Epicor Advanced MES

An MES designed to enhance manufacturing operations by providing real-time visibility and control over production processes.

Product Overview

Epicor Advanced MES is a manufacturing execution system designed for a range of industries, including aerospace, electronics, and medical devices. It provides real-time data visualization and analysis through reports and dashboards, which are crucial for monitoring performance and making informed decisions. The software also focuses on quality management, production definition, and monitoring, ensuring efficient production processes and quality control.

Epicor Advanced MES focuseson statistical process control (SPC) and statistical quality control (SQC) so businesses can maintain high-quality standards and customer satisfaction. Additionally, its energy monitoring and digital twin applications offer modern tools for sustainability and data visualization.

Pros

- Automatic part qualification and rejection

- Flexible deployment options

- Over 1,000 out-of-the-box analysis choices

- Real-time production metrics and analytics

Cons

- Limited mobile usability

- Integration process can be complex

- Pricing details not provided by the developer

Target Market

Businesses in industries like aerospace, electronics, and medical devices that require real-time monitoring and quality management in their manufacturing processes.Not Recommended For

Small operations that need a more basic system, or process manufacturers that require batch or recipe tracking.Video Overview

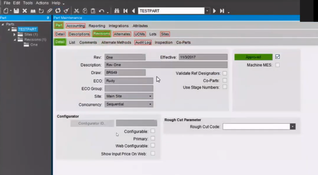

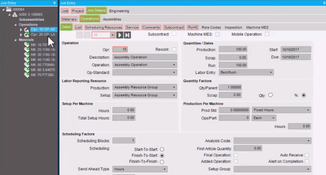

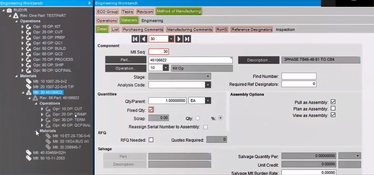

Features

- Real-Time Data Capture: Automatically collects data from machines and sensors on the shop floor. This allows manufacturers to monitor equipment performance and identify inefficiencies.

- Production Monitoring: Includes capabilities for monitoring Overall Equipment Effectiveness (OEE), run rates, scrap rates, yield, and energy consumption.

- Quality Management: Supports quality management through features like Statistical Process Control and Statistical Quality Control.

- Deployment Options: Offers flexible deployment options, including cloud and on-premise installations.

- Security and Support: Incorporates role-based access controls, data encryption, and compliance with standards such as SOC 2 to ensure data security.

Supported Industries

Epicor Advanced MES is best suited for discrete manufacturers in the following industries:

- Industrial Machinery

- Medical Device

- Plastics

- Metal Service Centers

- Aerospace & Defense

- Construction & Engineering

- Electronics & High Tech

- Furniture

Benefits of Epicor Advanced MES

- Eliminate manual data collection with real-time, automatic data directly from machines and operators

- Boost efficiency with clear manufacturing facts and real-time information

- Improve overall equipment effectiveness (OEE), cycle time, plant productivity, scheduling, and machine downtime

- Pinpoint critical issues to reduce waste and improve quality and customer service

- Examine tradeoffs between using existing equipment and capital investments

- Role-based displays and dashboards for operations, plant, and management

- Over 1,000 analysis choices available out-of-the-box

- One-click drill-down visual root-cause analysis

- Automated production monitoring for downtime and runtime, every cycle and every machine, 24x7

- Automated monitoring for process parameters

- Consistent, automated, OEE and other efficiency metrics

- Visual drag-and-drop, real-time scheduling and planning for machines and tools

- Automatic part qualification/rejection

- Part and machine process data for traceability purposes

- Statistical quality control (SQC) and statistical process control (SPC)

- Machine and tool preventive maintenance (PM)

Product Overview

Developer Overview

Related Products

User Reviews of Epicor Advanced MES

No reviews have been submitted. Do you use Epicor Advanced MES? Have you considered it as part of your software evaluation process? Share your perspective by writing a review, and help other organizations like yours make smarter, more informed software selection decisions!