Datatex NOW ERP

4 Reviews 5/5 ★ ★ ★ ★ ★An ERP system for the textile and apparel industry that offers inventory management, production tracking, and traceability.

Product Overview

NOW ERP from Datatex is a management software suite specifically designed for the textile and fashion industry. It stands out for its flexibility in adapting to various business processes and its ability to handle the unique demands of the sector, such as managing a diverse range of products.

The software employs object-oriented technology, allowing for dynamic integration and traceability of business processes from the fiber stage to the final product. It’s scalable, allowing companies to start with necessary modules and expand as they grow. It integrates advanced web standards like Jakarta EE, web services, and XML for Industry 4.0 advancements.

Pros

- Scalable modular implementation

- Flexible business process adaptation

- Industry-specific features for the apparel industry

Cons

- Complex for non-textile sectors

- Potential high customization demand

Target Market

Companies in the textile and fashion industry, especially those looking for a solution that offers flexibility, scalability, and detailed control over various business processes. It’s particularly well-suited for companies seeking to manage a wide variety of products, ensure short delivery times, and maintain lower costs.

Key Features

Order Management

- Sample Development: Various stages, bill of material, final approval.

- Order Receipt: Quantity by color/size, price confirmation, and time of entry in the system.

- Planning: Production and material planning.

- Procurement: Purchase orders, material receipt, quality checks, issue to production.

- Production: Laying, cutting, bundling, sewing, quality inspection, finishing.

- Packing and Loading: Assortment packing, carton sticker printing, container loading.

- Invoicing: Customer invoicing.

User-Defined Item Code Structure

- Item Type Definitions: 10 Sub-codes, primary/secondary, mandatory/non-mandatory.

- Item Natures: Products, containers, tolls, recipes, designs.

- Multiple UM Handling: Independent product conversions.

- Sub-codes: Customer/supplier/sizes/user group.

- Product Approval: Approval process and quality levels.

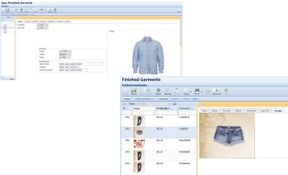

Merchandising

- Order Types: Made-to-stock/order, forecast/open/confirmed orders.

- Customer Handling: Multiple customer management (bill to, ship to).

- Sales Order: User-friendly sessions, real-time availability check.

- Sales Management: Season, collection, channel management.

- Customer Management: Credit, claims, sales return.

Procurement Management

- Order Types: Open, normal with flexible schedules.

- Order Entry: Matrix, carton/box-based.

- Purchase Requests: Auto-generation linked to sales/reorder levels.

- Approvals: Multiple levels, value-based.

- Expense Management: Invoice booking, purchase block, MRN rejections.

Planning

- Planning Methods: Sales order, availability, mix model, project-based.

- Production and Purchase: Auto-generated demands and requests.

- Sales Order Impact: Adjustments to changes in sales orders.

- Demand Types: Firm and non-firm.

Scheduling

- Planning Boards: Multiple boards for various processes.

- Resource Handling: Manpower, tools, special machines.

- Scheduling: Semi-automatic, production order realignment.

- Planning Reports: Customizable structures and filters.

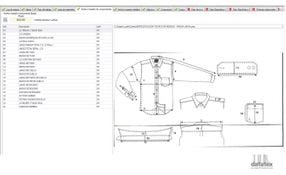

Production

- Cutting: Integrated with quality, marker generation, and bundle progress.

- Sewing: Progress tracking, rework handling, shift-based production.

- Washing: Recipe management, rejected/reworked quantity management.

- Finishing/Packing: Carton generation, packing calculations, numbering.

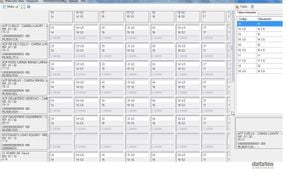

Inventory

- Single Click Inventory: Multiple locations/warehouses.

- Zone/Row/Rack/Bin Management: Definitions and control.

- Quality Levels: Multiple levels with the same product code.

- Stock Transactions: Easy search/filter, multi-product transactions.

- Integration: Barcodes, RFIDs, weighing bridges, readers.

- Warehouse Movements: Provisional and confirmed at all levels.

- Internal Orders: For inter/intra-warehouse transfers.

Product Overview

Developer Overview

Related Products

User Reviews of Datatex NOW ERP

Write a ReviewDatatex NOW ERP Review

it’s user friendly, very logic and comprehensive.

Pros

It's a tailor made solution, but base on best practices in the industry. very smart.

Cons

interface, a bit too flexible

- Internet Software & Services

- 51-250 employees

- Annual revenue $10M-$50M

Datatex NOW ERP Review

Financial module now available, fully integrated end to end solution , purchase to sales, fiber to garment.

Pros

Flexible dynamic solution for the industry.

Cons

Its perfect

Datatex NOW ERP Review

This one great ERP for SME business

Pros

It gives benifit to end user

Cons

Finance module need to develop

Real time integration & user-friendly interface

This is one of great soft ware for textile & apperal manuafacturing industry.

Pros

It gives real time integration any other soft ware & of cause user friendliness is main advantage of it.

Cons

finance module it need to implement further