Takt Time vs. Cycle Time vs. Lead Time: The Differences Explained

Three common ways of measuring manufacturing production are takt time, cycle time, and lead time. Takt time is the rate of production needed to meet customer demand, cycle time is the actual time it takes to produce one unit of a product, and lead time is the time measured from order placement to the delivery of a product.

They are calculated using three different formulas:

- Takt Time = Net Production Time ÷ Customer Demand

- Cycle Time = Net Production Time ÷ Number of Units Produced

- Lead Time = Pre-Processing Time + Processing Time (Cycle Time) + Post-Processing Time

Takt Time

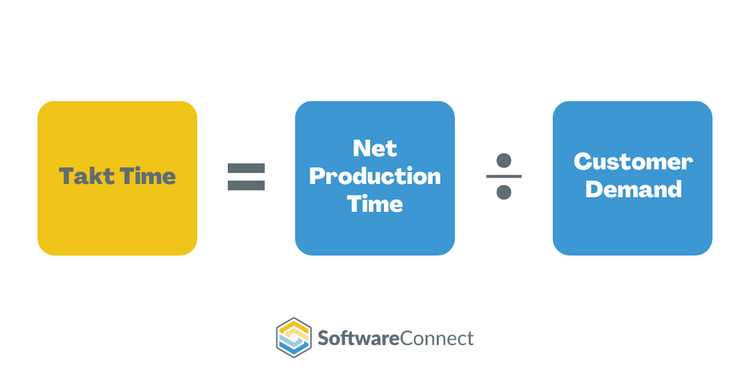

Takt time is the average duration between the start of production on successive product units. From the German word “taktzeit,” meaning “rhythm,” this time method is typically used in lean manufacturing operations.

Further Reading: Lean Manufacturing Tools and How to Use Them

Takt time calculations help set goals for product production. Manufacturers can optimize takt time to nearly match cycle time to meet customer demand and avoid supply deficits.

Calculating takt time also allows manufacturers to maintain a consistent flow of production and increase efficiency.

The formula to calculate takt time is:

Takt Time = Net Production Time ÷ Customer Demand

Example

A company has 8 active working hours in a day and must fulfill 50 widgets. To calculate the takt time, you would convert 8 hours to 480 minutes (net production time), then divide it by 50 (customer demand). Businesses commonly use production tracking software to acquire accurate production times.

480/50=9.6 minutes

The company must complete one widget every 9.6 minutes to meet customer demand.

Further Reading: Demand Planning vs. Supply Planning: What are the Differences?

Cycle Time

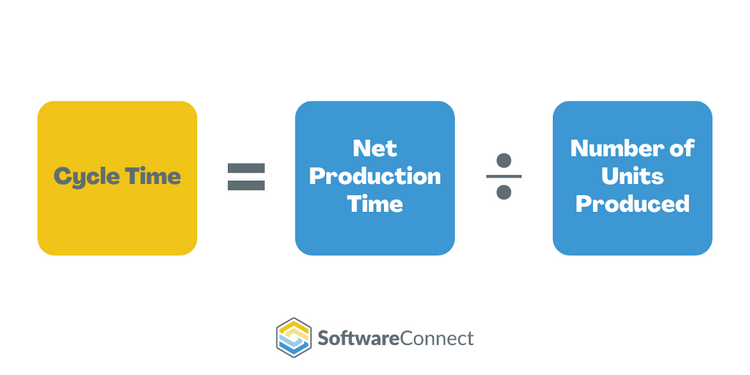

Cycle time is the average duration it takes to produce one product unit. Cycle time is used in all types of manufacturing operations.

Note: Takt time and cycle time are often confused. See our section below to clarify the differences.

Manufacturers aim to reduce cycle time as much as possible (while maintaining quality standards) to minimize costs. Reduction typically involves addressing potential bottlenecks in production cycles. Additionally, knowing your cycle time helps you set customer expectations for deliverables.

Manufacturers often use Material Requirements Planning (MRP) software to help gain control over production, inventory, and supply chain management.

The formula to calculate cycle time is:

Cycle Time = Net Production Time ÷ Number of Units Produced

Example

In the same scenario as above, a company has 8 active working hours to fulfill 50 units of a product. During a week of production runs, the average number of units that could be completed was 48. To calculate the cycle time for this product, you would again convert 8 hours to 480 minutes (net production time), then divide it by 48 (number of units produced).

480/48=10 minutes

Each product has an average completion time of 10 minutes.

Lead Time

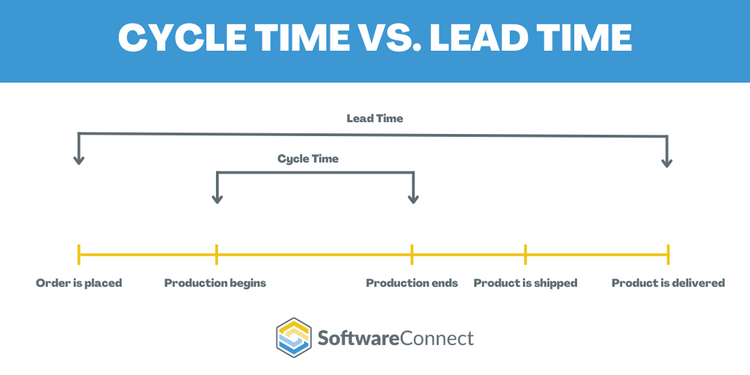

Lead time is the total time from order placement to delivery.

Product lead time is a crucial measurement of manufacturing efficiency, as it clearly shows how long it should take a customer to receive a product.

In addition to manufacturing, lead time is an important calculation in supply chain management and project management. In supply chain management, lead time is the time between order placement and delivery of supplies. In project management, lead time refers to the time it takes to complete a task or set of tasks within a project.

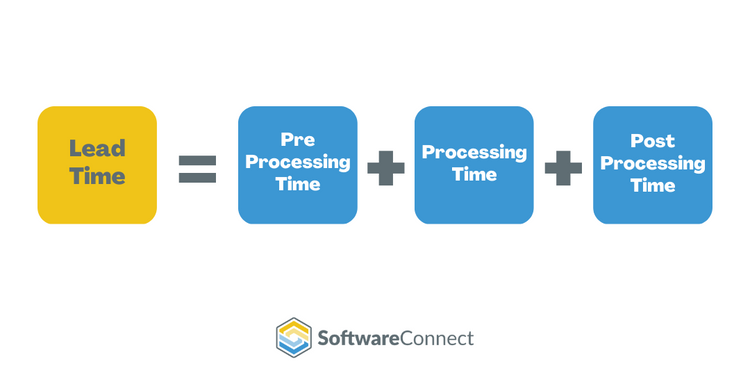

The formula to calculate lead time is:

Lead Time = Pre-Processing Time + Processing Time (Cycle Time) + Post-Processing Time

Pre-processing time includes purchasing raw materials; post-processing time includes quality control and shipping to consumers.

Example

A customer orders 50 units of a product. After they place the order, it takes 3 days before production begins. Production of the 50 units is completed in 8 active production hours or 1 business day. After production is complete, quality control and shipping to the customer take an additional 4 days. With these days added together, the lead time is 8 business days.

3 Days + 1 Day + 4 Days = 8 Day Lead Time

Takt vs. Cycle vs. Lead

| Specifications | Takt Time | Cycle Time | Lead Time |

|---|---|---|---|

| Definition | Goal rate of production of one unit | The average time it takes to produce one unit | The time from pre-production to the delivery of product |

| Purpose | Meet customer demand | Calculate completion rate and rate of output | Calculate arrival rate |

| Formula | Net Production Time ÷ Customer Demand | Net Production Time ÷ Number of Units Produced | Pre-Processing Time + Processing Time + Post-Processing Time |

Takt Time vs. Cycle Time

Scenario 1 (Not Meeting Demand):

Customer Demand: 50 Units

Amount Produced: 25 Units

Net Available Production Time: 500 Minutes

Takt Time = 500 Minutes ÷ 50 Units = 10 Minutes Per Unit in Demand

Cycle Time = 500 Minutes ÷ 25 Units = 20 Minutes Per Unit

In this scenario, takt time is significantly lower than cycle time. You are not adequately meeting demand.

Scenario 2 (Overproduction):

Customer Demand: 50 Units

Amount Produced: 100 Units

Net Available Production Time: 500 Minutes

Takt Time = 500 Minutes ÷ 50 Units = 10 Minutes Per Unit in Demand

Cycle Time = 500 Minutes ÷ 100 Units = 5 Minutes Per Unit

Here, takt time is significantly higher than cycle time. If you continue to make products, this will lead to overproduction.

Scenario 3 (Ideal Output):

Customer Demand: 50 Units

Amount Produced: 52 Units

Net Available Production Time: 500 Minutes

Takt Time = 500 Minutes ÷ 50 Units = 10 Minutes Per Unit in Demand

Cycle Time = 500 Minutes ÷ 52 Units = 9.6 Minutes Per Unit

Here takt time is slightly higher than cycle time. This is the ideal scenario as you are meeting customer demand with a little time to spare and not overproducing.

FAQ

What does it mean if takt time is higher than cycle time?

If takt time is higher than cycle time, this usually indicates overproduction. Products are being produced faster than needed to meet customer demand. Ideally, takt time should match or slightly exceed cycle time. However, if the takt time is significantly higher than the cycle time, excess products could occupy your warehouse if you keep stock.

What does it mean if cycle time is higher than takt time?

If cycle time is higher than takt time, customer demand is not being met. Production speed must increase to meet customer demand. Inefficiencies in your production line may be causing bottlenecks and ultimately slowing down the cycle time. Bottlenecks can be slow equipment, an inefficient manual process, or even an employee who needs more training. If you aim to improve your cycle time, you must adjust the production or manufacturing process.

What is the difference between lead time and cycle time?

Cycle time is a subcomponent of lead time. While cycle time only includes production, lead time also includes planning, preparation, quality control, and shipping.