MISys Manufacturing

3 Reviews 3.5/5 ★ ★ ★ ★ ★A manufacturing software with MRP, inventory, purchasing, forecasting, scheduling and more.

Product Overview

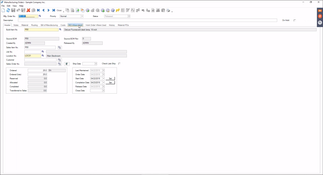

MISys Manufacturing software is a versatile solution designed for businesses in the manufacturing industry. Key features include quote management, forecasting, resource management, and supply chain management to streamline manufacturing processes. It offers advanced functionality in various modules, including advanced purchasing, labor tracking, custom reporting, material requirements planning, shop floor control, bin tracking, labor tracking, and advanced production. It’s available as a cloud-based and on-premise system.Pros

- Flexible deployment options

- Offers QuickBooks integration

- Supports a wide variety of manufacturing types

Cons

- Exact pricing not provided by the developer

- Steep learning curve for new users

Target Market

Small to mid-sized manufacturing companies, especially those operating in sectors like electronics, computer equipment, food and beverage, aerospace/defense, auto parts, chemicals, health and beauty, industrial machinery, medical device, transportation, plastics, and pharmaceutical industries.Key Features

Bill of Materials

MISys Manufacturing features extensive bills of material capabilities for documenting assembly processes. These can handle sub-assemblies of any size and delve up to 16 levels deep. The BOM features in MISys are integral to managing complex stock transfers, complete with back-flushing.

For instance, when the production of 1,000 items is initiated in MISys, the system automatically manages materials, sub-assemblies, and finished goods throughout the structure. This includes instant updates to inventory counts for accurate tracking. Throughout all BOM levels, costs are adjusted with roll-up to ensure proper costing for finished goods.

Inventory Control

This software controls inventory, efficiently managing raw materials and work-in-process (WIP) across countless locations. The system’s item master stores detailed information for each raw material and sub-assembly, covering aspects like detailed costing and stock status. It allows for cross-referencing an unlimited number of qualified suppliers for each item, including optional approved manufacturers.

MISys accommodates batch and direct stock transfer transactions, enabling raw material inventory management that aligns with existing business methods and procedures. The stock check feature allows for what-if simulations of stock transfers and the analysis of potential material shortages. The inventory is promptly adjusted after a stock transaction, and the details are logged in the system’s master transaction log file. Businesses can also forecast inventory based on history, lead times, and supplier performance for further optimization.

Material Requirements Planning (MRP)

The MRP feature in MISys acts as a connector between the master production schedule and actual purchase or manufacturing orders. The system offers various scheduling reports detailing the items that need purchasing, their quantities, and the timing for order placement to ensure material availability in line with production needs. Similarly, production advice reports provide insights into internally manufactured items.

Upon finalizing a master production schedule, the “create MRP” button can scan the schedule to identify any remaining shortages. The program can then generate purchase and manufacturing orders either manually or automatically.

Supported Manufacturing Industries

MISys Manufacturing can be configured to a wide range of industries, including:

- Electronics

- Food and Beverage

- Aerospace/Defence

- Auto Parts

- Chemicals

- Health and Beauty

- Industrial Machinery

- Medical Device

- Pharmaceutical

- Plastics

- Transportation

MISys Manufacturing Integrations

- QuickBooks Online or Desktop

- Sage 50

- Sage Intacct

- Sage 300

Video Overview

Product Overview

Developer Overview

Related Products

User Reviews of MISys Manufacturing

Write a Review- Internet Software & Services

- 1-10 employees

- Annual revenue $0-$1M

Meeting all our shop floor needs

We had been operating on Fishbowl but it was not able to meet the promised expectations. After a thorough search, we are now in the implementation phase for MISys where we find it meeting all our shop floor needs. The only negative we have found is that when you start to create a new BOM it doesn’t automatically give you a new line to enter; you have to click on a new line icon each time. But beyond that one feature we have been happy with how the system is meeting our needs.

- Industrial Conglomerates

- 51-250 employees

- Annual revenue $10M-$50M

MISys Manufacturing Review

I find the system to be limiting in terms of it’s functionality and reporting. We build everything made to order and it doesn’t do a good job keeping track of inventory.

- Food Products

- 1-10 employees

- Annual revenue $0-$1M

MISys Manufacturing Review

Misys did a fine job for inventory control, but lacked some of the reporting features we were looking for. It was not the most user-friendly software, and it required a lot of adjustments