Warehouse management systems (WMS) help maintain inventory and coordinate actions throughout a warehouse, storage, or distribution center. Through our advanced review methodology, we’ve assessed the top WMS solutions, considering factors like customization capabilities, inventory tracking features, and adaptability to different warehouse setups.

- NorthStar WMS: Best Overall

- Logiwa WMS: Extensive Integrations

- Fishbowl Inventory: Best for Inventory Management

- Infoplus WMS: Best for Small Businesses

- Körber: Best for Distributors

- Blue Yonder Luminate: Best Supply Chain Planning

- Da Vinci WMS: Best for Cartonization and Cart Picking

- ShipHero: Best for Direct-to-Consumer Sellers

- NetSuite: Support for Multiple Warehouses

- 3PL Warehouse Manager: Best for 3PL

- Infor WMS: Best 3D Visualization Capabilities

1 NorthStar WMS - Best Overall

Why we chose it: NorthStar WMS has secured its position as our top choice due to its support for multi-company and multi-warehouse operations. Feature-rich and adaptable, it offers functionalities like order fulfillment, 3PL modules, EDI capabilities, vendor comparisons, and productivity tracking.

Our assessment of NorthStar WMS revealed its scalability and cost-effectiveness, making it an ideal solution for businesses of varying sizes. With flexible deployment options including cloud-based, private cloud, and on-premises, coupled with a public API for custom integrations, NorthStar WMS is highly configurable for different warehousing environments.

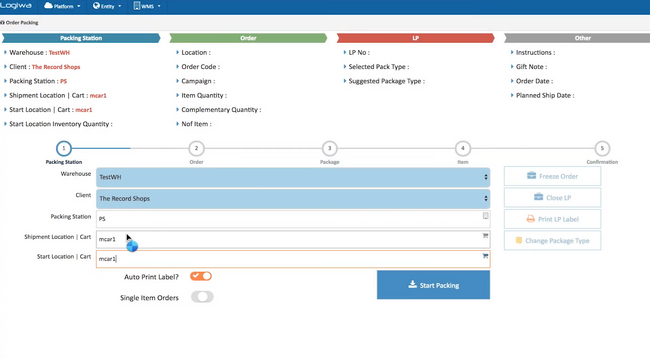

2 Logiwa WMS - Extensive Integrations

Why we chose it: We recommend Logiwa WMS for online retailers or businesses with diverse sales channels due to the platform’s many integration options. With connections to over 240 eCommerce, shipping, and accounting platforms, including Amazon, eBay, and Shopify, Logiwa WMS offers versatility.

The platform best serves wholesalers, distributors, and 3PLs, focusing on direct-to-consumer fulfillment methods. We recommend Logiwa WMS for businesses wanting to automate their picking and packing while integrating with leading eCommerce platforms and carriers. However, we found Logiwa less compatible with manufacturing companies or small businesses that do not consistently handle high-volume fulfillment or shipping.

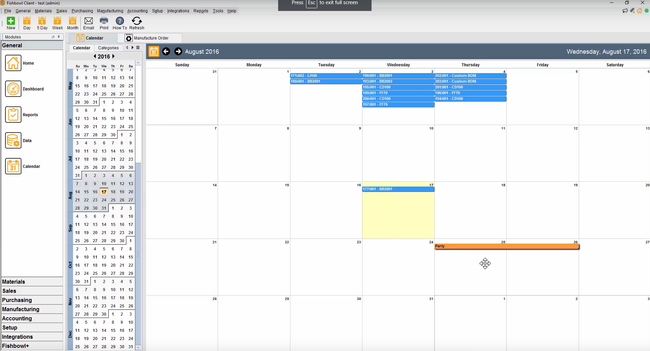

3 Fishbowl Inventory - Best for Inventory Management

Why we chose it: Fishbowl Inventory software made our list due to its inventory management capabilities. The platform helps track the location and status of every stocked item, whether in a single warehouse or across multiple locations.

One notable feature is the Today View tool, which consolidates all ongoing functions onto a single screen. This intuitive dashboard offers a quick overview of pending sales and purchase orders awaiting receipt, items requiring picking, and ready-to-ship inventory, streamlining decision-making processes.

4 Infoplus WMS - Best for Small Businesses

Why we chose it: We recommend Infoplus WMS for small to medium-sized businesses in the 3PL, eCommerce, and wholesale sectors. It made our list because it’s adept at managing critical inventory, warehouse, and shipping processes. Additionally, it offers customizable workflows and rule-based automation, allowing small businesses to tailor the system to their specific needs.

Despite its comprehensive feature set, Infoplus maintains a user-centric interface. This ease of use is vital for small businesses without dedicated IT support or extensive technical training, enabling them to manage their operations without a steep learning curve.

5 Körber - Best for Distributors

Why we chose it: Cloud-based Körber, formerly known as HighJump WMS by Accellos, is our top pick for distributors due to its cloud-based infrastructure and adaptable warehouse management platform. Offering scalability and flexibility, Körber serves as a supply chain solution, integrating with EDI, Crystal Reports, and accounting software.

Körber offers distributors inventory tracking through radio frequency (RF), RFID, and barcode hardware. Leveraging these tools for automated scanning accelerates picking, packing, and shipping operations while minimizing human error.

6 Blue Yonder Luminate - Best Supply Chain Planning

Why we chose it: Blue Yonder Luminate, previously known as JDA Demand Planning, is a supply chain planning software with an emphasis on warehouse management, along with transportation, labor, and distribution networks. We found this platform best for organizations needing to unify logistics operations and optimize transportation with warehouse and labor.

In addition to WMS, Blue Yonder Luminate focuses on various aspects of Planning, Logistics, and Commerce. This makes it an ideal solution for businesses needing warehouse management to complement their supply chain planning.

7 Da Vinci WMS - Best for Cartonization and Cart Picking

Why we chose it: We found Da Vinci WMS best serves 3PLs, retailers, and distributors needing advanced cartonization and cart-picking capabilities. This cartonization feature uses a heuristic algorithm to optimize carton size and contents, ensuring space efficiency and reduced shipping costs. This smart packing approach takes the guesswork out of packing, saving time and avoiding transit issues.

We also found the cart picking feature useful for fast and accurate order fulfillment, enabling simultaneous picking and packing of multiple orders. This streamlines the picking process and minimizes errors, enhancing overall warehouse efficiency.

8 ShipHero - Best for Direct-to-Consumer Sellers

Why we chose it: We think ShipHero is best because it’s a cloud-based WMS and fulfillment software designed specifically for online D2C supply. This solution allows users to deliver a better eCommerce experience by syncing channels, optimizing shopping, and simplifying operations all on one platform. ShipHero addresses all the specifics of eCommerce logistics. It includes inventory and order management tools, along with mobile pick and pack capabilities.

9 NetSuite - Support for Multiple Warehouses

Why we chose it: We went with NetSuite because its WMS supports multiple warehouse locations and bin management. This functionality allows businesses to manage inventory across many storage facilities, providing detailed information on where items are stored down to the bin level. This level of detail is particularly good for large or complex warehouse operations, as it ensures accurate inventory location tracking, leading to more efficient retrieval and stock management.

Additionally, NetSuite features sophisticated wave planning and picking functionality. This feature enables businesses to optimize the picking process. Wave planning in NetSuite allows for grouping sales orders into waves, which can then be processed together. This approach streamlines the picking process, reducing the time and effort needed to fulfill orders.

10 3PL Warehouse Manager - Best for 3PL

Why we chose it: 3PL Warehouse Manager by 3PL Central is a third-party logistics software for warehouse owners that charge customers for inventory storage space and the services they provide. We found this platform can handle your inventory, customized billing, and shipping to suit each customer or product.

3PL Warehouse Manager also makes managing inventory easier, automating tasks, and providing visibility to customers. And various iterations mean you can send invoices seamlessly to your accounting package in programs like QuickBooks or Peachtree.

11 Infor WMS - Best 3D Visualization Capabilities

Why we chose it: We think that Infor WMS offers some of the best 3D visual representations of warehousing operations. Employees can virtually “navigate” through the space, seeing the layout, storage locations, racks, aisles, and inventory items as they would appear in reality. This makes stock management intuitive and reduces the complexity of identifying and locating items within the warehouse.

Its emphasis on inventory, order, and labor visibility ties back to the 3D visual representation. The software gives users a comprehensive view of various elements, making management more efficient. Users can streamline their supply chain processes by assessing and tracking inventory and orders visually.

What is Warehouse Management Software?

Warehouse management systems (WMS) software is a digital solution that optimizes warehouse and distribution center operations, including inventory management, order processing, and logistics coordination.

To oversee warehouse operations, WMS software gives warehouse managers powerful tools to design a warehouse’s workflow, control stock, schedule labor, generate bills, analyze reports, and coordinate with shipping yards and docks.

To make the supply chain run efficiently, key warehouse management systems must be in place to control product distribution and fulfillment in real time. The software automates how stock is logged, received, put away, picked and packed, shipped, and reported upon by this software. Using WMS to streamline these complex tasks helps control costs by ensuring items get to the correct place at the lowest possible price without mistakes.

What Are the Key Features of WMS?

- Inventory management: Keep track of all information about the items your company builds, buys, stores or sells

- Pick-and-pack optimization: Create specific routes to pick products from storage to reduce excess traveling during retrieval

- Order management: Capture, track, and fulfill orders across multiple sales channels by connecting inventory data to sales orders, creating shipping schedules, tracking fulfillment, and creating reports

- Shipping management: Calculate shipping costs and estimated delivery times; create accurate shipping labels

What are the Benefits of a Warehouse Management System?

If you’re seeking the best for your warehouse, look for these key benefits offered by top WMS software solutions:

| Benefits | Functionality |

|---|---|

| Higher accuracy of order fulfillment | For an optimized omnichannel experience, WMS software makes order management possible through any sales channel. The result is a solution that makes it easier and faster for customers to receive your goods, ensuring fewer missed shipments and customer chargebacks. |

| Optimized picking and shipping | Identify what is needed to fulfill an order. Comprehensive picking tools can define steps for preparing, packaging, and provisioning goods from anywhere within the warehouse. Specific instructions can be set to optimize moves and transfers to help ensure efficiency. |

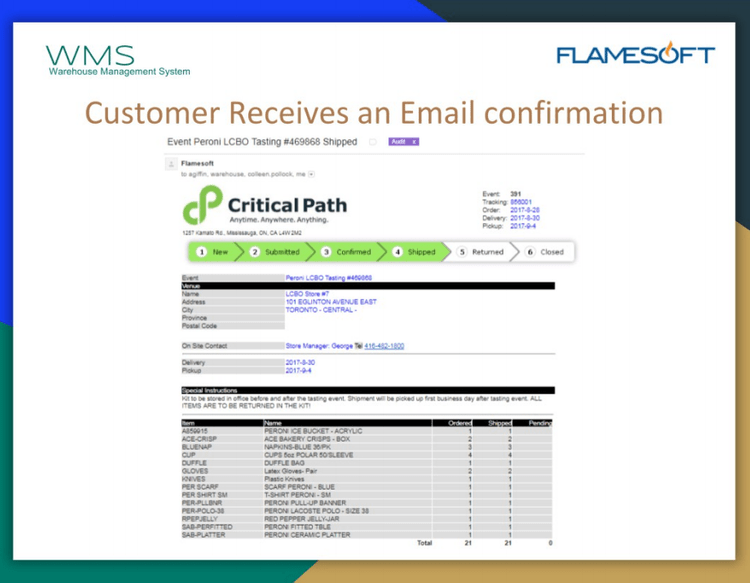

| Faster delivery times | Streamlined warehouse operations and increased transparency into inventory levels make it possible to speed up delivery. As soon as products have been packed, invoices and packing lists can be automatically generated by WMS software to inform other locations of pending deliveries. |

| Efficient labor management | Labor management tools make it possible to measure the efficiency of warehouse employees through key performance metrics. Combined with lot zoning and task allocation, employee workflows can be streamlined in order to define and carry out their work. WMS software can also track labor expenses and minimize employee theft. |

| Increased visibility of an order’s status | With WMS software, inventory and order status can be tracked with greater real-time accuracy. Automated data collection through barcoding or radio frequency identification (RFID) scanning, can show users the status of their orders, which is particularly valuable for tracking through 3PL warehouses. |

| Optimized storage space | WMS offers ways to design a warehouse’s material handling, picking logic, and bin slotting by ensuring space is being optimized for storage and retrieval. |

| Minimized inventory movement | Because of the sheer scale of a warehouse operation, inventory needs to be stored correctly to prevent misplacement and loss. |

| Improved yard management | Manage the movement of vehicles as they come and go from yards or loading docks. Real-time tracking lets you see where shipments are, allowing employees to prepare for loading and unloading. Cross-docking can also be managed with some WMS solutions to cut down on storage time. |

How Do I Choose a Warehouse Management Software?

Choosing the right WMS software for your warehouse depends on the size and structure of your warehouse operations. It’s important to fully understand your warehousing and supply chain management needs in order to determine the correct solution:

- Startups and small businesses can benefit from web-based WMS software for small companies, placing warehousing operations in a supply chain solution with warehouse management modules. For growing businesses, cloud-based WMS software platforms provide the flexibility to customize the experience as needed.

- Medium-sized businesses often outgrow manual or simple warehouse processes, requiring standalone WMS software that can better assist and provide additional flexibility in order to track inventory and ship goods with greater accuracy.

- Large warehouses deal with complex tracking requirements like serial numbers and the need for retail compliance laboring. When a warehouse also uses transportation management software (TMS) or legacy solutions, it is important to choose WMS software that fully integrates with existing operations set by a 3PL warehouse manager or enterprise resource management tools.

eCommerce businesses of any size need accurate inventory information to prevent overselling products. Many eCommerce companies work through 3PL warehouses and need WMS with inventory tracking which can be integrated with third party logistics.

With the right WMS software, a warehouse can improve operational efficiency, resulting in better delivery times and customer satisfaction. If there are budgetary concerns, remember many of these management features can be included as part of fully-integrated distribution software or supply chain management systems. Additionally, standalone 3PL software solutions can integrate with management systems for third party warehouses which are not directly controlled by your company but still impact your supply chain.

What Are the Latest Trends in Warehouse Management?

New trends in WMS software have allowed it to keep up with changing markets and user demand. Our recent Warehouse Management Software Buyer Trends report found that barcoding was far and away the most-used scanning tech in warehouses. In fact, 3/4ths of WMS buyers want barcoding.We also found that over half of WMS buyers are looking for a system that can manage multiple warehouses.

Top challenges warehouse managers want software to address include:

- Integration with an existing logistics operation: Depending on the scale of the operation, an improved WMS software package may need to work well with transportation management systems or order fulfillment applications already in use.

- Ease of use: Because WMS software can offer complex functionality, it’s important that solutions offer users clear interfaces that are easy to understand. Solutions that workers can adapt to are crucial to maximizing overall efficiency.

- Improved order picking methods: Plenty of order picking methods are available that can optimize your inventory picking methods, like discrete, batch, zone, wave, and hybrid.

How Much Does WMS Software Cost?

The cost of warehouse management software will differ based on a number of factors, including deployment method (on-premise versus cloud-based), number of users, level of support included, any additional services provided by their vendor. As WMS is generally more complex than inventory management software, it will generally be more expensive.

WMS systems can start at subscription-based pricing models or perhaps have bulk pricing that lets you purchase users in tiers. SaaS costs for anything but basic WMS functionality would average between $3,000 and $4,500 per concurrent user for on-premise, with professional services being between 75% to 100% of the software costs, plus between $5,000 to $25,000 for integrations into ERP systems. Optional upgrades, of course, increase the total price.

Radio Frequency Identification (RFID) Costs

RFID tracking is more and more common in WMS options. While RFID does have many beneficial uses in today’s age, those processes generally have to do with asset management at multiple locations in order to reduce mistakes along the supply chain. However, RFID hardware is more expensive than what most WMS companies offer in terms of the cost of the software alone, as scanners can cost from $2,500 up to $4,000 each. Combined with tagging, companies will need to be prepared to spend upwards of $50,000 for the hardware of a small 5-user system.