Aptean Industrial Manufacturing ERP Workwise Edition Review

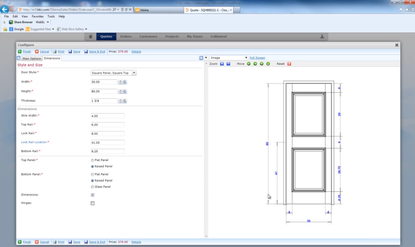

We like Aptean Industrial Manufacturing ERP for its customizable reporting, multi-warehouse support, and mobile accessibility. It features strong scheduling algorithms and product configurability.

However, the sheer breadth of features means users may need time to grasp the various modules and workflows. We found that, compared to other ERP solutions, Aptean also offers limited integration options.

- Mobile accessibility

- Multi-warehouse support

- Customizable reporting

- Strong product configurator and scheduling

- Requires consultation for pricing

- High learning curve

- Fewer integrations than NetSuite

- Developer WorkWise Software

- Client OS

- Deployment On-Premises

What is Aptean?

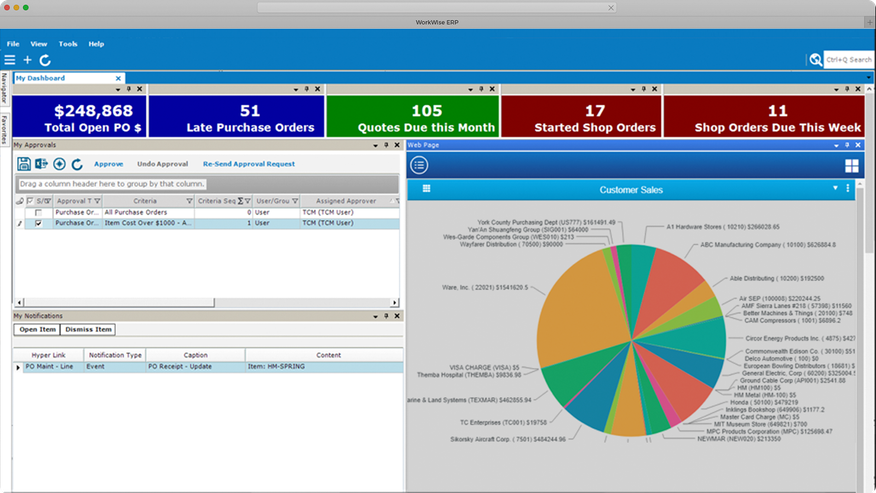

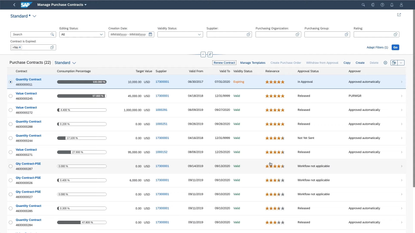

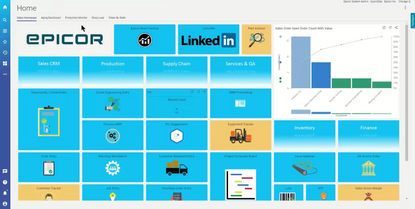

Aptean Industrial Manufacturing ERP WorkWise Edition is a sophisticated and flexible manufacturing ERP that enhances visibility over delivery and shop floor operations. Its core features include production and materials management, accounting, sales, and CRM. It offers seamless integration of advanced planning and scheduling capabilities with comprehensive shop floor execution features.

Our Ratings

| Usability - 8 | Offers a user-friendly interface and intuitive workflows; provides robust navigational search; financial functions like bank reconciliation are cumbersome; learning curve can be challenging for new users. |

| Support - 10 | Great support functionality within software; offers phone, email, and customer portal; users report quickly reaching customer service agents. |

| Scalability - 6 | Offers fewer integrations than competitors; integrates with CADLink, UPS/FedEx shipping; only supports single-site operations; provides mobile solutions for EAM and maintenance operations |

| Security - 10 | Provides user access controls over actions and resources in the system; Action Center dashboard allows user-specific workviews; exports data into PDF, HTML, RTF, and Excel formats. |

| Value - 7.5 | Provides good value considering its extensive functionality and customization options; pricing may be higher than some competitors. |

| Performance - 8 | Delivers reliable performance even with large data sets and complex manufacturing processes; can work in multiple workflows without losing your progress; experienced slight lag when loading into item master list, purchase orders, and sales orders. |

| Key Features - 10 | Margin Analyzer allows you to monitor labor and overhead, variances, and more; provides real-time reporting with customizable layouts, filters, and sorting options and calculated fields and formulas; can create quotes based on previous job orders. |

Who Uses Aptean?

We recommend Aptean Industrial ERP for single-site mid to enterprise-level discrete production operations, including job shops and mixed-mode manufacturers. The software’s deep functionality and flexibility meet specific engineering requirements, diverse product configurations, and the need for comprehensive inventory and production management. The ERP offers deployment models for both on-premises and cloud-based solutions, with compatibility across different operating systems.

What Features Are Missing?

-

Multi-site support: This edition of Aptean Industrial Manufacturing ERP does not support multi-site operations, which is a huge drawback for manufacturers looking to expand. We recommend Aptean Industrial Manufacturing ERP Traverse Edition if you have several locations.

-

Third-party integrations: Integration with popular third-party apps, such as e-commerce systems or advanced analytics tools, is limited. A lack of integration options could require additional development or manual data transfers, leading to increased effort and potential discrepancies down the line.

Aptean Pricing

Aptean’s pricing depends on several factors, including the company’s size, user count, and your preferred deployment model. While specific pricing details are not publicly disclosed, Aptean offers flexible licensing options to accommodate different budgetary requirements.

Some Value-Added Resellers (VARs) may also provide consultation services for an additional fee. Their expertise in the software and manufacturing processes can facilitate a smoother implementation.

Which Companies Use Aptean Industrial ERP?

Corporations utilizing Aptean Industrial Manufacturing ERP include Anderson Dahlen, EHOB, the Metalworking Group, Portable Pipe Hangers Systems/Design, and Tek Pak, Inc. The system best serves the computers and electronics, electrical equipment, fabricated metals, transportation equipment, and related industries.

Alternatives

Summary

We recommend Aptean Industrial Manufacturing ERP for its robust functionality and sophisticated reporting capabilities. It’s well-suited for mid to enterprise-level make-to-order and engineer-to-order manufacturing businesses. The ERP system enables expert planning, scheduling, execution, and operations tracking.

However, the software will require additional training to learn its UI, navigation, and terminology. It has limited integrations, which might interfere with the overall scalability. Finally, users will also need to consult with Aptean to determine the exact pricing of the system, which hinges on company size, deployment models, and other facets.

Overall, we think Aptean is suitable for larger manufacturing companies that prioritize comprehensive manufacturing functionality and extensive customization options.

User Reviews of Aptean Industrial Manufacturing ERP Workwise Edition

Write a ReviewThe integrated system brought us greater efficiency

The main reason we were looking for a new ERP system was because we were a Y2K company. Our existing software had been purchased some time ago and modified heavily. We determined that maintaining it wasn’t feasible from an economic standpoint.

Having a full featured, fully integrated system, with all of the modules working together, the ability to look at inventory control and all of the manufacturing requirements, were things that we didn’t have before. The integrated system brought us greater efficiency.

With our previous system there was double, sometimes triple data entry because the modules weren’t integrated so there wasn’t any information being passed back and forth. That alone was a tremendous time saver for us.

The visibility of information, being able to import certain information and being able to create customer orders via spreadsheet, were major performance enhancements for us.

We use close to ninety percent of the modules in the system. We certainly use the customer order processing side of it, all of the inventory controls, we use MRP, all of the purchasing modules, accounting.

What’s really nice is to have everything in one package

We had a system that had been in place for about ten years and it turned out it was not a very good manufacturing system. It was more of an accounting system that they tried to put manufacturing into.

What’s really nice is to have everything in one package. My financials are in the same package as the manufacturing and the customer orders. Everything integrates seamlessly. Bringing in inventory management has been a huge benefit for us. Being able to jump between workbenches and different points of data has been really nice.

We have about twenty folks that use the system, that are not here in Topeka, Kansas. So in our prior system they would have to pick up a VPN connection and log into our system and with being on the road and traveling, that did not work well for them at all.

We really hope that it’s going to help the guys in the field manage their sales and prospects so that way when they are out, they have a good understanding as to what’s going on with their customers and who their new customers potentially are.

Everything is seamlessly integrated. As soon as we create an order, that order flows into manufacturing, manufacturing can understand where the demand is coming from, purchasing can understand where the demand is coming from and be able to see all of that data seamlessly.

- Industrial Conglomerates

- 51-250 employees

- Annual revenue $10M-$50M

WorkWise ERP has many strong modules to manage the shop floor

WorkWise ERP has many strong modules to manage the shop floor, manage the financials and since it is SQL based, you can easily get at the data for custom reporting.

Pros

With the eProduction add on, the shop floor has a clean interface to interact with shop orders. The Workbenches give users control over how they work day to day.

Cons

We would like the ability to group sales orders and the related shop orders into 1 manageable unit for shop floor scheduling