Deacom vs. Acumatica Comparison Guide

- Client OS Windows, macOS, iOS, Android, Web

-

Price Range

$ $ $ $ $$ $ $ $ $

- Starting Price $1,800/month

- Client OS iOS, Android, Web

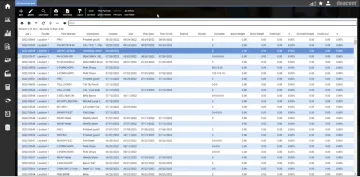

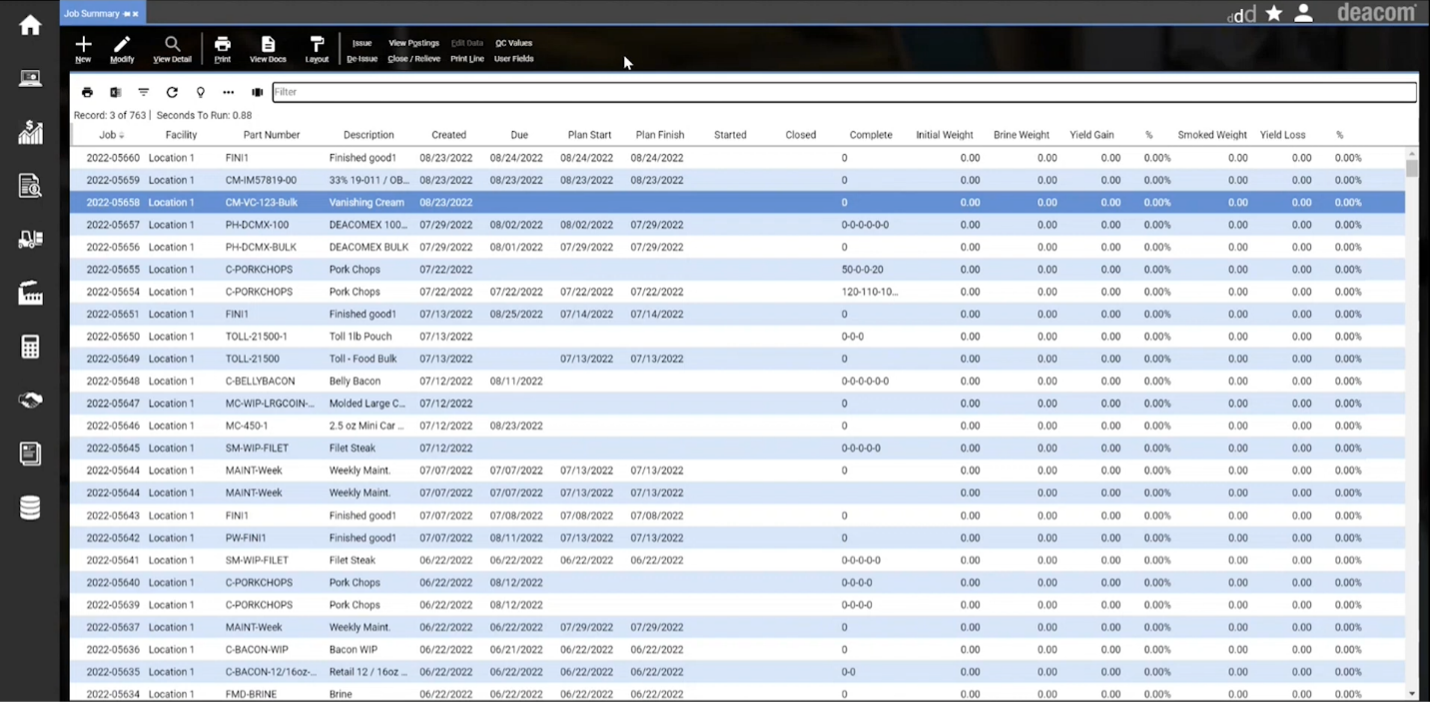

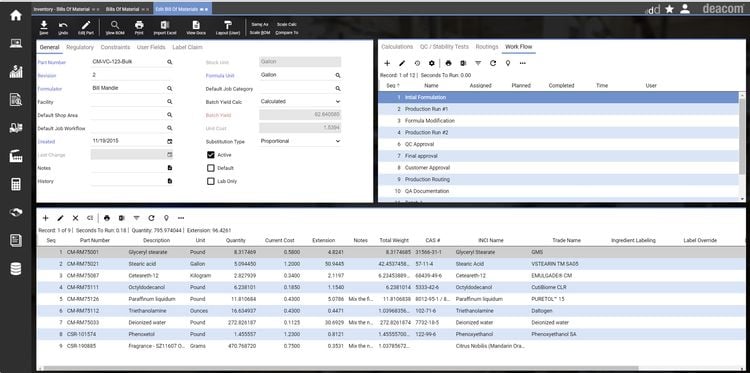

Deacom is a cloud ERP system designed for batch and process manufacturers in the food, beverage, chemical, and cosmetics industries. It includes traceability tools, manufacturing support, quality control, and production development capabilities.

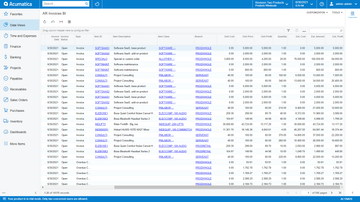

Acumatica, meanwhile, is a general-purpose ERP software that’s modular by design. It includes editions for manufacturing, construction, distribution, retail, and professional services. As a process manufacturing system it covers the basics like lot and expiration date tracking.

Deacom Company Profile

Deacom was founded in 1995 and acquired by ECI Software Solutions in 2021. Under ECI’s ownership, Deacom now serves as their global platform for batch and process manufacturing ERP systems. It has since expanded its resources and reach while maintaining its focus on its niche user base.

It’s an all-in-one enterprise resource planning software that features an array of business functions, from formulation to compliance, in a single platform, eliminating the need for third-party bolt-ons.

Target Market

Deacom offers two packages based on your company’s size.

Deacom Essentials best suits smaller manufacturers with revenue between $5 and $50 million; it provides an affordable, user-friendly ERP with core features.

Deacom Enterprise is a good fit for established manufacturers with revenue between $50 million and $1 billion; it supports complex operations and substantial growth plans. Supported industries include meat processing, candy and snacks, consumer packaged goods, dairy, wine, spirits, beer, paint, adhesives, sealants, and more.

Acumatica Company Profile

Acumatica is a cloud-based ERP launched in 2008. With its roots in the US, the company has received acclaim over the years for its adaptable platform and integration capabilities. It was developed by a team including co-founder Serguei Beloussov, known for Parallels and Acronis. While EQT Partners acquired a majority stake in 2019, Acumatica continues to operate independently, maintaining its brand identity and product roadmap.

Unlike early 2000s’ NetSuite during the desktop-centric era, Acumatica emerged during the rise of mobile devices. While these older systems had to adapt, retrofitting their solutions to cater to the mobile world, Acumatica took a mobile-first approach from the outset.

Target Market

Acumatica serves small to mid-sized businesses with 10-200 employees. It’s a strong fit for growing companies because it allows them to license only the modules they need. As businesses continue to scale, they can add more to support their evolving operations.

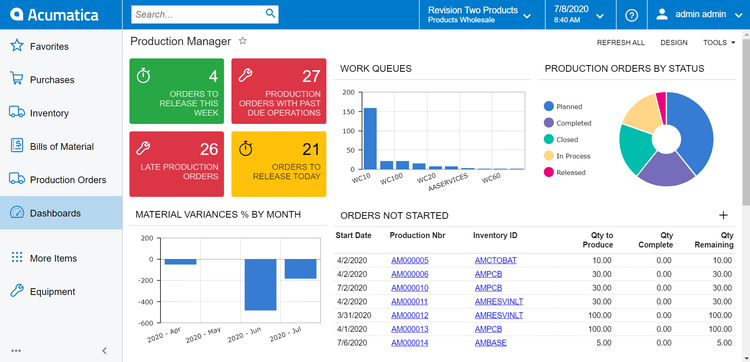

Beyond generic functionalities, Acumatica offers tailored solutions for specific industries. For manufacturing in particular, Acumatica provides production management, scheduling, and material requirements planning, among other tools.

Key Features

Deacom Features

- Manufacturing operations: production, maintenance, inventory, quality in one place; batch production and weigh-up features

- Traceability: track a lot’s lifecycle from receiving to shipping; drill down into complete audit trails

- Production development & quality control: adjust/scale formulas, enforce QC, run stability development tests

- Document generation & regulatory compliance: nutritional labels, batch tickets, invoices, bills of lading, certificates of analysis, safety data sheets

- Accounting: AP, invoicing, financial reporting, cost analysis, profitability

- Warehouse Management System (WMS): handheld scanners and GS1-128 barcodes; tracks batch numbers, best-before dates; real-time inventory transactions

- Supply chain planning: MRP, sales forecasting, capacity planning; production line scheduling and dock scheduling

- Sales: CRM, POS, product configurator, and engineering imports for BOMs

- EDI: ANSI-compliant EDI with a Value-Added Network

- Mobile app: system access on the go; BI reports on dashboard

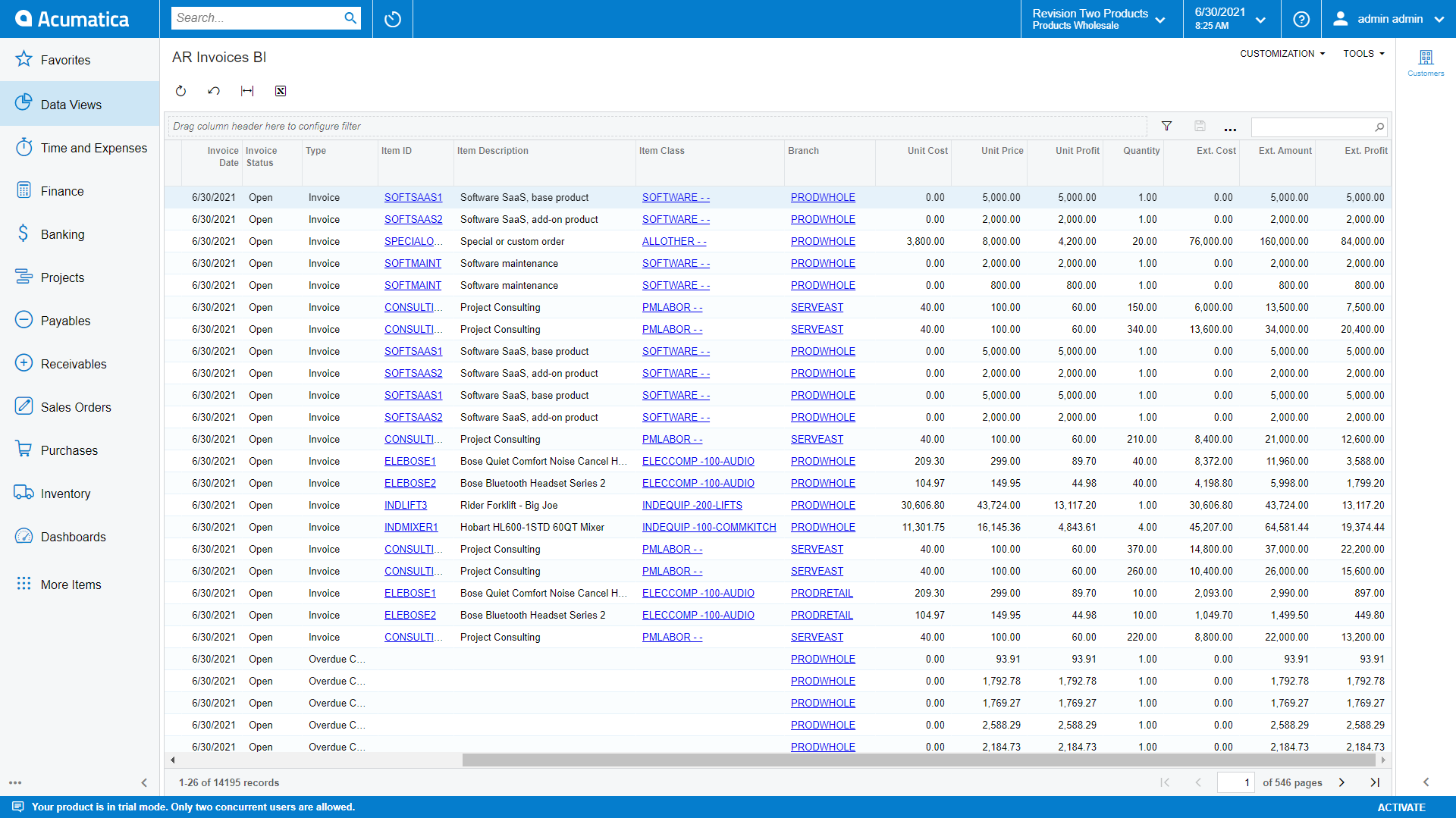

Acumatica Features

General Capabilities:

- Open architecture for rapid integrations

- Multi-entity support

- Mobile accessibility

- Multi-warehouse inventory management

- Modular architecture supporting scalability and integrations

Manufacturing Edition:

- Production management

- Multi-level BOM and routing

- MRP

- Production scheduling

- Engineering change control

Acumatica can be a strong fit if your requirements are relatively straightforward. The base system covers:

- FEFO picking

- Multi-warehouse inventory management

- Lot tracking

- Expiration dates

But if your operations need deeper process controls–especially around formulation, quality, and compliance–you may need these add-ons:

- Process Manufacturing Suite

- Quality Manufacturing Suite

Key Questions to Ask

1) Is manufacturing the whole business—or just one piece?

Go for Deacom if your core competitive advantage is on the production floor. Here, formulation accuracy and yield optimization are critical, and you need these capabilities to be foundational to the system.

Choose Acumatica when manufacturing is only one operating model among several. If you’re running a blended organization, this cloud ERP can support fundamentally different workflows side-by-side in a single system.

2) How much process complexity are you dealing with?

If you’re running complex formulations, co-packing, and property-based adjustments, Deacom is built assuming that level of complexity. Recall traceability, CoA generation, and more essential functionalities are available in the system from day one.

With Acumatica, there’s risk in underestimating your process complexity during the buying process. You may go live with the base system and discover later you needed stronger formulation controls or traceability than initially planned.

3) Do you want flexibility—or certainty?

If you value flexibility, go for Acumatica. It lets you start with the base system and add capabilities as needs emerge. This can be especially useful if you expect significant change over the next 3–5 years.

If you value certainty, Deacom is the better fit. You’ll have one system, one vendor, and native coverage for process manufacturing needs—without “which add-ons do we need?” conversations after go-live.

Pricing and Cost Expectations

Deacom Pricing

- For smaller operations, Deacom Essentials starts at $500/month.

- The original Deacom package with advanced features starts at $5,000/month.

- Final Deacom pricing requires a consultation call.

Acumatica Pricing

- Starting price: $1,800/month

- Most starting fees range $1,800–$2,900/month

- Small businesses should expect about $21,000–$34,000/year

- Pricing is not publicly available; businesses must contact Acumatica for a customized quote.

Which Is Best?

When to Choose Deacom

Choose Deacom if:

- You’re a batch or process manufacturer that generates between $5 million and $1 billion in annual revenue

- You want a vertically-integrated system with embedded formulation, compliance, and recalls

- You prefer certainty over modular decision-making after go-live

When to Choose Acumatica

Acumatica is the best option if:

- Your formulation needs are fairly basic

- You want flexibility to add capabilities over time

- You’re comfortable managing partner relationships and add-ons

Deacom and Acumatica can both be viable—if they match how your business actually works. The expensive mistake isn’t in picking a bad ERP; it’s picking the wrong architecture for how your company runs. Acumatica is best if you want to take a more modular approach to your ERP, while Deacom’s purpose-built system is ideal if you need built-in process and batch controls.