QAD Adaptive

4 Reviews 5/5 ★ ★ ★ ★ ★A manufacturing ERP system designed by QAD for mid-sized and large enterprises.

Product Overview

QAD Adaptive is a cloud-native enterprise resource planning (ERP) software purpose-built for manufacturers. The system is powered by Champion AI, a proprietary agentic platform that transforms ERP from the traditional “system of record” into a “system of action”. Through this platform, a curated suite of AI agents with deep manufacturing domain expertise automates mundane tasks and optimizes critical processes such as inventory management and job costing.

QAD Adaptive also offers accelerated implementation timelines that deliver actionable outcomes for manufacturers quickly.

Pros

- Uses Champion AI to turn ERP into a proactive "system of action"

- Accelerated implementations (as little as 90 days)

- Integrated with QAD EQMS for quality management

- Stores test results, inspection records, certificates of compliance

Cons

- Feature-heavy for small business needs

- May require costly migration for complex customizations

- Weaker for ETO manufacturing

Target Market

Medium to large manufacturers with 200+ employees operating globally or across multiple sites. Particularly strong in regulated industries such as automotive, life sciences, food and beverage, consumer products, and high-tech.Not Recommended For

Small single-site manufacturers with under 100 employees and engineer-to-order (ETO) operations.Video Overview

Industries Served

QAD Adaptive is a complete ERP suite that supports the needs of global manufacturers. No two organizations have the same requirements, so QAD offers tailored solutions with industry best practices. Only a select number of industries are supported by QAD Adaptive ERP, including:

- Automotive

- Consumer Products

- Food and Beverage

- High Tech

- Industrial Manufacturing

- Life Sciences

- Distribution and Logistics

Feature Overview

QAD Adaptive ERP consists of modules, or operational suites, which manage specific business processes. QAD Adaptive includes tools for:

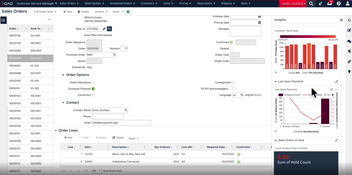

Sales: Streamlines the customer lifecycle from quote to fulfillment with an integrated CRM and rules-based product configurator. Sales teams can generate accurate quotes for complex products, apply dynamic pricing or promotions, and convert opportunities directly into sales orders.

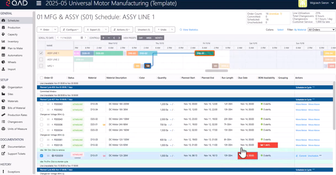

Manufacturing: Supports discrete, process, repetitive, and lean manufacturing with integrated planning, scheduling, and shop floor control. Real-time traceability and built-in quality checks help meet compliance requirements while giving managers visibility into performance.

Production Execution: Connects production planning with shop floor execution by tying live BOMs, routings, and work instructions directly to ERP transactions. Operators can record production activity in real time, from inventory consumption to labeling and packaging.

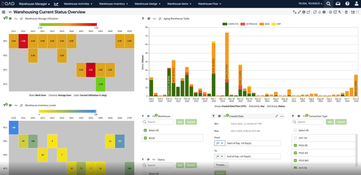

Inventory & Traceability: Provides lot and serial number inventory tracking across raw materials and finished goods. Manufacturers can track items through receiving, storage, production, and shipment, ensuring compliance with regulatory mandates and simplifying product recalls.

Data Collection & Labeling: Includes built-in barcode scanning and label printing tools for capturing transactions throughout the entire supply chain. Eliminates manual data entry and speeds up warehousing tasks.

Financials: Delivers global financial management with multi-GAAP, multi-currency, and tax compliance capabilities. Enterprises can manage multi-entity consolidations and intercompany eliminations across multiple sites or entities.

Purchasing: Manages the entire procurement process for supplies and materials. Buyers can automate purchase orders, manage supplier performance, and keep costs under control.

Field Service: Provide aftermarket services with technician scheduling, spare parts control, and repair tracking. Service requests are connected to product and quality data, helping teams resolve issues faster.

Enterprise Asset Management: Tracks the full lifecycle of equipment and manufacturing facilities. Manage preventative and predictive maintenance with spare parts tracking, capital project management, and machine OEE monitoring.

Global Support and eDocuments: Includes country packs for local jurisdictions and global markets. These support country-specific tax, reporting, and compliance requirements to help manufacturers align with regional and international reporting regulations.

EDI: Integrated electronic data interchange supports ASNs, invoices, and other trading partner documentation. Automotive, consumer goods, and other supply chain–driven manufacturers can meet strict trading partner requirements without manual re-entry or bolt-on systems.

QAD Adaptive Pricing

QAD Adaptive ERP is offered on a quote-based model. Pricing varies by number of users, modules selected, deployment model, and support requirements. Organizations typically work directly with QAD or a certified partner to receive a tailored proposal.

Why Choose QAD Adaptive ERP?

QAD is built for manufacturers who need an ERP tailored to their industry rather than a one-size-fits-all system. Its strengths include industry depth in regulated verticals, global compliance coverage, and strong manufacturing execution and traceability features. For mid-sized to large organizations operating across multiple plants or countries, QAD Adaptive ERP provides the scalability and adaptability to stay competitive in complex global markets.

The new QAD Champion AI suite transforms ERP from a “system of record” into a “system of action”. Manufacturers can now utilize agent-based AI for tasks right inside the ERP platform. Implementation can also be accelerated (in as little as 90 days) to provide actionable insights and provide ROI quickly.

Product Overview

Developer Overview

Related Products

User Reviews of QAD Adaptive

Write a Review- Industrial Manufacturing

QAD Adaptive Review

QAD did a great job partnering with us through the upgrade, along with Roundview, to make sure that we were successful and our business was protected.

Gary and his team really engaged with our business, worked on-site to understand our processes and then made sure we had the tools to move forward.

They make sure that QAD Adaptive ERP is up and running day or night, and respond very quickly if we do have any issues.

- Automotive Manufacturing

QAD Adaptive Review

We’ve grown with QAD because of the functionality built into the system. It really has to do with the fact that QAD is focused on manufacturers for specific vertical markets.

Not only are we a huge manufacturing company, we also have our own trucking company. We also have our own integration shop. We have our own dye shops. We have our own design centers.

We can use everything internally and use those basically interchangeably.

- electronics contract manufacturing

QAD Adaptive Review

We were looking to move from an on-premise ERP to a cloud ERP. We were able to roll out QAD in a new facility in a matter of months and we have a methodology and team to do it that works well. We’re very confident that we are going to be able to grow with QAD in the coming years.

QAD Adaptive Review

QAD Enterprise Edition having all finance options which were in eB2.1 were not available. In other words we can say its Complete ERP with .NET UI Interface and reporting tool is excellent.

Pros

User Interface and user options even from you can upload the data in QAD EE, now its very simple.

Cons

Financial Module which was week in QAD eB2.1 but now all features are available.