The Best Yard Management Software

The best yard management software offers tools for gate scheduling, trailer tracking, and real-time yard mapping. We evalutated the top systems for warehouses, distribution centers, and yard operations of all sizes.

- Real-time data and reporting tools

- User-friendly interface

- Mobile compatibility with iOS and Android devices

- Dock Scheduling module controls loading and unloading

- Quick setup and rapid integration

- Significant time savings for users

- Real-time supply chain visibility

- Advanced features available to increase functionality

- Real-time supply chain visibility

Shipping yards are one of the most important parts of the global supply chain. These yards may serve cargo ships, freight trains, trucks, or a combination of transportation methods. Each hub is where new goods arrive from manufacturers before getting sent on to retailers all over the world.

Using our review methodology, here’s our picks for the best yard management software:

- YardTrac Pro: Best Overall

- GoRamp: Best for Transportation Management

- FourKites: Best for Supply Chain Visibility

- YardView: Best Mobile App

- Samsara: Best for Fleet Management

- Luminate by Blue Yonder: Best for Supply Chain Planning

YardTrac Pro - Best Overall

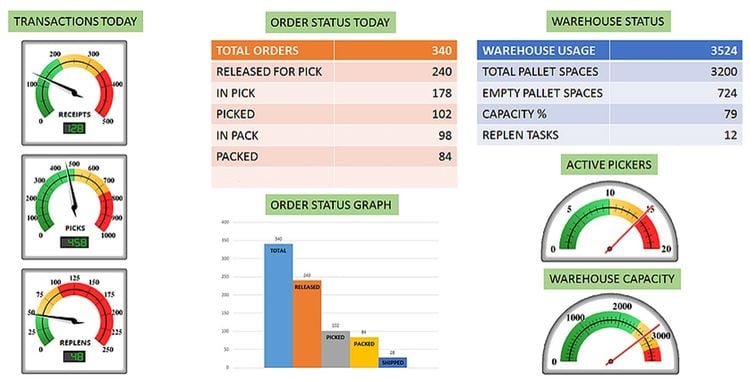

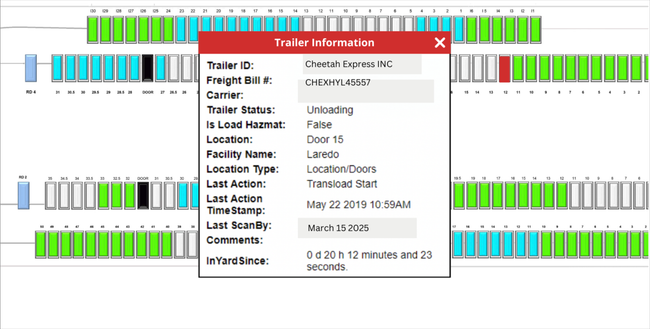

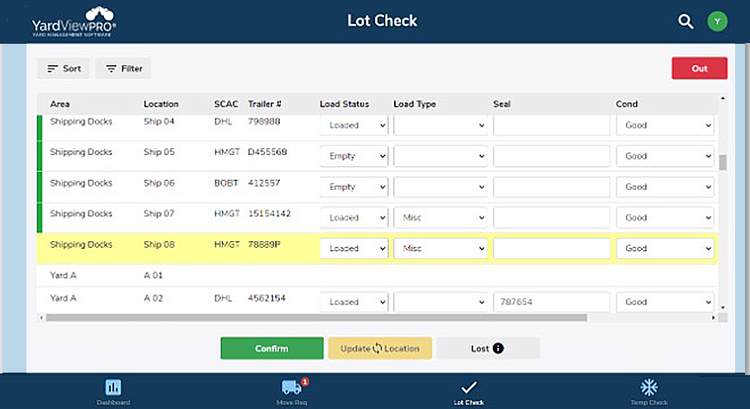

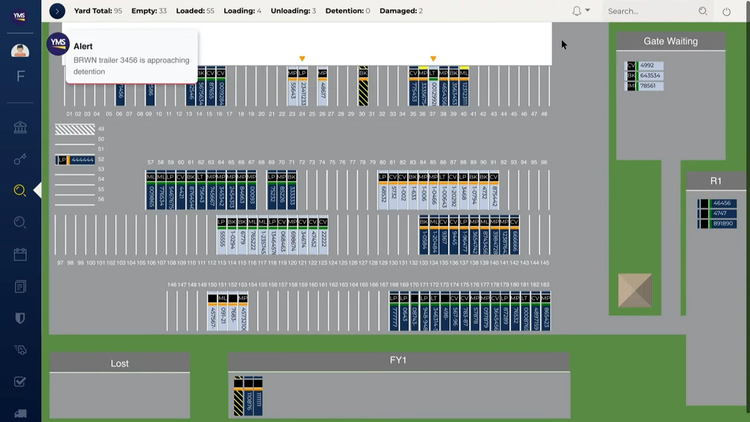

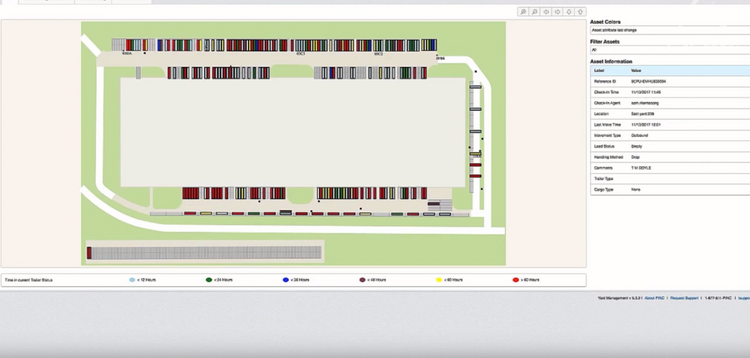

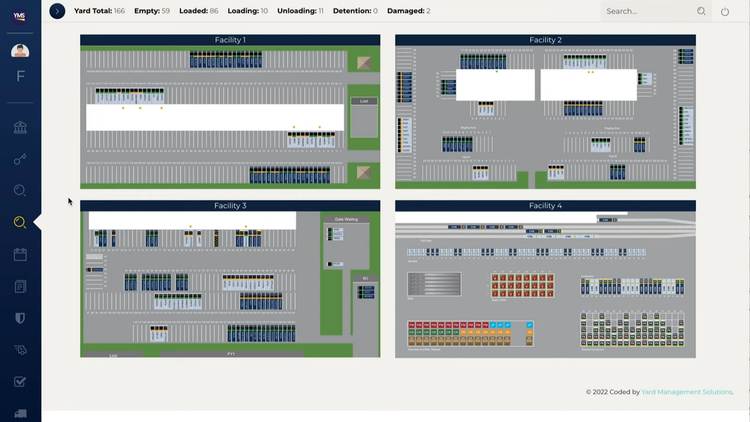

YardTrac Pro is a cloud-based yard management software built to give teams full visibility and control over their yard. It features an interactive map that shows trailer locations, availability, and movement history. The system works with both iOS and Android mobile devices, making it easy to use for teams in the field or right at the gate.

The standout feature of YardTrac Pro is its ability to optimize dock scheduling automatically. The system monitors inbound and outbound trailer activity and dynamically assigns dock doors based on appointment times, door availability, and the load type. Instead of relying on static schedules or manual coordination, YardTrac Pro adjusts on the fly, rerouting trailers when delays occur and automatically notifying teams of early or late arrivals. This ensures the yard has faster turnarounds and fewer bottlenecks.

To receive fully automated yard and dock management, the system must integrate with required hardware like cameras, RFID tags, and readers. So, expect additional setup costs for hardware for fully automated and advanced setups. Also, pricing for YardTrac Pro is not listed publicly and requires a custom quote.

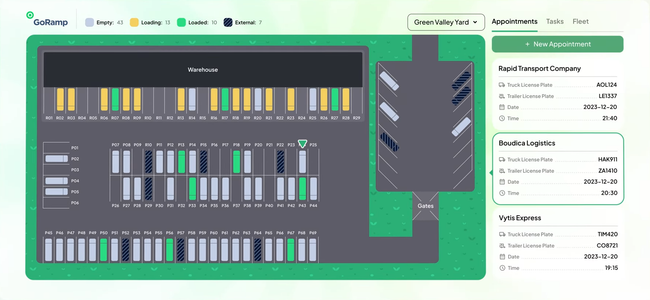

GoRamp - Best for Transportation Management

GoRamp, is a transportation management and dock scheduling software, for streamlining logistics operations at shipping facilities and docking yards. The Dock Scheduling module helps it stand out by optimizing warehouse workflow and controlling loading and unloading.

The SaaS cost of GoRamp starts at $250 per month. Total pricing depends on the quantities of orders or warehouse loading docks. While there is no free version, a free trial is available for users to test out.

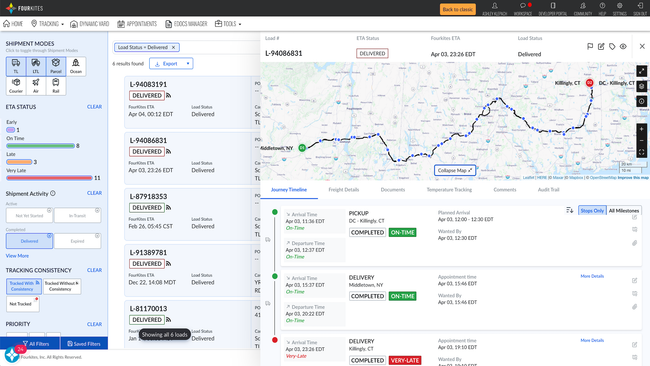

FourKites - Best for Supply Chain Visibility

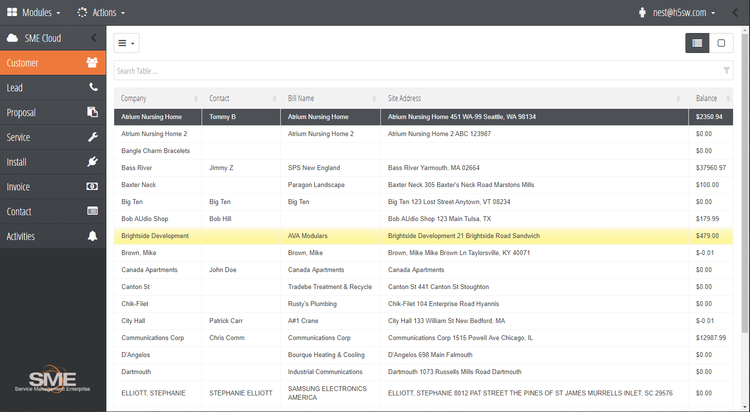

FourKites is a full service supply chain management and visibility platform that has advanced features and capabilities including yard management. It assists shipping businesses of various sizes in managing warehousing, yard management, procurement, OTIF compliance, sustainability, and more.

The FourKites platform includes several advanced features like appointment scheduling, document management, network visibility, freight tracking, and workflow automation. These optional features, combined with predictive capabilities like ETA prediction through weather and traffic analysis, make FourKites a powerful tool for yard management.

YardView - Best Mobile App

YardView is another of our top YMS picks. Its cloud-based nature ensures real-time visibility into yard activities from any device at any time, making it a flexible solution for modern logistics needs. Users on-the-go gain full visibility into asset location, trailer contents, gate and dock management, and driver move coordination.

YardView’s subscription pricing model includes unlimited users and transactions, even offering access to carriers, customers, and other partners. And implementation is notably quick, averaging four weeks or less.

Samsara - Best for Fleet Management

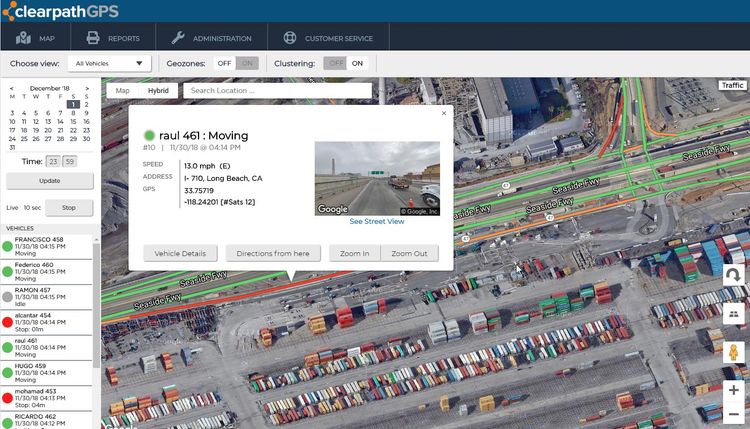

Samsara advanced tracking, safety features, and driver management tools make it a strong candidate for businesses looking for a comprehensive yard management solution. These features are particularly beneficial for large fleets, as they streamline maintenance management and enhance operational efficiency. Samsara’s strong focus on driver safety includes various tools for tracking driver performance and encouraging safer driving habits.

Beyond driver safety and performance, Samsara offers shipment tracking capabilities with a 30-second refresh rate, detailed fleet reports, and the ability to optimize routes automatically. And the fuel management capabilities, including reports on fuel usage and idling time, help in optimizing fuel consumption and reducing operational costs.

Luminate by Blue Yonder - Best for Supply Chain Planning

Luminate by BlueYonder includes tools for yard management as part of a larger supply chain planning platform. Some of these features are on-demand fulfillment and forecasting for more accurate inventory management.

The Luminate platform uses both artificial intelligence and machine learning to improve predictions and prevent disruptions to the supply chain.

What is Yard Management Software?

Yard management software is a scheduling and inventory management solution suite for the shipping industry. This type of software helps yards automate and optimize the flow of inbound and outbound assets. And real-time visibility lets users monitor and audit shipping loads to meet compliance regulations.

Yard management systems (YMS) have several similarities to transportation management software (TMS) as it provides logistics for vessels, trucks, and other modes of distribution. A YMS goes further to provide complete control of incoming and outgoing inventory. Whether you operate a full port of entry or a single shipping yard, you can benefit from yard management software.

Yard Management Software Functionality

- Dock Scheduling Logistics: Make a timeline for inbound and outbound vessels to prevent delays.

- Manifest Management: Keep important documents like cargo manifests in one easy-to-access location.

- Transportation Logistics: Manage all inventory transportation in and out of your yard. May include some fleet management tools.

- Shipping Load Auditing: Meet operation compliance by monitoring and auditing cargo as it arrives at your yard.

- Traceability: Use barcodes or RFID systems to track products in warehouses, trucks, or vessels.

- Inbound and Outbound Coordinating: Ensure every inbound vessel or vehicle knows where to go. Give clearance for trucks to leave and ensure moored vessels know when they can make way.

- Weather Reports: Get the latest weather conditions to keep yard operations safe and predict possible delays.

Benefits of Yard Management

There are many benefits to using yard management software, including:

Delivery and Distribution Coordination

Working in a shipping yard means dealing with a lot of different levels along the supply chain. You have to maintain clear communication with individual ship captains, local suppliers, delivery drivers, and your own team of dock workers. If you don’t keep everyone on the same page, you could end up with late or missing shipments.

Scheduling tools make it easier to create a timeline for arriving and departing cargo. If there is a sudden delay, you can generate an updated timeline and find ways to make up for lost time. For example, if stormy weather causes ships to arrive late, you can quickly edit the schedule to accommodate incoming vessels. Or if a truck has a flat tire, you can account for that too.

Warehouse Management Integration

Many ports are surrounded by warehouses to store cargo before it is distributed to its final destination. You need to make sure any onsite warehouses are not operating overcapacity. Otherwise, your entire port operation could be in violation of safety protocol. Warehouse management programs help you balance incoming inventory against what is being distributed.

A full warehouse is more than just a safety concern - it’s a lost opportunity to accept more inventory. If you operate wharf warehouses, you can use inventory optimization solutions to increase warehouse capacity and take on more shipments.

Faster Transportation with Cheaper Fuel Costs

Shipping is incredibly expensive due to rising fuel costs for both cargo carriers and trucks. Transportation management lets you control all inbound and outbound freight logistics at your yard. Plan optimized routes for truckers in order to cut down on mileage and save on fuel. And use in-depth analysis to find cost-effective ways to consolidate shipping loads.

Automated Asset Flow

Even small wharves can bring in thousands of assets a day. If you’re relying on handmade spreadsheets to keep shipments in order, you’re putting your entire yard at risk for errors. You don’t want to find out your warehouse is at full capacity after accepting a new shipment. An automated system can do all the work for you to reduce mistakes.

Another benefit of automated flow is scalability. Track individual trailers or entire intermodal containers from one dashboard. Graphical yard view tools let you see your entire yard with an eagle-eye view. Know where trucks are or which berths are available in real-time.

Auditing for Shipping Compliance

As an industry based around importing and exporting goods, cargo ports have to follow U.S. Custom and Border Protection regulations. You’ll need to ensure your cargo manifests and inventory levels are accurate in case of a CBP inspection.

In addition to CBP requirements, the shipping industry has to deal with union rules, OSHA regulations, and occasionally maritime law. Document management modules organize and protect all your important records digitally.

Mobile Weather Apps

Bad weather can mean a bad day on the wharf. Severe storms can prevent inbound vessels from arriving and delay moored ships from leaving. Even strong winds on an otherwise fair-weather day can put a stop to crane operations necessary for loading and unloading cargo. These weather delays can add up to thousands of dollars in lost fuel costs and missed deadlines. Weather tracking modules within your yard management software can provide real-time updates on possible weather problems.

How Much Does Yard Management Software Cost?

Yard management software typically ranges from $300 to over $2,500 per month, depending on deployment size, depth of features desired, and complexity of automation. Most systems are offered as SaaS with a small number of enterprise-level platforms providing perpetual licensing. Below are estimated pricing tiers for yard management software:

Yard Management Software Pricing Tiers

| Tier | Estimated Monthly Cost | Ideal For | Key Features |

|---|---|---|---|

| Basic | $300–$700 | Small yards, single location | Manual move logging, yard map, basic reporting |

| Standard | $700–$1,500 | Midsize yards with light automation | Dock scheduling, mobile access, trailer tracking |

| Advanced | $1,500–$2,500 | Large multi-yard operations | Real-time yard visibility, integrations, automated workflows |

| Enterprise | $2,500+ | High-volume yards with full automation | GPS/RFID tracking, camera integration, dynamic dispatching |

Additional Costs

For fully automated yard systems, software is just one part of the investment. Expect additional hardware costs for capabilities like:

- GPS tracking: For real-time trailer or asset location tracking

- Cameras: To verify trailer movements and gate events

- RFID hardware: For fast, contactless, and automated identification of trailers and assets

- Network infrastructure: Required to support wireless sensors and devices

- Installation and maintenance: One-time setup fees plus recurring service or calibration fees

Common Yard Management Problems

Yards face a lot of difficult issues, especially if they work with more than one mode of distribution:

Broken Down Trucks

It’s an unavoidable rule of the road: vehicles break down. Tires go flat, engines fail, and accidents happen. Fleet management software can help you stay ahead of maintenance to prevent possible breakdowns in the future.

Too Many Inbound or Moored Vessels

Ships may need to stay moored for a few days in order to refuel and take on new cargo. Unfortunately, that means you’re no longer able to accept inbound ships until a berth becomes available.

For example, imagine a large dry bulk carrier and a slightly smaller reefer ship are scheduled to arrive at the same time. Yet you only have one general berth available because moored vessels. Can you turn away ships with perishable goods? With a scheduling application you won’t have to. Add in real-time data to estimate which outbound ship is due to leave next so you can get another berth ready.

Weather Delays

The shipping industry is dependent on favorable weather conditions. A big storm could delay vessels for days, leading to multiple cargo ships arriving all at once. Soaring temperatures could cause reefer ships to expedite their shipping schedule. A mobile weather app can keep you informed of daily and long-term weather forecasts so you can prepare for any changes in shipping patterns.

Cargo Examinations by US Customs

Another major headache for port operations is delays from US Customs inspections. CBP has hundreds of laws meant to protect national and international legal trade. One way they do this is through cargo examinations. While this is meant to ensure cargo manifests are accurate, they can also cause delays if the CBP agent takes a long time to finish their inspection.

Yard management software lets you keep records on cargo manifests. You can use your documentation to help speed up examinations.