Ignition by Inductive Automation

1 Review 5/5 ★ ★ ★ ★ ★A cloud-based or on-premise industrial automation software that connects all devices, including SCADA, IIoT, MES, and HMI.

Product Overview

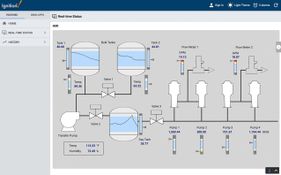

Ignition is a software module designed for industrial automation. It primarily stands out for its ability to create scalable, web-based applications for monitoring and controlling industrial processes. Its responsive design ensures compatibility with various devices, including smartphones and tablets, enhancing accessibility and ease of use.

Ignition provides fully integrated modules for SCADA, IIoT, MES, and more. All modules are hot-pluggable so they can be installed, removed, and upgraded without impacting your operations. The system is offered for both cloud-based and on-premise installation.

Pros

- One-time fee for the main platform

- Applications are scalable

- Easy to configure and implement

Cons

- Extra modules increase the cost

- Customer support is not 24/7

Target Market

Industrial organizations seeking to modernize their control systems with web-based solutions, especially if they need remote access and multi-platform support.Video Overview

Ignition Features

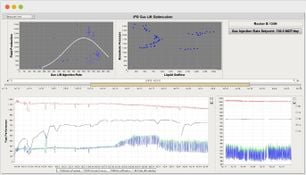

- SCADA: Easily control, track, display, and analyze processes.

- IIoT: Make data more accessible and efficient with MQTT.

- MES: Track production, manage recipes, calculate OEE, and more.

- HMI: Build optimized screens to monitor and control machinery.

- Alarming: Build complex alarming systems with ease and get notifications instantly.

- Reporting: Easily create and deliver dynamic, database-driven industrial reports.

- Edge Computing: Capture and visualize critical data at the remote edge of the network.

- Enterprise: Empower your teams with better data to make smarter decisions.

- Mobile: Build mobile-responsive industrial applications using HTML5.

- Fully Integrated Modules: Core modules such as perspective, vision, SQL bridge, and reporting are all integrated within the system.

Ignition Pricing

The cost of the base Ignition platform costs $1,100/one-time, with the lowest possible cost for a package being $3,018. Ignition is a-la-carte and allows customers to build their own package, customize an existing package, or get personalized recommendations based on their needs.

Visualization

- Perspective Unlimited: $11,225

- Reporting module: $3,900

Data and Logic

- SQL bridge module: $2,245

- Tag historian module: $2,365

- Sequential function charts (SFC) module: $3,760

- Web development module: $1,890

Alarm and Notification:

- Alarm notification module: $2,245

- Voice notification module: $945

- SMS notification module: $945

- Twilio notification module: $590

Enterprise Administration

- Deploy, commission, and monitor systems: $1595

Product Overview

Developer Overview

Related Products

User Reviews of Ignition by Inductive Automation

Write a ReviewIt’s so easy to build stuff

We find that we can overload our users with new features. It’s so easy to build stuff. We’re way ahead of the user-curve. We have found that we have to wait for them to digest what we’ve built, and then wait for them to start asking for more.

Now, all of a sudden the data is all there. It’s the keys to the kingdom. We’ve now been able to manage some pretty heavy workflow problems.

We approached the software with skepticism. There was no support among our automation engineers for using it as a control system for both philosophical and practical reasons: Philosophically, because we treat our control system as a stand-alone system–completely unconnected from any other network–and practically, because our corporate Windows-based PC network had such a rotten reliability record.

Fermentation is a 24/7 process, so our plant controls staff were in no mood to introduce Windows-style downtime to their lives. The Inductive Automation software was so inexpensive, however, that we decided to try it for data acquisition and production reporting–two areas where there were no good alternatives on the market.

It was easy to configure. The reason it’s easy is because I only had to install it on the server–one install. It took me no time, except installing it on the server. Its easiness comes from the client-side because there are no clients to install individually. There’s not a lot of overhead work to get it out to everyone in the plant.

Most of it seemed intuitive. All these functions are well documented. Python is clean and concise; which makes Jython really familiar. Jython is super easy to learn because it was familiar to what we learn in school.

But I think everyone agrees that the changes are good. We’re a growing company. Five to ten years ago when we had to make a production decision, we would simply walk over and talk to someone… but now, you can’t always find that person. Using Inductive Automation’s software, we can always find the screen. Operation is much easier than before.