TACTIC Production Scheduling Software

4 Reviews 5/5 ★ ★ ★ ★ ★A manufacturing production scheduling software to improve delivery and cut costs.

Product Overview

Waterloo Manufacturing Software’s TACTIC system is designed for both production scheduling and advanced planning and scheduling (APS). It integrates with your existing ERP system, enhancing operational efficiency without requiring a complete system overhaul. TACTIC streamlines production processes, reduces downtime, optimizes resource allocation, and improves forecast accuracy. By leveraging TACTIC, manufacturers can manage complex production scenarios, ensure timely delivery, and achieve greater efficiency, flexibility, and control over their production processes, improving productivity and cost savings.Pros

- Ideal for discrete part and batch manufacturers

- Reduce inventory and supply costs

- Unlimited what-if capabilities

Cons

- Pricing details not provided by the developer

- Limited mobile functionality

- No cloud option

Target Market

Discrete, part, and batch manufacturers of all sizes seeking a highly customizable solution for scheduling and managing production processes.Production Scheduling Software

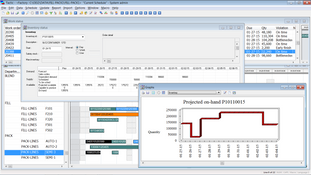

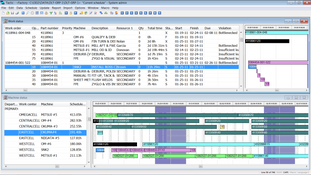

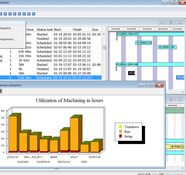

TACTIC Production Scheduling Software, also known as manufacturing scheduling software or finite capacity scheduling (FCS) software, enables manufacturing staff to generate detailed dispatch lists for production machines, labor units, and other resources. These lists account for the finite capacity constraints of the resources being scheduled.

TACTIC helps users determine:

- The next job to run

- Whether to work overtime on weekends

- Which job might be delayed

Typically, TACTIC focuses on the near-term time frame, handling released or soon-to-be-released shop orders. These orders can be supplied through an interface with MRP/ERP systems or entered manually. It is generally used within a single facility.

Advanced Planning and Scheduling Software

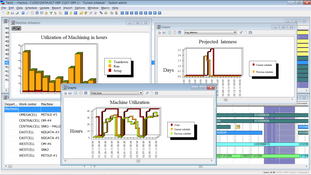

TACTIC Advanced Planning and Scheduling (APS) Software goes beyond production scheduling by considering a wider range of factors. APS software accounts for:

- Shop floor capacity constraints

- Inventory and bill of material constraints

- Inventory stocking and replenishment levels

- Order generation policies

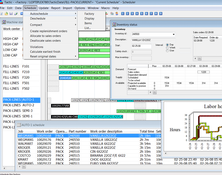

TACTIC APS can operate over longer time frames than the sum of procurement and production lead times. It accepts both sales and forecast orders and, through a bill of material explosion, creates purchase and manufacturing orders. TACTIC APS can function in conjunction with or independently from MRP/ERP systems. It can generate plans for a single location or multiple locations across the supply chain, making it a key component of supply chain management software suites.

Product Overview

Developer Overview

Related Products

User Reviews of TACTIC

Write a Review- 11-50 employees

- Annual revenue $1M-$10M

One time purchase and some great scheduling capabilities

We are in the implementation process of getting TACTIC set up for our production scheduling. We looked at a lot of systems and TACTIC stood out because of its pricing structure and ability to be customized to our needs.

We really liked how it was a stand alone program and as a one time purcahse. The support has been great and one of the main support resources is the owner of the company so he really has helped us feel comfortable with the system.

Pros

Was a one time purchase no subscriptions

- Specialty Retail

- 10K-50K employees

Automates the scheduling process

The software enables us to schedule production at multiple work stations within work centers based on due dates. Software groups orders with like attributes up to the point impacts delivery.

Pros

Automates the scheduling process. Lets me try what-ifs so I can make better decisions.

Cons

I like the software. Only issue is like any software it needs to be updated to reflect changes in the way we run our business.

- Pharmaceuticals

- 5K-10K employees

- Annual revenue $1B-$10B

A great tool to schedule day-to-day, week-to-week pilot plant work activities

A great tool to schedule day-to-day, week-to-week pilot plant work activities.

Pros

The software is relatively easy to learn and use. It has improved our pilot plant productivity and has drastically reduced the number of scheduling conflicts we encounter.

have seen immediate savings in time and material

have installed this software at 2 different companies. I have seen immediate savings in time and material, and much better visibility. I would recommend this software to anyone looking for a great scheduling package.

Pros

The tech support was great.