The Best MRP Software

Materials requirements planning (MRP) software helps you efficiently manage the materials, inventory, and production processes needed to meet customer demands. We reviewed the top systems for various industries, including job shops and food and beverage manufacturers.

- Affordable pricing

- User-friendly interface

- Integrates with Xero and Shopify

- Detailed cost reports with access to historical data

- Enhanced job costing

- Logical database structure

- Recalls and mock recalls are easy to perform

- Greatly increases the ability to fill orders

- Wide variety of reports

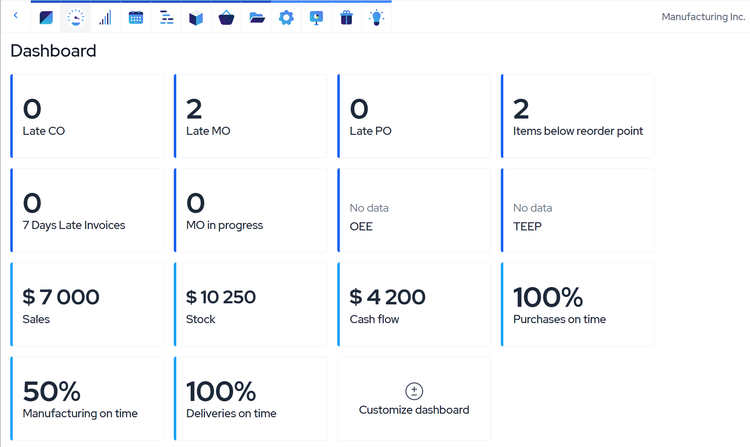

We evaluated the most popular products on the market with features like production scheduling, batch tracking, and multi-level BOMs. We used our advanced review methodology to select the best systems.

- MRPEasy: Best for Small Businesses

- JobBOSS²: Best for Job Shops

- Mar-Kov: Best for Batch Manufacturers

- xTuple: Best for Discrete Manufacturers

- Katana MRP: Best for Food and Beverage Manufacturers

- Total ETO: Best for ETO Manufacturing

- SOS Inventory: Best for QuickBooks Users

- Fulcrum Pro: Best for Metal Fabricators

- Fishbowl: Best for Mixed-Mode Manufacturers

- MISys: Best for Pharmaceuticals

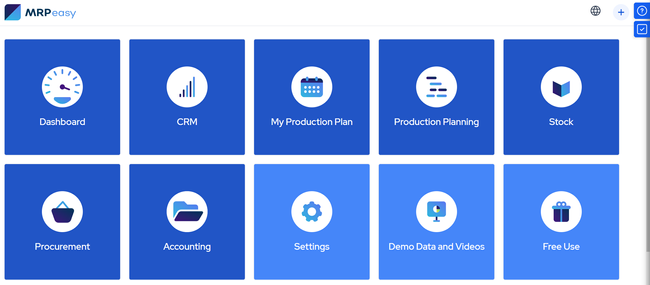

MRPEasy - Best for Small Businesses

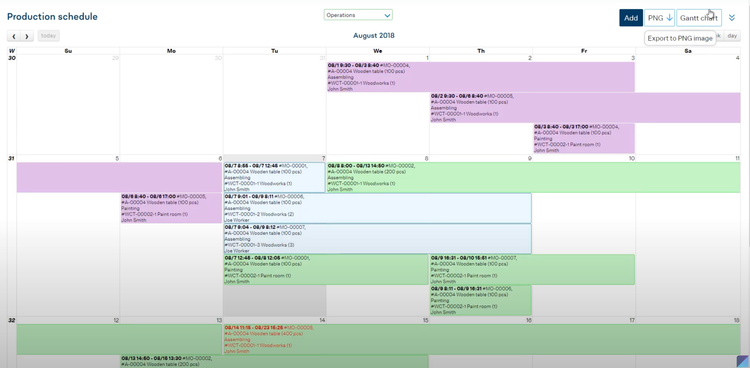

MRPEasy’s production scheduling allows you to easily adjust timelines by dragging and dropping tasks, offering you more flexibility to respond to production priorities. The capability consolidates input from order management, inventory levels, and resource availability.

For example, maybe you’re a small furniture manufacturer who receives an influx of orders for chairs and tables near the holidays. You can manually enter the purchases into the system when they come through. Then, MRPeasy will automatically check available resources such as wood inventory, machine time, and workforce capacity.

The system will create a production schedule and allocate specific tasks for cutting, putting the pieces together, and applying the finishing touches. If a supplier delays a shipment of wood, you can use your drag-and-drop tool to adjust the schedule to prioritize chairs while waiting on the materials needed for tables. The Gantt charts will show the adjusted timeline, ensuring clear team communication and preventing missed deadlines.

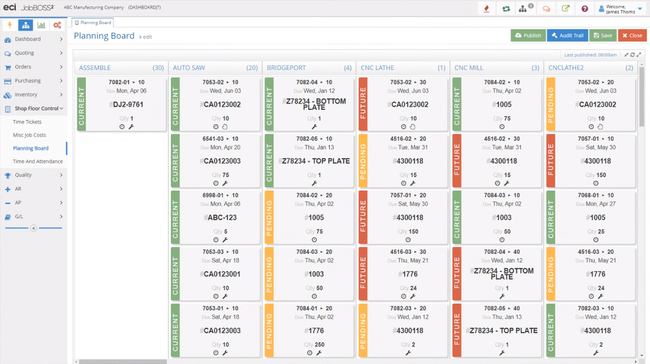

JobBOSS² - Best for Job Shops

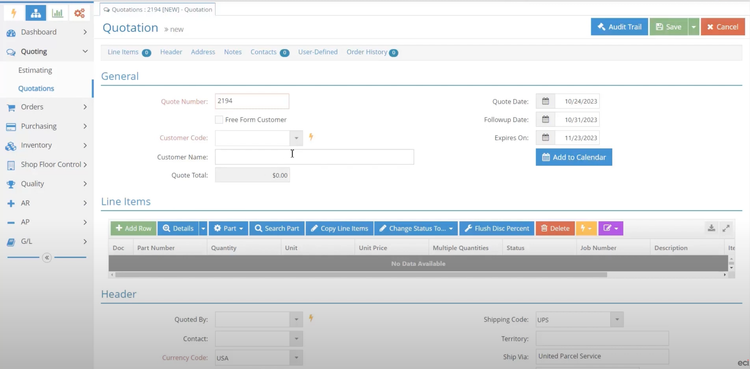

JobBOSS²’s job costing and quoting capability can automatically calculate expenses based on material usage, labor hours, overhead rates, and other variables.

For instance, maybe you specialize in custom metal fabrication and receive a request for 100 steel brackets that must be delivered within 4 weeks. You can input the job specifications into the system, including the material, dimensions, and finishing details.

JobBOSS² calculates the material cost by checking inventory and determining current steel prices. It will also estimate labor hours based on your shop’s historical data for similar jobs and add overhead costs.

The software checks on material lead times and will adjust the quote to include expedited shipping for steel since the deadline is tight. Once the system produces a quote, you can send it to the customer through its portal.

JobBOSS² costs around $3,000/year, which could be expensive for smaller job shops with limited budgets. If you’re looking for a more affordable option, check out our best job shop roundup to view your options.

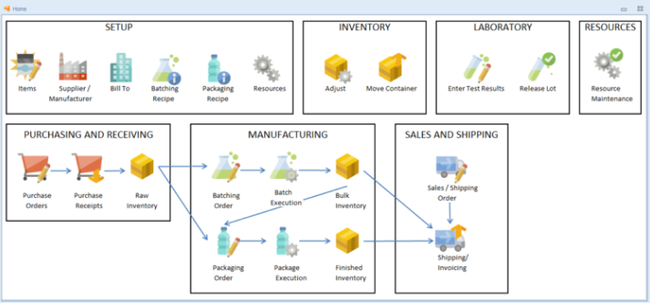

Mar-Kov - Best for Batch Manufacturers

Mar-Kov offers strong features for several types of batch manufacturers, including food and beverage, cosmetics, alcohol, and pharmaceuticals. Specifically, its formulation control module centralizes all your recipes and batch records in one place. This gives you a better handle on your production operations and ensures every batch meets your quality standards.

The formulation control module also includes full revision management, which is crucial for tracking every change to a recipe. When changes are made, the system displays costing information, helping you figure out the pricing for raw ingredients for each variation. Further, you can assign user-based access and roles so that only approved users can publish recipes or approve changes.

Mar-Kov’s formulation control module is part of its broad MRP suite, which fits the needs of batch manufacturers. With its detailed costing or end-to-end traceability with parent-child relationships, the system is well-suited for mid to large-sized companies. Pricing starts at $321/month, but you will need a custom quote for specific figures.

See our Mar-Kov profile for more info.

xTuple - Best for Discrete Manufacturers

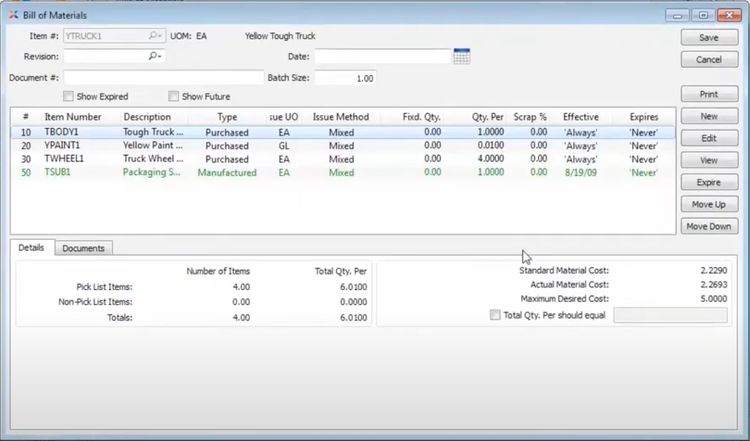

xTuple’s bill of materials (BOM) feature lets you effectively define and manage complex product structures. Whether you’re working with multi-level assemblies, subcomponents, or raw materials, xTuple keeps everything organized. It even auto-populates BOMs and routing steps for repeatable designs while allowing you to manually adjust for custom builds.

For example, a smart thermostat consists of multiple parts, such as a plastic casing, circuit board, and LCD screen. Each part has subassemblies, like the circuit board, which includes resistors, capacitors, and connectors. With xTuple, you can create a BOM for the smart thermostat and link it to the BOMs for the circuit board and other pieces.

Beyond materials, xTuple also tracks tooling like molds and machine parts without lumping them into inventory counts. Additionally, BOMs can enforce quantity requirements, which means that when you mix or assemble materials, everything stays in the right proportions. If something’s off, xTuple sends an automatic alert before it causes issues.

xTuple starts at around $175/user/month. The pricing can vary depending on whether you choose cloud or on-premise hosting and any additional support packages. Pricing is based on named users, with a five-user minimum for the manufacturing edition.

Katana MRP - Best for Food and Beverage Manufacturers

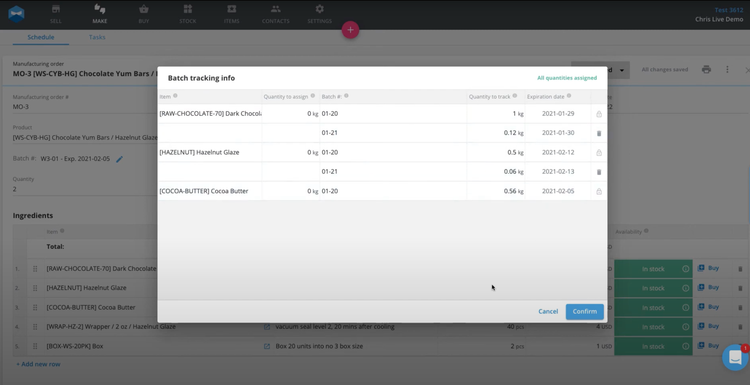

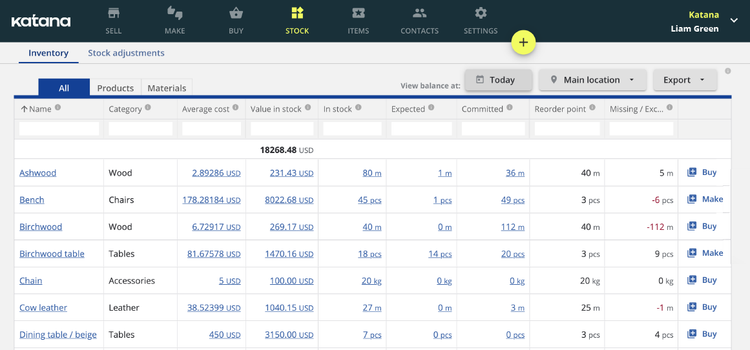

Katana MRP offers precise batch tracking capabilities that ensure your company maintains quality, safety, and efficiency throughout the production and distribution process.

When raw materials or finished goods are added to your inventory, Katana assigns batch numbers to each group of items. These batches can include essential details such as expiration and production dates. This can be beneficial if you often deal with perishable items, as batches with the earliest expiration dates are prioritized. Additionally, Katana can flag materials nearing expiration and notify you through its real-time inventory tracking system. The software can also track specific ingredients, which is crucial for managing allergens and meeting labeling requirements.

As items move through production, the software provides real-time visibility into each batch’s location, quantity, and status. In the event of a product recall, Katana enables you to identify and isolate the affected batches quickly, reducing waste, limiting disruptions, and preserving your brand’s reputation.

Total ETO - Best for ETO Manufacturing

Total ETO’s change order management feature simplifies the process of handling revisions and updates throughout the manufacturing lifecycle. This capability allows you to track and manage project alterations, documenting and communicating all changes in real time.

For example, you’re in the middle of a project and receive a client’s request to add protection features to a specialized machine, like safety guards. This change will require you to adjust the design and parts list.

You can add this request to Total ETO, which will analyze the cost and schedule implications of adding a safety guard. The software will identify the required components and recalculate the project timeline. This change will then route to your engineering and procurement teams for approval.

Once approved, the system will update the BOM with the new safety guard components and notify your procurement team to source additional parts. Your production team can integrate the safety guard into the build process, and the database will log the changes for future audits and client reporting. This capability lets your client receive their machine with the requested features without delays or miscommunication.

Total ETO requires a higher initial investment, starting at $7,500 annually. If you’re looking for something less costly, MRPeasy is our most affordable choice, with its price starting at $49/user/month.

SOS Inventory - Best for QuickBooks Users

SOS Inventory’s demand forecasting feature can help you predict future inventory needs based on historical sales data and trends. It provides insights for better planning and inventory management by ensuring the right products are available at the right time, minimizing overstocking and stockout issues.

Planning for the holiday season can be challenging, especially if you run a specialty food manufacturing company. During this season, you might see a spike in demand for festive products. If you’re a QuickBooks user, you can pull historical sales data from previous years to identify sales peaks and account for the seasonality of your business.

The demand forecasting feature will analyze the trends in your product sales. For example, it can recognize if there is a 15% increase in demand for gingerbread cookies starting in early December. The system will generate a forecast and recommend ordering a specific quantity of ingredients by mid-November to meet the expected demand. It can also align production schedules to ensure timely fulfillment of customer orders. SOS Inventory will adjust the forecast as new sales orders are recorded in QuickBooks.

With this capability, you can ensure you have your raw materials in advance, avoiding costly rush orders or lost sales due to shortages. It can also help optimize your inventory levels and reduce waste from overstocking during the holiday season.

SOS Inventory is a highly affordable solution starting at $64.95 per month. However, the system’s full potential is best utilized when paired with QuickBooks, as it is designed to complement and extend its capabilities. If you’re not a QuickBooks user, you might want to explore whether the system’s standalone features meet your specific needs.

Fulcrum Pro - Best for Metal Fabricators

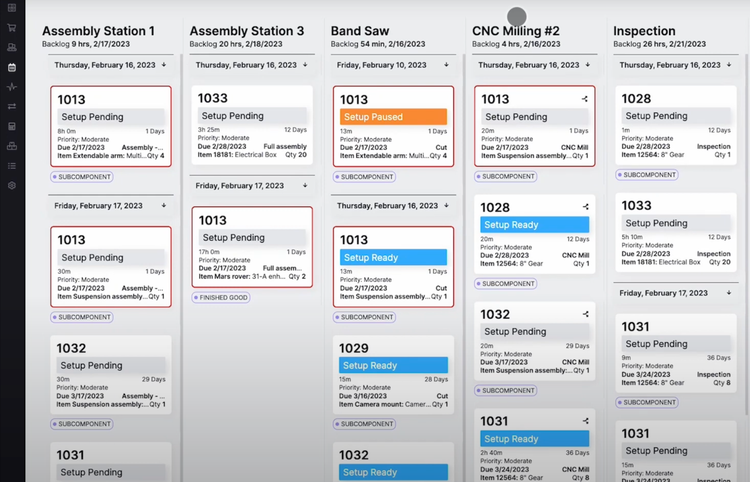

Fulcrum Pro’s dynamic scheduling feature optimizes planning and resource allocation by providing real-time visibility and flexibility in managing production schedules.

The dynamic scheduling functionality leverages real-time data from the shop floor and integrates it with production plans. For example, you specialize in custom steel parts and receive a rush order for 200 machined components needed in four days. Your team can enter the order into the system, where the dynamic scheduler will evaluate your current workloads, machine capacity, and labor availability. It will identify a CNC machine and two operators who can take on the job without significantly delaying existing orders.

During production, if a machine experiences downtime, the system automatically reassigns the job to an available machine to ensure that rush orders stay on track. If raw materials for a rush order are delayed, the scheduler can shift jobs around to fill the gap without leaving machines idle.

If there are any last-minute changes on your rush order, you can use a scenario simulation tool to assess how switching materials will impact your timeline. The system integrates real-time data, ensuring that the simulation is based on the most current and accurate information. Fulcrum’s pricing model involves unlimited users and an initial investment of $20,000 for configuration and implementation. This is followed by recurring monthly fees for cloud hosting, support, and updates, making it one of the higher-priced MRP systems.

Fishbowl - Best for Mixed-Mode Manufacturers

Fishbowl’s barcode scanning feature lets you instantly update inventory records when items are received, moved, or shipped. This real-time tracking can help reduce discrepancies and ensure accurate stock levels.

Fishbowl integrates barcode scanning with its stock and production management modules. You can assign barcodes to inventory items, work orders, and storage locations.

When raw materials arrive, your workers can scan the barcodes on the items, and the system will automatically update with the quantities received and assign them to designated storage locations. For machinery production, team members can scan components when they pick them for assembly. This ensures that you use the correct parts for each order.

As machinery moves through various stages of assembly, workers will need to scan barcodes at each step. This provides real-time updates on the work order status, ensuring efficient scheduling and tracking. You’ll scan the finished product for custom machinery, ensuring the right product ships to the customer. You can also scan barcodes on bulk containers or packaged goods for accurate lubricant order fulfillment.

However, one drawback we found with Fishbowl is that it may lack advanced features like recipe management for process manufacturing.

MISys - Best for Pharmaceuticals

MISys Manufacturing offers a raw material control feature that can help ensure compliance with stringent regulations and accurate inventory management.

If you’re a pharmaceutical company that produces a pain relief medication, you’ll likely find that the active ingredients include raw materials with strict expiration dates and quality standards. When a new shipment arrives at your warehouse, you’ll need to log the materials into MISys with their lot numbers, expiration dates, and supplier details. A quality control team will inspect the materials, and all non-compliant batches will be flagged and quarantined.

If a production batch is scheduled for the pain-relief medication, the system will allocate the oldest approved active pharmaceutical ingredients (APIs) that meet the required quality standards. The software minimizes waste by ensuring First In, First Out (FIFO) usage.

During production, the inventory team can monitor the real-time availability of APIs and other excipients through MISys. You will receive alerts if any raw materials are running low or nearing expiration, prompting timely reorders. The system also generates reports detailing APIs’ lot numbers, suppliers, and quality certifications, ensuring accurate compliance.

What is MRP Software?

Manufacturing resource planning (MRP), or material requirements planning software, helps streamline the manufacturing process through production planning, scheduling, and inventory control. Known as a leading type of manufacturing software, MRP systems allow manufacturers to plan and calculate material requirements, coordinate personnel and machine workloads, and optimally plan purchasing to meet customer demands.

Read more: What is Material Requirements Planning (MRP)?

Key Features and Benefits

At a high level, material resource planning software bridges the gap between demand and manufacturing capacity by ensuring materials are available when needed. Here are the core functionalities of MRP solutions.

| Feature | Description | Benefit |

|---|---|---|

| BOM Management | Manages and tracks raw materials, components, and sub-assemblies required for production. | Ensures accurate production planning and reduces assembly errors. |

| Demand Forecasting | Analyzes sales data, order history, and demand trends to predict future material and production needs. | Improves planning accuracy and minimizes excess inventory costs. |

| Production Scheduling | Aligns production activities with available materials and labor resources. | Enhances efficiency, reduces delays, and optimizes resource use. |

| Material Requirement Planning | Calculates needed materials and components based on production schedules, inventory levels, and lead times. | Reduces waste and ensures timely procurement, avoiding production stoppages. |

| Procurement and Supply Chain Management | Automates purchase orders and coordinates with suppliers for timely material deliveries. | Streamlines procurement, minimizes delays, and improves supplier relationships. |

| Resource Optimization | Allocates labor, machines, and materials efficiently to reduce idle times and bottlenecks. | Maximizes productivity and reduces operational costs. |

| Shop Floor Control | Tracks machine usage, downtime, and production efficiency with real-time reporting. | Enhances production visibility and minimizes equipment-related disruptions. |

| Equipment Maintenance Scheduling | Organizes and tracks preventive and critical equipment maintenance tasks. | Prevents unplanned downtime and extends machinery lifespan. |

| Production Cost Reporting | Produces detailed cost reports covering labor, overhead, storage, waste, and other expenditures. | Helps identify cost-saving opportunities and improves pricing strategies. |

| Inventory Management | Tracks raw materials, work-in-progress, and finished goods inventory to ensure optimal stock levels. | Prevents overstock and shortages. |

Latest Trends

IoT Integration

The Internet of Things (IoT) refers to connected devices that can collect, exchange, and analyze data through sensors and software over the internet. These devices can include anything from industrial equipment and smart sensors to everyday objects like wearables.

By integrating MRP software with IoT devices, you can gain valuable insights into your operations by tracking machine performance and inventory levels and identifying bottlenecks in the production process.

IoT-enabled sensors can monitor inventory levels in real time, pulling accurate data on raw materials, components, and finished goods. This helps ensure that MRP systems work with up-to-date information, reducing the risk of overstocking and stockouts.

With IoT, MRP systems can trigger automated purchase orders when inventory levels fall below a predefined threshold. This reduces manual intervention and ensures that materials are reordered promptly. These devices can also track shipments and supplier performance, allowing you to adjust schedules dynamically in response to delays or disruptions in the supply chain.

Artificial intelligence (AI)

AI refers to the simulation of human intelligence processes by machines. These include learning, reasoning, and self-correction. In terms of MRP systems, you can utilize AI to optimize production schedules, predict demands, and identify any potential problems.

AI can analyze historical sales data, market trends, and seasonality to accurately predict demand and help you plan production schedules and inventory levels. These systems can also enable dynamic scheduling by factoring in real-time changes such as supply chain disruptions, machine downtimes, and sudden shifts in demand. This ensures that your manufacturing schedules are optimized for efficiency and customer needs.

What’s the Difference Between ERP Systems and an MRP?

Enterprise resource planning systems (ERP) are large suites of tools that help plan and account for the resources of an entire organization. While incorporating some of the functionality of material resource planning software, these systems handle more of an organization’s data management, including customer relationship management (CRM), supply chain management, and accounting tools. ERP solutions can be fully integrated into an organization’s data operations to handle most major aspects of the business. Large companies often utilize it.

MRP, in comparison, is a narrow but highly specialized set of tools designed specifically for manufacturing purposes. More nimble than a full ERP suite, smaller manufacturers or businesses looking for complete control over their manufacturing often select MRP to oversee their manufacturing operations.

Read More: ERP vs. MRP: What are the Key Differences?

Pricing Guide

Like most software, pricing for MRP systems depends on several factors, like your user count, desired features, and deployment method. Here are some general cost ranges of what you can expect to pay and applicable systems based on your company size:

Low-Tier

- Company Size: 1-25 employees

- Average Annual Cost: $1,000-$8,000 per year

- Examples: MRPeasy, Katana MRP, Statii

Mid-Tier

- Company Size: 25-150 employees

- Average Annual Cost: $8,000-$50,000 per year

- Examples: Fishbowl Manufacturing, ECI M1, JobBOSS², xTuple

High-Tier

- Company Size: 150-500 employees

- Average Annual Cost: $50,000-150,000 per year

- Examples: MISys Manufacturing, Global Shop Solutions, Epicor Advanced MES

Enterprise

- Company Size: 500+ employees

- Average Annual Cost: $150,000+ per year

- Examples: Infor CloudSuite Industrial (SyteLine), Plex Manufacturing Cloud, IFS

Starting Prices for Systems

| Software | Best for | Deployment Options | Starting Price |

|---|---|---|---|

| MRPeasy | Small Businesses | Cloud | $49/user/month |

| JobBOSS2 | Job Shops | Cloud or On-Premise | $3,000/year |

| Mar-Kov | Batch Manufacturers | Cloud | $159/month |

| Katana | Food and Beverage Manufacturers | Cloud | $179/month |

| xTuple | Discrete Manufacturers | Cloud or On-Premise | $175/user/month |

| Total ETO | Engineer to Order | On-Premise | $7,500/year |

| SOS Inventory | QuickBooks Users | Cloud | $64.95/month |

| Fulcrum Pro | Metal Fabricators | Cloud | N/A |

| Fishbowl | Mixed-Mode Manufacturers | Cloud or On-Premise | $150/user/month for cloud WMS |

| MISys | Pharmaceuticals | Cloud or On-Premise | N/A |

The starting price of MRP software ranges from $49/month to $200/month. MRPeasy is our most affordable pick, starting at $49/user/month. Other options, such as Katana and xTuple, are a bit pricier, with costs starting near $180/month.

In a subscription model, you’ll need to consider the number of users, the level of included support, and any additional features with your base package. Other options may require more of an upfront investment. These solutions tend to be locally hosted and may include one year of support in the price. Ongoing costs will include future support and any additional services you may need for the software.