Opcenter APS Review: Pros and Cons, Features

Opcenter APS excels in complex planning and scheduling for manufacturing operations, specifically in auto parts, food and drink, or tank farms. While it won’t be winning accolades for web-based functionality, its impressive capability to integrate with ERP and MES is worth noting, as is the on-demand CTP feature.

However, it may not be the best fit for new businesses or those operating with minimal data. Some might find its richness overwhelming. That being said, OpCenter APS is a solid choice, with strengths in managing complex manufacturing operations.

- Offers full API for ERP and MES integrations

- On-demand CTP (Capable to Promise)

- Handles complex planning and scheduling

- Not suitable for all manufacturing industries

- No full web-based option available yet

- Developer Preactor International

- Client OS Windows

- Deployment On-Premises

What is Opcenter APS?

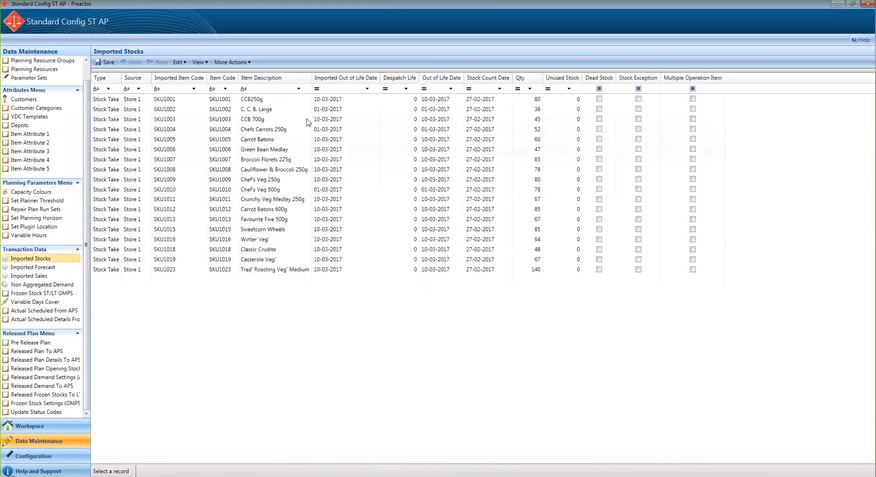

OpCenter APS, formerly Preactor APS, is an advanced planning and scheduling software that uses advanced machine learning to generate achievable production schedules. The software is highly configurable and can integrate with popular ERP and MES systems.

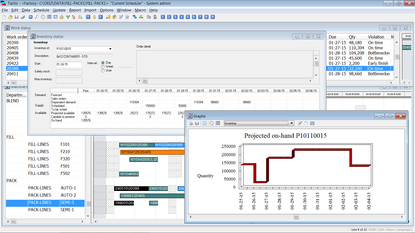

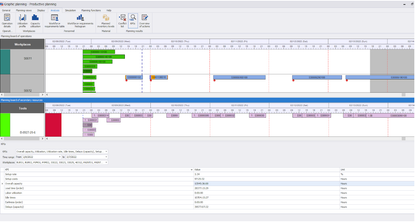

Key features include bill-of-materials level planning, order-based multi-constraint scheduling, advanced constraint modeling, and schedule optimization. It also provides visualizations of assembly processes and interactive schedule visualizations.

It facilitates resource and raw material management for both make-to-stock and make-to-order operations and allows for interactive adjustments to the master production schedule to meet changing demand requirements.

Our Ratings

| Usability - 7 | Very simple and intuitive interface; Aesthetically outdated interface. |

| Support - 8 | Technical support offered via ticketing system; Community support forums and tutorials; Knowledge base relies heavily on community forums rather than help guides. |

| Scalability - 7 | Great for companies of all sizes; Hybrid and full SAAS options; No full web-based application yet. |

| Security - 5 | Siemens 2023 data breach; Siemens 2020 critical vulnerability discovered; Brightly (owned by Siemens) data breach. |

| Value - 10 | Great value for price |

| Performance - 10 | Software is fast and responsive. |

| Key Features - 10 | Has all the features we would expect for this type of software. |

Who Is It For?

Opcenter APS is an excellent choice for companies in the manufacturing industry, especially those involved in producing auto parts and food and beverage products. It is particularly well-suited for companies with tank farms, as it offers complex planning and scheduling solutions that help avoid line transfers and other issues.

Although it may not be the best fit for companies just starting out or those with insufficient data, it is suitable for both small and large businesses. The company has worked with companies of all sizes over the years, from very small businesses to large enterprises.

Opcenter APS is an excellent tool for companies that need to improve their planning and scheduling processes. It is designed to make it easier for companies to plan and schedule production, and the latest release includes improvements to integration between planning and ERP software, which was a top customer request.

While the company is working on a web-based application, it is important to note that the current software offers high performance and is an excellent option for companies that require a high level of performance from their planning and scheduling solutions.

What Is The Difference Between OpCenter and OpCenter APS?

OpCenter is the software environment that includes different modules and products designed to support overall manufacturing operations management. It is a comprehensive solution that covers various aspects of the manufacturing process, including planning, scheduling, and execution.

OpCenter APS (Advanced Planning and Scheduling) is one of the modules within OpCenter. It focuses on production planning and scheduling, helping companies synchronize their production processes, increase visibility and control, and improve resource utilization and on-time delivery. It can handle complex scheduling scenarios and optimize production based on various constraints, such as equipment availability, labor skills, changeover times, and more.

OpCenter APS is part of Siemens’ broader OpCenter portfolio, which includes other modules and products like TeamCenter for product lifecycle management, Simcenter for simulation, and OffCenter for operation center management. Siemens has acquired various companies to build this portfolio and has renamed some of the products to align them under the OpCenter brand.

Pricing Plans

| Plan | Pricing | Description |

|---|---|---|

| Opcenter Planning | Pricing by Request | Strategic planning for long- and mid-term decisions. Supports forecasting, order feasibility, and production direction. |

| Opcenter Scheduling | Pricing by Request | General production scheduling with accurate models of the manufacturing environment. Ideal for optimizing workflows and resource use. |

| Opcenter Scheduling SMT | Pricing by Request | Specialized scheduling for SMT (Surface Mount Technology) environments. Focuses on order prioritization, resource allocation, and production efficiency. |

These products are part of the Opcenter APS suite but are licensed separately. Customers typically select one or more modules based on their industry needs. Opcenter scheduling is available in multiple tiers (Standard, Professional, Ultimate) to manage scheduling complexity.

Alternatives

Summary

OpCenter APS is ideal for manufacturing businesses, notably in the auto parts and food & beverage sectors, excelling in environments with tank farms by mitigating line transfers and similar issues. It caters to both small and large businesses, though it might not be suitable for startups, data-limited companies, or automotive assembly operations.

The software effectively enhances planning and scheduling processes and, responding to customer feedback, has improved ERP integration in its latest release. While not completely web-based, it offers on-premises, hybrid, or full SAAS, with a web application currently in development.

User Reviews of Opcenter APS

No reviews have been submitted. Do you use Opcenter APS? Have you considered it as part of your software evaluation process? Share your perspective by writing a review, and help other organizations like yours make smarter, more informed software selection decisions!