The Best Aviation MRO Software

We tested and reviewed the top aviation MRO software on the market and reviewed our favorites below.

- Advanced reporting capabilities and allows exporting data to Excel

- Users have reported excellent customer support

- Integrated platform that includes several modules

- Integrates with other systems like SAP

- Single solution for multiple functions

- Allows for adoption of paperless maintenance

- Has built-in templates with over 400 models of fixed-wing and rotary-wing aircraft

- Provides peer-to-peer support from analysts who are A&P mechanics

- Offers expert aircraft enrollment

Aviation MRO software enables companies to streamline and optimize their aircraft maintenance operations. We used our review methodology to review and rank our favorites.

- Ramco: Best Overall

- Veryon: Best for OEMs

- Traxxall: Best for Business Jet Operators

- Component Control: Best for Air Carriers

- Smart145: Strong Mobile Support

- OASES: Best for CAMOs

- Aircraft Maintenance Systems: Best for Military Aviation

- CORRIDOR: Best for FBOs

Ramco - Best Overall

Ramco offers a suite of modules that cover all aspects of MRO operations, including maintenance planning, execution, engineering, supply chain management, financial control, and compliance tracking. This approach provides end-to-end visibility across the entire MRO lifecycle.

This MRO software helps aviation companies comply with industry standards, such as tracking continuous airworthiness, managing technical records, and allowing digital collaboration with regulatory bodies. The software also has pre-built APIs with third-party systems like flight operations and HR, enabling collaboration and data exchange across the MRO system.

However, some reviewers believe that Ramco has a steeper learning curve due to its strong features and capabilities.

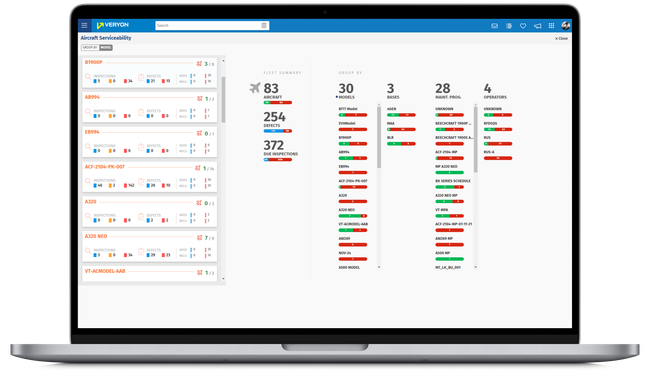

Veryon - Best for OEMs

Veryon delivers a strong maintenance tracking and work order management module for OEMs. With a clear, color-coded interface, you can check open work orders, statuses, and approvals, all from the maintenance calendar. Plus, this aviation maintenance software even links your work orders to inventory requests and procurement, so you’ll always have the right parts on hand.

The system takes the guesswork out of maintenance by auto-generating work orders based on usage data and manufacturer recommendations. So, if you need to plan ahead, you can schedule servicing around aircraft availability. But if technicians spot an issue during inspections, they can submit a Non-Routine to log it instantly. From there, your supervisors can add it to scheduled maintenance or create a new work order if it requires separate servicing.

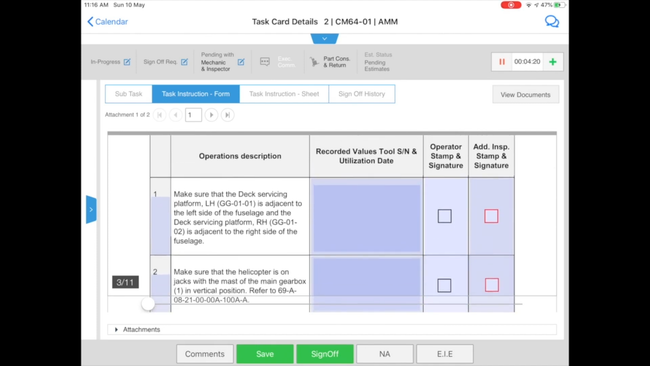

Additionally, Veryon supports electronic sign-offs, so your techs and inspectors can digitally verify completed tasks. This ensures all the critical steps and documentation, like parts used and safety checks, are in place before final approval. The sign-off is then time-stamped, recorded, and stored as a part of your work order history for compliance with OEM warranties and legal requirements.

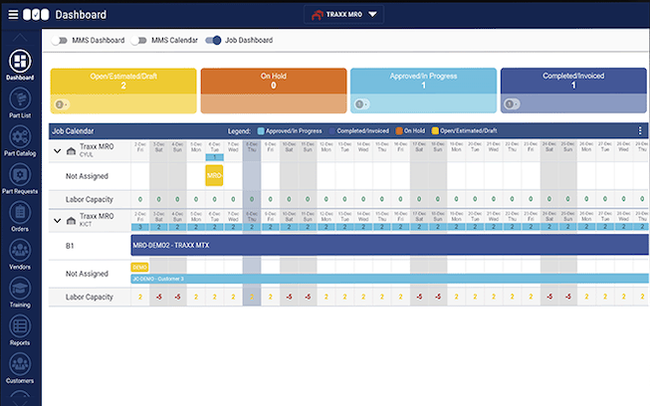

Traxxall - Best for Business Jet Operators

Traxxall delivers advanced tracking capabilities with built-in templates for over 400 models of fixed-wing and rotary-wing aircraft from manufacturers like Bombardier, Gulfstream, and Hawker. It also offers customizable dashboards and screens for users to personalize the system to meet their operational needs.

The system also provides peer-to-peer support from analysts who are A&P mechanics and have worked on aircraft. These analysts perform aircraft enrollment, ensuring that all data is accurate from the start. This can help minimize aircraft downtime and contribute to operational savings and efficiency.

However, Traxxall wouldn’t be a great fit for commercial airline operations. Its capabilities and support are geared specifically towards private and corporate aircraft.

Component Control - Best for Air Carriers

Component Control’s core product, Quantum Control, provides features that manage the entire MRO process. This includes shop control, repair order management, publications tracking, barcoding, and mobile technician access, which can help air carriers streamline their operations.

This aircraft maintenance software provides visibility into exceptions, such as part shortages, cost overruns, and schedule slips. This helps carriers maintain regulatory compliance and ensure quality management. Quantum Control is also installed in over 60 countries and can be deployed as a single-site or multi-national solution, making it a suitable choice for aviation companies with global operations.

However, some users have mentioned that although Component Control has impressive capabilities, it may have some unnecessary features, and new users face a steep learning curve.

Smart145 - Strong Mobile Support

Smart145 offers a customer portal and mobile app for iOS and Android. These allow aviation technicians to manage their operations seamlessly when on the go or working in the hangar.

With the customer portal, clients can view service details, invoices, and quotes with just a click. Smart145 also incorporates advanced capabilities like automated task scheduling, real-time collaboration, and intelligent data analysis. These features enable data-driven decision-making and optimize workflows. However, users have mentioned that Smart145 can be costly to purchase, customize, and maintain.

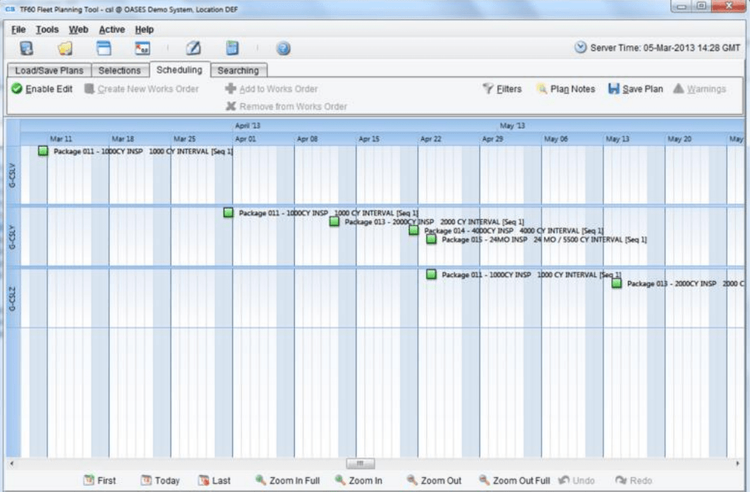

OASES - Best for CAMOs

OASES provides a suite of modules that cover different aspects of MRO operations, such as maintenance planning, scheduling, inventory management, and warranty management. There is also a dedicated airworthiness module that maintains detailed data on aircraft configurations, airworthiness directives, service bulletins, and component life cycles.

OASES has a cloud-based repository for storing and managing aircraft technical records digitally. This can ensure compliance with regulatory requirements by maintaining up-to-date records. The software also manages issues related to repetitive defects, reliability, and trends for a compliant maintenance program.

The software can integrate with flight schedules, electronic flight bags, electronic tech logs, and e-enabled aircraft data feeds for short-term maintenance planning. However, given the number of features OASES offers, new users may require significant training.

Aircraft Maintenance Systems - Best for Military Aviation

Aircraft Maintenance Systems (AMS) delivers compliance management, inventory control, and service bulletins. It also ensures compliance with military regulations, such as those set by the FAA and DoD.

AMS can track parts and tools, minimizing downtime and maintaining readiness in military aviation. The software also automates tasks like tracking service bulletins and airworthiness directives and generates compliance reports to ensure that military aircraft are maintained according to the latest guidelines.

CORRIDOR - Best for FBOs

CORRIDOR can manage the full range of FBO processes, from amenities to fuel sales and concierge services. The system also features time-tracking capabilities, as well as quoting, invoicing, and compliance for aircraft serviced at the FBO.

This aviation MRO software includes paperless e-signature support to comply with regulatory standards. It also offers specific configuration forms, such as FAA and EASA, to comply with aircraft maintenance standards. The system features a bi-directional data flow between maintenance providers and aircraft operators to maintain compliance.

CORRIDOR allows service centers to accurately track who uses specific repair and maintenance tools for each task. This can help with labor cost tracking and billing for maintenance work and aid in managing personal qualification records to ensure techs are properly certified and trained for their work. However, CORRIDOR may have a steep learning curve for new users and smaller organizations. Proper training and support are required to navigate the system confidently.

What Is Aviation MRO Software?

Aviation MRO software is an aircraft maintenance, repair, and operation solution. It provides maintenance tracking, inventory management, and flight operation functionalities for a fully integrated flight department management option. This type of aircraft maintenance software is used by any business involved in the maintenance, repair, and overhaul field. These MRO companies streamline airplane fleets’ maintenance, engineering, and logistics and can be used by maintenance directors, inventory parts managers, flight schedulers and dispatchers, and even C-level executives.

Aviation MRO software is responsible for aircraft airworthiness. Engineering directors must ensure compliance with maintenance activities, while logistic managers must source the right spare parts. Advanced forecasting features can plan maintenance, manage work orders, carry out material management, create and distribute purchase orders, and manage warranty replacement.

Any company implementing an aviation MRO solution will aim to improve its organization’s logistics, engineering and planning, maintenance, production, and quality assurance control.

Key Features

- Inventory Management: Manage the parts you need for maintenance purposes and monitor inventory costs to stay within budget. View available parts in a catalog, put in requests for items, create purchase orders, monitor prices between vendors, record physical inventory counts, and handle cycle counts.

- Maintenance Tracking: Manage the aviation business’s predictive and preventative maintenance. With maintenance tracking, you can scan equipment data for performance trends and use condition-based monitoring to alert the appropriate staff of potential issues.

- Maintenance Scheduling: Create schedules, track procedures, set maintenance routines, and balance workloads. Includes line maintenance, hangar maintenance, shop maintenance, engine maintenance, tool management, dent and buckle work, and employee time tracking.

- Supply Chain Management: Optimize and view a product’s entire lifecycle. Key features include parts administration, supplier management, warehouse management, procurement, material planning, repairs and exchanges, scrap management, and receiving goods.

- Work Order Management: Create a trackable document identifying what aircraft maintenance work needs to be done and how it should be accomplished. Key features include rules-based approval management, scheduling management, change orders, and reporting.

Benefits

Some of the top benefits of aviation MRO software include:

Ensure Aircraft Reliability, Durability, and Safety

Whether commercial or military, maintaining the safety and reliability of an airline fleet depends on a product’s availability, reliability, and quality. When these new parts, materials, and structural concepts are implemented via maintenance programs, safety and reliability measures should be taken care of. Proper preventive maintenance ensures no deterioration process occurs and can provide your business with the needed information for when a design modification needs to happen when inventory is not available.

Proper MRO software will provide both structural and component maintenance. Structural maintenance for aircraft will assess fatigue and damage tolerance. Component maintenance will take care of hardware items that wear out, meaning parts will be removed from service once they reach a certain level of use or a period of time has passed. Many components will have this measure of deterioration and be removed for periodic maintenance.

Shorten the Planning of Maintenance

If an airline can better plan its maintenance, its aircraft will be out of commission for a shorter amount of time. For a commercial airline, this can be the difference between handling more flights for paying customers and ultimately creating more revenue.

Aviation MRO software can help your business plan maintenance better and shorten the time needed for any needed work. Some aviation MRO solutions have been known to reduce the time it takes to produce a yearly production plan from three days to three hours.

MRO Cost Tracking For Accurate Quotations

Providing accurate quotes starts with proper cost tracking. When trying to win business with a customer, you’ll want to ensure any figures you give them or any bid you may be submitting clearly states the cost of each service. These costs are determined through processes your business can standardize.

Cost management is important for efficiently maintaining equipment and facilities outside of winning maintenance contracts. Most MRO software will integrate scheduled maintenance capabilities into your master production calendar.

You’ll want to ensure your business can cover the cost of each scheduled maintenance job, which starts with knowing how much it costs to provide routine maintenance. This includes the cost of any labor, utility costs for running power on machines, depreciation on machines, materials used during maintenance, and new parts that need to be ordered.

Billable Time and Expenses

During maintenance, shop staff must record their time worked and log it with the appropriate project/job. They’ll also record any inventory items used and any expenses incurred during the maintenance work (an example is the transportation costs to get to the job site). These hours will be used to calculate the cost being billed to the customer.

Time-tracking MRO tools will let all aviation MRO divisions record and analyze their workforce. Managers will monitor the time employees spend on productive work versus non-production time and be able to make better decisions about the best personnel fit for specific jobs.

MRO Invoicing

Invoicing is about labor tracking, production management, managing pricing structures, cost management, and providing real-time results.

Many invoices include charges for time spent working on various tasks. A proper invoice for maintenance, repair, and overhaul work will detail each maintenance activity. It will clearly describe the work completed and the hourly rate being charged for labor.

Some services may have variable labor rates if agreed upon during contract negotiations. This usually happens when certain maintenance work requires different skills, such as work that needs to be handled by both junior-level and senior-level staff members. Work involving a distinct classification of parts will also have different markups.

Modern aviation maintenance software will provide real-time invoicing, allowing the customer to see up-to-date changes to their account, including new charges that may have been added on.

The Rise of Mobile MRO Solutions

Depending on the size of the operation, going mobile can be an extremely cost-effective way of running your aviation MRO software. These solutions let maintenance workers use mobile devices (such as iPads) to monitor upcoming flight plans, the vehicles involved, pilot notifications and messages about issues, and scheduled maintenance schedules.

Mechanics can anticipate defects, which allows them to gather the necessary tools and parts ahead of schedule and be ready when the aircraft rolls into the shop. Mobile solutions also let the business go completely paperless, as it does not have to print documents, manuals, or procedures. They can even allow job completion to be noted via electronic signatures and notifications sent back to pilots.