eTurns TrackStock

4 Reviews 5/5 ★ ★ ★ ★ ★A cloud-based inventory management software that uses real-time RFID tracking.

Product Overview

eTurns TrackStock is simple, cloud-based inventory software that automates replenishment based on need and provides real-time inventory visibility into remote stockrooms. Using barcode scanners, smartphones, IoT weight sensors and RFID, eTurns TrackStock manages inventory at the point-of-use to increase sales and service levels, optimize inventory and eliminate stockouts.Pros

- Provides straightforward picking process

- Real-time inventory visibility

- Multiple tracking methods with RFID and sensors

Cons

- Cannot print labels during picking process

- Cannot customize program

Target Market

Businesses managing large and varied inventories, especially in medical and healthcare settings like clinics and hospitals. Also serves industrial distributors, multi-location manufacturers, and contractors with service trucks.Video Overview

Solutions

- eTurns TrackStock Replenish streamlines the ordering process by allowing users to scan bins of parts with a smartphone or PDA to order directly from suppliers, bypassing the need for manual entry. eTurns TrackStock Manage helps manage inventory by scanning to use or receive items, adjusting min/max levels based on actual usage, and providing alerts on inventory status. It also supports billing on consigned usage.

- eTurns TrackStock RFID simplifies transactions by enabling orders, usage, or receiving through a single scan of a tagged bin.

- eTurns TrackStock eVMI offers an automated inventory management solution with IoT weight sensors that trigger replenishment orders based on the weight of parts. This system integrates with distributors’ ERP systems for automated ordering and restocking.

- eTurns TrackStock Truck provides real-time visibility into service truck inventories, tracking parts and labor usage, and automating inventory management.

- eTurns TrackStock Asset tracks and maintains assets, optimizing the inventory of materials needed for maintenance. Additionally, it allows users to add materials to work orders and sends maintenance alerts.

- eTurns TrackStock Tool keeps track of tools, sends alerts for recalibration, and prevents checkouts until tools are serviced.

Sectors

Industrial Distributors: This includes wholesale industrial distributors needing automated replenishment for their customers’ stockroom inventories. eTurns supports consigned inventory by recording consumption using barcode scans or RFID towers, allowing distributors to bill based on usage and providing a single invoice for reconciliation.

Contractors with Service Trucks and EMS Companies use eTurns for replenishing and managing inventory on their trucks.

Healthcare companies utilize eTurns to replenish supplies in stockrooms using a simple iPhone app.

Manufacturers rely on eTurns to keep MRO inventory in stock using min/max levels for optimization.

Modules

- Inventory

- Bills of material

- Quicklists

- Counts

- Staging

- Move material

- Consume

- Pull

- Work order

- Requisition

- Project spend

- Replenish

- Cart

- Orders

- Receive

- Transfer

- Return orders

- Assets/Tools

- Tools

- Assets

- Scheduler

- Scheduler mapping

- Maintenance

- Kits

- Build/break kits

- Reporting

- Barcode label configuration

- Catalog printing

- Customized reports

- Scheduled alerts

- Dashboard alerts and analytics

- User configurations

Cycle Counting

- Perform physical inventory or cycle counts

- Manage a variable cycle count process for the stockroom

- Set the number of times each of the inventory classifications are counted per year

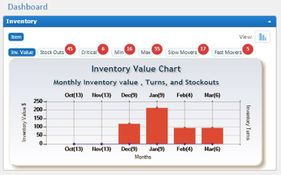

Dashboard Alerts and Analytics

- Focuses user’s attention on their “to dos” with red circle alerts

- Examples of alerts:

- Items below minimum or critical quantity

- Requisitions that need approval

- Orders that need approval

- Pulls that need to happen

- Assets that need maintenance

- Tools that need calibration

- Cycle counts that need to be performed

- Projects that have exceeded $ or item quantity limits

- Receives that are ready

- Transfers that need completion

- Optimize min/max levels based on consumption or orders

- Analyze stockroom: valuation, turns, stockouts, category/supplier allocation

Kitting

- Monitor items needed to build kits using WIP (work in process)

- See how many kits can be built based on components in inventory

- Maintain inventory of kits using min/max levels

- Create suggested orders for components when kit quantities fall below the minimum

- Order kits or components from suppliers

Managing Assets and Tools

- Track multiple identical tools

- Prevent tool checkout if calibration is due

- Track who last checked out a tool and when

- Send maintenance alerts

- Add parts, kits, and labor to work orders

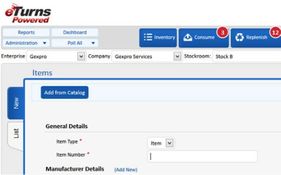

Managing Bills of Material

- View items in picture or grid view

- Manage consigned or customer-owned material

- Set critical/min/max levels at item or location level

- Create multiple supplier or manufacturer numbers for the same item

- Add new items from distributor catalogs

- Share BOMs across multiple stockrooms

- Create multiple cost units of measure

- Track items by serial numbers, lot numbers, and expiration dates

- Value inventory using LIFO, FIFO, average, or last cost

- View purchase orders and transfers related to item quantities

- Reclassify items nightly based on inventory turns or cost

- Create quicklists to group items for orders or pulls

- Use quicklists as simple kits

- Assign unlimited barcodes to each item

- View two images for each item

- Apply taxes to item consumption and labor

- Display bonded inventory value for any customer

- Assign default reorder and pull quantities

- Import large lists of items at once

Material Staging

- Allocate material from general inventory for later use

- Order directly into a stage

- Pull at one time all material in a stage

Project Spend Limits

- Apply consumption to one project spend

- Assign consumption to multiple project spends

- Make project spend selection mandatory to complete pull

- Set spend limits on total dollar amount or item quantity

- Stop pulls that exceed spend limits and display a message

Pulls

- Consume inventory using a scanner or RFID tags

- Add up to five user-defined fields for each transaction

- Create requisitions for users without pull authority

- Prioritize customer-owned material before consigned material

Receiving

- Receive material by item

- Receive all or part of an order, supplier, or category

- Receive material into any location using a scanner or web

Replenishing

- Improve VMI/CMI ordering productivity using mobile devices to scan barcodes

- Automatically create suggested orders based on min/max levels

- Automate order sending based on user-set schedules

- Use eVMI sensors for automated inventory monitoring and replenishment

- Receive orders through various integrations or emails

- Allow change orders

Reporting

- View a variety of standard reports

- Customize report parameters

- Add or delete columns, reorder or resize columns, and subtotal amounts

- Sort columns in reports

- Save reports in multiple formats

- Schedule email reports

Requisitions

- Create requisitions for users without pull authority

- Automate subcontractor requisitioning for tracking consumption and billing

- Send approval emails for requisitions

- Approve requisitions within emails

Transferring

- Transfer material between stockrooms or trucks

- View transfers by status

- Set permissions for viewing, editing, approving, or deleting transfers

- Move material between locations

User Configurations

- Search for data within grids

- Narrow searches by various categories

- Perform multi-column sorting

- Show or hide columns

- Reorder and resize columns

- Set permissions at role and user levels

- Change font size and terminology across the company

- Use multiple languages

- View change logs for updates

- Use up to five user-defined fields for transactions, items, tools, assets, and orders

Work Orders

- Track parts, kits, and labor consumption on jobs

- Include customer information

- Create requisitions for material if authority is needed for consumption

- Add up to five user-defined fields for each work order

- Use a full-page description if needed

Product Overview

Developer Overview

User Reviews of eTurns TrackStock

Write a ReviewA great program

eTurns TrackStock had about 95% of the capabilities we needed from an inventory system. The system was great with a straight forward picking process. If you need an inventory and picking software this is a great program for most people!

However, they were not able to customize the program at all. In our picking process we have loose products in our inventory and needed the ability to print labels as we are in the picking process. So ultimately becasue they could not offer us that we are sticking with what we have.

Pros

A great program.

Cons

They need to add the ability to print labels during the picking process! This would help alot of their customer base!

eTurns TrackStock Review

eTurns pays for itself within 1-2 months of each new customer installation and it allows us to stock 35% less inventory at our customers’ stockrooms because of the visibility it provides.

eTurns TrackStock Review

It’s user-friendly, has easy navigation, an accessible platform, is versatile, and offers exceptional customer service. It’s been great. We now have the ability to streamline our ordering, tracking, and replenishment process.

Switching to eTurns demonstrated significant change

We were using a completely manual process that led to a stockroom filled with unused supplies and lots of stuff expiring. Switching to eTurns demonstrated significant change in a short period of time. The value of our inventory on hand was north of $75,000 when we started using the system; now we have around $20,000 sitting on the shelves. The drain on my time has been significantly reduced and continues to improve.