The Best Bill of Materials Software

Whether you’re a small or large manufacturer, bill of materials (BOM) software is essential in discrete production environments. We’ve reviewed top options for companies of all sizes, considering features like multi-level BOM support and version control.

- Robust integration with CAD tools

- Efficient real-time collaboration features

- User-friendly "Excel-like" interface

- Configurable using low-code embedded solutions.

- Integrates customer feedback with product insights.

- Embedded analytics.

- Affordable pricing

- User-friendly interface

- Integrates with Xero and Shopify

Using our review methodology, we evaluated platforms based on performance, value for money, and key features like product lifecycle management and quality control.

- OpenBOM: Best Overall

- Oracle Fusion Cloud PLM: Best EBOM Tool

- MRPEasy: Best for Small Businesses

- Fishbowl: Best Inventory Integration

- Katana MRP: Best for Production Planning

- Arena PLM: Best for Product Lifecycle Management

- Master Control: Strong Regulatory Compliance

- PDXpert: Great Engineering Collaboration

- Total ETO: Best for Custom Manufacturing

- Craftybase: Best for Small Batches

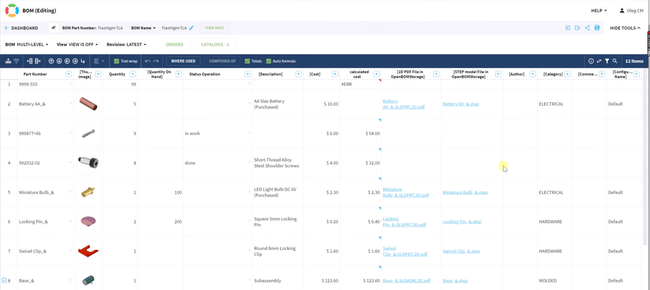

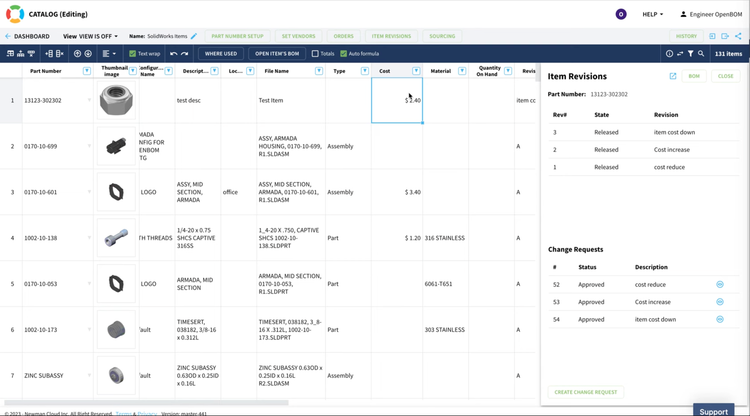

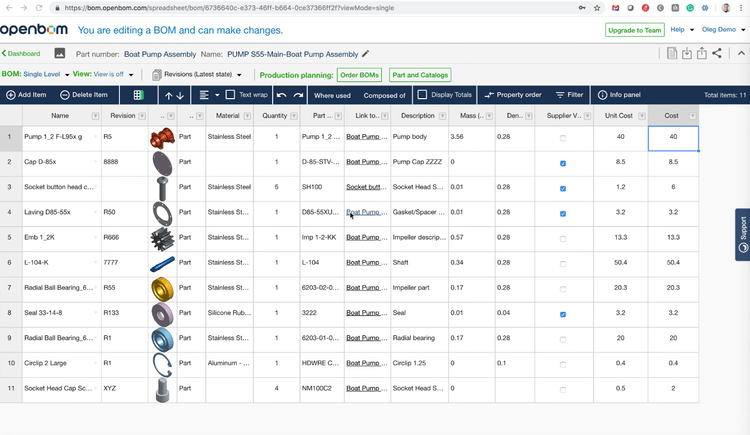

OpenBOM - Best Overall

OpenBOM’s change management tool helps manufacturers control complex BOMs during new product development. Click on any item in the BOM to see its entire revision history and whether the change was released or declined. You can also create a new revision by simply changing one of the fields, such as cost or total number. The system automatically captures any change to an item or BOM, helping you easily track every version.

For more control, you can configure role-based approval workflows. Create permissions that allow some users to submit requests but not outright changes to items or BOMs. The system then notifies management or engineers to allow efficient approvals. The change status is public on a collaborative dashboard, so everyone can see the current progress of revisions. This allows for more collaboration between teams and helps improve the accuracy of your BOMs.

OpenBOM has a cloud-based architecture and allows for seamless integration with popular CAD tools. The familiar “Excel-like” interface helps shorten the learning curve for new users, especially for businesses upgrading directly from spreadsheets. Pricing starts at $100/seat/month, making it affordable for smaller teams and jobshops.

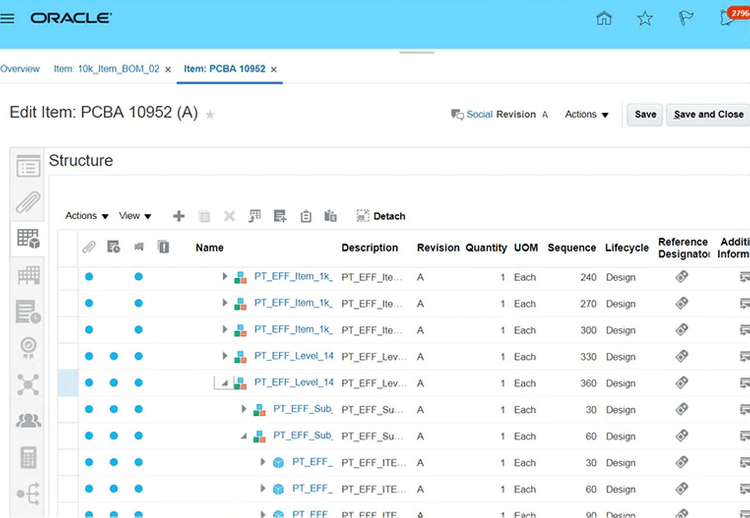

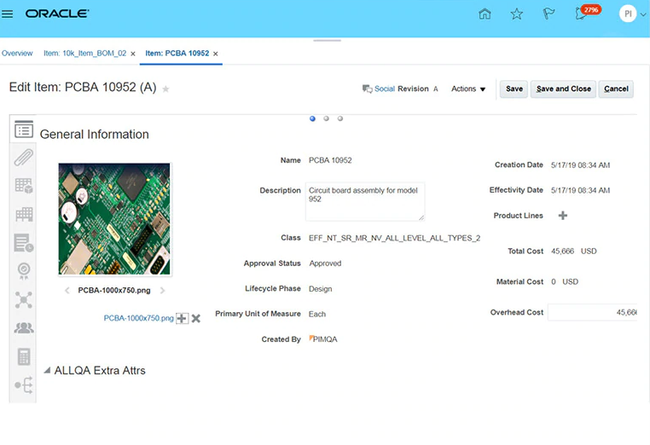

Oracle Fusion Cloud PLM - Best EBOM Tool

Oracle Fusion Cloud Product Lifecycle Management (PLM) includes a concept and engineering BOM workspace that converts ideas into revision-controlled bills of materials. It offers a structured table for multi-level BOM editing with a real-time graphical navigator for visual impact analysis.

You can create a new concept and drag in existing items, CAD files, or placeholder “virtual” components. Oracle tags each line with weight, cost, power compliance score, and preferred supplier. This means you can build a rough BOM in minutes, without locking in part numbers. From there, you can click “Analyze” to auto-roll up cost and weight and flag any compliance gaps.

Oracle PLM lets you switch to the Graphical Navigator pane, where nodes show test cases, requirements, and components. Color coding helps you spot incomplete requirements or over-budget parts, instantly visualizing ripple effects across every BOM level. In one click, you can convert the approved concept into an engineering BOM, so you don’t have to re-key data between design and manufacturing.

The core engineering/BOM editor starts at $350/user or $3,500/month for a minimum of ten users. However, the Innovation Management Cloud, Configurator Modeling, Quality Management, and Product Hub Cloud services are separate components, each with its own costs.

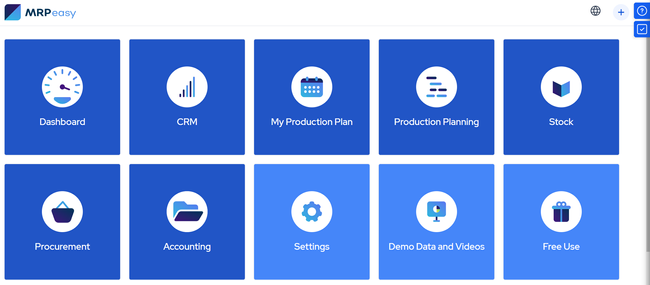

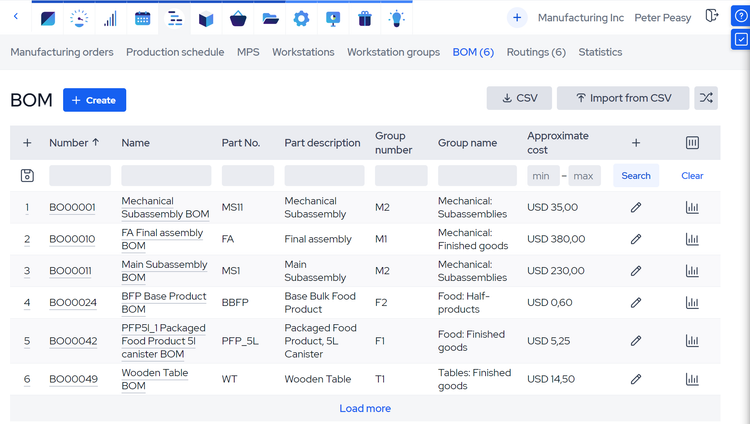

MRPEasy - Best for Small Businesses

The bill of materials offered in MRPEasy is intricate and has a tailored approach to manufacturing. Recognizing the nuanced needs of both discrete and process manufacturing, MRPEasy adapts its BOM functionalities for distinct industries, from electronics to food production. We liked the flexibility of managing both single- and multi-level BOMs. If a business has simple or highly complex products, MRPEasy can work, making it attractive to smaller businesses as a scalable option.

MRPEasy offers engineering and manufacturing BOMs, which allow you to be more precise with your BOMs. This is important in accounting for real-world variables like wastage. Its intuitive interface also aids in adding or revising BOMs, which can simplify the manufacturing process.

Since BOMs aren’t siloed and are tied directly to production planning, purchasing, and sales, MRPEasy works great as complete MRP software for the production process. The version control system embedded within the software ensures traceability, making BOM revisions straightforward and transparent.

Fishbowl - Best Inventory Integration

While most bill of materials software focuses mainly on production workflows, Fishbowl’s BOM capabilities integrate with its granular inventory management tools. This syncs your operations, giving you better visibility into materials usage and replenishment needs directly from the BOM workflow.

Fishbowl’s part-first approach lets you create a BOM directly from the parts screen, which lists all items in your inventory, like components, raw materials, and finished goods. Start by selecting the part you want to manufacture; Fishbowl auto-fills details for the finished good. From there, you can easily set quantities, add raw materials, and define production stages. These processes are all connected to your current inventory levels, meaning any changes to the BOM immediately update your stock counts in real time.

However, the BOM management tool extends beyond materials tracking. With support for multi-level BOMs, Fishbowl lets you manage complex assemblies and sub-assemblies. It links these together to help track dependencies between production stages and parts, which is helpful if you’re in machinery or electronics manufacturing. The system allows you to track your materials through each assembly stage and ensures any components needed for later stages are available on time.

Katana MRP - Best for Production Planning

Katana MRP is an accurate and optimized MRP that offers an in-depth BOM module. The solution caters to both small manufacturers and large factories. Katana ensures real-time insights into production progress, design alterations, and raw materials consumption.

Katana is successful for businesses transitioning away from static spreadsheets. The BOM module auto-allocates available raw materials and products, providing a resource allocation method that prioritizes schedules.

Moreover, Katana’s commitment to precise costing is evident. With the ability to track sales and production orders in real time, businesses can adjust raw material and resource costs, making pricing decisions more straightforward. Multi-level BOMs with subassemblies refine the costing process, providing a clearer understanding of product margins and cost of goods sold.

Arena PLM - Best for Product Lifecycle Management

Arena PLM can handle bill of materials and much more. Its cloud-native platform centralizes vital product records, which could be a great boon to enabling real-time collaboration among internal and external stakeholders.

The comprehensive access to designs, parts, BOMs, and quality management processes paves the way to eliminating operational silos and should (in theory) foster agile product development.

This product is a great choice for those who need more than just a simple tool for creating a BOM. By connecting BOMs, design files, and change processes, Arena PLM accelerates product delivery, reducing costly production errors. The platform not only enhances visibility across design and supply chain activities but also gets the process started on moving products toward commercialization.

Master Control - Strong Regulatory Compliance

Master Control Manufacturing Excellence delivers advanced compliance and quality management capabilities in regulated pharmaceuticals and medical devices. The software seamlessly links BOMs with quality processes, ensuring that every aspect of production adheres to necessary compliance protocols.

Master Control offers detailed audit trails and documentation control, essential for companies undergoing frequent audits and inspections. The software’s ability to provide real-time visibility into the manufacturing process and quality control ensures that companies can proactively manage compliance, reducing the risk of non-conformance.

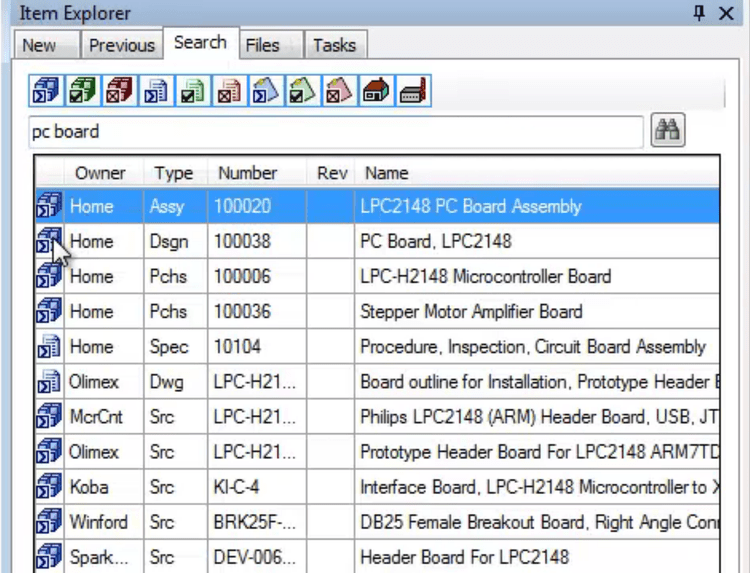

PDXpert - Great Engineering Collaboration

PDXpert fosters collaboration between engineering and manufacturing teams. This benefits companies where close coordination between these departments is critical for product development and manufacturing efficiency. PDXpert manages complex engineering BOMs (eBOMs) and converts them into manufacturing BOMs (mBOMs). It can maintain the integrity of the product design throughout the production cycle.

Another standout feature of PDXpert is its version control and change management system. It allows for detailed tracking of revisions, ensuring that all team members are working on the latest version of a product design. This is useful for companies dealing with frequent design changes or requiring a high level of precision and accuracy.

Total ETO - Best for Custom Manufacturing

Total ETO, designed specifically for engineer-to-order (ETO) and custom design manufacturers, demonstrates significant potential as a BOM software for businesses in these sectors. Based on the information provided and corroborated by various online sources, Total ETO stands out for its dynamic BOM functionality plus integration capabilities with popular CAD systems.

The dynamic BOM feature allows for the release of BOMs in stages, addressing concerns over material changes or redesigns. This facilitates early procurement of parts and maintains the momentum of overall production. Total ETO can also integrate with various accounting systems like QuickBooks or Sage, and CAD solutions like Inventor and SolidWorks, enhancing its utility.

Craftybase - Best for Small Batches

Why We Chose It: Craftybase is an inventory management software focused on helping small-batch manufacturers. It is specifically designed to cater to the unique needs of small to medium-sized businesses in the handmade arts and crafts sector. In addition to basic BOM functionality, it offers features for pricing guidance, cost of goods sold (COGS) calculations, GMP and CPSC traceability, product and order management, expense tracking, materials and components management, reporting, consignment, and stocktaking.

Additionally, it integrates with several major sales platforms and marketplaces, such as Etsy, Shopify, Amazon, WooCommerce, and more, enabling efficient synchronization between sales and inventory data.

What is Bill of Materials Software?

Bill of materials (BOM) software specifies the raw materials, parts, and sub-assemblies needed to manufacture each specific product. By providing precise instructions on what is needed for each manufacturing job, a bill of materials module allows you to complete more jobs in less time with cost savings on both labor and materials.

In short, the BOM breaks down how a finished product is made. Bill of materials software provides specific instructions on both material needs and assemblies required to create a product. In order to do this, the software takes product information from order entry systems, inventory control, and master production schedule modules. By integrating different functional areas, the BOM allows you to coordinate a variety of tasks into a single instruction set.

How to Choose Software

Here’s our methodology for selecting the most suitable bill of materials software for your business:

1 Detailed Requirement Analysis

- Operational Workflow Mapping: Understand and map your company’s complete production and inventory workflow to identify the key areas where BOM software can add value.

- Feature Specificity: Identify specific features needed in each area of operations, such as real-time inventory tracking, multi-level BOMs, batch processing, or serial number tracking.

2 Data Management and Analysis

- Data Handling Capabilities: Ensure the software can handle the volume and complexity of your data, including historical data analysis and future forecasting.

- Advanced Analytics: Look for advanced data analytics capabilities to improve decision-making, such as trend analysis and predictive maintenance.

3 Integration and Compatibility

- Seamless Integration: The software should integrate seamlessly with existing systems (ERP, CRM, procurement, etc.) without disrupting current operations.

- APIs and Custom Integrations: APIs are available for custom integrations with unique or niche systems your company might be using.

4 Supply Chain Coordination

- Supplier Management: Features for managing supplier information, purchase orders, and tracking supplier performance.

- Material Requirements Planning (MRP): Tools for efficient material planning, forecasting, and procurement.

5 Product Lifecycle Management

- Version Control: Can manage different versions of BOMs through various stages of the product lifecycle.

- Change Management: Tools for tracking and managing changes in BOMs, including approvals and audit trails.

6 Quality Control and Compliance

- Quality Assurance Features: Tools for ensuring product quality and consistency, such as inspection checklists or integration with quality control systems.

- Regulatory Compliance: Features to ensure compliance with industry-specific regulations and standards, including documentation management.

7 Customization and Scalability

- Configuration Options: The ability to customize the software to fit unique business processes or specific industry requirements.

- Scalability: The software should be scalable to grow with your business, accommodating increased data, users, or complexity.

8 Cost-Benefit Analysis and Decision Making

- ROI Consideration: Assess the potential return on investment by considering efficiency gains, cost savings, and improvements in decision-making.

- Decision Matrix: Use a decision matrix to evaluate and compare software options based on the identified features and requirements.

Key Features

- Single and Multi-level BOM: Single-level BOMs are top-level assemblies that grab all subassemblies and parts from one level and put them into a list. Multi-level BOMs create a hierarchy of parts and subassemblies that can be managed separately.

- Flattened BOM: A report that shows the quantity of all components or parts across multiple assemblies used in the product. Displays a flat representation of your BOM with distinct components and quantities collected from all sub-levels

- Revisions and Change History: Create multiple versions of BOMs that can be approved or adjusted. Track and propose changes made to all BOMs.

- User-defined views: Create custom views for all team members. Add/update user permissions.

- Production Planning (Routing) and Purchase Orders: Helps plan production on your shop floor by determining the need for materials and capacity to complete a production order.

- Document Management: Create a single working version of a document through collaborative storage and management with other users.

- Material Take Off (MTO): The process of analyzing drawings and determining all the materials required to accomplish the design

Benefits

A strong bill of materials software or an integrated BOM module within your ERP suite or inventory management solution can provide a number of benefits for your business:

Enforce Rules for Each Assembly Part Type

Ensure the correct bill of material creation in your company by automatically assigning documents and part numbers according to specified rules. Quality BOM software will let you find the exact materials needed to complete an assembly or suggest possible alternatives via search tools within the program. You can also look at the release status and life cycle and monitor revision history for any changes that do occur within your bill of materials.

Saving Time with Automation, Collaboration, and Templates

With a bill of materials software module, you can save time by eliminating the need to manually gather data. A BOM will automatically grab information from engineering drawings, part number lists, spreadsheets, and other paper documents. Bill of materials software modules promote collaboration by allowing employees from multiple locations to access the same information in real time. You can basically eliminate the need to mail or fax a list of production components between plants. Another time-saving feature is the ability to edit previous instructions to create a new bill of materials based on your existing templates.

How Much Does Bill of Materials Software Cost?

BOM software can range from just $50 per user per month to $5,000 per month. Here’s an overview of the typical pricing tiers:

-

Low-Tier Pricing ($50-$99 per user per month): Suited for small businesses or startups in the nascent stages of their operations. At this price point, users can expect basic functionalities that cover the essentials of BOM management. It includes features like simple inventory tracking and basic reporting.

-

Mid-Tier Pricing ($175-$410 per user per month): This pricing range targets medium-sized businesses and offers a more comprehensive set of features. Companies can expect enhanced capabilities such as advanced reporting, better integration options, and more sophisticated inventory management.

-

High-Tier Pricing ($5,000 per month): This premium tier is tailored for large enterprises with extensive requirements. At this price point, the software often provides a highly advanced set of features, including extensive customization options, high-level integrations, in-depth analytics, and AI-driven insights for inventory and supply chain management.

What Does a Bill of Materials Look Like?

Bills of materials are hierarchical, as in they have a top level that represents a completed or manufactured product. From there, any levels below the top are known as sub-assemblies.

For instance, if you are building a clock, you might have two levels of assembly: one for the internal clock-works and one for the outer casing. The bill of materials for each assembly would detail the materials and the steps needed in each assembly. It would also cover resource planning, determining which parts are available and which need to be ordered or created.

For example, the outer casing assembly might include a materials list, including the wood for the casing, screws, and paint. It would also specify the correct order of steps needed to cut the wood, assemble the casing, and paint it. Finally, the bill of materials would specify the labor and machine requirements for that step of the assembly.

In the real world, a bill of materials can be used to manage much simpler but usually considerably more complex assembly processes.

Best Practices

Here are some tips on how to use your BOM software effectively:

- Centralized Data: To ensure proper quality and compliance, you should keep all data in a single repository. This helps eliminate discrepancies in BOM revisions and keep costing error-free.

- Version control: Implementing BOM software with a strong version control system allows you to track changes. Configure access controls so only authorized users can make edits with full visibility.

- Templates: Create standardized templates to enhance consistency and structure when creating new BOMs. Creating BOMs faster can lead to quicker new product development.

BOM vs PLM Software

There has been a lot of debate as to where a BOM can be used outside of a manufacturing concept, and thus become a critical part of a product lifecycle management (PLM) process. This is due to the extended definition some may give to BOM, which is based on the idea that a BOM can define products as they are designed (engineering bill of materials):

The concept of an engineering bill of material (EBOM) was introduced in PLM systems since there is very rarely a single tool that fully defines the design intent of a product. This is most commonly due to the increasing number of products that require mechanical, electronics, and software engineering … PLM EBOM addresses individual design tool limitations by synchronizing the CAD design structures from multiple tools to items in a single product’s EBOM. Jon Gable, Director of Sales, Adaptive Corporation

Product lifecycle management software, or PLM software, keeps your business organized so you can manage the entire lifecycle of a product from conception through design and creation and finally disposal. A bill of materials is just a part of a product lifecycle and is usually the first step in structuring a product towards the creation, engineering, or manufacturing process. The best PLM tools will give additional capabilities that help a product design move forward, such as change management, quality management, product data management, and more.