The Best Enterprise Asset Management Software

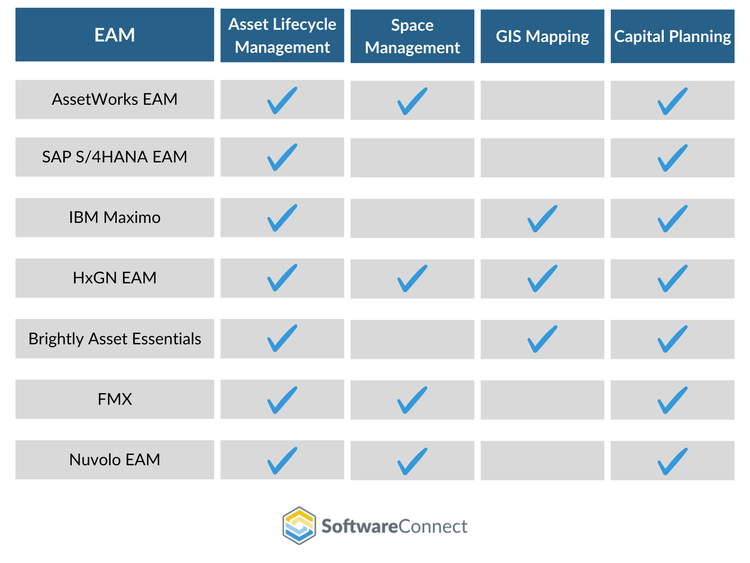

We’ve reviewed the top EAM systems on the market for all different industries and functionalities. Whether you require GIS mapping or condition monitoring for your manufacturing production lines, you’ll be able to find a solution that fits your company’s needs.

- Assign health scores to each asset

- Supports assets with dependencies for power grids

- Offers public pricing

- Supports global operations

- Offers proprietary IoT sensors

- Monitors asset conditions in real time

- Fully integrated EAM module within the ERP system

- Asset performance management with IoT sensor monitoring

- Configurable maintenance strategies

We’ve ranked EAM systems across different industries, such as utilities and energy, oil and gas, and manufacturing. We also considered their support for key functionalities like geographic information system (GIS) mapping and capital planning, helping you find the best solution for your business needs.

- IBM Maximo: Best for Utilities and Energy

- eMaint: Best for Condition Monitoring

- SAP S/4HANA: Best for Manufacturing

- Nuvolo EAM: Best for Healthcare Organizations

- HxGN EAM: Best for Oil & Gas

- Brightly Asset Essentials: Best GIS Mapping

- FMX: Best for Energy Management

- AssetWorks EAM: Best for Capital Planning

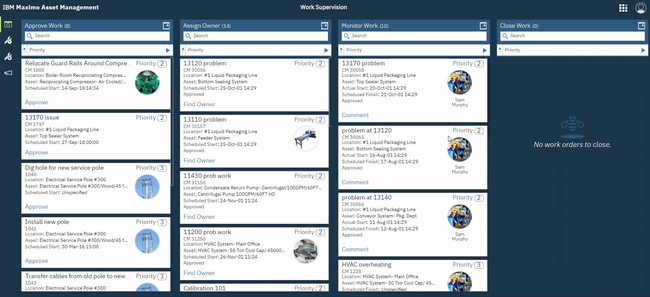

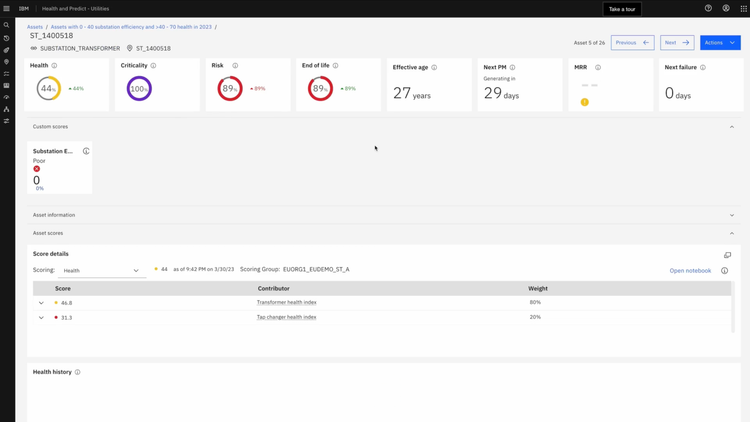

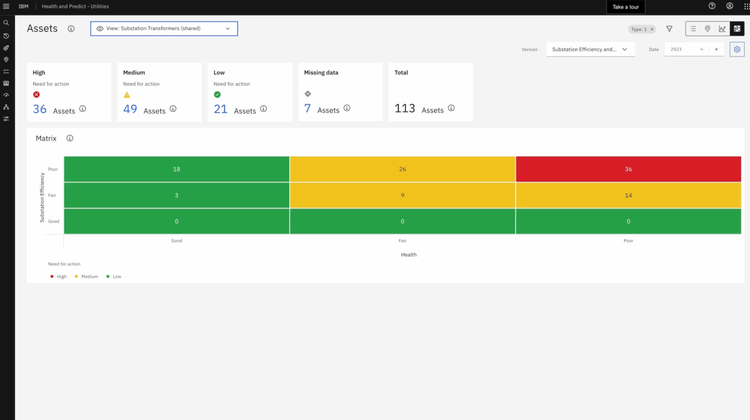

IBM Maximo - Best for Utilities and Energy

The health and safety for utilities module in IBM Maximo helps you monitor the health and status of assets like power grids, substations, and transformers. It features a map view of assets that shows each asset’s color-coded health scores. This helps identify any possible risks to that asset and those it is connected with.

For example, if a transmission line shows a red health score, you can quickly view nearby transformers and substations to see if cascading failures are likely. The map lets you prioritize maintenance based on criticality and the interconnected nature of your utility network.

Any asset can be singled out and viewed in detail. This view shows essential data such as health score, criticality, and effective age. The system uses the following criteria to determine the asset’s health:

- Historical data: Shows operational history, including downtime, repairs, and maintenance. Utility companies can use this data to decide whether to repair or replace aging infrastructure based on past breakdowns and comparisons to similar assets.

- Environmental influences: Takes into account environmental causes of damage, such as temperature fluctuations, weather conditions, or lightning strikes. Companies operating in severe weather-prone regions can use this to determine future maintenance strategies.

- Inspection reports: Uses information from inspection reports to better determine when failure will occur.

Considering these variables enables you to see a complete overview of the asset’s life and determine appropriate next steps, if necessary, to prevent further damage or failure.

Additionally, the module helps you implement effective asset maintenance strategies. For example, if the health score of a high-value transformer is consistently lower than the other transformers on the power strip, you can use Maximo to analyze contributing factors like extreme environmental conditions, higher operational loads, or infrequent maintenance. By pinpointing these issues, you can tweak your maintenance schedule or reassign operational loads.

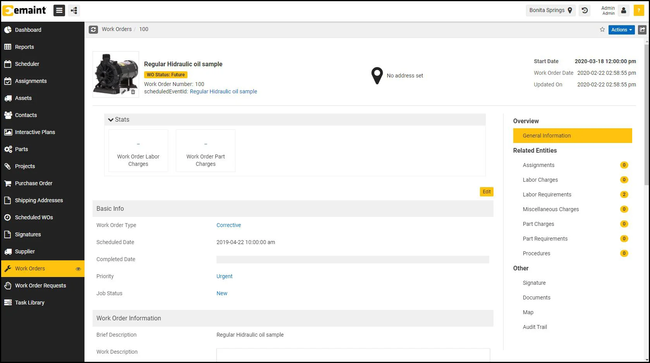

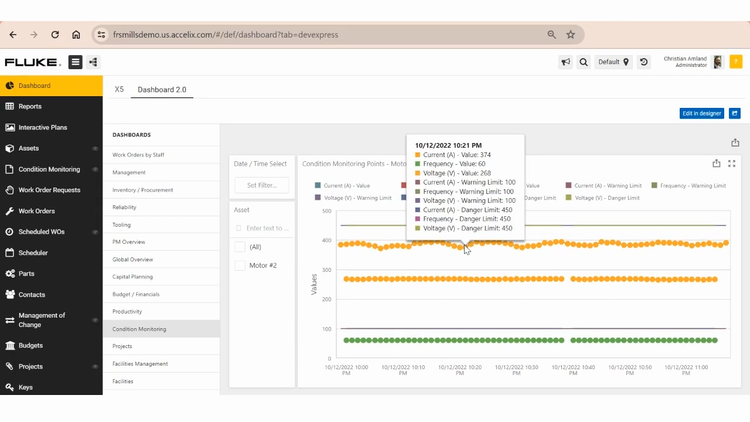

eMaint - Best for Condition Monitoring

eMaint offers its own Fluke IoT sensors that let enterprise manufacturers monitor the condition of their high-value production assets. The sensors evaluate your machine’s vibration, voltage, temperature, and other metrics to detect any potential failures. When readings pass beyond the configured threshold, the system instantly alerts you so you can respond as soon as possible. That way, you can reduce critical production asset downtime and catch faults before they become costly breakdowns.

Also, the condition monitoring module lets you analyze data using AI. The AI analysis feature recognizes over 1,600 combinations of fault factors, giving you recommendations for each. It’s great for super complex equipment, like multi-axis CNC machines, where you or your technicians won’t always know the exact solution to a problem immediately. The AI can point you in the right direction and give suggestions based on the data it receives, boosting your uptime, OEE, and MTTR.

eMaint is well suited for global manufacturing operations, as you can connect additional systems like your SCADA and ERP. It also offers an affordable $85/user/month plan that includes the condition monitoring module, but large companies may need to opt for the Enterprise plan, which requires a custom quote.

Read our full eMaint review for more information.

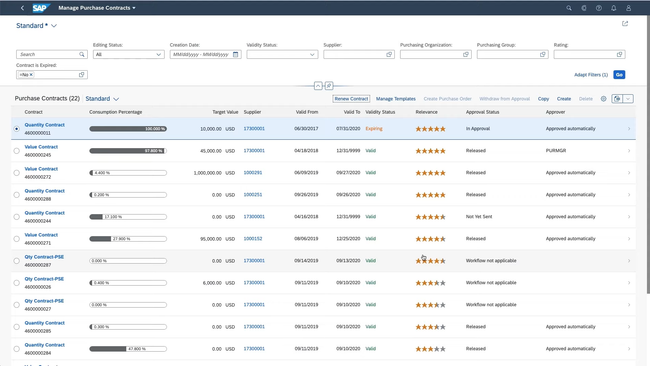

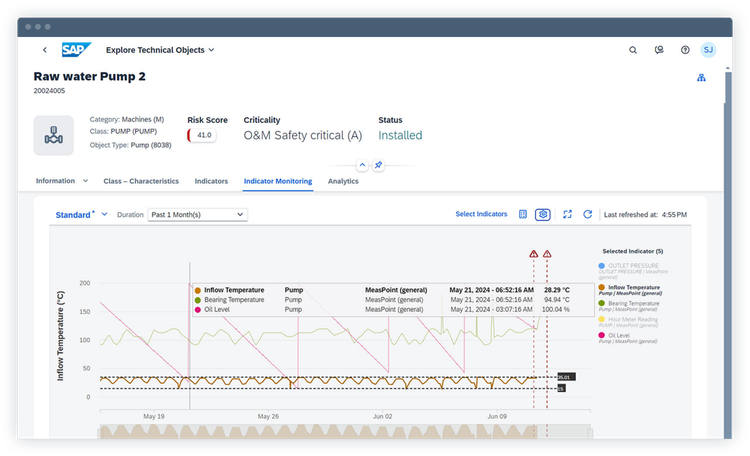

SAP S/4HANA - Best for Manufacturing

SAP S/4HANA offers an effective EAM suite with an asset performance management tool for manufacturers that helps monitor machine behavior and create maintenance plans. For a reliability engineer, the ability to assign a scale of business impact to each asset is crucial. This allows you to develop the appropriate maintenance strategy—whether it be reactionary, preventive, or predictive—based on how critical the asset is to production. Say a piece of equipment won’t have any impact on production if it fails; you don’t have to create a complex preventive maintenance schedule. Simply mark it as “run to fail” and repair or replace it accordingly when it breaks down.

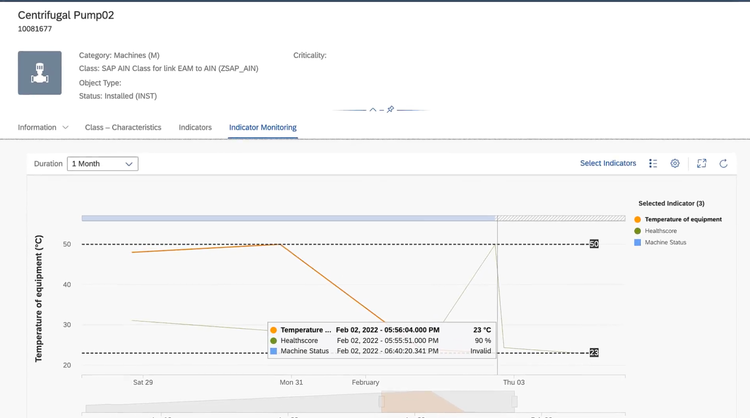

The system integrates with third-party IoT sensors to track real-time machine data for condition and indicator monitoring. You can see indicators such as equipment temperature, machine status, and health score to ensure smooth operation. Customizable rules can be applied to equipment to set optimal indicator ranges, so when levels become unstable, alerts are sent.

All IoT sensor data is archived and leveraged with machine learning to help predict future maintenance needs and strategies. It analyzes historical failures and other data to determine equipment criticality, allowing you to assess your current approach to reduce machine downtimes.

While S/4HANA offers a strong EAM module, we wouldn’t recommend this system for companies with an existing ERP system that don’t want to switch. It’s a highly complex solution that requires significant time and financial investments. You may find it easier to integrate your ERP with a standalone EAM system, such as IBM Maximo or HxGN.

Read our full SAP S/4HANA review.

Nuvolo EAM - Best for Healthcare Organizations

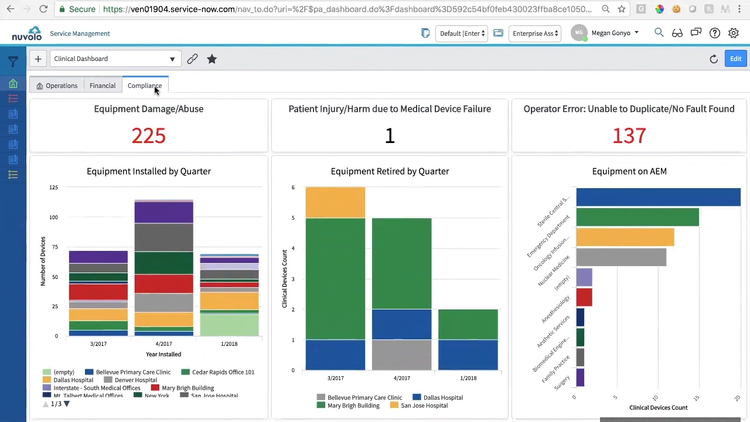

Nuvolo EAM includes a clinical dashboard module that helps healthcare organizations stay compliant and manage asset maintenance operations. Specifically, the compliance tab of the module shows detailed information about medical equipment from every hospital and clinic in your organization. You can see how many patient injuries were caused by medical device failures and other equipment information, which is vital for passing The Joint Commission (TJC) audits.

The operations tab of the dashboard visualizes maintenance KPIs for all medical devices and equipment across your organization. For example, it includes a graph showing trends for root causes, such as error codes, improper training, and configuration issues. This allows you to identify problematic processes and better understand why certain equipment fails, which helps keep equipment safe for patient use in a clinic or hospital setting.

Nuvolo EAM’s clinical dashboard even has a financial tracking section for medical device asset lifecycle tracking. This makes managing hundreds or even thousands of assets across multiple hospitals much easier, as all the financial metrics are consolidated into easy-to-read charts. It’s highlighted by the projected end-of-life chart that shows which assets will need replacing in the next 10 years. This helps you ensure budgets are accurate for every location and devices are replaced before they reach end-of-life to maintain operational safety.

HxGN EAM - Best for Oil & Gas

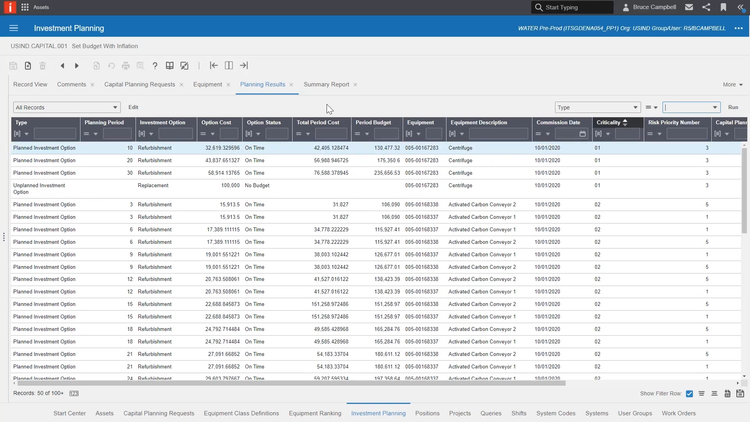

HxGN EAM includes an asset lifecycle management tool that helps oil and gas companies track critical infrastructure health for pipelines, rigs, and refineries while developing spending strategies. The investment planning function allows you to outline strategies for future repairs or new equipment purchases. It considers inflation adjustments for multi-year projects, time, risk, and current criticality to determine total costs.

The asset lifecycle management tool combines condition monitoring with investment planning to actively monitor and track current equipment for its health and financial impact. You can choose between different investment options, like total replacement or refurbishment while setting the cost of the option and tracking the status. Criticality and risk can also be viewed on the same dashboard. This helps you assess and prioritize projects more effectively, ensuring high-risk or high-impact assets like pipelines or offshore platforms are managed with appropriate urgency and budget considerations.

The data from the menu is then compiled into dashboards and reports that provide a broader overview of asset lifecycle data. This includes planning and equipment data and work order reports to help provide a holistic view of asset maintenance across the company. This helps spot trends and lets you see which equipment requires repairs to prevent unplanned downtimes.

Brightly Asset Essentials - Best GIS Mapping

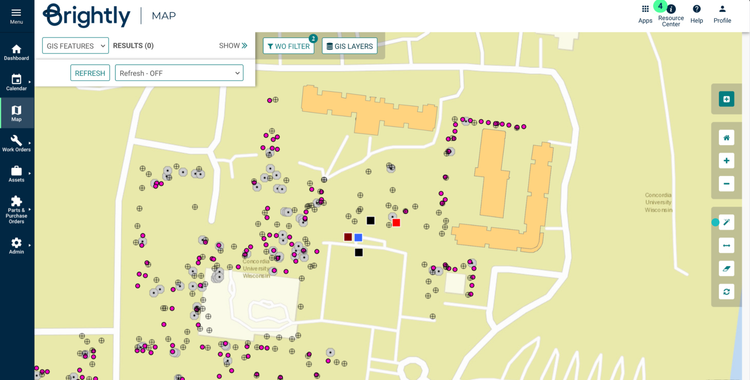

Brightly Asset Essentials offers direct integration with Esri ArcGIS to help enterprises in the energy, education, and government industries map their assets and infrastructure. This is useful for accurate asset plotting, whether for one facility or powerlines spanning miles. It also gives an accurate spatial understanding of asset locations to deploy the correct maintenance team to the exact location of the asset/facility.

The GIS mapping tool features spatial data layering to provide more advanced visuals. You can overlay different datasets on a single map to view multiple types of assets at once. This includes information like underground infrastructure and individual power lines with detailed equipment. Furthermore, you can even include natural features if the equipment is in rough terrain to prepare your technicians or analyze how it affects maintenance needs.

Brightly Asset Essentials also integrates with IoT sensors to monitor asset health. You can view sensor data directly from the GIS map by selecting any individual asset to view performance and overall health. This capability helps you respond promptly to potential issues and ensure the optimal performance of critical infrastructure like pipelines or water treatment systems.

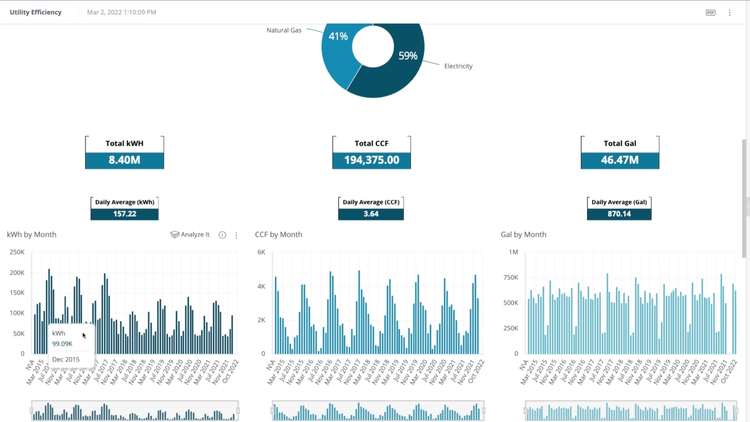

FMX - Best for Energy Management

FMX helps enterprises manage and reduce energy costs with its utility tracking module. Within the module, you can configure new utility tasks with detailed information about their type, whether it’s time- or meter-based, and their provider. This allows you to customize the module to your specific industry and is especially useful for manufacturers, educational institutions, and municipalities managing a large amount of energy.

The utility tracking tool also consolidates energy usage data into easy-to-read charts to view total consumption and costs. Separate different types of energy, like electricity, water, and natural gas, to see which is costing you the most. You can then drill into each one to view costs per building or per month and compare them with industry standards. The data can be used to implement targeted energy-saving measures, like optimizing HVAC schedules to reduce usage during off-hours or upgrading to energy-efficient lighting.

FMX is best suited for large government and education organizations that manage and maintain several facilities and their assets. We wouldn’t recommend it for those in the oil and gas industry, as it lacks advanced condition monitoring capabilities. HxGN or SAP S/4HANA will better suit that industry.

Read our FMX product page to learn more.

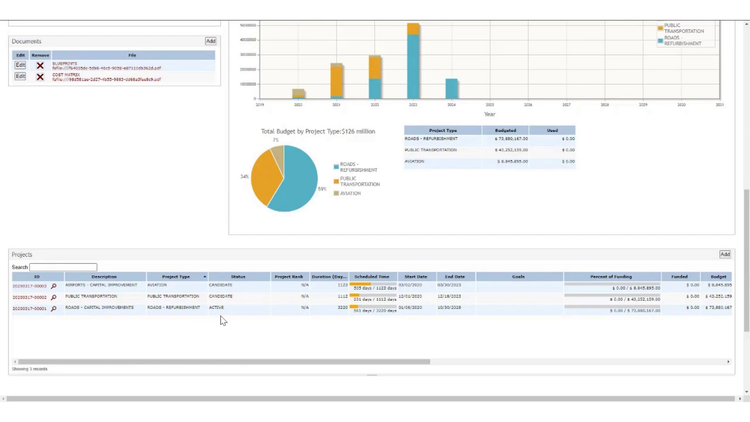

AssetWorks EAM - Best for Capital Planning

AssetWorks EAM offers a strong capital planning and budgeting module for managing high-value projects. It offers multi-year planning for long-term investments up to 30 years, such as implementing new infrastructure or repairing several pieces of equipment. You can calculate the initial budget for the investment, and it dynamically adjusts as the project progresses, ensuring you always have the most up-to-date information.

For example, say there’s an ongoing project to update multiple transformers, and the powerline is discovered to be corroded and needs replacing. You can coordinate with the maintenance team to calculate the new cost of repairs, update the project details, and adjust the budget accordingly.

Additionally, projects can be viewed in detail, so you can analyze the real-time budget, schedules, work orders, and approvals. This gives you a more detailed breakdown of where the budget is being allocated, and you can see if there are inefficiencies or overspending in certain areas of the project.

AssetWorks’s capital planning module also has a lifecycle cost analysis tool to calculate the total cost of ownership for all assets. This includes variables like initial investment, depreciation, maintenance, and replacement cost. For example, if a critical piece of equipment or production line machine is experiencing frequent breakdowns, you can use the module to evaluate its replacement costs and determine if there’s room in the budget to replace it completely.

Other Systems We Recommend

Champs EAM is also a good option for manufacturing and utilities industries. It offers strong procurement modules, meter tracking, and equipment monitoring features.

What is EAM Software?

An enterprise asset management (EAM) system is a tool used to manage the entire lifecycle of an organization’s physical assets, from acquisition to replacement. It also helps maintain asset health and generates analytics on data and conditions.

Often considered an extension of CMMS, EAM systems provide more advanced features for higher-value asset management. They’re built to handle large data volumes and manage assets for national and global enterprises.

Common Challenges

- Lack of asset visibility: Assets can slip through the cracks within enterprise companies, especially for national and global operations. This can lead to unplanned downtimes and costly repairs for critical equipment.

- Investment management: Creating a plan for each investment on new infrastructure or complex repairs will help ensure your company can afford it and that it’s worthwhile.

- Compliance: Different industries must ensure compliance with various laws and regulations to keep their workers safe and assets operational.

- Maintenance planning: Managing maintenance strategies for hundreds of high-value assets is crucial to keep operations running smoothly.

Key Features and Benefits

- Asset lifecycle management: Track assets from initial purchase to replacement while monitoring their financial and operational impact.

- GIS mapping: Accurately plot equipment and facilities on a geographic basis to help technicians quickly find them for repairs and monitor health. Many have built-in integration with leading GIS systems like Esri ArcGIS.

- Condition monitoring: EAM systems integrate with IoT sensors to monitor machine and other asset performance and conditions to ensure proper operations. Data is collected and sent to the system for real-time health analysis.

- Analytic dashboards: Analyze asset data, including performance, health, costs, and risk.

- Capital and investment planning: EAM systems let you track the costs of asset investments against your total capital budget, helping you allocate funds efficiently.

- Space management: Track utility costs across all facilities and infrastructure to monitor anomalies and overall costs.

- Predictive maintenance: Predict asset failures based on data and performance metrics to stay ahead of machine breakdowns.

How to Choose the Right EAM System for Your Business

Some EAM systems are designed for specific industries, so it’s important to select one that fits your business’s needs.

| Industry | Best System | Important Features | Example of Assets Maintained |

|---|---|---|---|

| Manufacturing | SAP S/4HANA, IBM Maximo, eMaint | IoT condition monitoring, FDA compliance, maintenance strategy planning | Production machines, robotics, tooling |

| Energy and Utilities | IBM Maximo, Brightly Asset Essentials | Asset health monitoring, predictive maintenance, GIS mapping | Power plant equipment, turbines, power grids |

| Oil & Gas | HxGN EAM, AssetWorks EAM | Asset lifecycle management, predictive maintenance | Drilling rigs, pipelines, refinery equipment |

| Healthcare | Nuvolo EAM, FMX | TJC compliance reporting, space management, asset tracking | Medical equipment - diagnostic tools, patient monitoring systems |

Pricing

Pricing for EAM systems can vary, ranging anywhere from $1,000 to $12,000/month. This largely depends on several factors, including:

- Implementation fees

- IoT sensor purchase and implementation

- User and asset count

- Cloud-based vs on-premise deployment

- Support and training fees

Unfortunately, most EAM systems do not publicly disclose their prices. However, one that does is IBM Maximo, which provides insight into what to expect when purchasing a complete EAM system. Their base plan starts at $3,150/month with up to 25 users, and the Standard plan starts at about $7,200/month. Its Premium version, which includes custom configuration, requires a quote.

Frequently Asked Questions

How is an EAM system different from a CMMS?

Both systems are similar, as both help manage assets and improve maintenance strategies. The main difference is that EAM systems manage high-value assets through their entire lifecycles, while CMMS is more maintenance-focused, helping organize work orders and inspections for smaller companies.

Read more: CMMS vs. EAM: What’s the Difference?

Does ERP software work as an EAM?

Enterprise resource planning (ERP) systems are much different than an EAM system. ERP has a broad scope covering financials, manufacturing, human resources, and some basic EAM functionality like financial planning for asset purchases. An EAM is a more focused system with the main goal of organizing and maintaining a company’s assets.

Most often, companies choose to invest in separate ERP and EAM systems and integrate them, as they both have different purposes and functionalities. Only in rare cases do ERPs have full EAM modules, like SAP S4/HANA.