Order Picking: Definition and Methods

Order picking is an important process in warehouse management that involves selecting and retrieving items from inventory to fulfill customer orders. Discover the different order picking methods and why having this type of system is important for your operations.

| Method | Definition | Best For | Pros | Cons |

|---|---|---|---|---|

| Discrete | Fulfills one order at a time | Operations with limited SKUs, small orders | High accuracy with individual orders, simple to implement | Requires more travel time between picks |

| Batch | Collects items for multiple orders simultaneously | Large companies with high order volume | Reduces travel time, more efficient for high-volume operations | Requires sorting of items into individual orders after picking |

| Zone | Pickers are assigned to different zones | Large warehouses | Reduces congestion in the warehouse, can be combined with other methods | May create uneven workloads between zones |

| Wave | Orders are released in waves at specific times | High-volume operations | Useful for time-sensitive orders | Not suitable for operations with unpredictable order volumes |

| Cluster | Pickers use carts to separate items for multiple orders | Small to medium-sized items in high volume fulfillment operations | Reduces downstream sorting | Not ideal for large items |

Order Picking Methods

Discrete Order Picking

Discrete picking is one of the most common types of order picking, in which one picker fulfills one order at a time. In this method, the picker moves through the warehouse, finding items for a specific order before moving on to another.

Discrete order picking is often used in distribution warehouses, where products are stocked in aisles and cartons/bins and sorted by SKUs and/or serial numbers. Warehouses that utilize discrete picking often use barcode scanners to scan items, which helps the warehouse workers quickly pick the right items for an order.

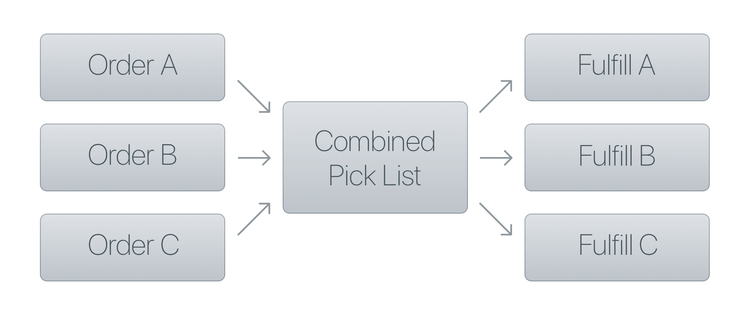

Batch Order Picking

Batch picking can also be referred to as consolidated or multi-order picking. With this method, a single picker grabs items with the same SKU for multiple orders at the same time. Batch picking is best for high order volumes with a high rate of shared SKU overlap.

Batch order picking can be used for many different types of orders. However, batch pickers usually pick similar orders. For example, it is often used to pick orders that contain a mix of items from multiple bins. The pickers select items and put them in batches. Then, the batches are placed on pallets and moved to the shipping area.

Zone Order Picking

Zone picking is typically more expensive than batch. With zone picking, SKUs are divided into separate areas or zones. Each picker is assigned to pick from a single zone per shift.

If an order requires items from multiple zones, an order box moves down (often using a conveyor) to the next zone. This is also called “pick and pass” or “sequential zone picking.”

Zone order picking is another common order-picking method. It is often used in warehouses where products are organized by product type. Many warehouses that use zone order picking organize products into product zones or pick zones. Then, the items in each zone are stored in specific warehouse areas.

Wave Order Picking

In wave picking, orders are released in waves at specific times, often aligned with shipping schedules. This method is executed multiple times per day (or shift) and balances more factors than product overlap. It also maximizes product overlap. Wave picking balances pick list capacities, product weight, shipping schedules, worker shifts, and more to avoid picking errors.

Wave order picking is often used with sophisticated warehouse systems. This helps the warehouse workers know what to pick and where to put things (pick locations) once they are picked. Wave order picking is often used in warehouses with lots of pallets. It is also used in warehouses that store items in bulk bins.

Cluster Order Picking

Cluster picking involves having the pickers use carts or bins to separate items for multiple orders as they pick. This reduces the amount of time an employee needs to spend at each station and increases their speed.

Cluster picking helps pickers fulfill multiple orders without intermixing them. This process begins once multiple orders have been assigned to an order picker. Labels are attached to each container, tote, or box. The warehouse management software generates these labels, helping cluster the orders into the most efficient and likely to be fulfilled from a single location.

The biggest advantage of cluster order picking is that orders can be satisfied in bulk, mostly because the order picker’s material handling simultaneously organizes the picked items into their appropriate shipments. There is no need to further parse through the collected SKUs later on to “build” the orders.

What is Order Picking?

Order picking is the process of selecting items from inventory to fulfill customer orders. This process involves finding specific items from various warehouse locations, organizing them, and preparing them to be shipped. It directly impacts order accuracy, delivery speed, and overall customer satisfaction.

Why is a Warehouse Order Picking System Important?

Having a warehouse order picking system is crucial for various reasons, including:

Accuracy: Minimizes errors in order fulfillment, reducing the likelihood that incorrect items are shipped. Efficiency: Reduces the time taken to locate and pick items, leading to quicker processing times. Cost Reduction: Reduced errors and a quicker packing process can lead to fewer returns and re-shipments, which could mean lower operational costs. Customer Satisfaction: Correct and timely deliveries can increase overall customer satisfaction.