What is RFID and How Does it Work? RFID Use Cases

What is RFID?

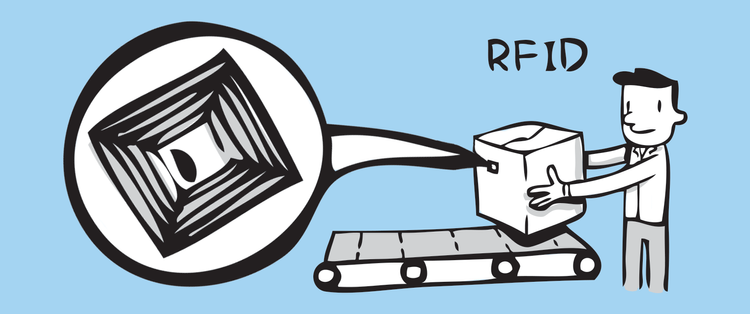

Radio-frequency identification (RFID) is an automatic identification technology that uses computer chips and radio. It comes in the form of tags, which are small computer chips that can be attached to items and used in place of bar codes. The tags have built-in sensors that communicate and are identified by readers. RFID technology encodes data into the RFID tags and labels that a reader can capture via radio waves. These can be managed using RFID software.

It is often used for tracking inventory, supply chain management, and access control. RFID has been around for decades but has only recently become viable for commercial use. Now, it is used in many industries, from retail to healthcare. While it is a useful technology, certain privacy and security concerns must be addressed. Such concerns need to be kept in mind, especially when implementing RFID tracking in supply chains.

History

RFID was first invented in the 1950s by George Wilder, who worked for General Electric as an engineer. Wilder wanted to create a system to help track inventory within manufacturing plants. He thought that existing technologies, such as barcodes and paper tags, were too burdensome and costly. In the years following, there were many failed attempts at implementing his ‘radio-frequency identification’ idea. However, in the mid-1990s, Japan’s automobile industry began to invest heavily in RFID research and development. This led to the creation of the first commercial RFID chips in 1999.

From the beginning, RFID technology displayed a certain knack for versatility. The earliest RFID tags tracked just about as varied a group of items as possible: keys, cows, and nuclear waste. Since then, engineers have further refined the technology–providing an abundance of RFID tag size, data storage, and power options.

Types of Frequencies

RFID systems can be categorized into low-frequency (LF), high-frequency (HF), and ultra-high frequency (UHF) bands. This refers to the radio waves and how they behave, each with advantages and disadvantages. For example, low-frequency RFID provides a short read range and slower read speed but is less sensitive to interference. The higher frequency gives a longer range and faster read speed but also makes the system more sensitive to interference.

The biggest users of RFID are in the world of warehouse management and shipping operations. The technology can accurately track inventory in real-time with fully automated tools that offer greater efficiency, accountability, and management capabilities. This ensures that packages can be handled properly and routed to their correct destinations.

How it Works

RFID technology uses radio waves to read and identify items and transmit data. An RFID system includes a computer, an antenna, and an RFID reader or scanner. The process follows these steps:

- The reader sends radio waves picked up by a nearby RFID tag.

- The RFID tag is a small computer chip with an antenna that sends its information back to the reader.

- The reader processes the information received from the tags and sends it to the computer database.

- The computer keeps track of the information from all of the nearby RFID tags and can be used to automate operations such as inventory management.

Because RFID uses radio waves to communicate, RFID tags only need to be within the read range of the reader to work—meaning RFID doesn’t need a line of sight. This provides a huge advantage over a barcode reader, which must be in direct contact with a barcode in order to pick up on the data within the barcode itself.

What used to involve scanning individual barcodes on items as they were removed from inventory could potentially become a situation where an entire pallet of items moves through an RFID scan zone, allowing all items to be scanned simultaneously.

What are RFID Tags?

RFID tags are small computer chips with an antenna that can be attached to items to track them. Tags are programmed with a unique identification number that an RFID reader can read. RFID tags can be embedded in products, animals, or people and are often used in place of barcodes. RFID tags are made of an integrated circuit, a tiny microchip, and an antenna. The chip stores data that can be transmitted to a computer. The antenna picks up radio signals from an RFID reader.

There are two primary types of RFID tags: Active RFID tags and Passive RFID tags.

- Active RFID tags are continuously operating via battery power. These tags are usually larger, making them more suitable for larger assets and giving them a longer read range. Active tags are used in more rugged environments or in industries commonly found outdoors, such as oil, gas, construction, and mining.

- Passive RFID tags don’t have an internal power source- the RF waves from the RFID scanner itself power them instead. These tags are smaller and far less expensive than Active RFID tags. They are best used on smaller assets and are more commonly found in indoor environments such as healthcare, manufacturing, and retail.

What are RFID Readers?

RFID readers are devices that read RFID tags and transmit the data to a computer. There are two types of readers: active and passive. Active readers use their own power source and emit their own radio waves that are picked up by nearby tags. Passive readers don’t have their own power source. Instead, they receive and decode radio waves from nearby active readers. RFID readers are often used in supply chain management. They are used to track items from the manufacturer to the end-user. They are also used to track livestock, pets, and people. RFID readers can also be used to gain access to secure areas. They can be used in place of a physical ID card.

Use Cases

RFID is an ideal building block technology. Simple, scalable, and inexpensive, RFID adopters are leveraging the technology to answer the questions of “what is it” and “where is it” in an ever-expanding set of instances.

Some common RFID use cases include:

- Retail: 100% inventory coverage and cashier-less, checkout-free stores. Retailers can add RFID tags to their inventory to improve inventory accuracy and reduce stockouts. RFID tags can also be used in smart grocery stores that offer no-wait checkout by tracking and billing for items placed into the shopping cart.

- Construction Sites: Smart belts to increase worker safety. RFID tracking devices can clip to workers’ belts and help ensure managers can contact them when needed. They also help register if a worker slips or falls, alerting safety managers who can make sure aid arrives quickly. Workers can also use the devices to notify managers of safety issues they encounter.

- Airlines: Customer visible real-time luggage locations. Fliers who check bags can receive mobile notifications as bags are loaded onto and off airplanes and when they reach carousels for pickup.

- Warehousing: LED-guided order picking. Helps pickers find items faster, reducing errors in the process. Real-time location-aware systems that track both the picker and items on the pack list can help toggle LEDs for aisles and bins, literally lighting the way for pickers.

- Hospitals: Take-one-leave-one system for staff scrubs, medication management, optimizing traffic flow in hospitals, and monitoring sophisticated equipment. RFID-equipped devices can distribute and monitor medical-procedure uniforms, which reduces the tendency of staff to treat scrubs as disposable.

- Child Safety: A lanyard alternative to GPS. RFID technology helps track children by wearing a lanyard and holding a card embedded with an RFID tag. Stationary tag readers can record when the child passes by and send a message to a parent’s phone to inform them of the child’s location. Police officers can use a handheld reader to scan the card and contact the parents to reunite the family quickly.

- Fashion: Smart fitting rooms from retailers outfit dressing rooms with interactive, RFID-powered kiosks. By scanning dressing room items, shoppers can access product data, find similar alternatives, and provide feedback.

- Credit cards: Contactless payment using near field communication (NFC) for efficient transactions. They implement heavy security measures to ensure information safety.

Security Risks

While widely used, RFID does pose some security risks. Because it uses radio frequency technology, it is possible that the tags are vulnerable to interception by unauthorized readers that intercept the signal. This is heightened by the fact that the frequencies can be transmitted over long distances and that you don’t have to see the tag to access information.

Despite these concerns, RFID tags are generally considered to be very safe to use. Most modern RFID devices have secure systems in place for storing sensitive information. These can include one-time codes to complete transactions and encryptions.