ERP vs. MRP Systems: What Are the Key Differences?

ERP and MRP software are essential tools many organizations use to streamline their operations and enhance efficiency. While they share some similarities in improving resource management and optimizing production processes, they cater to different aspects of business operations.

What is ERP Software?

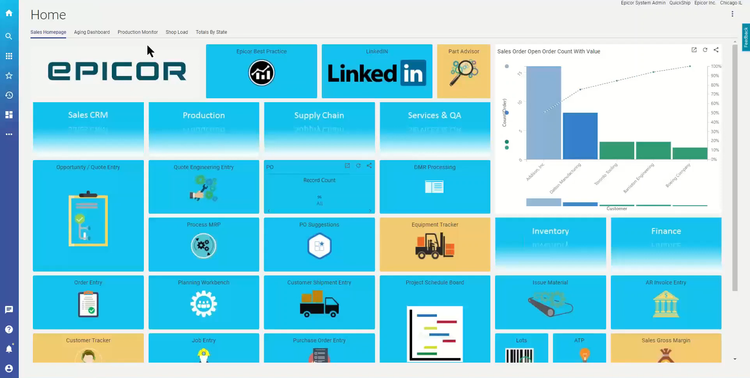

Enterprise resource planning (ERP) is a software suite that includes general business management tools for accounting, human resources, and inventory control. Its wide range of features makes it a popular solution for managing multiple departments within the same company.

With an ERP software, companies can optimize their business processes by streamlining work and using reporting analytics to inform better decision-making. This solution can be applied to just about any business, from small businesses to enterprise corporations.

Read More: What is ERP Software?

What is MRP Software?

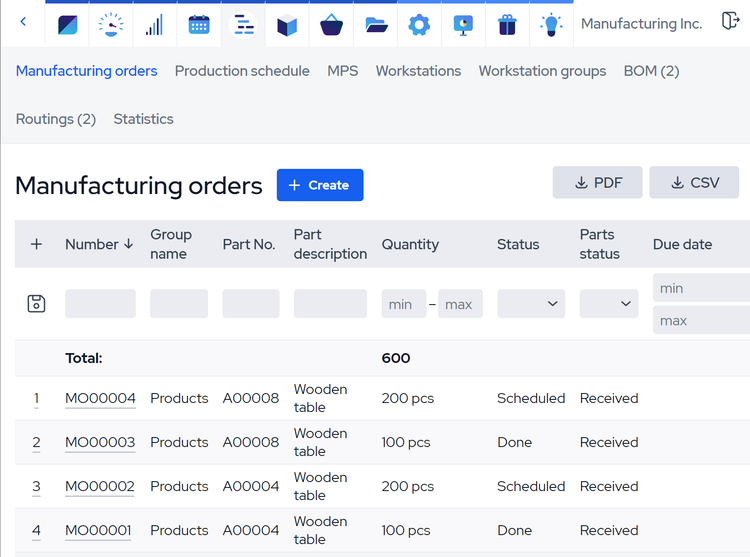

Manufacturing Resource Planning, also known as Material Requirements Planning, is a system used by manufacturing companies to manage and optimize their production processes through production planning, scheduling, and inventory control.

By using MRP software, manufacturers can plan and calculate material requirements before manufacturing begins, cutting down on raw material costs. Additionally, there are applications to coordinate schedules between labor and machine workloads.

Read More: What is Material Requirements Planning (MRP)?

Key Differences

Intended Users

Modern ERP systems can be customized to fit any industry, from apparel to automotive, higher education, and cannabis sectors. In contrast, MRP solutions are limited to the manufacturing industry but can cater to various fields such as aerospace, chemical, cosmetics, food, medical devices, and more.

Software Function

Since MRP is based on optimizing manufacturing processes, it includes modules for:

- Inventory control

- Production and maintenance scheduling

- Demand forecasting

- Shipping logistics

- Shop floor control

ERP, on the other hand, is based on applications used in office settings. Features include:

- Accounting

- Budgeting

- Human resources

- Inventory and supply chain management

There are some areas of overlap between the two. Both have tools to make product purchasing easier and inventory control measures. However, ERP modules streamline overall business operations, while MRP is focused on just one facet of the supply chain—the manufacturing process. Some ERP solutions include basic MRP functions.

Integration Possibilities

ERP software can be integrated into many other software suites to create a complete package of tools for optimizing business operations. However, larger ERP suites can take years to fully integrate into company processes.

MRP is made only for manufacturing workflow. While it can integrate with other systems, MRP is meant to operate as a standalone software. As a result, the system is far more limited than an ERP suite.

Implementation Costs

Since ERP systems are incredibly expansive in scope, they can be costly and time-consuming to implement. Exceptionally broad ERP suites can take years to properly set up. Some Cloud ERP implementations are faster, though they can cost more since they include monthly or annual subscription fees.

Due to their limitations, MRP systems are generally faster to install and more affordable. Training sessions may be limited to a few management positions, saving you even more time and money. Once implemented, you can quickly get the system running and shorten your lead times.

What is an ERP MRP System?

While there are differences between the two software, they also share significant similarities, where some software have fallen under an ERP MRP category label. This covers ERP systems designed for manufacturers and includes modules more associated with that industry’s needs. Some MRP systems offer the additional functionality of an ERP. Both of these can be called ERP MRP software.

Which Resource Planning Software is Right for Your Business?

Usually, the type of software system you need depends on your business type. If you need a way to automate back-office functions, an ERP is best for you. If you need to improve manufacturing processes, MRP software will help. And even if you are a manufacturing company, you can still utilize an ERP.

Need an ERP or MRP system? Get free recommendations from one of our software advisors.