The Best Metal Fabrication Software

Metal fabrication software helps efficiently design, estimate, and produce metal-based products. We evaluated the top systems and reviewed them below.

- 3D model viewer

- Offers material optimization nesting

- Integration with BIM software

- Lean setup process

- Effective shop floor control

- CAD integration

- Complex BOM support

- Live job-tracking module

- SolidWorks and Autodesk integration

Metal fabrication software is a suite of digital tools designed to aid in the planning, design, and production of metal-based products or structures. Using our advanced review methodology, we’ve evaluated the top metal and steel fabrication software based on value for money, integration options, and supported manufacturing environments.

- STRUMIS: Best for Structural Metal Fabricators

- ProShop ERP: Best for Machine Shops

- Fulcrum Pro: Best for Sheet Metal Fabrication

- RealSTEEL: Best for Production Planning

- Tekla PowerFab: Best for Construction Metal Fabricators

- SecutraFAB: Best Estimating and Quoting System

- ConstruSteel: Best Nesting Tools

- SYSPRO: Best for General Steel Fabricators

STRUMIS - Best for Structural Metal Fabricators

STRUMIS can help streamline business processes from procurement to project completion, but one of its strongest features is its 3D model viewer. This allows companies to view the progress of components and structure assembly, define loads, and assign fabrication and delivery dates. This is crucial for structural fabricators who need to visualize complex structures, like bridges and industrial buildings, and ensure accuracy during assembly.

We also appreciate STRUMIS’s material optimization nesting features. It supports linear, plate, and bevel nesting, and users can retrieve saved requests from the central repository. These tools can help structural fabricators minimize costs as raw material purchasing becomes more accurate, eliminating over/under ordering.

Due to the large feature set, we wouldn’t recommend STRUMIS for small businesses, as the cost and complexity may be too large.

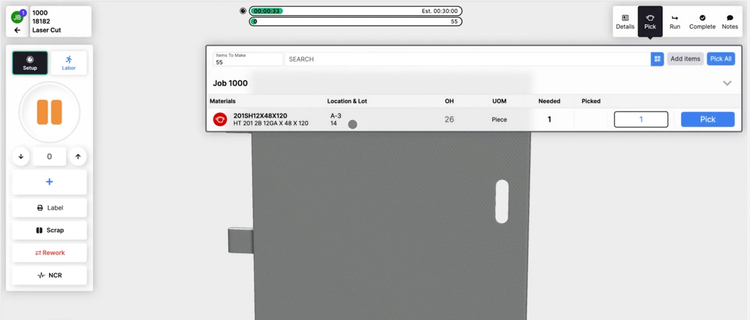

ProShop ERP - Best for Machine Shops

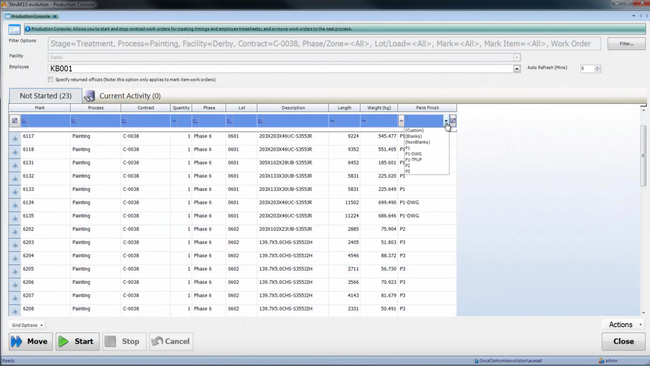

ProShop ERP is best for machine shops involved in metal fabrication due to its lean setup process. It ensures machinists have everything to start production without leaving the machine. ProShop integrates with tools like Mastercam, facilitating the export of tool information and reducing setup friction by adding tool measurements directly from the pre-setter and uploading the resulting offsets to the machine.

ProShop ERP provides tools for everything from shop floor control and visual scheduling to CAD integration and CRM. Its capacity requirements planning and mobile metrics help metal fabricators manage shop floor changes, quality, and machine maintenance schedules.

Fulcrum Pro - Best for Sheet Metal Fabrication

Fulcrum Pro offers strong design-to-production features. Fulcrum integrates with SolidWorks and Autodesk Fusion 360 for straightforward CAD/CAE/CAM design imports and modifications. The system can also handle complex BOMs, which is necessary for sheet metal fabrication, which deals with designs with several materials, components, and customizations.

Fulcrum’s integrations and simplified BOM features pair nicely with its live job-tracking module. We appreciate this tool because it tracks labor, inventory, and machine costs in real time and compares them with estimated costs. It also displays operation progress so everyone can view the status of jobs from any device, helping businesses stay informed on granular and site-wide operation statuses.

Despite its effective features, we wouldn’t recommend Fulcrum Pro for businesses with over 200 employees, as large data inputs can cause the system to experience slow load times and lag.

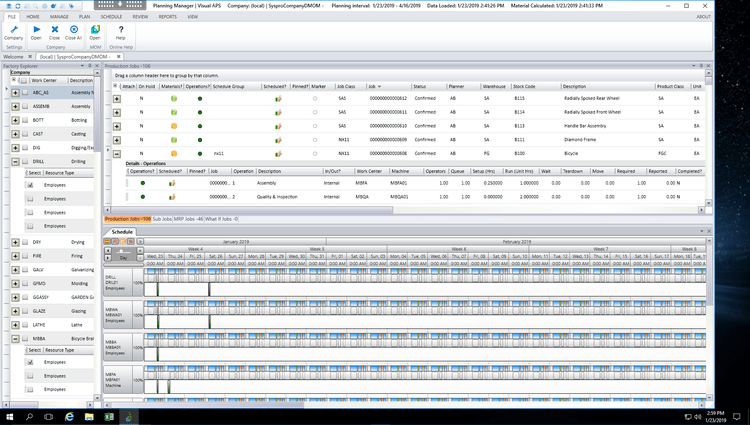

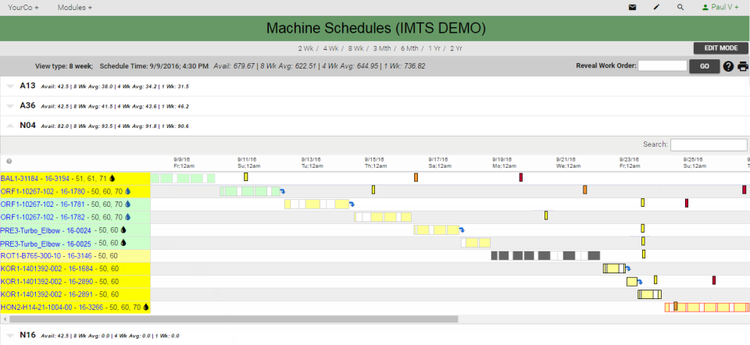

RealSTEEL - Best for Production Planning

RealSTEEL’s production planning and scheduling module is built specifically for the metals industry. The system uses sales demand to easily generate production order NESTs and make plate and sheet burning more efficient. It also helps minimize scrap on cut-to-length materials, boosting your profitability. This means fabrication shops can stay on top of shifting demand while protecting their margins.

Additionally, the production planning tool helps your shop floor team drive efficiency. It features MES workstations that allow workers to report real-time order activity from anywhere, so you’re always up to date on statuses. Plus, you can use the data to identify inefficiencies and adjust schedules to stay flexible.

RealSTEEL is a cloud-based ERP built on the Microsoft Dynamics 365 platform. It combines strong native inventory and finance tools with industry-specific processes like production planning, making it an effective option for mid to large-sized companies. Unfortunately, it does not list its prices publicly, so you must get an individual quote.

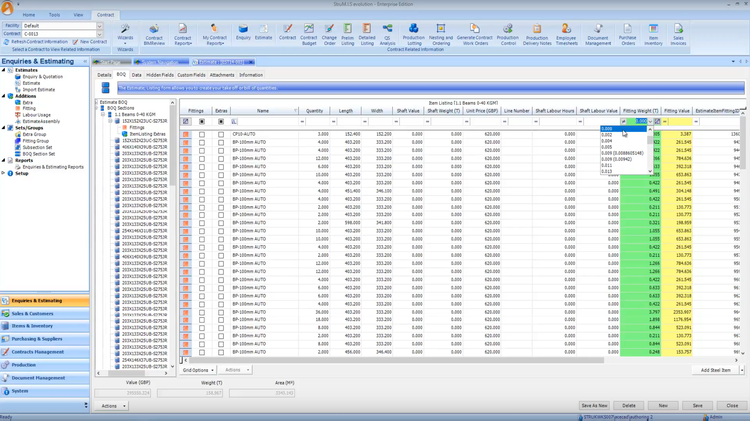

Tekla PowerFab - Best for Construction Metal Fabricators

Tekla PowerFab is a strong option due to its widely used BIM system, Tekla Structures, which integrates directly with PowerFab. The integration creates a truly all-in-one system from design to the finished building. The system also integrates with leading ERP and accounting systems like Viewpoint, QuickBooks, and Sage for financial management capabilities.

We also like Tekla PowerFab because of its production management tools. It offers a model-based estimating module that eliminates manual data entry. Users can access a supplier database through this module for up-to-date pricing and delivery information. This allows for accurate and efficient estimates on complex construction projects, helping the company save money on extra raw materials ordering.

However, one downside to Tekla PowerFab is its high price, making it only viable for large companies.

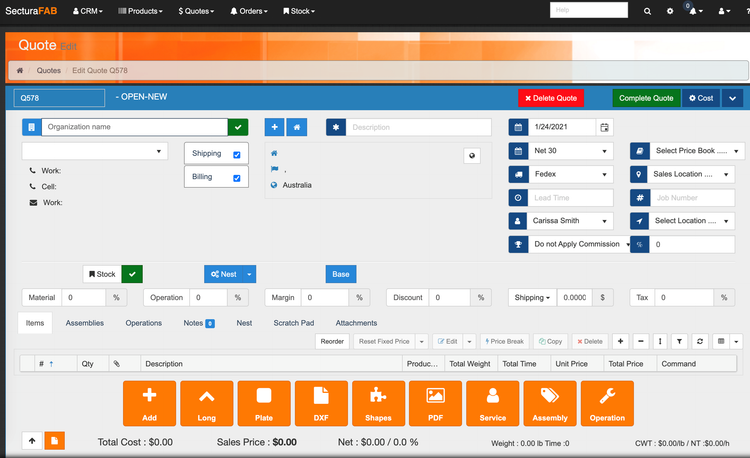

SecutraFAB - Best Estimating and Quoting System

SecturaFAB is ideal for businesses looking for a specialized estimating and quoting system for the metals industry. Its estimating module offers geometry tools, a basic CAD editor, bend recognition, and true-shape nesting algorithms to help better estimate costs. In addition to CAD files, other supported formats include SolidWorks, STEP, Vector PDF, and NC1, allowing flexibility in a business’s design format.

SecturaFAB’s product and price management tools are also effective for metal fabricators. Businesses can use price books to apply specific labor and materials pricing and account for different locations/customers. This ties into its quoting module, including a CRM for managing clients and vendors in one central location.

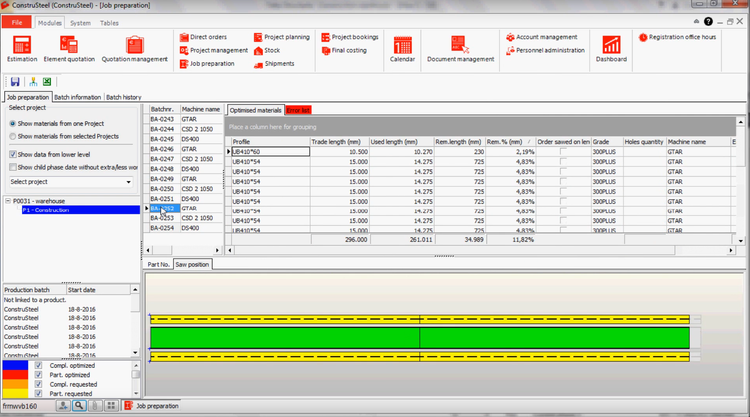

ConstruSteel - Best Nesting Tools

ConstruSteel’s bar nesting tool allows fabricators to save money by reducing material waste. It supports skew and angular bar nesting functionality, automatically rotating parts to minimize the number of cuts. Additionally, it features built-in formulas for calculating clamping width for accuracy. Some supported machines include Voortman, Ficep, and Behringer.

In addition to nesting, we found ConstruSteel’s production management capabilities effective. It offers customizable CAD importing and 3D visualization, helping businesses accept customized job orders and complete them with accuracy. Companies can also view progress overviews to identify slow areas and monitor overall production timelines.

Because ConstruSteel has a smaller user base than other leading systems, companies may have to invest more time in training new employees who haven’t used the system before.

SYSPRO - Best for General Steel Fabricators

SYSPRO offers a deep level of industry-specific functionality that can benefit metal fabrication businesses looking to optimize their manufacturing processes. This includes advanced features for handling complex product structures, CAD integration, and stringent quality control requirements.

SYSPRO delivers detailed scheduling, job costing, and workflow management, essential for metal fabricators needing precise control over their production operations and cost management. Overall, it’s a global ERP solution with a vast network of partners and customers worldwide, presenting an extensive community for users to leverage. However, for advanced reporting, businesses will need to integrate a dedicated report writer.

What is Metal Fabrication Software?

Metal fabrication software is a type of manufacturing software designed to streamline the cutting, shaping, and assembling of metal or steel structures and components. This type of solution helps optimize quotation turnaround times, boosts the quality and speed of delivery, reduces waste, optimizes capacity, and improves throughput for your entire metal fabrication processes.

Metal fabricators expect to produce quality products to exact specifications, synchronize production schedules with customer expectations, and deliver products promptly. This is all accomplished via key features offered by metal fabrication systems. These functionalities include quoting and estimating, bill of materials (BOM), and production scheduling.

Most importantly, steel fabrication software will help your business compete effectively in the metal fabrication industry through a layer of consistency throughout your manufacturing processes. A fully integrated metal fabrication ERP software will help you plan, execute, control, streamline, and expand your business by creating a blueprint for your employees during the manufacturing process. This blueprint is a project management tool that helps improve turnaround times, reduce loss, speed up delivery, and lower production costs.

Whether your manufacturing business is engineer-to-order, make-to-order, or a mixed-mode environment, metal fabrication software will help your job shop reach its optimal potential.

Key Features

- Quoting and Estimating: Calculate material, overhead, labor, and other fees to create accurate quotes for interested buyers.

- Bill of Materials: Specify the raw materials, parts, and sub-assemblies needed to manufacture each specific product.

- Sales Order Processing: Capture, track, and fulfill orders across multiple sales channels via connections with inventory and shipping schedules.

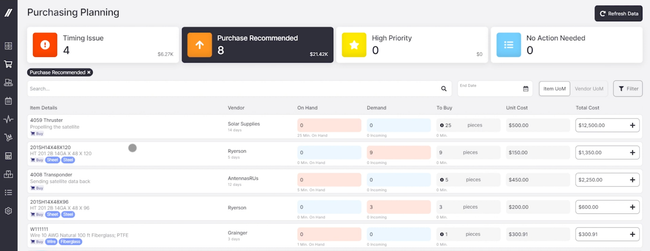

- MRP: Plan and calculate material requirements, coordinate personnel and machine workloads, and optimally plan purchasing to meet customer demands.

- Production Scheduling: Plan production on your shop floor by determining the need for materials and capacity in order to complete a manufacturing production order.

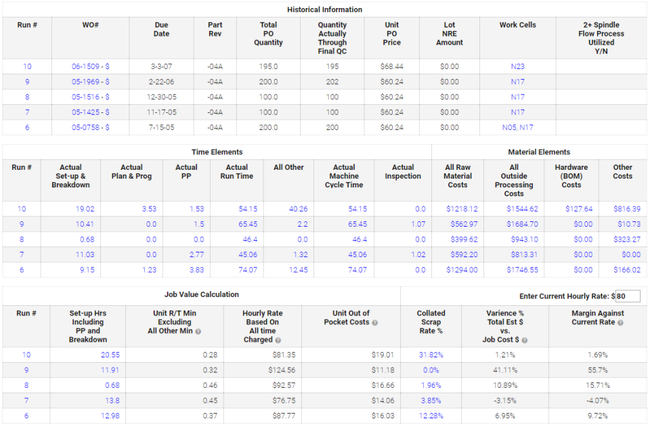

- Job Costing: Facilitate the assignment of costs to individual cost categories to improve cost control and job profitability.

- Product Lifecycle Management: Manage the entire lifecycle of a product from conception through design and manufacture and finally disposal.

- Quality Management: Analyze risks, set quality objectives, and implement workflows to achieve standards.

- Shipping: Transport your manufactured goods from one place to another.

- Accounting: Handle inventory valuation and the cost of goods sold.

Primary Benefits

The top benefits of using metal fabrication software include:

Improved Inventory Management

Inventory control capabilities within your metal fabrication software can track your raw materials in several ways:

- Stock: The most popular type of inventory tracking found within manufacturing software. Shows how much current stock you have at any one time. Raw materials are received and issued on a perpetual basis.

- Lot Tracking: Create a batch of products into a distinct or uniform group identified by a shared identification number. Lots are typically created to represent quantities, production variations, or common expiration dates. This is useful for tracking different aluminum sheets and coils, structural channels, angles, and other types of plates or tubings used at different cuts and weights.

- Made-To-Order: Purchase needed parts and materials as needed. Once a sales order is received and a job created, you can order the parts, begin the job upon their arrival, and move on. This limits the number of raw materials stocked in your inventory sitting idle. This is commonly found in a custom environment requiring unique steel, aluminum, and other items not usually kept in stock.

Streamlined Production Planning

Steel fabrication management software can help improve your production planning process, leading to faster turnaround times and, ultimately, more orders produced. This is a quick way to improve your ROI on the software investment while also keeping customers happy and returning for repeat business.

A powerful metal fabrication management software will optimize part routing on the type of cut needed, automate repetitive tasks (such as work orders) that reduce cost/time/errors, and create and edit DSTV files. A metal fabrication system can also help your business implement a lean manufacturing process that can minimize waste without sacrificing productivity.

Real-time piece tracking will ensure you know what items at what quantity are currently involved in the production process, are still stuck in the planning stage, or if the items have even arrived at your facility yet. Finally, most systems will be able to integrate with any CNC machines needed for the design process that may be needed during production planning.

Improve Your Metal Fabrication Design Software Process

A particular type of metal fabrication software, called metal fabrication design software, can be used during the planning stages. These options can create 2D drawings and diagrams, handle computer-aided designs (CAD), and provide an electronic method for making and modifying parts. These solutions help with structural steel erection, fabrication, and light gauge steel bending and forming.

Another benefit of incorporating design software into your fabrication process is to help you calculate bends and draft very specific sheet metal features. Good drafting with an integrated bill of materials can help you reshape your metal fabrication manufacturing process through high-quality graphics to catch errors and issues before they occur.

This type of software can sync to your MRP or customer database. You can then import the files that make up the component of the weld or fabrication job. You can assign properties such as material grain, thickness, and quantities. A built-in nesting option can calculate nesting weight. Finally, a PDF quote can be printed or emailed directly to a customer, fully tying the design process into the management side of things.

Pricing Guide

The starting cost of metal fabrication software ranges from $49-$200/month/user. A subscription-based pricing model is commonly found in web or cloud-based software options. These solutions usually have lower setup/implementation fees in exchange for an ongoing monthly or annual subscription rate.

The cost of purchasing a metal fabrication manufacturing software outright will range between $10,000 to $100,000 depending on the size of your operation, the number of users needed, and the amount of any services needed, such as implementation and training. Usually, the software provider offers ongoing costs for annual updates or support.

Primary Users

Several professionals use metal fabrication software throughout an organization. The primary users include:

- Designers: Engineers and design teams use CAD integrations to create parts, assemblies, and models.

- Shop Floor Staff: These can include the actual welders and fabricators, machine operators, and production managers. They access blueprints and complete orders to cut, weld, and form the metal into the final product.

- Estimators and Sales Teams: They use the software to generate quotes and job estimates based on material and labor costs and total production time. They can also track orders and project timelines to ensure client satisfaction.

What Does My Business Need?

Getting the best metal fabrication software for your business will depend largely on the size of your organization and the software budget you’re willing to invest in. To determine what level of software you need, you can look at what we recommend based on how large your manufacturing operation is:

Small Manufacturing Businesses

Small businesses have a smaller staff, meaning more people must take on multiple job roles to ensure their metal fabrication services can be uninterrupted. One person in the company may be well-versed in welding processes and metals while having a good sense of incoming sales orders or inventory shortages.

When it comes to software preferences, a small business owner will care about becoming more automated at an affordable price. This will allow them to produce a quality product at a fair price and get better control of their shop. These businesses should focus on a metal fabrication solution that can communicate with the shop floor and track time spent on different tasks.

This shop floor control and routing type will be comprehensive enough to show you how productive your operation is and where you can improve. It will also allow your managers to identify bottlenecks and deal with issues before they become problems. Machines can also be used more efficiently, as proper routing means a machine’s downtime is minimal.

Mid-Sized Fabricators

Smaller businesses can usually get by using an off-the-shelf accounting program such as QuickBooks Online in combination with a production tracking and inventory management tool. A mid-sized business should focus more on integrating all business functions under one option.

Once a manufacturing business grows, it may become a specialized shop. Since branching out to different customers and industries is a great way to grow your business, many small businesses take this path once they feel ready. Once your business has been around for a bit, you may have a diverse client base or serve a variety of industries.

Mid-sized manufacturers still need to care about building relationships with their clients. Routine contact management can help ensure uninterrupted payables and receivables schedules. Many mid-sized metal fabrication systems can help determine which customers are paying, how quickly they’re paying, and where your overall cash flow will come from. If payments begin to be held back, it can lead to delays in paying vendors for needed parts and disrupt the flow of your business.

Once a business has integrated its accounting and financial processes into its metal fabrication software, you’re left with a complete solution that is easier to audit, manage your employees, and maintain accurate records.

Large and Enterprise-Level Metal Fabrication Businesses

A large fabrication shop will have very complex needs. They may use unique methods such as additive manufacturing or require integrated CAD tools to create 3D models for custom jobs. They may also use the latest technologies, such as 3D printing, smart tagging, or automated equipment maintenance.

Fabrication shop software for enterprise-level businesses will need to be fully integrated ERP systems ready to accommodate any changes that may come in. This includes a change in due dates and quantities of items received, which can happen when dealing with a larger volume of goods each week.

Larger businesses should look for a solution to review many orders and help you quote more accurately. All detailed routing information and available materials can help determine if a job is appropriate for your business or what is needed to accomplish the job in a decent turnaround time. Order entry capabilities can then handle all release schedules, split deliveries, and complex assemblies.