Tulip Platform

1 Review 5/5 ★ ★ ★ ★ ★A cloud-based frontline operations platform to connect people, machines, and devices through interactive interfaces to extract real-time production insights for manufacturers.

Product Overview

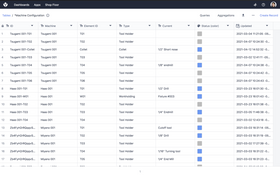

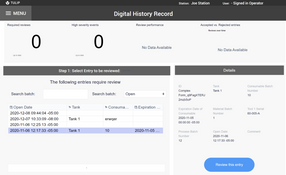

Tulip is a cloud-based frontline operations platform. The no-code, cloud-based solution with edge connectivity is designed to transform production floors with interactive interfaces and AI augmentation. Key features include managing material systems replenishment, tracking work order status, visualizing real-time production progress, guiding operators through digital workflows, responding to alerts, and streamlining workflows with integration to ERP systems.

The platform offers flexibility and intuitive operations, assisting manufacturers in creating applications that guide operators and collect data efficiently. That way, it enables the digital transformation of operations with real-time visibility.

Pros

- Has connectivity to Oracle and SQL Server databases, along with others

- Manages cross-functional operations

- No-code, low-code, and drag-and-drop customization

Cons

- Custom widgets doesn't support many Javascript libraries

- Does not offer complex data manipulation

Target Market

Mid to large-sized manufacturers, including those who produce pharmaceuticals, medical devices, and agricultural equipment. It works best for companies requiring solutions to specific challenges and already have existing systems.Video Overview

Tulip Features

- Edge and Industrial IoT: Connect to machines, sensors, and smart tools; build triggers and workflows using data from these devices.

- Serialize: Integrate barcode or RFID for dynamic process control.

- Measure: Create apps with data from scales, calipers, thermometers, and sensors.

- Capture Images: Record defects with camera integrations.

- Computer Vision: Error-proof work by identifying and tracking parts or motions.

- Guide Operators: Enhance instructions with IoT, media, and CAD integrations.

- Monitor Machines: Gain visibility into machine data, including legacy machines.

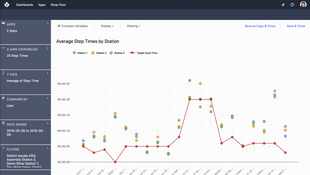

- Data and Analytics: Automatically collect and store data for real-time production analysis and KPI calculation.

- Build dynamic workflows: Visualize data in digital workflows.

- Aggregate data from apps: Combine app, machine, and sensor data.

- Dynamic analysis: Filter data dynamically for analysis.

- Communicate with Tulip APIs: Integrate external systems with Tulip data.

- Prebuilt apps: Access a library of operational apps.

- Tulip Player: Run applications on various interfaces, including tablets and phones.

- Connectors: Integrate with existing infrastructure, systems, and machines.

- Create a Connector: Easy configuration for data exchange with HTTP APIs, SQL databases, OPC UA servers, and Tulip.

- Build functions and logic: Control data push/pull with no-code logic.

Pricing

- Essentials: $1,000/month ($100/interface/month with a 10-interface minimum.) Includes tables, mobile apps, and analytics.

- Professional: $2,500/month ($250/interface/month with a 10 interface minimum) Everything in essentials plus advanced edge connectivity, on-premise connector host, and Tulip API.

- Enterprise: Custom pricing

- Regulated Industries: Custom pricing

Add-Ons

- AI actions

- Machine monitoring

- Automations tasks

- AWS GovCloud

Product Overview

Developer Overview

Related Products

User Reviews of Tulip Platform

Write a ReviewTulip helps us determine the root cause of problems

We implemented this system together with our operators. Including them in the process from the start has been a great success.

The Tulip software helps digitize shop floor processes that vary by customer. The intuitive software is flexible and easy to configure, making it a sustainable and scalable solution.

We use Tulip at every DMG MORI site. Each site has a different focus. At DECEL-MAHO Pfronten we focus on the production of motor spindles.

Tulip provides timely information to operates and can be installed quickly on the shop floor. A complicated data network is not required. After four weeks, we gained insight into how we could significantly reduce errors and stabilize production.

Our spindle line assembly consists of over 16 stations. It’s important that the operator knows exactly which task they need to perform to complete the job. Tulip supports this 100%.

Now there’s live information from the operators and stations and we know where improvement is needed in order to reduce errors.

Tulips helps us identify the root cause of problems. It’s easy to configure with no programming skills required. This helps us reflect daily changes tor requirements.

Tulip helps us determine the root cause of problems with absolute certainty.