The Best Predictive Maintenance Software

We’ve evaluated top predictive maintenance software on the market for key functionalities like IoT sensor integration and machine learning. These platforms support various industries, including manufacturing, energy and utilities, and healthcare.

- Proprietary Fluke sensors

- Machine condition monitoring

- Configurable anomaly detection alerts

- Pre-built or configurable asset health scores

- KPI dashboard for each asset

- Uses several metrics to predict failures

- Real time asset risk monitoring

- AI-generated work order descriptions

- Integrates with all sensor types

Predictive maintenance software automates equipment maintenance scheduling based on usage, age, and other factors. We’ve evaluated top options for manufacturing, aviation, and energy companies.

| System | Standout Feature | Best Industry Fit |

|---|---|---|

| eMaint CMMS | Machine condition monitoring with Fluke IoT sensor integration | Manufacturing |

| IBM Maximo | Asset health and predict module | Energy and utilities |

| Fiix | Asset risk predictor | Oil and gas |

| Veryon | Veryon diagnostics and defect analysis | Aviation |

| Limble CMMS | IoT integrations and compliance reporting | Healthcare |

| Samsara | Vehicle telematics with fault detection | Transportation and logistics |

| UpKeep | Edge IoT sensors | Manufacturing or facilities management |

- eMaint CMMS: Best for Manufacturing

- IBM Maximo: Best for Energy and Utilities

- Fiix: Best for Oil and Gas

- Veryon: Best for Aviation MRO

- Limble CMMS: Best for Healthcare

- Samsara: Best for Fleets

- UpKeep: Strong Advanced Analytics

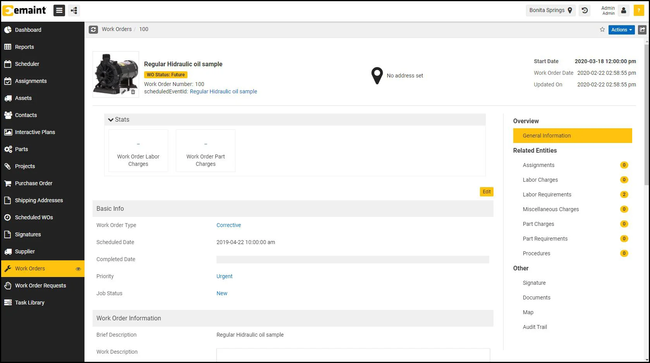

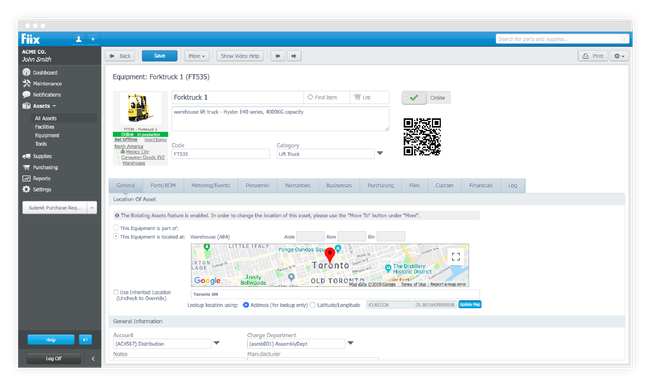

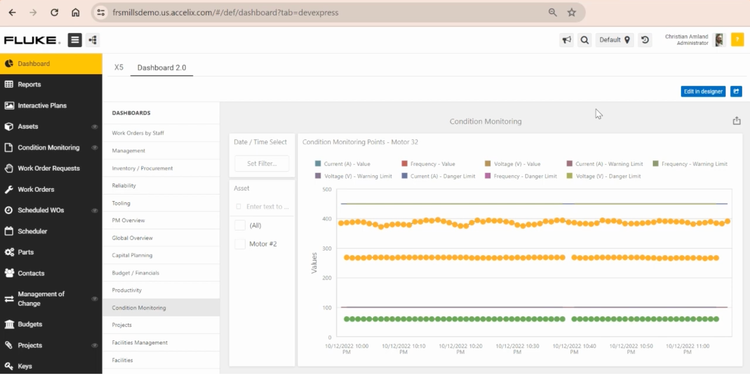

eMaint CMMS - Best for Manufacturing

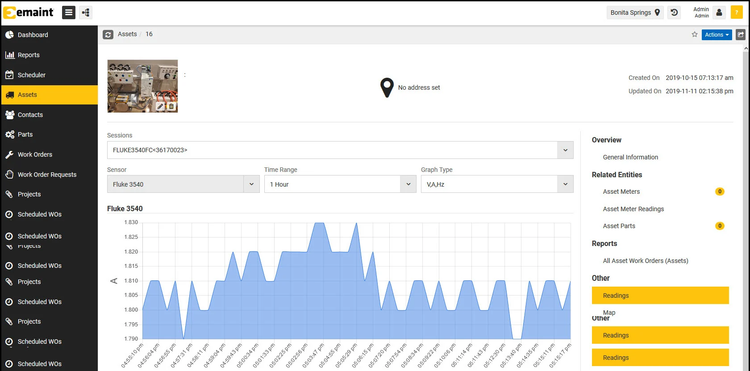

eMaint CMMS’s condition monitoring module can help manufacturers reduce machine downtime during high-level production schedules. Integrating IoT sensors allows you to analyze vibration, temperature, and voltage data across several pieces of equipment to gain health insights. The dashboard lets you drag and drop charts for machine comparison and set acceptable limit thresholds to trigger instant alerts of potential faults. This allows you to catch issues early, reducing overall maintenance costs and keeping your equipment running longer.

The module also includes AI analysis. It recognizes over 1600 fault factor combinations and provides recommendations on corrective action based on the specific issue. This is beneficial for operations in automotive or electronic industries, as issues with complex machinery may not have obvious solutions. AI response actions are included in notifications, helping you prescribe fixes efficiently.

Because Fluke owns eMaint, their proprietary IoT sensors seamlessly integrate with the software. Popular devices include the Azima Accel 310 wireless vibration sensor or the Azima handheld Trio analyzer. This is an advantage compared to other systems, as you don’t have to search through different third-party sensors for compatibility.

eMaint’s condition monitoring module is only included in the Professional plan, which starts at $85/user/month with a three-user minimum. This plan is best for mid to large-sized manufacturers because of the higher subscription price and additional IoT hardware costs.

See our full eMaint CMMS review for more info.

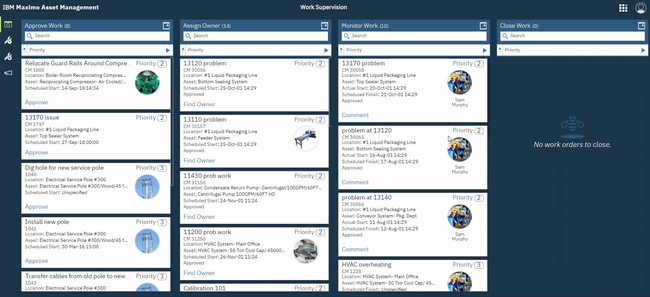

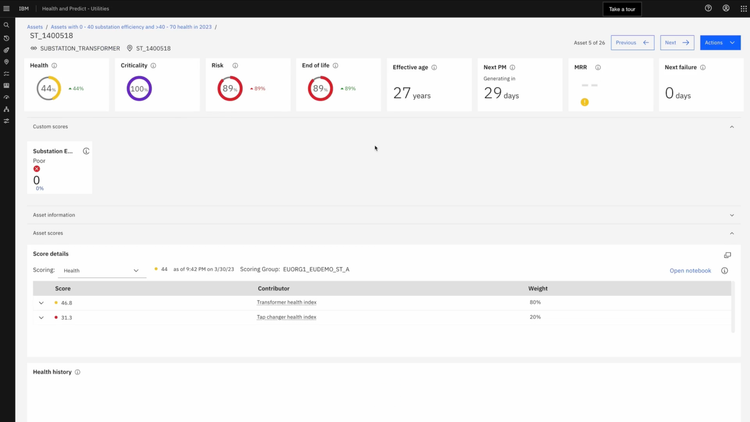

IBM Maximo - Best for Energy and Utilities

IBM Maximo lets you track the status of your energy grid with its health and predict module. It assigns assets individual health scores, which are pre-built based on industry standards. These are also customizable, so you can add personalized contributors like other dependencies or environmental influences. Once configured, you can sort the dashboard by the lowest score to prioritize maintenance on high-risk assets.

Selecting an individual asset displays several scores, including health, criticality, risk, and end-of-life percentage. It breaks down the top contributors to declining health so you can quickly gain insight into the causes and better understand any required maintenance. This can be crucial for large energy companies managing diverse assets like substations, renewable energy sources, and transformers, as failures can have a chain effect on other equipment. The individual screen also displays several other graphs and metrics, including:

- Estimated time to failure: Using historical data, sensor readings, and built-in AI, the system calculates when the next asset failure will occur. This will help you stay proactive in your maintenance and prevent future failures.

- Asset timeline: Shows a record of events for the asset along a plot graph, like performed PMs, failures, and inspections. This helps you make better-informed decisions by having a holistic view of overall maintenance.

- Anomaly detection history: This lets you view each detected anomaly to spot trends in data.

IBM Maximo is a good fit for large-scale operations because it is an enterprise asset management (EAM) system rather than a smaller CMMS. Its pricing starts at around $3,100 per month, includes up to 25 users, and increases with additional work orders per hour. That said, remote monitoring is only available in the Standard plan, starting at about $7,250/month. With IoT sensors requiring additional upfront investment, it’s well-suited for companies managing a large number of assets along multiple energy grids.

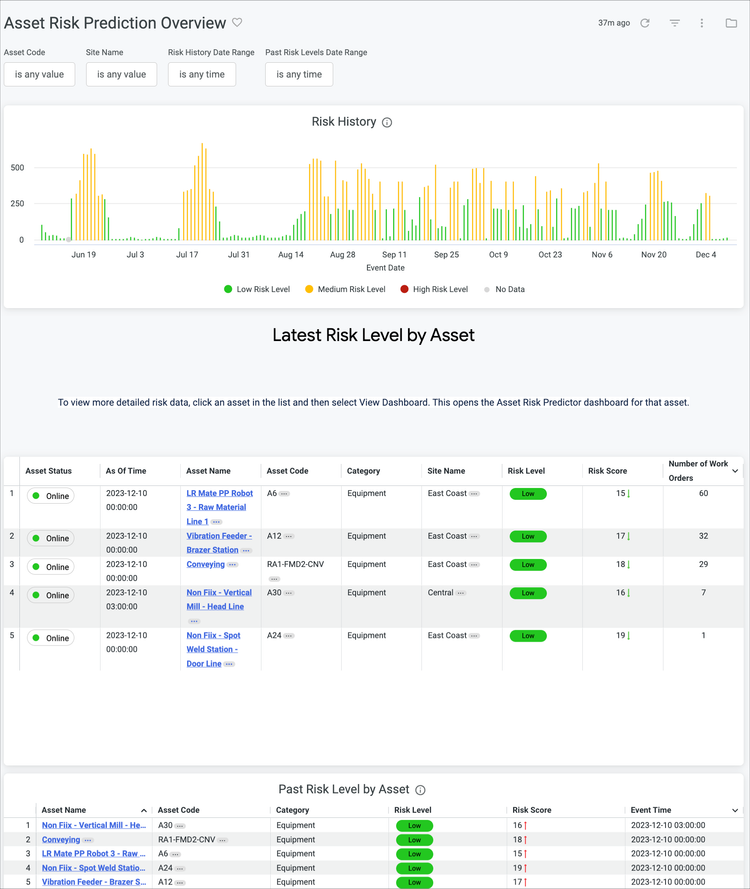

Fiix - Best for Oil and Gas

Fiix’s asset risk predictor is ideal for oil and gas companies managing high-value assets, from drilling equipment to upstream operations like pressure valves and turbines. It uses AI and IoT sensor data to monitor daily risk for critical components in your operation. The interactive dashboards provide hourly or daily updates on overall conditions and individual reports by sensor and asset. By evaluating current risk volatility, you can better predict future maintenance to avoid failures.

When the system flags something as high-risk, it automatically sends an AI-generated work order to your CMMS. It includes a description of the issue and some inspection steps to help you complete work order instructions efficiently. This can help keep oil rigs safe by fixing issues before accidents occur. For further automation, the tool includes the Fiix Maintenance Copilot AI assistant. The chatbot is trained on your data, and you can ask it questions about your operations to find granular insights faster.

Fiix’s asset risk predictor can be purchased and used independently or by existing CMMS users. Pricing starts at $2,400/asset/year, making it best for multi-entity companies managing several critical rigs. It’s also sensor-type agnostic, so any IoT device can monitor vibration, temperature, or voltage.

Check out our full Fiix review.

Veryon - Best for Aviation MRO

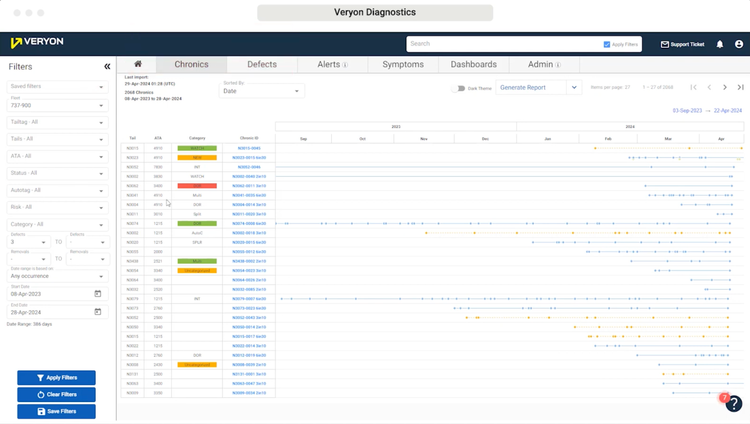

Veryon’s diagnostics module helps commercial and regional operators predict aircraft maintenance and downtimes. The system consolidates data from several sources, including historical performance records, aircraft sensors, and real time operational metrics. It then analyzes the information using AI-driven algorithms to anticipate component failures or potential faults before they occur. This allows maintenance managers to be proactive and extend the life of your fleet.

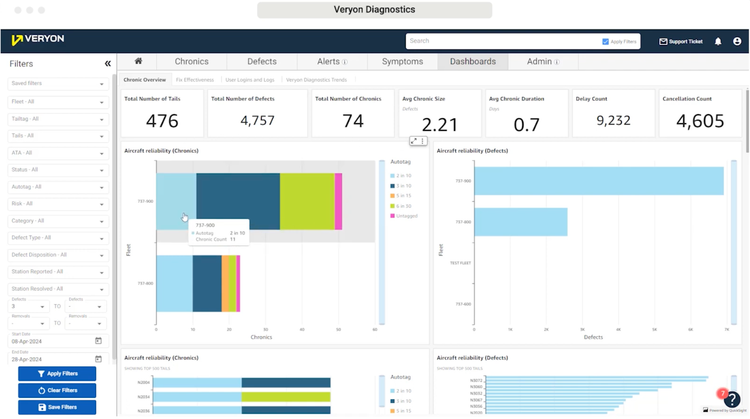

The “chronics” tab lets you generate defect reports for your entire fleet. You can filter the report using the sidebar to show relevant information, such as a specific risk category, number of defects, or time period. Once you narrow it down, click on any defect instances along the chart to see the exact work order. This feature can help you identify trends within chronic problems and conduct root cause analysis to predict future maintenance.

For further analysis, the dashboards tab displays metrics in easily digestible graphs and charts. It’s fully customizable, letting you track only relevant information. KPIs can include first-time fix (FTF) rate, aircraft reliability trends, and total chronic defects. By consolidating high-volume data sets into one configurable view, Veryon allows you to evaluate overall maintenance performance and troubleshoot individual problems.

Veryon is specifically designed for the aviation industry and integrates fleet management and maintenance into a single system. Unfortunately, they don’t release their pricing figures publicly. Also, due to the breadth of features, it has a steep learning curve for new users, though it provides extensive webinars to help.

See our Veryon product page.

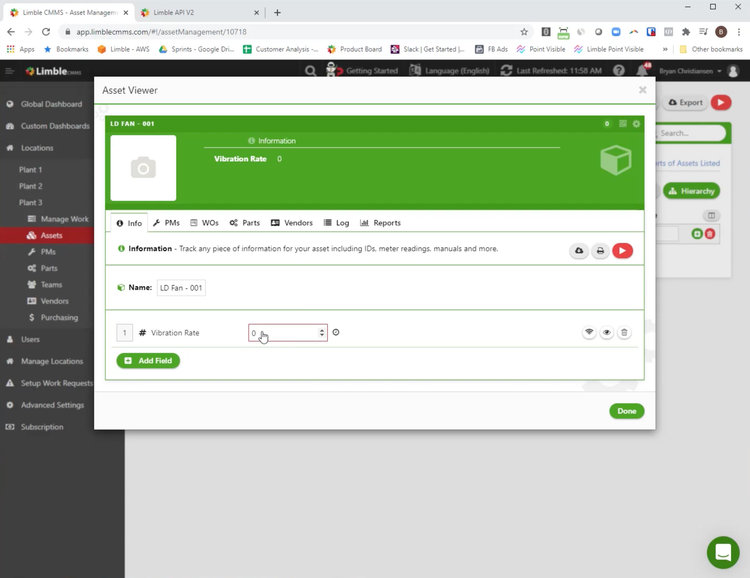

Limble CMMS - Best for Healthcare

Limble CMMS offers an open API to connect IoT sensors to monitor medical equipment conditions. The system sends instant alerts when conditions pass maximum thresholds to ensure you avoid unexpected breakdowns. Depending on the asset, this can be for vibration, temperature, or other variables. By tracking real time data, you can ensure ventilators maintain proper air pressure or MRI scanners don’t overheat.

Further, the platform can help you comply with The Joint Commission (TJC) audits. Limble logs all maintenance activity, including historical sensor data. Using this, you can reference past work orders with every detail showing that equipment is up to TJC code and safe for patients. This will help you pass unannounced audits to become accredited and avoid substantial fines.

One downside to Limble is it lacks proprietary sensors for condition monitoring, so you have to shop for compatible sensors on your own. This can be a tedious task, as there are several brands and types to choose from. If you’re looking for a one-stop shop for software and IoT devices, eMaint or Fracttal are good alternatives that offer proprietary sensors.

While Limble offers affordable plans for its basic features, IoT sensor integration is only available on the Enterprise plan, requiring a custom quote. That said, it offers multi-location support and connects with other software.

Read our full Limble CMMS review for more information.

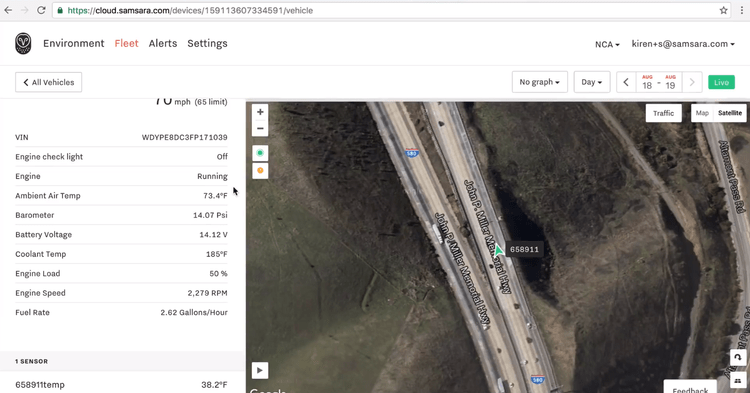

Samsara - Best for Fleets

Samsara’s real time vehicle diagnostics allow you to predict future problems for your fleet. It works similarly to a condition monitoring system, except it’s specifically designed for vehicles. It monitors key metrics like engine health, temperature, fluid levels, and even cargo temperature for food and beverage transport. This lets you predict breakdowns and proactively schedule maintenance, protecting drivers and fleet longevity.

Samsara automatically detects faults and immediately alerts you to problems. It shows the data reading, occurrence count, and severity level so you can take appropriate action. These carry over to the maintenance tab, where you can create work orders detailing the exact issue for technicians. Combining these functionalities can reduce costly unplanned breakdowns and keep your vehicles running longer.

It’s important to note that Samsara is a fleet management system, and its predictive maintenance capabilities don’t extend beyond vehicles. While a great option for logistics companies, those requiring maintenance for other asset types must integrate with a CMMS system like Limble.

Read more about Samsara.

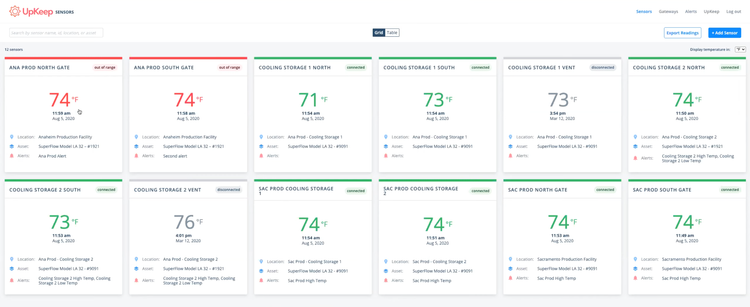

UpKeep - Strong Advanced Analytics

UpKeep offers proprietary Edge IoT sensors that monitor assets in real time, allowing you to report on key analytics. They offer four sensor types, including:

- Temperature Sensor: Monitors the temperature of assets like manufacturing machinery to predict overheats.

- Humidity Sensor: Monitors data like humidity, dew point, moisture weight, and heat index to identify possible moisture buildup, which can cause rust, short circuits, and corrosion.

- AC Current 150 Amp Sensor: Tracks maximum and minimum current levels so you can ensure optimal energy output for assets and track runtime hours.

- Vibration Sensor: Senses vibration data like frequency, acceleration peak, and crest factor to predict operational failure.

The sensors capture critical asset data, which is exported to the analytics module for streamlined reporting. Here, you can track asset reading history to see every atypical sensor reading. This can help you predict when the next downtime event will occur so you can instantly create a work order before the asset breaks down to extend its useful life. Plus, when the sensor data exceeds the configured limits, you’ll be instantly notified.

UpKeep is best for midsize companies that don’t need the complex features of a larger system like IBM Maximo. And while the sensors are effective, they’re more basic and offer fewer options compared to eMaint’s industrial-grade Fluke sensors. That said, UpKeep’s pricing is more affordable, but you’ll need the Business+ package for the full analytics module, which requires a custom quote.

Learn more in our full UpKeep review.

Other Systems We Like

Fracttal One is a CMMS that offers proprietary “Sense” IoT devices for predictive maintenance. It’s a good option for manufacturers and energy companies requiring condition monitoring for their machines and assets.

What is Predictive Maintenance Software?

Predictive maintenance software is a subset of CMMS software that uses data from IoT sensors, machine learning, and advanced analytics to monitor equipment and predict potential failures. It enables organizations to track real-time asset performance, identify anomalies, and schedule maintenance tasks before breakdowns occur, minimizing downtime and repair costs.

This method is opposed to reactive maintenance, which only occurs after equipment or assets have broken down, or preventive maintenance, which offers more routine scheduling regardless of performance.

Key Features

| Key Feature | Description | Benefit |

|---|---|---|

| Condition monitoring | Tracks machine parameters like vibration, temperature, and pressure to detect anomalies. | Helps you become proactive in maintenance and reduce downtimes by catching faults before they result in failures. |

| Failure prediction | Uses historical and real time analytics to predict when equipment may fail. | Reduces maintenance costs and extends asset lifespans by mitigating unexpected downtimes. |

| Alerts and notifications | Receive proactive alerts on asset statuses and maintenance needs based on predictions and sensor data. | Allow you to take action before failures occur. |

| Maintenance scheduling | Automatically schedules work orders based on predicted needs. | Gives your technicians clear instructions for the job and helps organize and delegate tasks. |

| Reporting and analytics | Compile asset and maintenance data onto customizable dashboards for analysis. | Let you analyze key metrics and extract insights to improve operations and reduce maintenance costs. |

Predictive vs. Preventive Maintenance

While both can be part of larger CMMS systems and share similar features, there are some important distinctions.

| Difference | Preventive | Predictive |

|---|---|---|

| Scheduling | Uses fixed time or meter-based intervals to schedule work orders, regardless of performance. | Schedules can fluctuate based on real time asset conditions, and maintenance is done only when necessary. |

| Data collection | Mainly relies on historical data and manufacturer recommendations. | Also uses historical data but incorporates AI, IoT sensor data, and complex predictive algorithms. |

| Requirements | A standard CMMS system with minimal technology. | Technology like IoT sensors and AI are required. |

| Cost | Lower initial and subscription costs, but higher potential maintenance costs. | Higher upfront costs but potentially lower maintenance costs. |

Different System Types

Predictive maintenance can be found within several different umbrella systems, including:

- CMMS: While not found in every CMMS, predictive maintenance is offered in more advanced systems, like eMaint and Limble. While they still include standard features like preventive maintenance, they can go beyond and connect with IoT sensors for remote monitoring.

- EAM: Enterprise asset management systems often include predictive maintenance capabilities. Products like IBM Maximo use sensors to monitor asset health and AI algorithms to predict failures.

- Fleet Management: Platforms like Samsara are specific to managing vehicle fleets, like trucks, vans, and heavy machinery. They often include predictive maintenance through diagnostic sensors.

- Aviation MRO: Similar to fleet management, systems like Veryon help maintain aircraft fleets and predict faults.

Pricing Guide

Prices for predictive maintenance software can vary widely depending on the type of system you need:

- CMMS systems typically range between $16-120/user/month for small to midsize operations and can even exceed that for larger businesses.

- EAM software is much more expensive, costing anywhere from $1,000-$12,000/month. These are more suited for enterprise companies managing many high-value assets.

Other factors and costs to consider include:

- IoT sensors

- Implementation fees

- Cloud or on-premise deployment

- User and asset count

- Support and training fees