Eyelit MES Software

5 Reviews 4/5 ★ ★ ★ ★ ★An MES software designed to optimize and control manufacturing operations across various industries.

Product Overview

Eyelit MES is a platform-independent system designed to coordinate, control, and optimize manufacturing processes from order receipt to finished goods. Key features include advanced root-cause analysis capabilities, comprehensive traceability, and mobile access to alerts and KPIs.

Recently, Eyelit expanded its capabilities by acquiring MESTEC, a leading cloud-based MES/MOM platform. This has allowed Eyelit MES to enhance its offering with real-time data collection, machine-to-machine integration, and AI-driven analytics.

Pros

- Flexible subscription licensing models

- Leverages AI, ML, and optimization

- Monitors inventory, production units, employees, and equipment in real-time

- Maintains compliance with FDA Regulation 21 CFR Part 11

Cons

- Developer does not provide price details online

- Users have mentioned system reliability issues

Target Market

Industries like aerospace and defense, electronics, medical devices, semiconductors, and solar energy, where complex manufacturing processes require precise control and optimization.Features

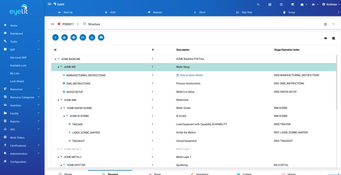

- Traceability: Maintains a history of all activities, including splits, merges, reworks, and batches.

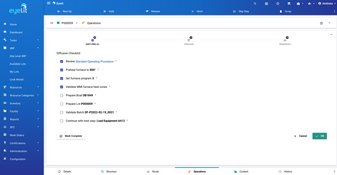

- Automated Decision-Making: Can automatically respond to unwarranted conditions and make unit-specific processing decisions.

- Integrations: Integrates with a variety of services, including XML, message bus, email, FTP, JDBC, and RMI.

- Quality Module: Provides tools for real-time SPC, CAPA management, regulatory compliance, non-conformance tracking, and audit management.

- Interactive Dashboards: Users can create custom views and reports, including Overall Equipment Efficiency (OEE), Mean Time Before Failure (MTBF), and Mean Time To Repair (MTTR), providing critical operational insights.

- Microsoft Power BI Integration: Tracks over 80 key manufacturing KPIs, offering enhanced flexibility and control.

- EquipmentConnect Module: Supports full, semi, and offline automation modes, facilitating machine-to-machine communication and integration with factory equipment and smart devices.

Eyelit Advanced Dispatching Rule Factors

- Global/Work order/batch/lot priorities

- Due dates/FIFO/LIFO/Critical Ratio

- Internal Eyelit/external attributes

- Variables/conditional flows

- Look ahead/batching considerations

- Min/Max batch sizes

- Inhibitions/Dedications

- Queue time/Enforced timers

- Tool recipes

- Custom rules/calculations

Product Overview

Developer Overview

Related Products

User Reviews of Eyelit

Write a Revieweasy to work with experts who have been around the block

Easy to work with experts who have been around the block and know all the issues that commonly affect a production floor

Pros

Hidden gem. Eyelit provided a quick implementation that has been running for almost 20 years in our factory. They have continued to evolve new modules with every release that help us drive value and eliminate costly processing errors. Highly recommend

Cons

Not having this at our previous company

System is down more than it runs

At first it seemed like it would be helpful, but as time mhas gone on, we really regret making this purchase.

Pros

Easy to install, but rarely works.

Cons

System is down more than it runs. We spend more time trying to get the system working then we do working on running the equipment.

- Diversified Consumer Services

- 251-1K employees

- Annual revenue $50M-$100M

Eyelit is a clear stand out product in our search

Eyelit is a clear stand out product in our search because of their knowledge and familiarity with semiconductor/MEM’s fabrication. They have a clear presence and penetration into our specific market. Coupled with their feature set, affordable cost, and customizability they have gone to the top of our list.

Eyelit came highly recommended to WD Lab Grown Diamonds

We selected and implemented Eyelit’s software for its ability to handle both semiconductor and industrial type manufacturing, as well as the flexible subscription licensing model. Eyelit came highly recommended to WD Lab Grown Diamonds; its software provides extensive capabilities to sustain our company’s rapid growth and meets our evolving needs.

Eyelit’s systems integration experience and flexible applications

Eyelit’s systems integration experience and flexible applications have helped us implement a platform for manufacturing efficiency and continual improvements. Great teamwork throughout the project, despite the pandemic, was a key factor for this deployment’s success.