The Best ETO Manufacturing Software

We reviewed the top engineer-to-order (ETO) software for aerospace, medical devices, and industrial machinery. Our picks offer engineering change control, multi-level BOM comparisons, and shop floor monitoring for one-off projects.

- HANA database

- Large network of resellers

- Strong BI tools

- Mostly straight-forward and user-friendly

- Built with over 40 years of manufacturer and distributor expertise

- Integration with AI, MI, IoT, and Cloud-hosting

- Consistent performance across software updates

- Excellent customer service with quick response time

- Training and implementation included in annual costs

In this guide, we reviewed manufacturing ERP for engineer-to-order (ETO) processes, focusing on tools for different sectors like custom metal fabrication, automotive, and electronics:

- SAP S/4HANA: Best for Aerospace and Defense

- SYSPRO: Best for Medical Devices

- Total ETO: Best for Industrial Machinery

- ECI M1: Best for Custom Metal Fabrication

- xTuple: Best BOM Functionality

- Infor CloudSuite Automotive: Best for Custom Automotive

- Acumatica: Best for Custom Electronics

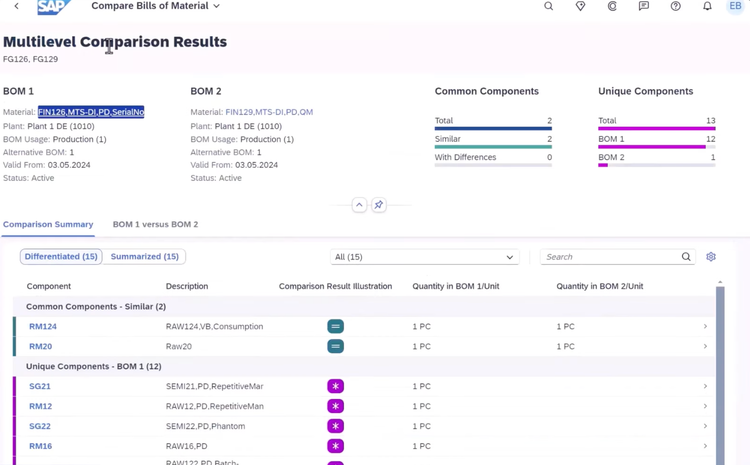

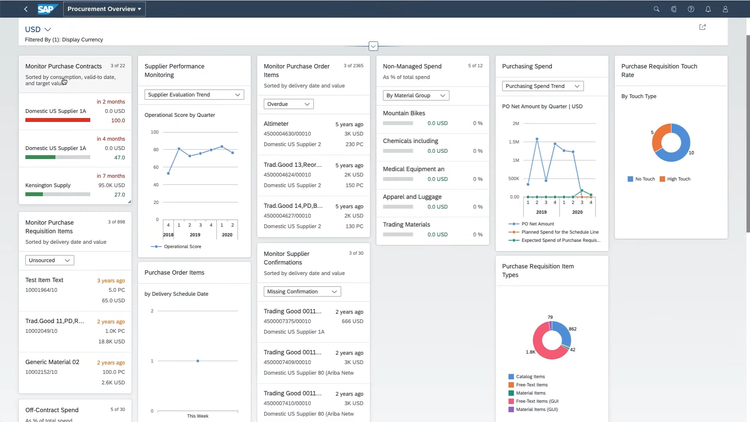

SAP S/4HANA - Best for Aerospace and Defense

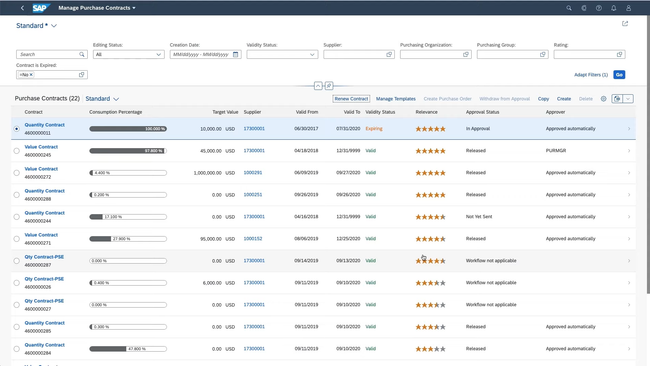

SAP S/4HANA features multi-level bill of material (BOM) comparison tools. These allow you to view BOMs side-by-side to analyze similarities and differences between complex systems like aircraft and vehicles. For example, if you’re managing two transport aircraft variants with distinct cargo setups, you can quickly identify unique and shared components. This ETO ERP ensures any changes to one variant won’t inadvertently affect the other.

This ETO manufacturing software also includes an intuitive change management process. Proposed adjustments trigger a structured workflow for creating change records, submitting requests for approval, and logging all activities for traceability. Detailed change logs show who made the request, what changes were made, and how those changes affect other assemblies. This helps you comply with industry standards like AS9100, providing an auditable trail to meet regulatory needs. Once approved, updates automatically cascade through nested BOM levels, minimizing manual errors.

S/4HANA integrates with SAP PLM and third-party platforms to sync engineering data like CAD files and 3D models. This means your manufacturing processes immediately reflect any design changes in real-time. Additionally, this ETO software offers impact analysis capabilities, which make it easier to understand how changes at one level of the BOM will ripple through production.

S/4HANA is an enterprise-level system, with hosted subscription costs starting at $20,000 per month and on-premise perpetual licenses ranging from $200,000 to over $2 million. While it is a premium product, its deep feature set positions it as a solid option for A&D manufacturers. Organizations with smaller budgets may consider alternatives like Infor CloudSuite Aerospace & Defense.

Read our full review of SAP S/4HANA.

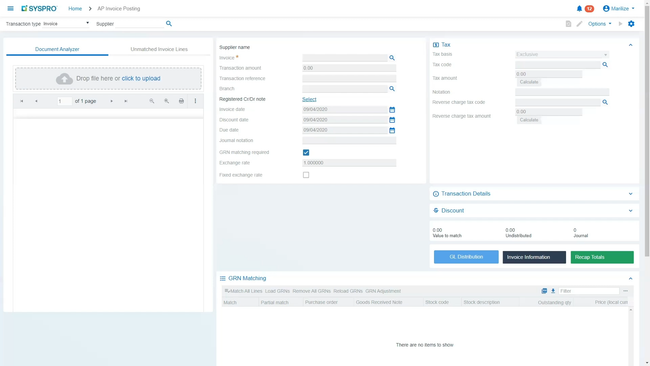

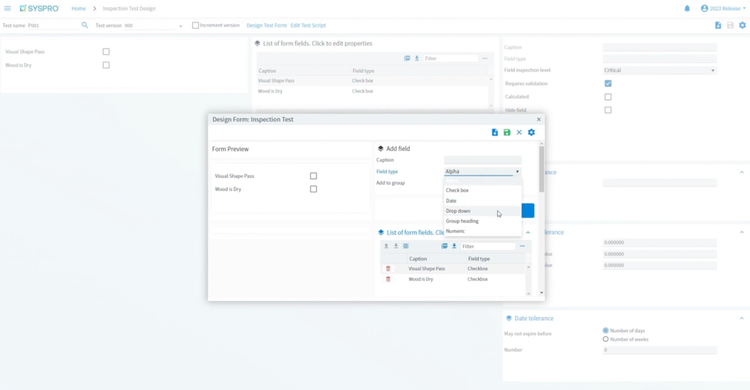

SYSPRO - Best for Medical Devices

SYSPRO’s quality management module helps you meet mandated guidelines like FDA 21 CFR Part 820. You can define acceptable quality limits (AQL) standards for each stock code, setting the maximum number of defective units permitted in a batch before it’s deemed unacceptable. You can do this for every part, component, or finished product to meet predefined quality thresholds.

SYSPRO’s inspection management feature uses industry-standard sampling plans, such as General Levels 1-3 for routine testing and Special Levels 1-4 for high-risk inspections. Based on the results, the system automates batch acceptance or rejection. This helps reduce manual errors and keeps decision-making more consistent for high-stakes manufacturing environments like medical devices.

The engineer-to-order manufacturing software also lets you assign these tests by supplier or warehouse, ensuring that inspections account for specific materials and processes. For example, if you’re making implantable devices like orthopedic screws or pacemaker components, you can set different testing rules for titanium parts versus electronic subassemblies. This ensures everything meets the high standards required for patient safety.

SYSPRO also lets you design custom inspection tests for specific products, accounting for unique requirements, like sterilization levels or biocompatibility. Flexible field types—such as text, numbers, checkboxes, dropdowns, and dates—make it easy to set precise parameters, including numeric tolerances.

Though pricing isn’t published online, SYSPRO starts at around $199/user/month. However, this doesn’t factor in license type, business size, maintenance and support, and implementation complexity.

Get pricing details, pros, and cons for SYSPRO.

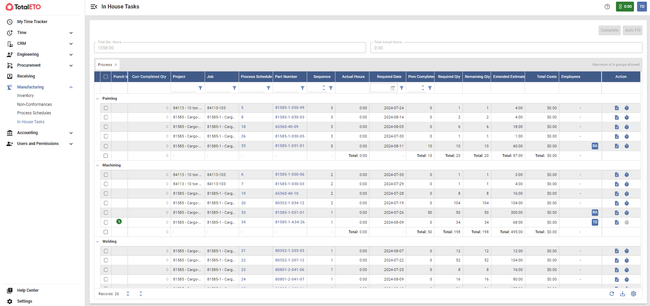

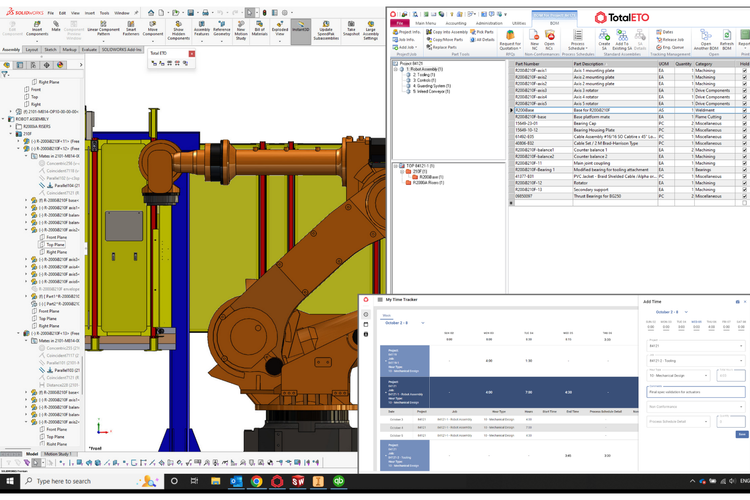

Total ETO - Best for Industrial Machinery

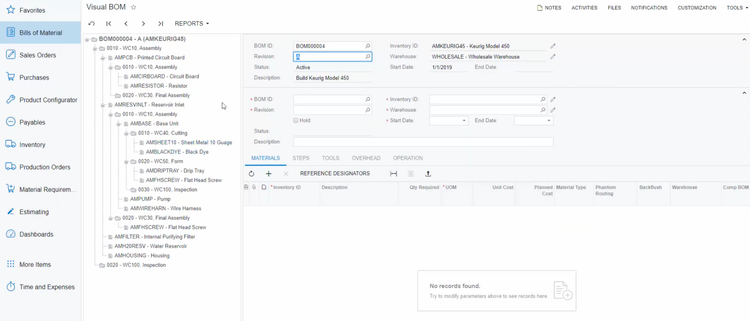

Total ETO’s BOMs functionality integrates with popular CAD systems like SOLIDWORKS and Autodesk Inventor. This allows your engineers to generate BOMs directly from CAD files, reducing the need for double-entry and manual updates even as designs evolve. Total ETO also supports quick modifications for change orders, reflecting any adjustments in labor, materials, and costs.

To improve shop floor efficiency, you can create routings for fabricated parts directly from the BOM. This ensures clear and precise production workflows, helping your team sequence and track components as they move internally or to external vendors. With this real-time materials traceability, it’s way easier to pinpoint and resolve quality issues before they escalate.

Since the BOM updates dynamically, your engineers can release parts to procurement in stages. For long-lead components, this staged release helps teams start sourcing materials early and secure competitive pricing. In this way, Total ETO bridges communication between your engineering, procurement, and accounting teams. It also helps custom machine builders avoid stock mismanagement and production delays.

Total ETO starts at $7,500 per year with a minimum of five users, but it focuses exclusively on engineer-to-order production. For mixed-mode manufacturing, like building custom machinery while producing standardized make-to-stock spare parts, consider Epicor Kinetic.

Find out more about Total ETO in our full review.

ECI M1 - Best for Custom Metal Fabrication

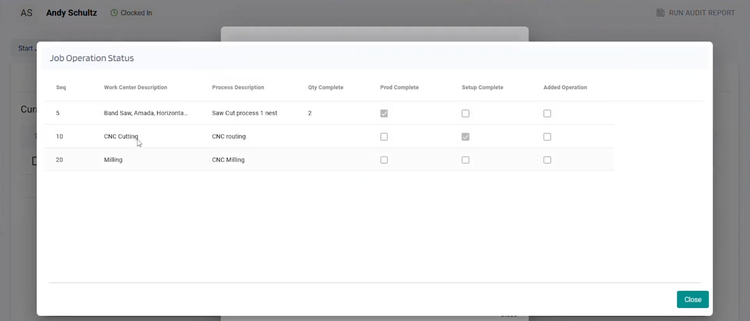

ECI M1’s Shop Floor Web App provides real-time job management and visibility across the production floor. You can navigate through multi-assembly parts and sequences to view complete, ongoing, or pending operations. For example, a team machining a custom metal part can:

- Check remaining steps, materials needed, and finished tasks

- Access job-specific notes like detailed assembly instructions or machine setup parameters

- Spot bottlenecks like pending steps at a welding or milling workstation

Your workers can clock into specific jobs using a personalized PIN. From there, they can record their progress at each stage, including setups, partial completions, and scrap reasons. This app also includes a digital job traveler, enabling barcode scanning to access work orders, CAD drawings, and specifications. All updates sync instantly with the core M1 system, which updates time cards and stock levels.

Supervisors can filter and sort jobs by priority, department, work center, or specific job IDs. This allows them to focus on high-priority assignments and allocate resources more efficiently. They can also analyze rework data to uncover trends, like recurring tool calibration issues, so you can proactively address them.

With pricing starting at $3,000/month, ECI M1 is a versatile solution for medium-sized manufacturers with 50-200 employees. However, its complexity and feature set might be overwhelming for smaller companies. If you’re an ETO job shop with under 50 employees, we recommend ECI’s JobBOSS² solution.

Read our full review of ECI M1.

xTuple - Best BOM Functionality

xTuple offers multi-level BOM management with revision control to help you track intricate, one-off designs. Since ETO manufacturers rarely use identical BOMs, xTuple allows for quick changes as project specs evolve.

This ETO ERP delivers revision-controlled BOMs to support frequent design changes. For example, when engineers update a design with a new material substitution, xTuple immediately updates purchasing, production, and assembly records. Your manufacturing and engineering teams can work with the latest approved version to minimize the risk of working with outdated documentation.

Additionally, xTuple includes material tracking to specify exact quantities and required tolerances per item within the BOM. This is vital when you’re handling custom-cut materials or welded subassemblies, allowing you to use resources efficiently. xTuple also flags any discrepancies if a quantity falls outside a predefined range.

xTuple starts at $175/user/month, with pricing based on named users (or how many users access the system at the same time). xTuple’s manufacturing edition requires a minimum of five users.

Infor CloudSuite Automotive - Best for Custom Automotive

Infor CloudSuite Automotive provides advanced supplier collaboration for managing custom-build supply chains. Its claims management table helps you monitor issues with one-off orders, highlighting delayed shipments or quality concerns in custom parts. With drill-down capabilities for part-specific statuses or associated costs, you can resolve issues quickly to stay on schedule.

This ETO ERP also tracks expenses tied to timeline changes or supplier adjustments, like substituting delayed components with alternatives. Its built-in monitoring tools for claimed amounts and thresholds help you stay within budget while maintaining the flexibility needed for ETO projects.

Infor’s Enterprise Collaboration Portal further supports engineer-to-order workflows with a built-in hub of communication tools. For ETO manufacturers, this means managing procurement orders for custom-built or prototype parts directly through the portal. Suppliers can review and update orders tailored to your unique production specifications, reducing errors and miscommunications that can lead to delays.

Additionally, this portal lets you store and share project-specific quality policies, engineering specifications, and compliance documents, ensuring alignment with IATF 16949 standards. By integrating these workflows, you have tight control over supplier contributions, maintaining quality for one-off builds or short production runs.

Read more about pros, cons, and ratings for Infor CloudSuite Industrial

Acumatica - Best for Custom Electronics

Acumatica’s engineering change control and multi-level BOM capabilities make it a good fit for the intricate designs and workflows behind control panels and specialized electronic devices. Treeview BOMs support layered assemblies and display all components, subassemblies, and materials in a hierarchical layout. Clicking through different levels automatically updates details, giving you a better understanding of dependencies and relationships between parts.

Acumatica also simplifies managing engineering change requests (ECRs) and engineering change orders (ECOs). You can merge multiple ECRs into one single ECO to save time and effort. You can even access BOM comparisons, with color-coded differences highlighting changes like quantity updates or material substitutions. This ETO manufacturing software helps reduce lead times by speeding up approvals. It also improves accuracy in choosing components, which can help you meet standards like RoHS or ISO certifications.

For better cost control, Acumatica provides breakdowns at each BOM level, separating material, labor, and overhead expenses. These reports help you evaluate the financial impact of engineering changes before implementing them, keeping profitability on track.

For 10 users or less, Acumatica’s manufacturing package starts at $3,500 per month. If you have 10-40 users, those costs increase to $6,500 per month. For a more affordable alternative, consider xTuple, starting at $175/user/month.

Check out our full review of Acumatica for pricing details and ratings.

What Is Engineer-to-Order Software?

ETO software streamlines the design, engineering, and fabrication of unique, client-specific products. As a type of discrete manufacturing software, it supports assembling individually identifiable and disassemblable items.

ETO manufacturing software emphasizes customer participation throughout the project and incorporates engineering tasks into lead time calculations, providing a more accurate timeline for buyers. Engineer-to-order platforms enable selling product concepts instead of predefined models, so the software must support custom-build processes in both the ideation and development phases.

How ETO differs from other manufacturing types:

- Make to Order (MTO): Produces items based on client orders with limited customizations, like different finishes, dimensions, or materials, often using product configuration tools.

- Make to Stock (MTS): Focuses on producing high-volume items for immediate sale, emphasizing automated inventory replenishment and demand forecasting.

Process Flow

- The customer submits a sales order, including quoted costs and anticipated delivery dates.

- The project team selects employees with specific skill sets, schedules production blocks, and determines raw materials needed for the job.

- The company creates a BOM detailing all components needed to complete the order, fulfilled by current inventory or through procurement.

- The team researches, ideates, and submits the custom design for client approval.

- MRP generates a finalized list of material requirements, allocates labor and machinery, and schedules purchasing to meet production timelines.

- After completing the planning phase, the company manufactures and assembles the final product.

Key Features & Benefits

| Key Feature | Description | Benefit |

|---|---|---|

| Estimates and Quotes | Create accurate quotes using templates or historical data; roll up material and labor expenses to assess total job costs; run “what-if” scenarios to evaluate alternatives. | Streamlines quoting process, improves cost accuracy, and improves decision-making. |

| Bill of Materials (BOM) | Lists components, parts, and sub-assemblies needed for manufacturing; integrates with CAD systems to import/export BOMs. | Reduces duplication, speeds up product revisions, and improves quote accuracy with configure, price, quote (CPQ) tools. |

| Job Costing | Assigns costs to categories, tracks them against budgets, and calculates BOM costs pre-purchase. | Improves profitability by identifying cost overruns and optimizing spending. |

| Engineering and Design | Validates BOM accuracy by updating purchasing data; imports parts from inventory by referencing previous BOMs. | Improves product accuracy and streamlines collaboration between engineering and purchasing. |

| Production Scheduling | Plans shop floor activities by analyzing material needs and capacity to complete orders. | Increases production efficiency and ensures timely delivery. |

| Time Tracking | Monitors time spent on operations across engineering and production to identify bottlenecks. | Reduces labor costs and optimizes workflow efficiency. |

| Spare Parts Management | Integrates with BOMs to track stock, reserve items for priority jobs, and plan orders for low inventory. | Prevents delays, ensures parts availability, and minimizes downtime. |

| Procurement | Tracks vendor details, purchase quantities, delivery timelines, and costs; forecasts reorder points to maintain optimal stock levels. | Ensures availability of materials, prevents duplicate orders, and stabilizes cash flow. |

How to Choose ETO ERP

Choosing the right platform for your business starts with identifying your sector and its unique requirements:

| Sub-Vertical | Market Cap | Example Products | Software Platform |

|---|---|---|---|

| Aerospace and Defense | ~$250 billion | Aircraft, spacecraft, defense systems | SAP S/4HANA |

| Medical Equipment and Devices | ~$150 billion | Diagnostic machines, surgical instruments | SYSPRO |

| Custom Metal Fabrication | ~$50 billion | Structural components, custom metal parts | ECI M1 |

| Industrial Machinery and Equipment | ~$40 billion | Manufacturing equipment, construction machinery | Total ETO |

| Custom Automotive and Transportation | ~$30 billion | Specialty vehicles, custom fleet solutions | Infor CloudSuite Automotive |

| Shipbuilding and Marine Equipment | ~$20 billion | Cargo ships, luxury yachts | Epicor Kinetic |

| Energy and Power Generation Equipment | ~$20 billion | Wind turbines, solar power systems | IFS Cloud |

| Electronics and Instrumentation | ~$10 billion | Control panels, specialized electronic devices | Acumatica |

To ensure a successful launch, partner with expert providers who understand ETO manufacturing and can support business transformation overall. For engineer to order manufacturers, this means working with ETO ERP specialists to demo different platforms. Evaluate features such as custom designs, purchase order functionality, and electronic collaboration tools.

Compare solutions like GLOVIA G2, SYSPRO, and Total ETO to find what you need to simplify operations and manage quality issues. Implementation is another key consideration. Work with vendors to determine how long setup is likely to take for your business, and follow our ERP implementation plan for further tips.

Pricing

Pricing for ETO manufacturing ERP depends on your company’s size, complexity, and the specific features you require. For instance, ECI M1 offers an affordable option starting at $3,000/month.

At the higher end of the spectrum, SAP S/4HANA’s monthly fees can range from $20,000 to over $100,000 for cloud subscriptions and between $200,000 and $2 million or more for on-premise licensing.

Most ERP providers do not provide pricing publicly; you’ll often need a custom quote to account for the following:

- Implementation: Setup costs vary depending on integration and customization requirements.

- Total User Count: Many ERP systems utilize a per-user pricing model that scales as you add more.

- Add-on Modules: Advanced features like advanced scheduling and capacity planning can raise costs.

- Training: Employee training expenses factor in system complexity and total user count.

- Maintenance and Support: Fees associated with technical support and regular updates depend on the service level you choose.

| Software | Pricing |

|---|---|

| SAP S/4HANA | Hosted subscription: $20,000/month On-premise perpetual: $200,000 to over $2 million |

| SYSPRO | Starts at $199/user/month |

| Total ETO | Starts at $7,500/year (minimum of 5 users) |

| ECI M1 | Starts at $3,000/month |

| Infor CloudSuite Automotive | Pricing not listed publicly |

| xTuple | Starts at $175/user/month (minimum of 5 users) |

| Acumatica | Starts at $3,500/month (for 10 users or less) Increases to $6,500/month for 10-40 users |