Product Overview

HYDRA X, previously known as HYDRA MES, is an advanced Manufacturing Execution System (MES) designed by MPDV that goes beyond the traditional scope of MES by integrating support processes such as intralogistics and operator guidance in complex assembly processes. It’s made to continuously monitor, control, and optimize production, allowing for more efficient utilization of company resources.

The HYDRA X platform has been developed to integrate with leading ERP systems, including SAP, Microsoft, and Oracle.

Pros

- Gathers real-time shop floor data

- Great customer support

- Logical, intuitive UI

- Seamless integrations with backend ERPs

- Scalable for growing and enterprise-level corporations

Cons

- High initial cost

- Limited one-piece flow support

- Confusing UI for some users

Target Market

Mid-sized manufacturers to large enterprises in the electronics, automotive, food and beverage, and medical devices industries.Hydra X, developed by MPDV, is an MES software that integrates support processes such as intralogistics and operator guidance in complex assembly processes. It monitors, controls, and optimizes production processes, ideal for discrete manufacturing environments.

Features

-

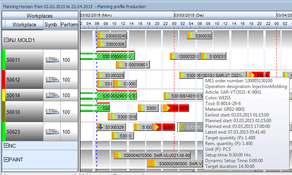

Production Tracking & Shop Floor Data: Monitors real-time production progress and machine status, ensuring transparency, minimizing downtime, and providing visibility into shop floor activities.

-

Quality Management & Production Inspection: Detects quality issues early through digitized inspections, enabling real-time adjustments to ensure compliance and reduce waste.

-

ERP Integrations: Seamlessly connects with ERP systems (e.g., SAP) to streamline data flow across the business, enhancing operational efficiency and collaboration.

-

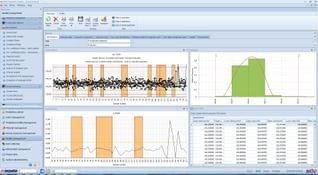

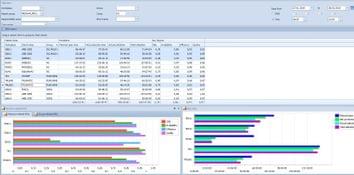

Advanced Reporting & Analytics: Provides customizable reports and dashboards with real-time analytics, enabling smarter decision-making based on production efficiency, costs, and other key metrics.

-

IoT Connectivity & Machine Data: Collects data from connected devices and machines to monitor performance, predict maintenance needs, and improve uptime through connected systems.

-

Automation Capabilities: Reduces manual tasks by automating routine processes, improving speed, accuracy, and consistency in operations.

-

Resource & Energy Management: Optimizes energy consumption and manages tools, materials, and resources to ensure efficient production and minimize costs.

-

Personnel & Time Management: Manages employee scheduling, time tracking, and attendance, aligning labor resources with production requirements for efficient workforce management.

-

Tracking & Tracing: Provides end-to-end traceability for materials and products, improving visibility across the entire supply chain.

Hydra X AI Features

Hydra X integrates AI into its platform through its AI Suite to enhances production efficiency and quality control. Key AI features include:

-

AI Planning & Workforce Allocation: Optimizes production schedules and allocates personnel based on availability and skills.

-

Predictive Quality & Scrap Analysis: Identifies potential quality issues and scrap causes to reduce waste and improve product consistency.

-

Capacity & Resource Optimization: Analyzes machine utilization and resource performance to maximize operational efficiency.

Video Overview

Product Overview

Developer Overview

Related Products

User Reviews of Hydra X

Write a Review- Hotels, Restaurants & Leisure

- 10K-50K employees

- Annual revenue $1B-$10B

They are one of our top contenders from a field of 13

They are one of our top contenders from a field of 13

Pros

Most notably is they requested to come on site to review our systems and processes to evaluate our facility prior to conducting the demo, Conversations continued to focus on the routing process and not disrupt what we were already doing. Can pull information from SAP without having to re-write the whole system.

Cons

Mixed feedback from our team on modular structure, but seems like it will fit our needs. Can get overwhelming with how many building blocks and modules they have as part of their system.

- Industrial Conglomerates

- 51-250 employees

- Annual revenue $10M-$50M

Seems like a powerful software but not user friendly

Seems like a powerful software and could work, it just didn’t seem like it was the most user friendly.

Pros

I thought they had a pretty good solution

Cons

Ended up not being in our top 2, compared to others seemed other solutions would be easier to work with

- Building Materials

- 1K-5K employees

- Annual revenue $500M-$1B

Hydra X Review

Going through capabilities tomorrow but should work in our assembly areas

Pros

Seems right up our alley and can support small and big companies

Cons

No concerns