Best Discrete Manufacturing Software

Discrete manufacturing software is designed to track individual parts, manage complex bills of materials, and coordinate multi-stage production processes. We’ve ranked our top picks based on their support for key industries like aerospace and defense, as well as their flexibility in handling different production methods, from make-to-stock to engineer-to-order.

- HANA database

- Large network of resellers

- Strong BI tools

- Built-in payroll capabilities

- Controls inventory of raw materials, finished goods, and assemblies

- Fully configurable dashboard

- Mostly straight-forward and user-friendly

- Built with over 40 years of manufacturer and distributor expertise

- Integration with AI, MI, IoT, and Cloud-hosting

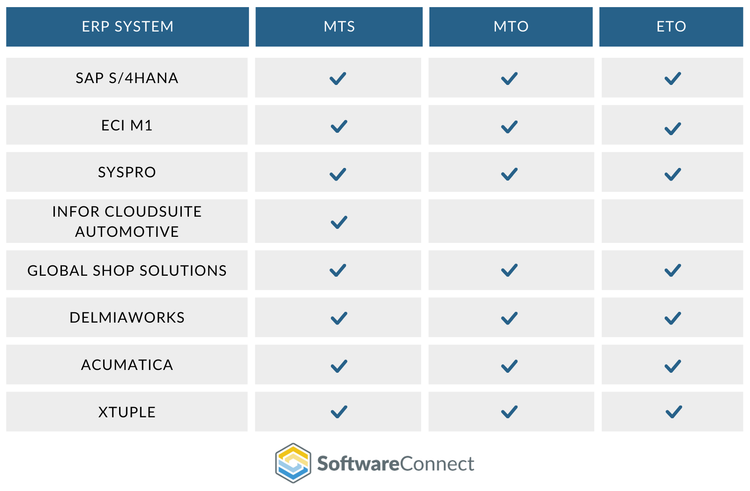

While ERP for discrete manufacturers shares some common features, there are some significant differences in industry specialization and support for different production strategies. These include make-to-stock (MTS), make-to-order (MTO), and engineer-to-order (ETO).

- SAP S/4HANA: Best for Aerospace & Defense

- ECI M1: Best for Electronics

- SYSPRO: Best for Medical Devices

- Infor CloudSuite Automotive: Best for Automotive

- Global Shop Solutions: Best for Furniture

- DELMIAWorks: Best for MTS Manufacturing

- Acumatica: Best for MTO Manufacturing

- xTuple: Best for ETO Manufacturing

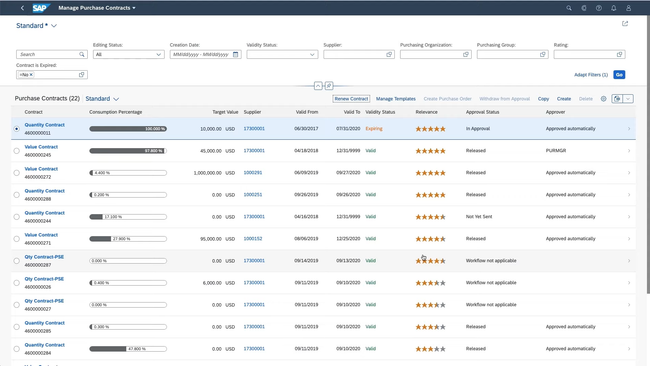

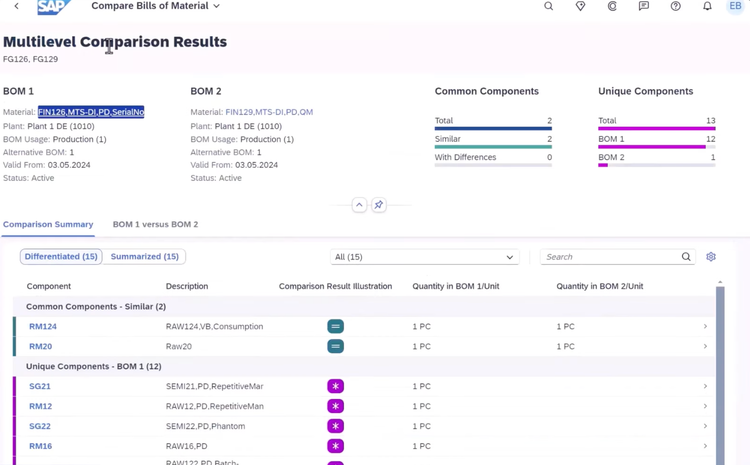

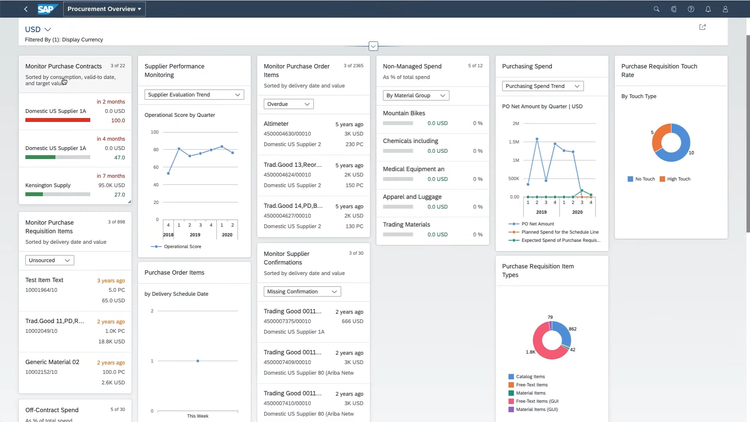

SAP S/4HANA - Best for Aerospace & Defense

SAP S/4HANA supports multi-level bills of materials (BOMs), making it easier to disassemble complex products into their core components. For example, you can break down a military fighter jet into nested assemblies, tracking propulsion systems down to individual components like engine parts, bolts, and sensors. This hierarchical approach helps you separate intricate projects into manageable layers, simplifying maintenance, production, and modifications.

The system’s advanced BOM features also support product variants, making it easier to track different configurations, like different weapon systems on military aircraft. S/4HANA lets you compare BOMs side by side so you can quickly pinpoint where they diverge. This helps ensure any modifications you make to one configuration won’t unintentionally impact the other.

Additionally, S/4HANA streamlines BOM updates through its built-in change management functionality. Any proposed adjustments trigger a structured workflow for review and approval, complete with change records documenting who made the request, what was altered, and the impact on other assemblies. Once approved, updates automatically cascade through the BOM, maintaining consistency across nested levels. These granular change logs help meet industry standards like AS9100, providing a transparent audit trail for better risk management and traceability.

With an exhaustive feature set, SAP S/4HANA is one of the pricier solutions available. Costs range based on specific requirements, but you can expect monthly fees of $20,000 to over $100,000 for hosted subscriptions and $200,000 to over $2 million for on-premise perpetual licenses. For those with smaller budgets, consider products like Infor CloudSuite Aerospace & Defense.

Learn more about SAP S/4HANA in our full review.

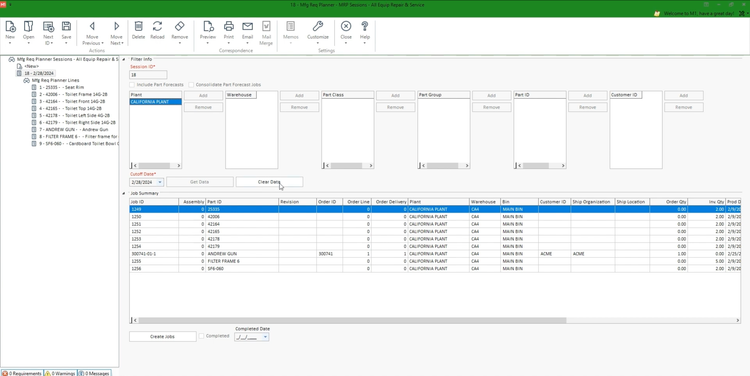

ECI M1 - Best for Electronics

ECI M1’s materials resource planning (MRP) module helps you better manage long supply chains and volatile component availability. With parts like semiconductors, displays, and circuit boards sourced from different suppliers across the globe, keeping production on schedule is a delicate balancing act. Fortunately, you can use the MRP module to select individual production sites, set cutoff dates, and plan precisely for each component’s lead time, so your production run is synchronized.

Instead of manually tracking what’s in stock or running the risk of missing critical parts, you can launch a new MRP session to review materials availability, check current stock, and initiate jobs for upcoming orders. Just click the “Create Jobs” button. ECI M1 generates jobs based on your selected criteria like plant, warehouse, and part ID. It also auto-updates your production schedule to reflect when and where each component will be needed.

You can monitor your MRP sessions at any time by clicking on the binoculars icon. This displays all created sessions, their statuses, and whether they’re still open or completed. This oversight helps you avoid complications from overlapping job creations. It also ensures all jobs are accounted for across multiple plants, minimizing bottlenecks or delays.

Additionally, the MRP module triggers alerts if more than one session is running at the same time. This is critical in electronics manufacturing when juggling multiple projects and component orders. The navigation ribbons and paneled windows give the UI a somewhat dated feel. However, its right-click navigation lets you quickly drill down into records to spot important details, helping you keep track of critical components even while managing complex production runs.

With pricing starting at $3,000/month, ECI M1 is a versatile solution for medium-sized manufacturers with 50-200 employees. It’s suitable not only for electronics but also for other discrete manufacturing models like job shops, engineer-to-order, and make-to-order environments.

Read our full review of ECI M1.

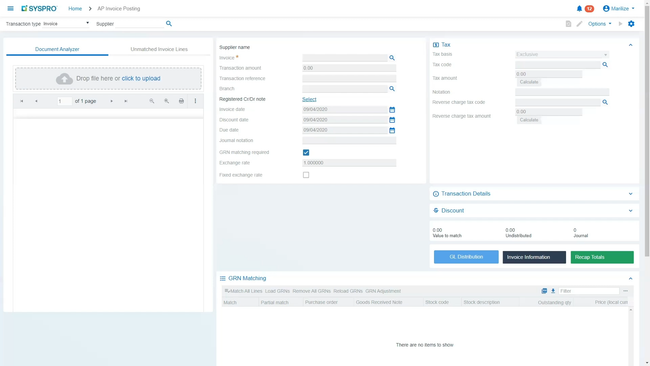

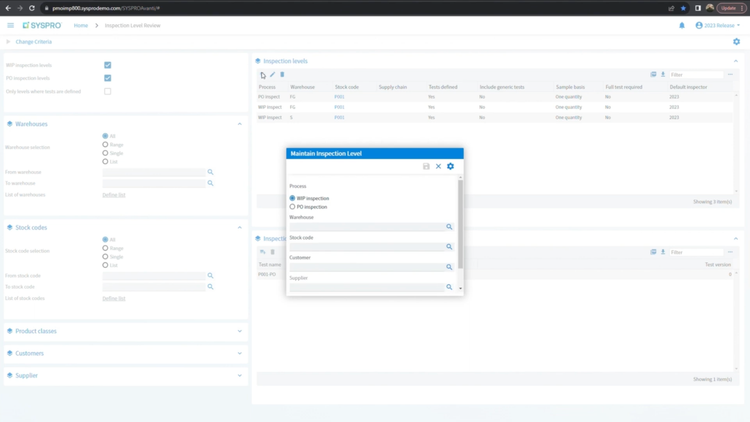

SYSPRO - Best for Medical Devices

Quality control is paramount for medical device manufacturers due to strict regulatory standards like FDA 21 CFR Part 820. SYSPRO’s inspection management tools let you define acceptable quality limits (AQL) for each stock code and customize inspection levels based on different stages of the production process:

- WIP: Occurs during various stages of production, allowing you to catch defects or deviations from quality standards before final assembly.

- PO: Involves checking incoming materials or components against purchase order specifications to make sure they comply with safety and quality regulations before starting production.

The platform also lets you assign these tests by supplier or warehouse, ensuring that inspections account for specific materials and processes. For example, if you’re producing surgical instruments, you can set different testing rules for stainless steel components versus plastic parts, ensuring everything meets the high standards required for patient use.

SYSPRO goes further by offering the ability to design custom inspection tests, which can include various field types (alpha, numeric, checkbox, drop-down list for selection, etc.) tailored to specific products. These specialized tests can reflect the unique specifications of different devices, like sterilization levels or component integrity.

The system supports AQL levels 1-4, including special and general levels, for handling different risk classes of medical devices. In this way, SYSPRO ensures you’re always prepared to meet industry regulations.

Learn more about SYSPRO’s features in our review.

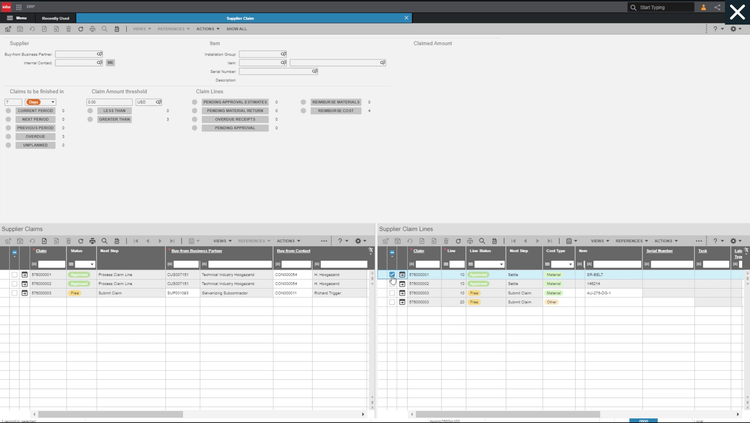

Infor CloudSuite Automotive - Best for Automotive

Infor CloudSuite Automotive comes equipped with built-in supplier collaboration tools that let you engage with logistics service providers, subcontractors, and component suppliers. These features allow your partners to submit and manage claims for orders or services, making it easy to resolve issues quickly and avoid production slowdowns on your end. Each claim can include multiple line items detailing specific components like steel, plastics, or electronic parts.

With the supplier claims table, you can easily see which claims have been processed and which ones need follow-up, so you can address any bottlenecks before they disrupt your schedule. CloudSuite Automotive lets you drill down into details related to the claim, like cost types, statuses, and associated parts. Additionally, the system lets you track claimed amounts and monitor thresholds, ensuring you’re not going outside your budget constraints.

Infor’s Enterprise Collaboration Portal is included in CloudSuite Automotive. It acts as a central hub for onboarding new suppliers and keeping your supply chain organized. Suppliers can review, accept, or decline procurement orders and submit payment applications directly, reducing back-and-forth communication and speeding up approvals. This kind of self-service keeps everyone in sync, so you can focus less on administrative tasks and more on production.

Finally, you can manage essential documents in this portal, including quality policies and processes specific to product safety and risk management required by the International Automotive Task Force (IATF) 16949. This ensures you and your suppliers stay up-to-date with industry regulations for better quality output and a stronger, more transparent supply chain.

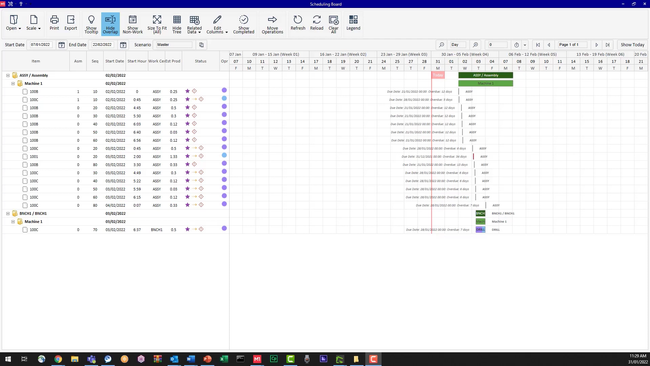

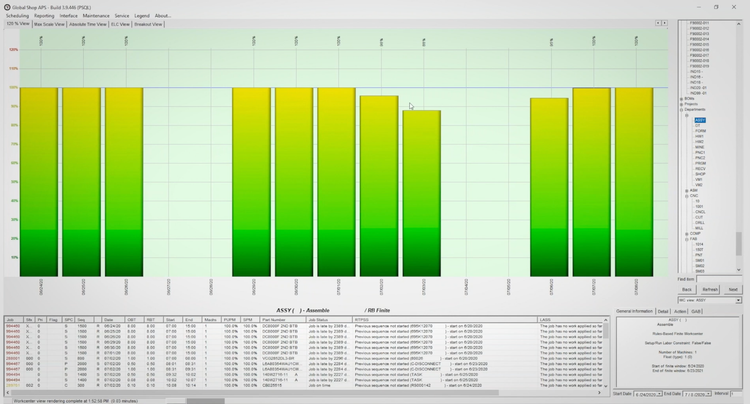

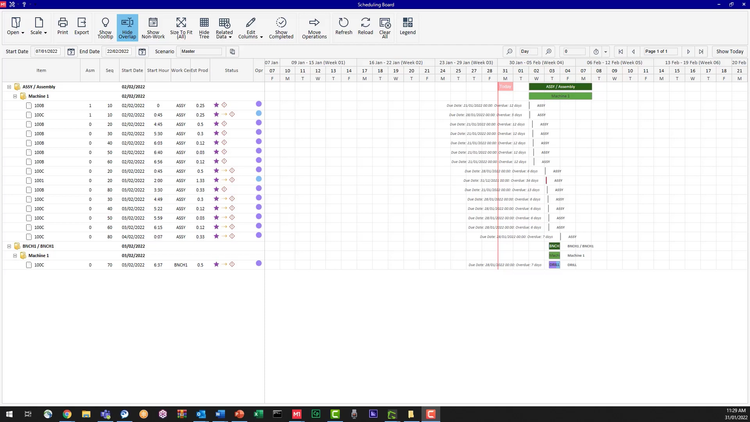

Global Shop Solutions - Best for Furniture

Global Shop Solutions offers an advanced planning and scheduling (APS) function that helps you optimize shop floor operations. It gives you a visual overview of activities, so you can pinpoint where capacity might be strained and adjust your schedules as needed. With a few clicks, you can even drill down into any work center for a snapshot of current workloads and performance.

A key feature of the APS system is its finite resource scheduling tool. It automatically prioritizes jobs based on available resources and each order’s due date without exceeding load capacities. This is important for managing multiple orders and machine constraints. For example, if a customer requests a rush order for a set of custom tables, the system can adjust the schedule to slot in the job without disrupting other commitments.

During peak periods—like gearing up for the holiday season—you can use infinite scheduling to accommodate extra orders that exceed normal capacity. This flexibility helps you meet seasonal demand surges without sacrificing quality or efficiency.

The APS system also lets you concurrently schedule multi-level BOM assemblies. In furniture manufacturing, where items like sofas include multiple components from frames to fabrics, this feature is vital. It even factors in lead times and operational requirements to help you plan effectively.

As customer demands change or supply chain issues arise, your schedulers can easily tweak plans using the drag-and-drop functionality. If a specific wood type is suddenly unavailable, you can quickly reallocate resources to another job that uses different materials. While Global Shop Solutions excels at managing complex schedules, some users have noted that the interface can be click-heavy, making navigating harder during busy periods.

Learn more about Global Shop ERP’s features in our review.

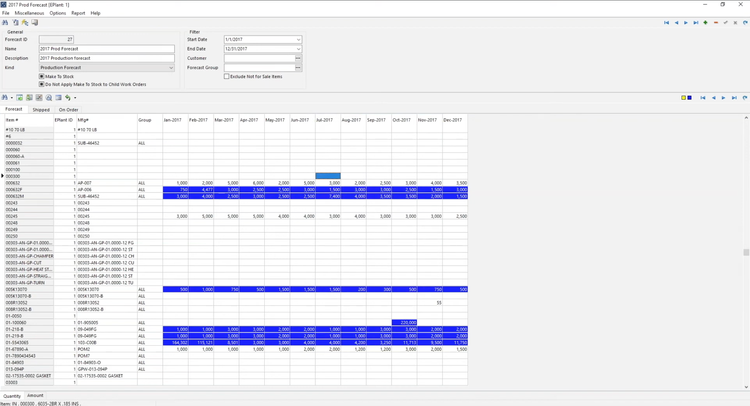

DELMIAWorks - Best for MTS Manufacturing

DELMIAWorks provides dual forecasting for sales and production, helping you stay ahead of customer demand and streamline inventory management. By anticipating changes, you can prevent disruptions like labor shortages, surplus stock, or material gaps.

Examples of forecasts you can run include:

- Sales Analysis Forecasts: Predict revenue for consumer electronics such as headphones or smartphones; this helps you tweak budgets and production plans if customer demand for certain models surges unexpectedly after a product launch or seasonal promotion.

- Production Forecasts: Plan material and resource needs in advance for household goods, like cleaning supplies or kitchen appliances. Maintain optimal stock levels to meet seasonal buying patterns or holiday rushes.

You can generate forecasts manually or automatically using past shipment or order data, ensuring your production syncs with predictable demand trends. You can even customize forecast formulas to suit different product lines, with recommendations based on your historical data.

But not all demand is predictable. DELMIAWorks also enables “what-if” scenarios using sales forecasts to help you prepare for unforeseen changes. For example, you can model how a sudden surge in demand might impact your labor needs, schedules, and procurement. If demand is expected to drop, these scenarios can help you avoid surplus inventory or overproduction long before either becomes an issue.

Finally, this ERP gives granular insights into customer-specific and general demand forecasts. This will help you prioritize production for high-demand items while maintaining adequate stock levels across the board. With these tools, you can balance your stock portfolio and ensure your most popular products are always ready to ship.

Learn more about DELMIAWorks in our full review.

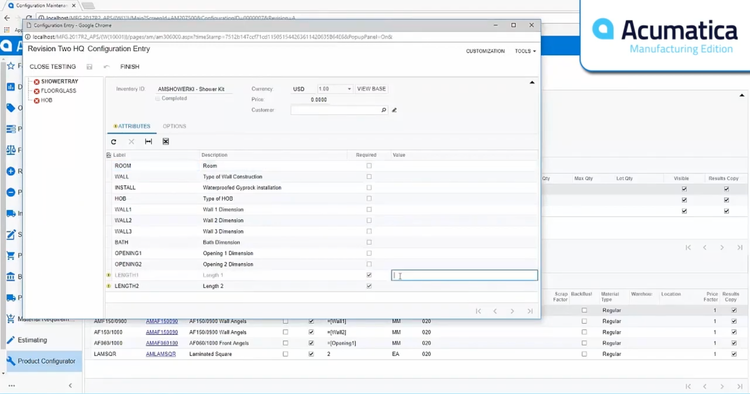

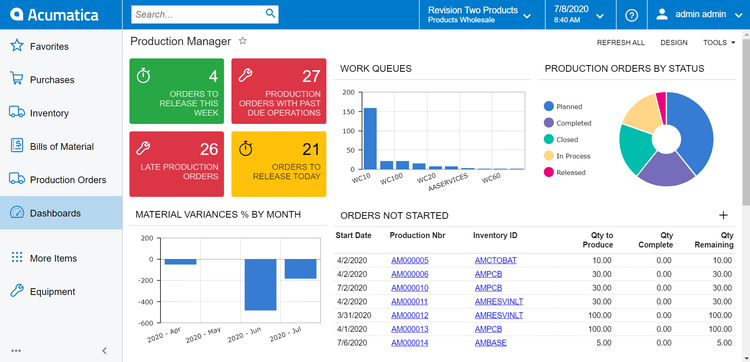

Acumatica - Best for MTO Manufacturing

Acumatica Manufacturing Edition includes a product configurator that makes it easy to manage customizable products based on your customers’ unique requirements. You can easily set various attributes for them to choose from during the ordering process. You can also create rules to automatically include or exclude certain options based on dependencies. That way, only valid combinations are chosen, which means fewer errors for you and a smoother production process.

Acumatica’s formula-driven configurations work well for products with varying dimensions, like doors or windows, where flexibility is key to meeting customer expectations. The test configuration mode feature allows you to see how attributes appear as customers make their selections. A green checkmark icon confirms when a choice is valid based on your rules, and a red x indicates the opposite.

Additionally, each product configuration connects directly to a BOM, which helps define the materials needed for each custom order. You can set default materials for the product and then layer in customizable options, like different types of wood or finishes. This helps you make sure all necessary materials are accounted for long before production begins.

Once configured, Acumatica integrates everything into the sales order. From there, you can generate a production order with all the details your team needs, speeding up the entire MTO process. The manufacturing package starts at $3,500/month, making it a solid option for smaller MTO companies.

Read more about Acumatica in our comprehensive review.

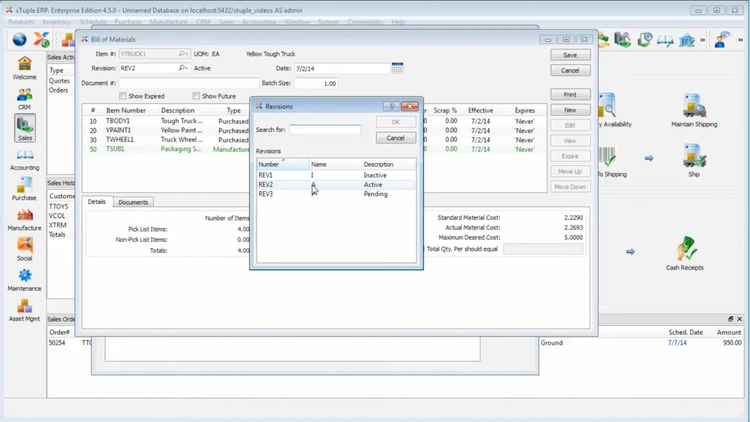

xTuple - Best for ETO Manufacturing

The revision control system in xTuple lets you manage and switch between multiple versions or revisions of BOMs and routings. This is especially useful in ETO environments where customer specifications frequently change or repeat orders require older product versions. Each revision is tracked independently for quick reference or rollback.

The system lets you assign different statuses to each revision—active, pending, and inactive—so you can work on new designs without disrupting ongoing production. For example, a new design can be marked as “pending” while the current version remains in use. This ensures seamless transitions between product versions without confusion or manufacturing errors.

xTuple also simplifies revision changes, letting you quickly activate new or alternative BOMs for specific orders. You can even generate work orders from inactive revisions to meet different customer requests. When you’re dealing with complex order variations, xTuple is a flexible pick that can help you handle evolving engineering specs and one-off project requirements typical in ETO settings.

Learn more about xTuple in our extensive review.

Other Systems We Like

SAP Business One is another great option for smaller companies looking to scale. It offers both cloud and on-premise deployment, which is rare as companies shift to all cloud-based platforms. Its features include BOM, production scheduling, inventory, and quality management, perfect for discrete industries. Also, if you like the S/4HANA interface but find it too expensive, B1 has a lower cost and a similar feel, so you get the best of both.

What is Discrete Manufacturing Software?

Discrete manufacturing software helps companies build distinct, countable items made from separate parts. Each item uses components that manufacturers can independently produce, track, and replace. For example, an automotive manufacturer uses discrete manufacturing processes to build engines, transmissions, and body frames, assembling each part to produce a finished vehicle.

The software handles tasks like BOM management, inventory control, engineering changes, and work order scheduling to ensure each component fits seamlessly into the final assembly. These platforms differ from process manufacturing software, which is designed for producing materials like liquids, powders, or chemicals that aren’t easily separated or counted.

Many discrete manufacturers prefer using a full manufacturing ERP to manage these processes. Small business manufacturers may rely on lightweight platforms that integrate with their current accounting software. However, a specialized tool is sometimes needed to handle the complexities of discrete production. For companies with automated shop floors, we recommend discrete manufacturing software with built-in manufacturing execution system (MES) features.

Read more on discrete vs process manufacturing.

Types

There are three major types of discrete manufacturing:

- Engineer-to-Order: Project-based manufacturing that leverages CAD integration, change management tools, and advanced BOM management to handle custom, one-off designs and evolving customer requirements throughout a project.

- Make-to-Stock: High-volume, large-scale production to keep items in stock for immediate sale, using demand forecasting, automated replenishment, and inventory management to optimize availability.

- Make-to-Order: Manufacturing based on customer orders with limited customizations, such as varying lengths, widths, or finishes, using tools for product configuration, dynamic scheduling, and order management.

Common Challenges

Discrete manufacturers often face the following challenges during production, especially when handling complex product lines:

- High Mix, Low Volume Production: MTO and ETO manufacturers frequently produce diverse product lines in small batches, making scheduling and resource allocation difficult. This can lead to higher production costs and longer lead times.

- Complex BOM Management: ETO manufacturers rely on multi-level BOMs that change frequently to accommodate custom specifications, making accurate production and inventory management challenging. MTO manufacturers also experience BOM variations, but these are typically on a smaller scale, as configurations change for each customer’s order.

- Change Management: Engineering change orders in ETO environments can lead to manufacturing disruptions if not managed properly, resulting in incorrect assemblies or defective products.

- Shop Floor Control: Bottlenecks and production inefficiencies arise due to a lack of real-time visibility into order status, machine capacity, resource utilization, and labor availability.

- Production Scheduling: Production schedules for custom or engineer-to-order products fluctuate with shifting customer demands, labor capacity, and material availability.

Key Features and Benefits

Discrete manufacturing software is designed to tackle a wide range of challenges, making it easier to handle the unique demands of each industry or production environment.

| Feature | Functionality | Benefits |

|---|---|---|

| MRP | Manages production planning, inventory control, and scheduling. Calculates material requirements and coordinates machine and labor workloads. | Reduces material waste, improves production efficiency, and minimizes stockouts or overstock. |

| Inventory Management | Tracks current stock levels of products, raw materials, and discrete components. Includes serial number tracking and inventory allocation for different work orders. | Monitors available inventory, reduces production delays, and ensures efficient use of components. |

| BOM Management | Provides detailed, hierarchical instructions on materials, components, and assemblies. Includes multi-level BOMs for complex assemblies and version control to manage configuration or design changes. | Ensures accurate production documentation, minimizes assembly errors, and streamlines change management. |

| Accounting | Manages budgeting, financial reporting, and tracking expenses for specific production activities. Integrates with job costing to track the financial performance of each job or product line. | Improves financial oversight and integrates financial data with production costs. |

| MES | Manages rules-based routing, order prioritization, and production sequencing for discrete products. | Enhances shop-floor control, reduces production bottlenecks, and increases overall production efficiency. |

| Quality Control | Implements risk management, defect tracking, and compliance monitoring. Includes features like part-level non-conformance tracking and corrective action management. | Reduces defect rates, ensures compliance with industry standards, and improves overall product quality. |

| Supply Chain Management | Coordinates procurement, inventory, and distribution of raw materials and finished goods. Helps manage supplier relationships, purchase orders, and logistics. | Streamlines material sourcing, reduces lead times, and improves vendor collaboration. |

How to Choose the Right Software

Different types of discrete manufacturing have their unique requirements. By identifying these needs, you can choose an ERP solution that aligns with your production goals.

| Manufacturer Type | Recommended Systems | Est. U.S. Market Cap | Key Features | Product Examples |

|---|---|---|---|---|

| Electronics Manufacturing | ECI M1 | $450 billion | Traceability, compliance, BOM management | Consumer electronics, computer hardware |

| Automotive Parts Manufacturing | Infor CloudSuite Automotive | $300 billion | Supply chain management, quality control, traceability | Engine components, braking systems |

| Industrial Equipment Manufacturing | Infor CloudSuite Industrial | $200 billion | Demand planning, production scheduling, project management | Construction machinery, HVAC systems |

| Aerospace & Defense Manufacturing | SAP S/4HANA | $150 billion | Complex supply chains, compliance, serialization | Aircraft components, defense systems |

| Medical Device Manufacturing | SYSPRO | $120 billion | Traceability, compliance (FDA, ISO), serialization | Diagnostic devices, surgical instruments |

| Furniture Manufacturing | Global Shop Solutions | $85 billion | Customization, inventory management, order tracking | Office furniture, home furnishings |

Pricing Guide

Pricing for discrete manufacturing ERP can vary based on the size and complexity of your business, plus any specific modules or features required. For instance, xTuple starts at $175/user/month, while ECI M1 offers an accessible option starting at $3,000/month.

At the higher end of the spectrum, SAP S/4HANA’s monthly fees can range from $20,000 to over $100,000 for cloud subscriptions and between $200,000 and $2 million or more for on-premise licensing. Here are some general price ranges you can expect:

- Low Tier: $10,000-$30,000 per year

- Mid Tier: $40,000-$110,000 per year

- High Tier: $150,000+ per year

In most cases, you’ll need to request a pricing quote directly from the ERP provider. Key factors influencing ERP costs include:

- Add-on Modules: Adding specialized modules like product lifecycle management can significantly increase the overall cost.

- Training Requirements: Employee training expenses can vary widely based on system complexity and user count.

- Initial Implementation: Setup costs often depend on integration needs and the time required to tailor the system to your unique manufacturing processes.

- Total User Count: Costs typically scale with the number of users, as many ERP systems utilize a per-user pricing model.

- Ongoing Support and Maintenance: This includes technical support and regular updates, with fees varying based on service levels.

Frequently Asked Questions

Can QuickBooks be used as discrete manufacturing software?

Yes, QuickBooks Desktop Enterprise can be used by small discrete manufacturers to manage basic inventory, sales orders, and purchasing. But it’s not a comprehensive manufacturing solution.

While third-party add-ons like Acctivate can extend its capabilities with bill of materials management and order fulfillment, QuickBooks lacks key functionalities. These include MRP, engineering control, and production management, making it insufficient for medium to large manufacturers.

How long does it take to implement a new manufacturing ERP software?

What is the difference between a discrete system and a continuous system?

Discrete manufacturing ERP is designed for manufacturers that produce distinct items made up of individual components that can be counted, assembled, and disassembled.

Continuous manufacturing ERP systems cater to process manufacturers producing goods in bulk, like food, chemicals, and pharmaceuticals. Ingredients combine to form a finished product and can’t be separated back into their original components.