The Best Food Traceability Software

Food traceability software tracks and monitors products from farm to fork. We tested various solutions for their industry-specific features, like batch and allergen tracking and compliance management.

- Customizable to different businesses with pre-built templates

- User-friendly and intuitive interface

- Reduces time spent on repetitive tasks

- Adheres to ISA-95 and ISA-88

- Connected production data

- Low code/no code offerings

- Affordable pricing

- User-friendly interface

- Integrates with Xero and Shopify

Using our advanced review methodology, we evaluated the best systems for batch manufacturers across various industries.

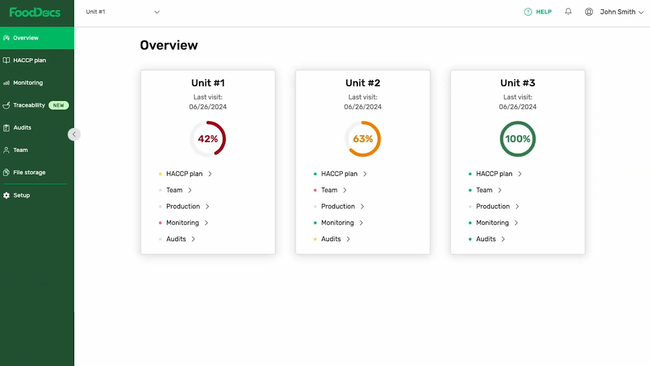

- FoodDocs: Strong Mobile App

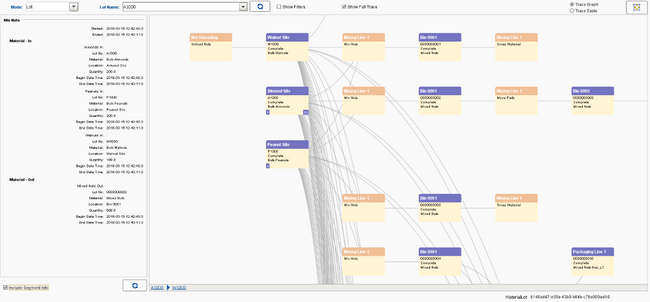

- Sepasoft: Advanced Traceability

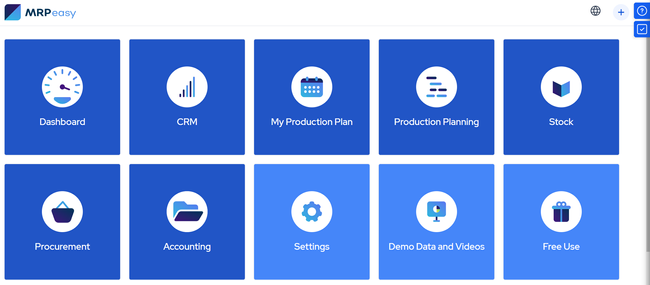

- MRPeasy: Best for SMBs

- Craftybase: Best for Artisanal Products

- Smart Food Safe: Best for Site-Based Pricing

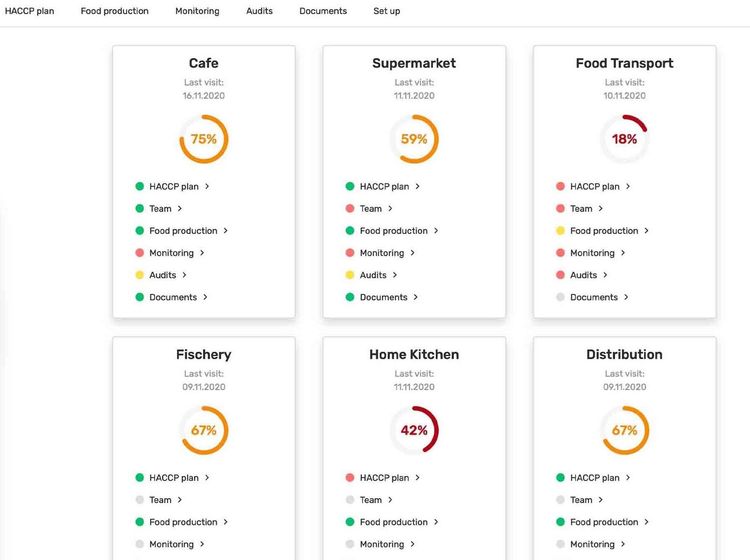

FoodDocs - Strong Mobile App

FoodDocs has a Smart Traceability App that streamlines tracking from raw materials to finished goods. This helps ensure compliance and enhances food safety.

When logging a new product, you can select products manually or use a built-in mobile scanner with EAN/QR codes. The app then calculates the necessary ingredient quantities and provides allergen information, aiding production planning. For example, if you select tomato sauce from your product list, the app will calculate the quantity of tomatoes, spices, and other ingredients and alert you if there are any present allergies.

The system will auto-fill relevant data, such as batch numbers and shelf-life dates, allowing you to confirm and adjust data as needed. Throughout this process, you can monitor task statuses in real time, ensuring all steps comply with safety standards.

Sepasoft - Advanced Traceability

Sepasoft delivers advanced traceability and quality control features. These include a built-in data historian to record and process data and alarms and the ability to distribute reports and trace information between departments. These features enhance the visibility of the product journey and facilitate compliance with traceability regulations.

The software aligns with important industry standards like ISA-95, ensuring it meets the necessary criteria for integration between enterprise and control systems. Additionally, Sepasoft offers a range of modules, including OEE Downtime, Batch Procedure, Track and Trace, SPC, and Document Management. This modular approach allows businesses to tailor the software to their specific needs.

MRPeasy - Best for SMBs

MRPeasy is suitable for small to mid-sized batch manufacturers. These companies often have complex supply chains with multiple suppliers. MRPeasy offers vendor and purchasing management, maintaining detailed records of vendors, their prices, and lead times. Users can raise pre-filled purchase orders with a single click, streamlining the order process for smaller businesses.

Manufacturers of this size often face challenges in balancing demand with production capacity. MRPEasy’s accurate and automatic planning tools, along with dynamic rescheduling capabilities, help them efficiently plan and adjust their production schedules.

Craftybase - Best for Artisanal Products

Craftybase allows the creation of complex, multi-stepped production flows, ideal for food artisans with unique or traditional production processes. This feature helps track material and labor costs from start to finish, ensuring pricing is accurate and reflective of traditional production methods.

For artisanal producers who often sell their products through multiple channels, including farmers’ markets or local stores, Craftybase’s integration with various sales platforms simplifies the workflow, making managing sales and inventory across different outlets easier. These include apps like Shopify, Square, WooCommerce, Wix, and more.

Smart Food Safe - Best for Site-Based Pricing

Smart Food Safe offers a site-based annual subscription with unlimited users and transactions. This can be more economical for businesses, especially those with many users, as they don’t have to pay per user or transaction.

Smart Food Safe is also considered cost-effective because it offers a comprehensive suite of modules. These include document management, digital records, supplier management, product specification, audit management, and CAPA management.

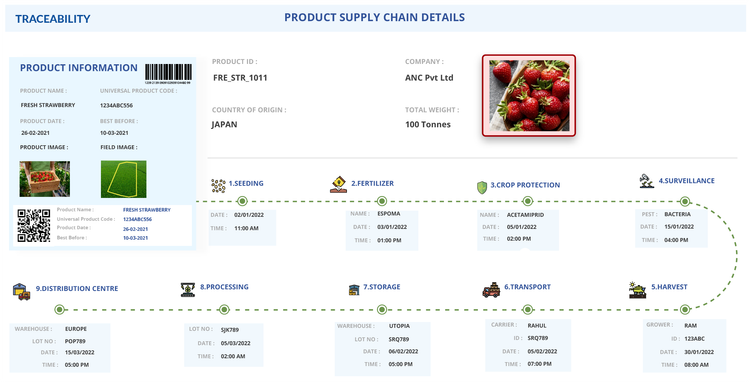

What Is Food Traceability Software?

Food traceability software is a specialized type of software used in the food industry to track and trace the movement of food products and their ingredients throughout the supply chain. Primarily used by companies that manufacture, produce, and/or prepare food, food traceability systems excel at providing food safety and will greatly reduce the risk involved in the processing and manufacturing stage.

Functionality in most food traceability software includes fully integrated accounting, inventory, supplier management, traceability, landed cost tracking, and catch weight capabilities. A food traceability solution can provide these features on-premise or in a SaaS (software as a service) environment.

Food traceability software keeps your business compliant with the Hazard Analysis and Critical Control Points (HACCP) requirements and the Food Safety Modernization Act (FMSA). It will also allow for any improvements suggested by government organizations such as the Food and Drug Administration (FDA).

Key Features

- Supplier Management: Manage the supplier approval process. Assign a rating to a supplier, score their risk factor, detect non-compliance risk, and create a workflow for supplier corrective actions.

- Traceability: Track and trace all raw materials and finished products through improved inventory control. Produce HACCP documentation to structure terms of reference, process flow diagram, and hazard analysis.

- Product Quality Control: Product testing, inspections, certificates of analysis, quality control KPIs, and real-time specification verification.

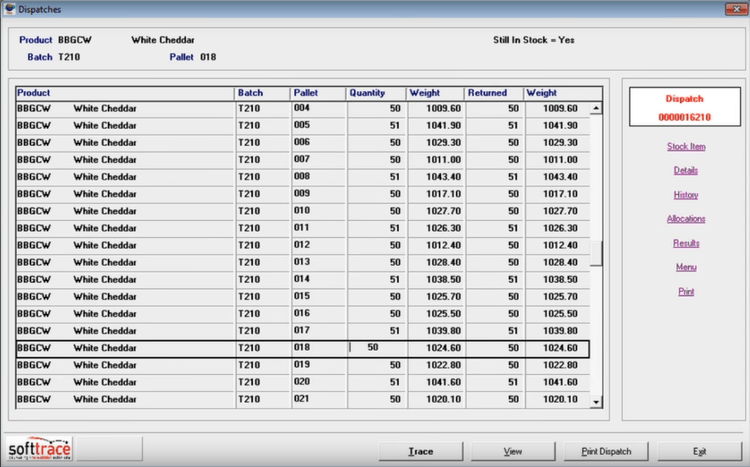

- Recall Management: Create common recalls or stock withdrawal workflows. Ensure proper action is taken, and customer interactions remain positive and handled quickly. Monitor how quickly the recall process takes within your organization.

- Business Intelligence: Build a dashboard to display food safety metrics and results of recent quality tests and monitor bottlenecks in the supply chain.

Benefits

By following the correct steps and precautions, manufacturers and distributors involved in food production can ensure they maintain best practices for material tracking, staying compliant, recalls, and more.

Improved Food Safety

Food traceability software helps keep food safe through the identification of faulty products and assistance in initiating the recall process for products that have already been distributed. It can also prevent your company from producing too much of said product. This can prevent contaminated food from hitting the shelves and ensure foodborne illnesses are not spread.

Food safety and foodborne illness prevention are reasons to look into food traceability systems. Food safety incidents in one product can affect an entire sector Having a proper solution allows your supply chain to prove their product is safe and not related to any ongoing outbreak.

Improved traceability also helps prevent fraud and “counterfeiting” of food, which cost the industry $10-15 billion per year. Some of the most counterfeited food items include olive oil, fish, and pomegranate juice, as detecting any adulteration can be difficult to detect with these products. Catching fraudulent products or raw materials before they are used in your food manufacturing process is critical to maintaining healthy relationships with your customers and not spreading disease or allergens unknowingly.

Better Inventory Visibility

Inventory management has always been a strong part of food traceability. Software that improves your food traceability process will provide increased visibility into your overall warehouse management through traceability initiatives to track and trace data. There is also a requirement to track and trace for regulatory compliance, such as food safety issues, if you risk spreading diseases such as E. coli.

Proper inventory traceability can mean identifying a problem quicker than ever imagined, which can potentially prevent a product recall. A supplier may contact a manufacturer about contaminated goods they recently sold. The quicker the manufacturer can identify the source of their raw materials and which shipments or batches they belong to (and if they’ve been used to create a now tainted product). Some examples of improved technology helping streamline inventory visibility are barcode capabilities and improved lot tracking.

An increase in inventory visibility also means saving significant time and money when dealing with an organization such as the FDA, which requires that a traceability report be produced within 4 hours of being notified of a food safety event.

Improved Supply Chain Efficiency

A food manufacturer or distributor can implement improved supply chain efficiency with food traceability software through increased audits, better inventory control, and proper record keeping.

Production equipment at your facility needs to be routinely maintained, and preventive measures should be taken to ensure it is working at its highest operating point.

Improving your inventory control can be one of the most beneficial capabilities of food traceability software. One example is storing up-to-date information on the expiration dates of your raw materials and finished goods. This can ensure you don’t accidentally use bad products in your production or distribute expired goods to customers.

One way software can increase efficiency is by a more selective inventory-picking process. The software can prioritize picking food with the closest expiration date to help prevent any future losses.

Compliance and Audit Management

Food and beverage manufacturers must comply with many regulations issued by the Food and Drug Administration (FDA).

To stay compliant with food industry standards via food traceability software, companies must find out how their record-keeping will be managed and what sort of information a food traceability software will store:

- Does the business have unique identifiers such as lot codes?

- Can every product or raw material used during production be traced back to an appropriate supplier?

- Do you know exactly where your products are being shipped to in the event of a product recall?

Hazard Analysis and Critical Control Points (HAACP)

HACCP is a management system in which food safety is addressed through analyzing and controlling biological, chemical, and physical hazards from raw material production, procurement, and handling to manufacturing, distribution, and consumption of the finished product. FDA.gov

In food traceability, hazard analysis is the first step towards identifying risk. A hazard can be defined as a condition that (if in existence with other conditions) can lead to failure or an accident during your food manufacturing or distribution. HACCP was created to give a systematic approach to controlling food safety hazards based on the seven principles:

- Conduct a hazard analysis

- Determine the critical control points (CCPs)

- Establish critical limits

- Establish monitoring procedures

- Establish corrective actions

- Establish verification procedures

- Establish record-keeping and documentation procedures

An established food traceability software should make HACCP adherence a top priority. Food traceability software can ensure HACCP compliance by helping to develop a HACCP plan (detailed below) that establishes any needed workflows in your business to adhere to the seven principles.

| HACCP Plan | Applying the Plan via Food Traceability Software |

|---|---|

| Assemble the HACCP Team | Assign a user license to the individuals who need to create HACCP plans. Consider granting staff members across the organization access to food traceability software, such as engineering, production, sanitation, quality assurance, and more. |

| Describe the food and its distribution | Store detailed descriptions of the ingredients and raw materials used to create your food product. Record every method of processing and preferred/required method of storage (such as the temperature the product must sit at) |

| Describe the intended use and consumers of the food | Store expected use details for each food item. Examples include human or animal consumption or age recommendations (such as alcohol sales) |

| Develop a flow diagram that describes the process | Outline steps each employee needs to take via a workflow management tool. This will help your staff understand and evaluate the flow required to maintain HACCP. |

| Verify the flow diagram | Verify the accuracy of any workflow performance. Monitor which employees need to complete additional tasks. |

Food Safety and Modernization Act (FMSA)

When used properly, food traceability software should give you all the tools necessary to prevent foodborne illness. Specifically, the FDA has finalized seven major rules for food manufacturers to implement FSMA:

| Rule | Definition | How Software Helps |

|---|---|---|

| Preventive Controls Rules for Human and Animal Food | Businesses must implement a written food safety plan, determine if any hazards require preventive controls, and outline measures to minimize or prevent the hazard. | Once hazards are identified, ensure the proper workflows are in place and assign tasks to employees. This includes supplier approval management and facility compliance management. |

| Produce Safety Rule | Ensures safe growing, harvesting, packing, and holding of produce. | Establish strict guidelines for quality testing of your products. Keep records of the expiration dates of raw materials. Set up routine examinations of areas that produce comes in contact with. |

| Foreign Supplier Verification Program (FSVP) Rule | Verify that foreign suppliers follow FDA requirements. | Keep a detailed record of all the suppliers your company imports products from. Ensure routine audits are performed of these suppliers. |

| Accredited Third-Party Certification | A voluntary program that lets third-party certification bodies conduct food safety audits and issue certifications. | Ensure inspection results are logged and sent to the FDA (either by the certification body or the company itself) |

| Sanitary Transportation Rule | Ensure food is kept safe during transportation through various requirements for shippers and receivers. | Store records of how food shipments will be handled (via truck, boat, air, etc.) and note who the specific carrier or loader is and when their pick-up and drop-off times are. Ensure carriers can handle specific temperature requests. |

| Intentional Adulteration Rule | Requires all facilities to register with the FDA as a good facility. | Create a written Food Defense Plan and monitor how well the plan is performing through checks and balances. |

| Compliance with FMSA | Track how well your company is meeting requirements set forward by FMSA | Develop and review custom plans to ensure you meet any compliance not covered above. |

Safe Quality Food (SQF)

The Safe Quality Food program is a global food safety initiative that provides a food safety and quality management certification system based on HACCP. This certification can involve all sectors of the food industry, including the manufacturers, the companies that transport the product, and the primary distributors. Companies implementing the food safety management software can proudly display their SQF certification to let customers know they provide safe products.

The benefits of SQF include managing risk, maintaining current customers, increasing your market reach, and preparing for new regulations that may come about.

Most food traceability software that will assist you with HACCP audits will help you adhere to the latest version of the Safe Quality Food Code (Edition 8). This is accomplished through built-in quality procedures that can enforce quality audits at different points of your food production or distribution cycle. It can also include in-depth inventory picking (such as picking first-expired goods).

Like many of the above-mentioned regulatory resources, SQF certification demonstrates a commitment to providing quality throughout the food production and distribution process, which starts with accurate record-keeping and transparency in your methods.