Sepasoft MES

4 Reviews 5/5 ★ ★ ★ ★ ★An MES to provide real-time control, traceability, and documentation of raw materials into finished goods.

Product Overview

Sepasoft is a leading provider of MES (Manufacturing Execution System) software that is designed to help manufacturing companies improve their production processes. Its key features include real-time tracking and documentation of raw materials transformation, statistical process control for quality data analysis, and document management capabilities. These features are particularly beneficial in controlling, tracking, and optimizing production processes. The company’s software is highly regarded for its advanced features, reliability, and ease of use.Pros

- Adheres to ISA-95 and ISA-88

- Connected production data

- Low code/no code offerings

- Easy licensing model

Cons

- Software complexity means deployment can be difficult

- Training recommended to fully utilize

Target Market

Industries that require robust tracking and management of manufacturing processes, such as food and beverage, automotive, building materials, aviation and aerospace, packaging, and pharmaceuticals.Sepasoft MES Software Features

- Real-time monitoring of production processes

- Native integration with Inductive Automation® Ignition® SCADA software

- Comprehensive data collection and analysis capabilities

- Advanced quality control and traceability features

- Customizable dashboards and reporting tools

- Support for machine, site, and enterprise

- Easy-to-use interface and flexible configuration options

Sepasoft Modules

- OEE Downtime: Reduce operating costs and boost profitability by collecting downtime info.

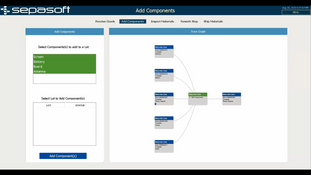

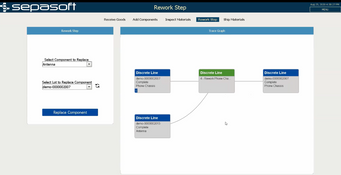

- Batch Procedure: Based on the ISA-88 Standard, see real time batch statuses, edit graphical recipes, and compare golden batches.

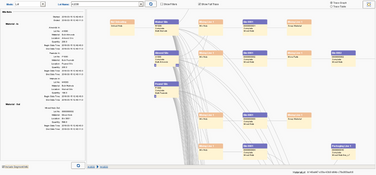

- Track and Trace: Automate your product tracking from raw materials to finished items.

- SPC Module: Accuratly collect SPC data. Includes automatic sample scheduling and control charts.

- Settings and Changeover: Build, manage, and monitor machine settings for things like recipes, changelogs, and variance.

- Document Management: Manage and keep track of SOP, MSDS, and quality documents in one location.

- Web Services: Communicate with and send data to remote and local web services.

- Business Connector: Integrate enterprise systems and the plant floor.

- Interface for SAP ERP: Adds native connectivity between Ignition and SAP with an SAP interface.

Pricing

Sepasoft charges a license fee per server for its MES modules. Individual module prices start at $2,750 and reach $31,500. These include:

MES Module Pricing

US Retail starting prices:

- OEE: $22,000

- Batch Procedure Module: $31,500

- Track & Trace Module: $22,000

- SPC Module: $8,800

- Settings & Changeover Module: $8,800

- Document Management Module: $2,750

Business Connector Suite:

- Sepasoft Business Connector Module: $5,250

- Interface for SAP ERP Module: $15,750

- Web Services Module: $5,000

- MES Enterprise Central Server: $13,750

Product Overview

Developer Overview

Related Products

User Reviews of Sepasoft MES

Write a ReviewIncreased Efficiences

We’ve implemented a solution that captures information across all five layers of the automation stack. Using the Ignition platform and Sepasoft modules, we’ve created a data-centric process that will help AriZona Beverages increase efficiencies and identify areas for improvement.

With our new system, we can perform detailed scheduling within the MES and transfer all required processing order information into SAP without manual intervention. This integration has been a significant step forward. Additionally, we receive real-time updates on production counts and inventory, enhancing our detailed scheduling capabilities.

- Utilities

- 1K-5K employees

- Annual revenue $250M-$500M

Real time OEE

We explored several different companies that had software that could produce real-time OEE and based on the ability for the software to provide quick development, to give us the information we needed in real-time, and based on the cost of implementation, the choice was obvious, we needed to go with Inductive Automation and Sepasoft.

- Semiconductors & Semiconductor Equipment

- 1K-5K employees

- Annual revenue $500M-$1B

Flexible Product

We picked Ignition and Sepasoft because of their flexibility and their ability to quickly connect to machines and to get us the real-time data very quickly to be able to throw up dashboards and all these things very rapidly.

Helped Reduce Scrap and Downtime

Since implementing Sepasoft’s products, we’ve been able to reduce downtime across all of our automation equipment and manual lines, drastically reduce scrap across the organization, prevent unnecessary overtime, and better quarantine our non-conforming products.