Aptean Industrial Manufacturing ERP Made2Manage Edition

6 Reviews 1/5 ★ ★ ★ ★ ★A discrete manufacturing software for made-to-order and mixed-mode manufacturers with tools like real-time scheduling, job costing, and shop floor execution.

Product Overview

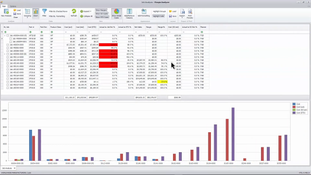

Aptean Made2Manage Edition is a discrete manufacturing software. It offers key features like real-time scheduling, job costing, and shop floor execution to enhance supply chain transparency. The software handles manufacturing operations and expenses, including production process planning and configuration management. Finally, Made2Manage increases on-time delivery by overseeing multiple suppliers for each item.Pros

- Extensive reporting capabilities

- Simple to set up and track job orders

- Integrates with Microsoft products

Cons

- Outdated user interface

- Cannot copy and paste data from spreadsheets into system

- Customer support slow to respond

Target Market

SMB mixed-mode and made-to-order manufacturers in specialized industries like industrial equipment, electronics, and fabricated metal.Aptean’s Industrial Manufacturing ERP Made2Manage Edition is a software solution designed for custom and discrete manufacturers with mixed production modes. It simplifies complex product production and covers various areas like ERP, BI, CRM, APS, MES, and configuration from a single supplier.

Aptean offers Intuitive ERP for repetitive, discrete manufacturers.

Video Overview

Key Features

Quoting and Order Management

- Generate accurate quotes

- Create sales orders

- Create custom products at the point of sale

- Set custom pricing for customers

- Orders are sent to trigger production

Procurement

- Plan procurement around requirements

- Lower supply chain costs

- Demand purchase order queue

- Create purchase order variance reports

- Single-command RFQ forms

Materials Management

- Part and material lot tracking

- Shop floor data collection tool

- Inventory and labor transaction automation

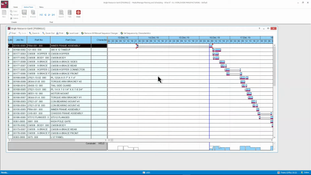

Production and Engineering

- Create and track job orders

- Drive efficiency and stay on budget

- BOMs and process routings

- Track production priorities and labor usage

- Evaluate job costs

- M2M Advanced Configurator for complex product configurations

Financial Management

- Easily track budgets and cash flow

- Automate billing

- Create detailed reports

- Multi-site support for warehouses and distribution centers

In summary, M2M ERP offers a comprehensive solution for manufacturing and business operations, covering production cost tracking, financial management, and supply chain optimization.

Product Overview

Developer Overview

Related Products

User Reviews of Aptean Industrial Manufacturing ERP Made2Manage Edition

Write a ReviewAptean Industrial Manufacturing ERP Made2Manage Edition Review

Terrible customer support. Support fees are outrageous – they raised the fee by 30% in 2025. Now they are asking $147K for 3 years subscription. They charge extra to fix bugs. All their customer support is based in India and lacks sufficient knowledge of the software. We’re exhausted with this system and are moving on to a different ERP.

Pros

Nothing

Cons

Horrible

Aptean Industrial Manufacturing ERP Made2Manage Edition Review

They like to say that the system will do everything for you and the reporting is amazing but we have found that it only causes headaches and more labor being needed in the office to keep things moving. A customer of ours used this system in the past and called it “made2bemiserable”

Pros

The one and only plus is that it is web based, but there are several other options that are web based so it is not really a pro.

Cons

The web based version is plagued with errors, glitches, issues and lack of support. After implementing this system 2 more people had to be hired just to fix issues caused by the software. If you are looking for an ERP I would highly suggest you look for something else like we are. We are going to end up changing to a different ERP after only 1 year of use.

Aptean Industrial Manufacturing ERP Made2Manage Edition Review

M2M is very unfriendly to use, hard to navigate

Cons

hard to use and find what needed

- Internet Software & Services

- 11-50 employees

- Annual revenue $1M-$10M

Everything in M2M is 10-steps for a 2-step process

Everything in M2M is 10-steps for a 2-step process. Support is argumentative and even after you prove a bug in the system, they say, “that’s a customization; pay $$$$$ and we will fix it.” System is based in FoxPro, and although they will claim they have transitioned to .NET (v7.5+), there is still FoxPro and it is slow, antiquated, and poorly implemented.

Pros

Nothing

Cons

Design; Support; Implementation; Aptean corporate attitude.

- Professional Services

- 1-10 employees

- Annual revenue $0-$1M

It is incredibly painful to setup

It has a lot of good features. But - the support to get things actually working for something you’ve paid for is expensive and very time consuming. Response is painfully slow. $250/hr for anything you want accomplished, on top of licensing.

I’d recommend looking at other products. M2M is well suited for manufacturing. It covers all aspects of the business, but I think if you had a couple of software packages to cover specific areas you would have less of a headache.

Pros

It has everything related to the operation of the company within one software package.

Cons

It is incredibly painful to setup. We have employee names that are hardcoded into some database with no way to edit except paying $250/hr.

- Industrial Conglomerates

- 11-50 employees

- Annual revenue $1M-$10M

Aptean Industrial Manufacturing ERP Made2Manage Edition Review

I like a lot of the things that it does, we don’t use it to the full capacity, I don’t like the support, the cost, and the fact that the upgrades crash, and it’s not very user friendly at this point. I’m not sure it was ever installed correctly