MicroMain CMMS

MicroMain is a solid choice for manufacturing firms aiming to digitize their assets and streamline maintenance procedures. Its task management capabilities concerning maintenance requests are notable. The software’s multi-site functionality ensures facility coverage for businesses of all sizes.

However, MicroMain falls short for those needing numerous custom integrations for smart devices. Currently, meters require manual input, which may be a drawback for some users.

- Comprehensive features (spare parts, OEE, depreciation, reporting)

- Unlimited sites, priced per user

- Tailored for manufacturing

- Mobile app (barcode scanning, labor rate tracking, offline use)

- Offers labor scheduling and planning to optimize resource allocation

- Custom integrations for smart devices may be costly

- External users require paid login for work orders

- Mostly focused on manufacturing, potentially limiting versatility

- Developer MicroMain Corporation

- Client OS Web

- Deployment Cloud Hosted

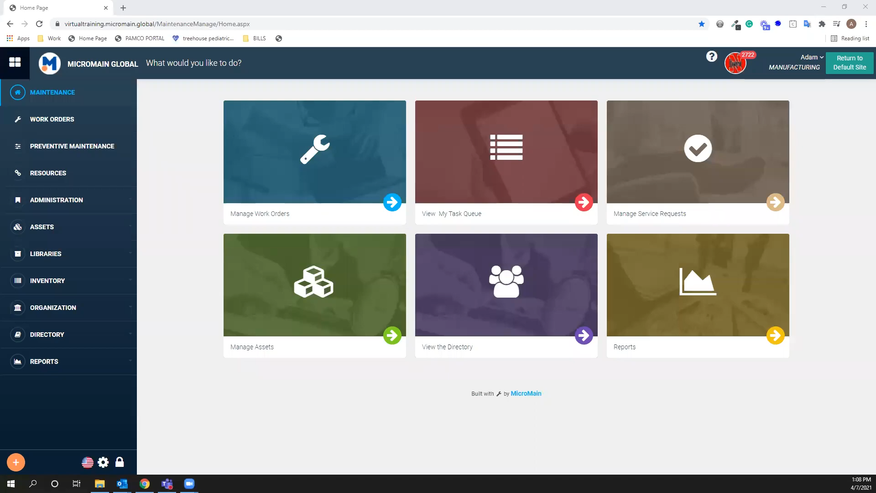

What is MicroMain?

MicroMain is a CMMS software that is designed for manufacturing, facility, and fleet maintenance. The software helps businesses digitize assets and maintain a history log of maintenance activities, which can be used to make data-driven decisions. With 30 years of experience and over 10,000 clients, MicroMain is a trusted maintenance and asset management solution.

Who Is It For?

MicroMain CMMS software is designed for tough, knuckle-busting, and under-pressure workers who require good technology to efficiently manage facilities and production floors.

Maintenance workers who do not have all day to learn how to properly become an expert on a software are the primary demographic the developers had in mind when creating MicroMain. The worker receives a task to create a work order and can add additional tasks, assign them to a different department, and create custom reports and dashboards.

MicroMain is primarily used by manufacturers but can also be used for fleet and facility maintenance.

Our Ratings

| Usability - 10 | User-friendly interface; easy to use for frontline employees; easy to navigate and perform tasks |

| Support - 9 | Support channels include phone, email, FAQs, and tutorials; support is generally responsive, with occasional long waits during peak hours. The software only directs to the help center, you have to go to the main website for contact information. |

| Scalability - 10 | Accommodates businesses of different sizes and industries; allows for multiple locations; manufacturing is their biggest priority which may limit versatility for companies in other sectors |

| Security - 9.3 | ASP.NET technology; secure data storage and transmission; supports single sign-on (SSO); the mobile app allows for offline use; API in development for meter interfacing |

| Value - 8 | A comprehensive set of features at a competitive price; getting smart devices and meters integrated may require future custom integrations, which could be costly. |

| Performance - 10 | The main dashboard easily lets you get started on work orders or managing assets; buttons are responsive, and the next screens load quickly. |

| Key Features - 8.5 | I was able to easily create a new asset and a work order associated with it; reports are easy to view; last generated reports let you quickly repeat tasks; analytics is a more in-depth part of reports that have to take you to a new screen |

Customization and Flexibility

We appreciated the ability to tailor field naming conventions to match our specific needs when using the software. Part of this customization includes the ability to upload documents and images alongside each piece of equipment or device–making this program more visual and less like you are staring at spreadsheets all day.

The customization offers can let businesses adapt to their own unique processes and requirements–making the management of assets, work orders, and maintenance tasks more efficient and streamlined.

Preventive Maintenance

One feature that really stands out in MicroMain is its preventive maintenance (PM) module. Create schedules based on meter readings, units produced, or by time. When triggered, the system automatically assigns a work order to the asset, ensuring timely maintenance. It’s a great way for manufacturers to avoid costly machine breakdowns and catch potential issues before they get worse.

Customer Support

We found the customer support offered by MicroMain to be exceptional. Most of the resources provided by the company (such as the FAQs and tutorials) allowed for many moments to self-teach various parts of the software. If that isn’t your style, phone and email support are available.

Pricing Plans

| Plan | Pricing | Features |

| Custom | $99/user/month | All plans are customized based on your needs. No features are hidden behind higher pricing tiers. MicroMain offers a free trial to help you determine what features you'll need most and how many users it may require you to get by, which will have the biggest impact on overall cost. |

Alternatives

Summary

MicroMain is a CMMS software primarily designed for manufacturing companies looking to digitize assets and streamline maintenance processes. It allows for efficient task management and includes a free requesting module for all employees to submit work order requests.

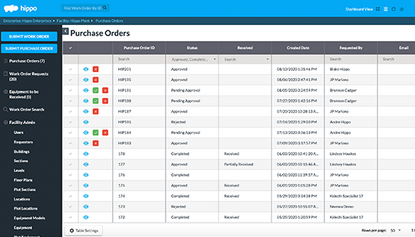

The software is user-friendly and comprehensive, with spare parts, OEE, depreciation, and reporting features. However, it may not be suitable for companies needing integrated purchase order functionality or a large number of custom integrations for smart devices. The software is priced per user, and custom plans are available based on specific needs, with a free trial offered.

User Reviews of MicroMain

Write a Review- Automotive

- 51-250 employees

- Annual revenue $10M-$50M

I was hoping for more customization across the report generator

The system is a great overall CMMS but there are a few areas it fell short for our specific company needs. First, we found the reporting lacking. It is great the way the system allows you to set filters to only pull specific data but you have to use the system’s canned reports. I was hoping for more customization across the report generator. It is also limited in it’s ability across travelers. It allows you to collect data, like pictures, while in the field but you cannot email the while using a tablet. It however functions well for work order requests, generation, PM scheudles, and parts inventory.

Very Customizable

Micromain just seemed to kind of fit what we were doing, and it was very customizable. One of our plants right now is working with them to get everything set up and try, and cookie cut the whole thing to each site and customize it. It just seems like it worked pretty well - a lot of the people liked when they set up the preliminary thing to look over the program.

Facility maintenance costs decreased by 52%

Facility maintenance costs decreased by 52%. Overtime is down by 48%, and more work is getting done with 42% less manpower. Overall our emergency responses have decreased greatly. This is a direct result of an increased focus on corrective and preventive maintenance work.

We lacked a lot of the information necessary to make informed decisions. Now we input the data, develop reports and track our trends so that we can make better decisions.

When we began looking at CMMS vendors, we saw that many of the systems available were very expensive. With MicroMain, we are getting everything that the competition offers and more, for a fraction of the cost.

If an industrial manufacturer wants to improve its maintenance function, MicroMain’s CMMS is a great tool to help evaluate current practice and chart a scheduled course for improvement. Mammoth’s maintenance department wouldn’t be where it is today without MicroMain’s software. The investment was reasonable and payback has been unbelievable.

MicroMain Maintenance gets us exactly what we want

When we decided to update our CMMS with barcode capability, we found out that it was going to cost us practically as much to upgrade as to purchase the MicroMain system. Our old CMMS was not flexible and it didn’t give us a lot of what we needed. It was also virtually impossible to get the reports we required.

With MicroMain Maintenance we’re getting exactly what we want, quicker and much easier compared to our old system. I needed the ability to show administration and our CFO what we are actually doing, including our productivity. Now with reports from MicroMain Maintenance, I can show work accomplished including inspections, which is especially important for health care facilities.