The Best Supply Chain Execution Systems

Get the best software for your business. Compare product reviews, pricing below.

What is a Supply Chain Execution System?

Supply chain execution (SCE) systems manage basic logistic operations along the global supply chain like order management, warehousing, product procurement, and transportation. These systems provide real-time data on hourly, daily, or weekly warehouse operations so you can make adjustments to workflow on a regular basis.

SCE is used by warehouses, distribution centers, and manufacturers. Advanced SCE software can streamline assembly, storage, and distribution operations as part of a larger supply chain management system. Execution systems can also operate independently depending on what your distribution center or warehouse needs.

Features of Supply Chain Execution Systems

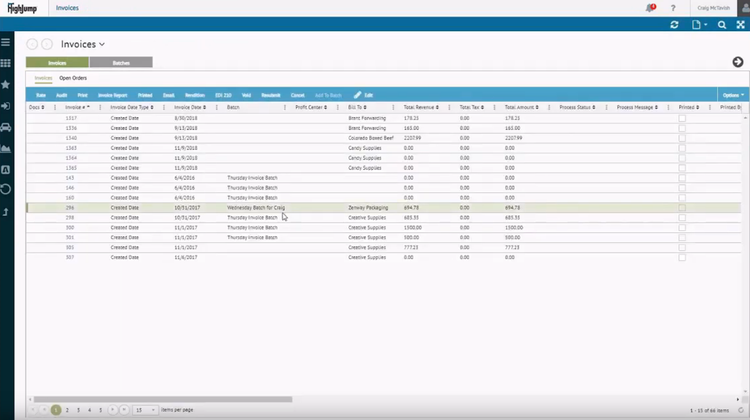

- Order management: Organize incoming orders to prioritize product fulfillment and distribution.

- Procurement and packaging: Fulfill orders in the most effective way possible by arranging procurement paths within your warehouse or distribution center. Then, plan how to effectively package products to minimize waste and increase delivery vehicle space.

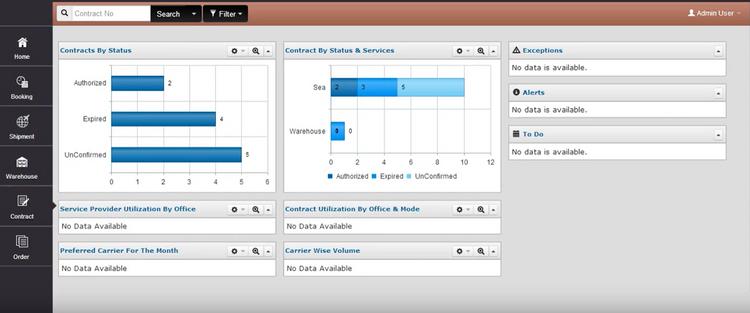

- Warehouse management and inventory control: Measure stock levels in real-time to know which products are in-stock, overstock, or about to run out.

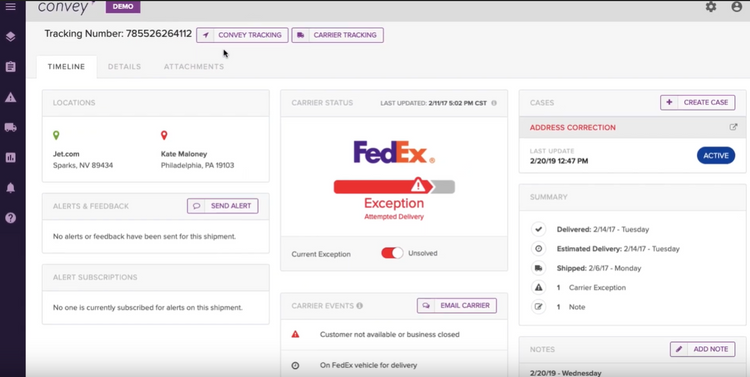

- Dynamic transportation management: Set timelines for product deliveries, calculate shorter routes to reduce fuel usage, and create optimized product loads to maximize distribution.

- Return and recall management: Handle logistics for returned or recalled products which are coming back to your distribution center.

- Labor management and scheduling: Use real-time data to determine when to schedule workers to maintain steady labor levels.

Benefits of Supply Chain Execution

Supply chain execution systems help businesses with:

Streamlined Order Fulfillment

Staying on top of orders can be difficult, especially if your distribution center works with multiple third-party suppliers and ecommerce retailers. In order to control orders, inventory management applications give you an overview of product pricing, stock levels, and even real-world location within your warehouse. With SCE systems, you can automate seasonal price changes, plan ahead for product re-ordering, and streamline in-house procurement procedures.

Fulfilling orders in an efficient manner depends on having a reliable manufacturing and procurement process. Logistics tools within SCE systems let you arrange your warehouse or distribution center to maximize material retrieval when orders are placed.

If your warehouse handles product assembly, you can use SCE to ensure each component is in the best spot for efficient construction. For example, if you manufacture chairs, you have to add the legs before you can add decorative cushions. If the legs are located far away, you’re wasting valuable assembly time whenever you have to retrieve more. SCE software finds the ideal pathways for arranging product components for streamlined assembly.

Inventory and Warehouse Management

One way to keep orders accurate is to accurately reflect your stock levels to customers to avoid overselling. A warehouse management system (WMS) alone only controls your on-site inventory. SCE systems manage how your inventory moves along the multi-echelon supply chain. You can coordinate incoming raw materials against outgoing products to ensure you continue operating at ideal capacity.

More Efficient Product Transportation

Once the product arrives in your customer’s hands, your work is finished. Until then, it is still your responsibility to ensure the product remains in good shape. Dynamic routing tools can create shorter delivery pathways which reduces vehicle wear and tear.

Another way to lower transportation costs is through better packaging. SCE modules can determine the best way to safely package your products. Going overboard on expensive protective equipment can weigh down shipments. In order to cut down on excess materials, SCE tools can find more effective ways to package your goods.

Next, cutting down on material usage can increase your delivery capacity. For example, you might be able to fit a single pallet of goods onto a truck using your current packaging system. By reducing materials with a SCE system, you can now double pallet capacity and get more products on each outgoing truck. This can lead to lots of long-term distribution savings and easier fleet management practices.

Reduced Operational Costs

All of these SCE benefits come together to provide lower operating costs. Faster order fulfillment means happier customers who are likelier to use your services again. Reduced packaging waste means production savings. By streamlining orders, procurement, and transportation, your company can avoid the extra costs associated with late deliveries or messed up orders.

How is Supply Chain Execution Different from Planning?

Supply chain management (SCM) software helps manufacturers, distributors, suppliers, and retailers manage the flow of goods and services between locations. SCM software streamlines the process of getting products from the manufacturer to the vendor to the final customer.

Supply chain planning (SCP) software develops real-time demand forecasts to streamline supply and demand to achieve the financial objectives of the business and improve overall decision-making. SCP software is designed to forecast far into the future to anticipate needs. This may range from weeks to months to years, while SCE systems deal with hours or days.

Both execution and planning fall within the scope of supply chain management operations. In fact, many SCM software solutions contain SCE and SCP applications. However, depending on your operation you may need an independent SCE system to better manage your daily warehouse operations.

Not sure what you need? Contact the experts at Software Connect for a free SCE software recommendation by emailing [email protected].