STRUMIS

4 Reviews 3.5/5 ★ ★ ★ ★ ★An on-premise steel fabrication management software for large steel fabricators that includes estimating, MRP, production control, and estimating tools.

Product Overview

STRUMIS is a steel fabrication management software designed to minimize overheads and costs while maximizing productivity and profitability throughout the steel fabrication process. It integrates with existing business environments, including main steel modeling systems, CNC machinery manufacturers, and accounting systems. The software streamlines and simplifies steel fabrication projects, offering full project traceability and reducing errors.Pros

- Comprehensive features such as parametric assemblies and importing of BOMs from various sources

- Integration with BIM software

- Custom reports

Cons

- Limited budget vs actual cost tracking

- Requires consult call for pricing

- No built-in 2D takeoff tool

Target Market

Mid to large-size steel fabrication companies looking for an MRP and production system that integrates various aspects of their business for enhanced efficiency and traceability.Not Recommended For

Small-scale fabricators or businesses outside of the steel fabrication industry due to its specialized nature and possibly the scale of investment required.Video Overview

STRUMIS Key Features

- Estimation: Quick creation of quotes and tenders using electronic data and design drawings, with capabilities for detailed cost analysis.

- Purchasing and Supplier Management: Automates purchasing processes, including inventory management and supplier analysis.

- Document Management: Simplifies data entry by importing material lists and drawings, with automatic updates for revisions.

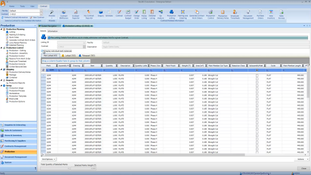

- Contracts Management: Facilitates contract creation and tracking, comparing estimated and actual costs.

- Sales and Customer Management: Enables creation of sales invoices at various production stages, with real-time profitability tracking.

- EDI: Receive purchase orders via EDI from suppliers directly through the system, instantly importing material requirements.

- QS Analysis: Provides detailed breakdowns of project costs and sales values.

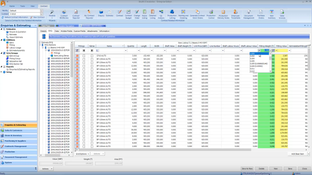

- Inventory Management: Controls material and miscellaneous items, offering comprehensive tracking and reporting features.

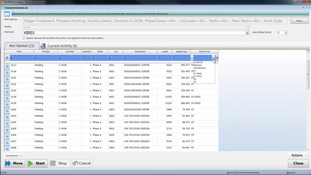

- Production Control: Monitors and progresses individual components and assemblies through bespoke workflow templates, with barcoding and automated feedback for machine formats. It also includes a StruCNC CAM/NC editing suite.

- Barcoding: Offers the STRUMIS mobile scan app that is usable on or offline. Also supports RF and batch barcoding to track production data and inspections.

Integrations

- All 3D detailing systems

- BIM authoring systems

- Established links with major ERP vendors and accounting systems

STRUMIS emphasizes integration, efficiency, and detailed analysis in managing steel fabrication projects.

Product Overview

Developer Overview

Related Products

User Reviews of STRUMIS

Write a ReviewI like the interaction with BIM

Not bad

Pros

I like the interaction with BIM. But when it comes to budget vs actuals is sadly bad. There is no way to check or differentiate between labor hours and machine hours.

Cons

said previously

Strumis' capabilities are endless and the response time to service calls are very short

Our experience has been great, they are always ready to work with us and we’re in regular contact with our account manager.

Pros

Strumis' capabilities are endless and the response time to service calls are very short. Strumis has been one of the core drivers of our growth from a small shop to a 1000 ton plus shop.

Cons

The only cons for Strumis are the same as any great software, and that's the investment required. It's well worth it, and the ROI is obvious, but it's understandable that small shops are hesitant to make the leap to any MRP software.

- Building Materials

The nesting features have been a game changer

It serves us well.

Pros

Strumis is very flexible and handles all of my small bridge, misc. steel, and structural fabrication requirements. One of the features that helps me tremendously are parametric assemblies. Most of my estimating is from a 2D electronic takeoff or from paper drawings, I also like that I'm able to import BOM's from almost every detailer or model something in my license of SDS/2 and simply import it. There are many reports, and I can create custom reports without any 3rd party software. The nesting features have been a game changer.

Cons

I wish it had a built in 2D takeoff tool.

- Building Materials

- 251-1K employees

- Annual revenue $100M-$250M

It makes my work impossible to get done in a timely manner

It makes my work impossible to get done in a timely manner. No simple reports such as, how much material do I have left over in a certain sequence. You have to export to excel and configure it yourself. It’s a waste of time.

Pros

Strumis continually bogs down. If you put everything into this program you will lose days worth of work. Reports are ridiculously complex and you end up making your own reports with their "export to excel" feature.

Cons

see above answer