It includes buttons like:

- Work orders: View high-priority or overdue work orders. When selected, check their status and urgency level.

- Scan code: This lets you scan a QR or barcode on an asset to show its information and start a work order.

- To-do list: You can see tasks assigned to you and your teams. Tap into each to complete, modify, or delete it.

- Plus button: Create new work orders, assets, locations, or parts. Have full access to templates and procedures.

MaintainX is ideal for small businesses managing facilities or single-site manufacturing plants. It offers a Basic forever free plan or an Essential plan for $16/user/month, though it only allows limited procedural work orders. That said, its most popular Premium plan is $49/user/month, which is still more affordable than comparable systems like Upkeep.

Read our full MaintainX review.

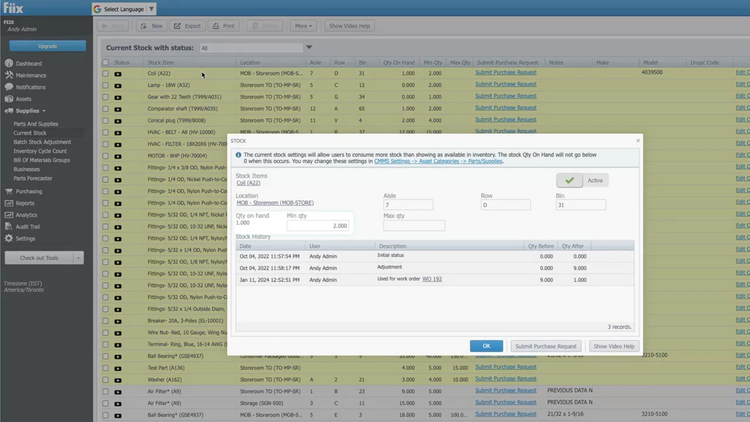

Fiix - Best for Spare Parts Management

Fiix provides a comprehensive spare parts management module to optimize inventory. Whenever parts are used in a work order, the system automatically adjusts its count, eliminating manual update processes. This is ideal for manufacturers or energy companies, as not having enough belts or circuit breakers results in costly downtimes.

The system also lets you set minimum stock quantities for spare parts. You’ll receive alerts via email or the mobile app when counts approach or exceed acceptable thresholds. This way, you can promptly send a purchase order to replenish inventory immediately. If you already have an inventory system, Fiix integrates with leading platforms like SAP Business One and NetSuite ERP for two-way data sync.

For further functionality, Fiix offers a parts forecaster report in its analytics dashboard. This AI-powered tool helps you predict how many components you’ll need based on historical data and the upcoming PM schedule. You can choose up to 25 parts to track, and it will provide recommendations to avoid shortages or overstock. This is best suited for large, multi-site companies that use hundreds or even thousands of spare parts, as it may be excessive for simple facility maintenance.

Fiix offers a free plan that includes 25 active PMs and an unlimited spare parts inventory for small businesses. However, the purchasing module isn’t available until the $75/user/month Professional plan, which is more expensive than systems with similar functionality like eMaint.

Visit our full Fiix review.

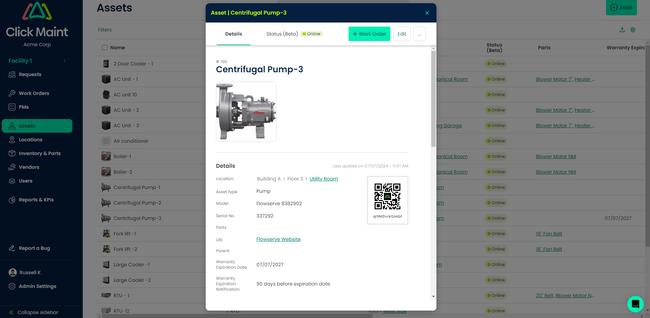

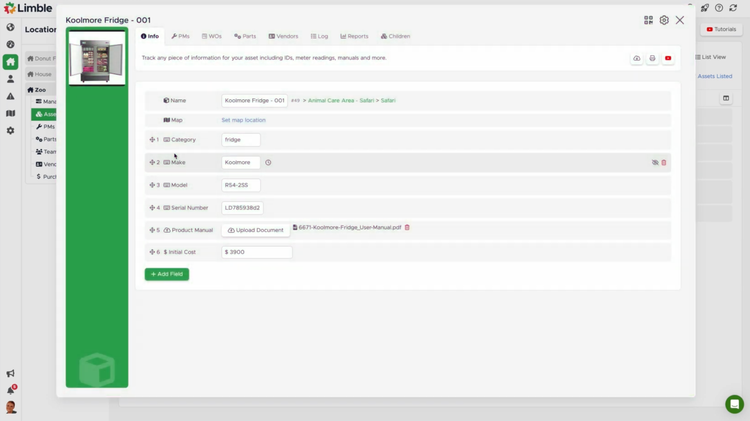

Limble CMMS - Best for Asset Management

Limble CMMS lets you manage lifecycles and track your assets’ PMs. The user-friendly interface allows you to add every asset with as many details as you need, including unlimited custom fields. It’s useful for tracking things like depreciation, initial cost, and even user manuals for your technicians. You can then drag and drop them into organized hierarchies, which is great if you’re a multi-site manufacturer or facility manager. While most CMMS platforms have similar functionality, Limble’s combination of ease-of-use and detail set it apart.

Additionally, you can create flexible PM templates directly from an asset profile to extend their useful life and reduce downtimes. You can select different recurrences based on time, threshold, or number of units. Once it’s set, Limble automatically puts them on a shared calendar so your maintenance team knows all upcoming work. It makes it easy to keep track of hundreds of different schedules throughout your company, helping to keep your machines and equipment up and running.

Limble CMMS is best suited for small to medium-sized companies in several industries like manufacturing, education, and healthcare. While it has a free plan for small operations, most businesses will want the Premium+ plan at $69/user/month billed annually. It’s more expensive than Click Maint or MaintainX, but it’s more scalable if you’re a larger, growing company.

See our full Limble CMMS review for more info.

Other Systems We Like

MicroMain is another good option for manufacturers. It features strong preventive maintenance scheduling, asset management, and spare parts inventory modules. It also supports single or multi-site operations to cater to a wide range of businesses.

What is Preventive Maintenance Software?

Preventive maintenance systems schedule routine maintenance tasks to reduce the risk of production errors, work injuries, and asset damage. These are often thought of as a subset of CMMS software that are more specialized to help automate the creation of maintenance schedules before problems occur. This is opposed to reactive maintenance, which is required once a machine or asset has broken down or experienced delays.

Key Features and Benefits

| Feature | Description | Benefit |

|---|---|---|

| Work order management | Create a trackable document identifying what work needs to be done and how it should be accomplished. | Organizes maintenance requests and ensures timeliness of completion. |

| Maintenance scheduling | Automatically create schedules based on time intervals or usage metrics. | Reduces the amount of missed maintenance tasks and improves asset uptimes. |

| Asset management | Tracks detailed information about all assets, including maintenance history, location, and condition. | Stores crucial information for complete visibility into performance and helps simplify audits for compliance. |

| Reporting and analytics | Track key details about your maintenance activities and analyze data. | Lets you monitor KPIs like the mean time between failures (MTBF) to gauge maintenance effectiveness. |

| Mobile access | Access maintenance information from your phone. Complete work orders, search asset information, and communicate with team members. | Allows technicians to complete work from anywhere without carrying a laptop. |

| Spare parts inventory | Maintain stock of vital supplies needed for your repairs; attach parts inventory to work orders and create purchase orders for restocking. | Prevents part stockouts or overstocking; optimizes inventory costs. |

| Condition monitoring | Using sensors and diagnostic tools, monitor equipment for signs of deterioration, like oil or vibration analysis. | Enables real time data monitoring to predict and prevent failures before they happen. |

How to Choose Software

| Industry or Priority | Recommended Systems | Key Features |

|---|---|---|

| Manufacturing | eMaint, UpKeep, MicroMain | Condition monitoring, meter-based scheduling |

| Transportation and logistics | Fleetio | Fleet maintenance, service reminders |

| Facility management | MaintainX, UpKeep, Limble | Easy-to-use mobile app |

| Affordibility | Click Maint, MaintainX, Fiix | Free and low-cost pricing plans |

Pricing Guide

Preventive maintenance systems can cost anywhere from $0-$100/user/month. While free options are offered for systems like Fiix or MaintainX, they are extremely limited in functionality.

Most systems offer tiered pricing plans that increase in cost with more features. For example, MaintainX has four packages to choose from, starting with its free Basic plan. The Essential plan is $16/user/month and lets you attach images to work orders. The Premium plan is $49/user/month, offering several additional modules like parts inventory management and advanced analytics. Finally, the Enterprise plan requires a custom quote and includes support for IoT integrations and asset health insights.

| System | Free Plan | Starting Price (for paid plans) |

|---|---|---|

| Click Maint | ❌ | $35/user/month |

| eMaint | ❌ | $69/user/month |

| Fiix | ✅ | $45/user/month |

| Fleetio | ❌ | $4/vehicle/month |

| MaintainX | ✅ | $16/user/month |

| UpKeep | ❌ | $20/user/month |

| Limble CMMS | ✅ | $33/user/month |