The Best Manufacturing Inventory Software

We tested and reviewed various solutions for manufacturers needing precise inventory tracking. We based our picks on factors like pricing, industry fit, and tools like automated reorder points and lot tracking.

- Competitive pricing; does not require a subscription

- Integrates with QuickBooks

- Can function as a light MRP system

- Integrates with QuickBooks Online, ShipStation, and Shopify

- Affordable pricing for SMBs

- Mobile app for warehouse inventory management

- Provides batch tools through the order manager to track process workflows

- Integrates directly with QuickBooks for easy data migration

- Can handle millions of SKUs for scalability

Manufacturing inventory software is a digital tool designed to manage raw materials, work-in-progress items, and finished goods throughout the production process. Based on our internal review process and user reviews, here’s a rundown of our top products.

- Fishbowl Inventory: Best Overall

- SOS Inventory: Best Traceability Tools

- Acctivate: Best Multi-Level BOM Module

- Zoho Inventory: Best for Small Online Retailers

- Katana MRP: Best for Batch-Based Manufacturing

- Prodsmart: Best for Data Analytics

- MRPEasy: Best for Production Planning

- MISys Manufacturing: Most Scalable Option

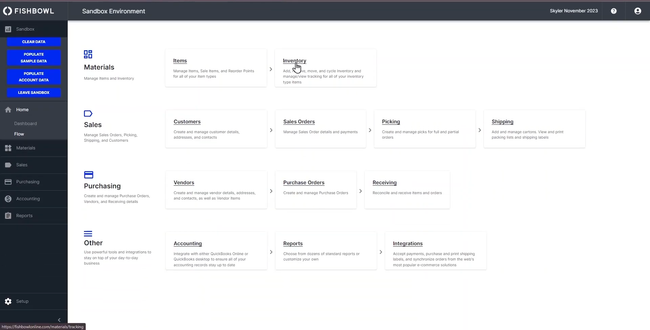

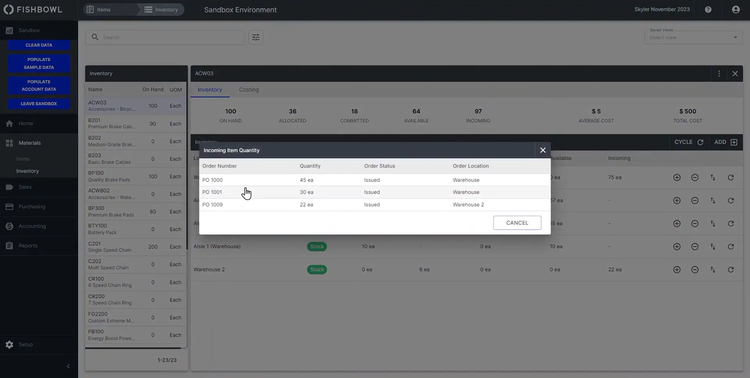

Fishbowl Inventory - Best Overall

Fishbowl Inventory’s manufacture order (MO) module automates how and when MOs are created. Sales orders, forecasted demand, or low raw-material stock levels trigger the Auto MO wizard. You can decide whether Fishbowl should only look at finished goods reorder points or roll demand up through nested sub-assemblies.

From there, the wizard builds one MO containing multiple work orders (WOs). Each WO inherits its routing steps, material lists, and default work center from the underlying BOM. When Fishbowl releases the MO, it allocates on-hand parts and alerts you if there are any shortages. If a component is out of stock, a linked MO-to-PO capability converts those shortages into purchase orders. This is ideal if you generally deal with outsourced or long-lead items, like in electronics production.

Your operators can scan barcodes with Fishbowl GO using handheld or mobile devices to start or finish each WO stage. Plus, Fishbowl Time clocks employees onto the job, updating actual labor cost back to the MO. When the last WO closes, Fishbowl rolls material, overhead, and labor into a single finished-good cost. It decreases WIP and sends the journal entry to Xero or QuickBooks without you ever having to open a spreadsheet.

The Manufacturing perpetual license pricing plan is a minimum of $8,895 for two users. The per-user cost goes down when additional users are added to the plan. Integration with QuickBooks streamlines inventory control functions, making it a top choice for businesses already using that software for accounting.

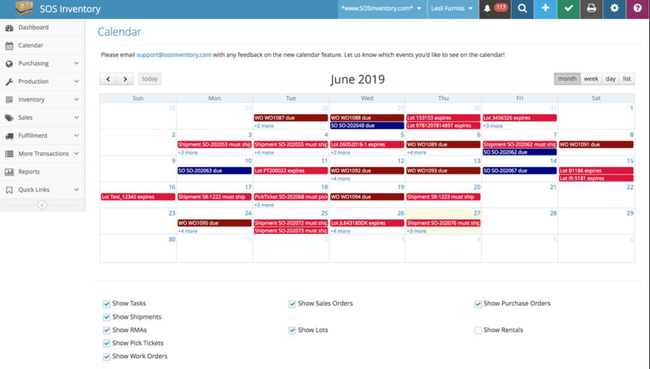

SOS Inventory - Best Traceability Tools

SOS Inventory delivers strong lot tracking functionalities. We picked it for industries like food manufacturing because it helps identify quality issues and enables targeted recalls if needed. Every item is assigned a unique identifier, such as a lot or serial number, ensuring traceability through every stage of the supply chain. This includes product coding and labeling, enabling meticulous procurement and customer delivery monitoring.

Additionally, this manufacturing inventory management system integrates lot tracking within the production process. As components are utilized in assembly, they’re automatically deducted from inventory, providing real-time materials tracking and updating lot information in real time.

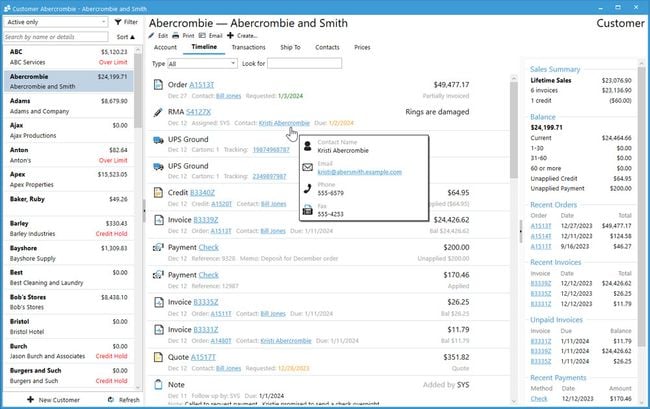

Acctivate - Best Multi-Level BOM Module

Acctivate connects multi-level bills of materials (BOMs) to inventory management. Whenever you create a work order, it reserves sub-assemblies and components based on the BOM. Then, as production progresses, Acctivate updates stock levels dynamically, deducting used components and adding finished goods after assembly.

Additionally, this inventory and manufacturing software’s BOM module integrates with inventory reorder points. This helps replenish your raw materials just in time rather than letting them sit idly in storage. And if a component is running low, this manufacturing inventory software can auto-trigger purchase orders. This saves you from stockouts and potential disruptions to your production line.

Acctivate supports complex product structures with multiple layers of materials and sub-assemblies. This makes it a solid fit for electronics, where tracking parts is vital to managing inventory accuracy and compliance with industry regulations. While it doesn’t offer RFID scanning, Acctivate includes granular lot and serial number tracking.

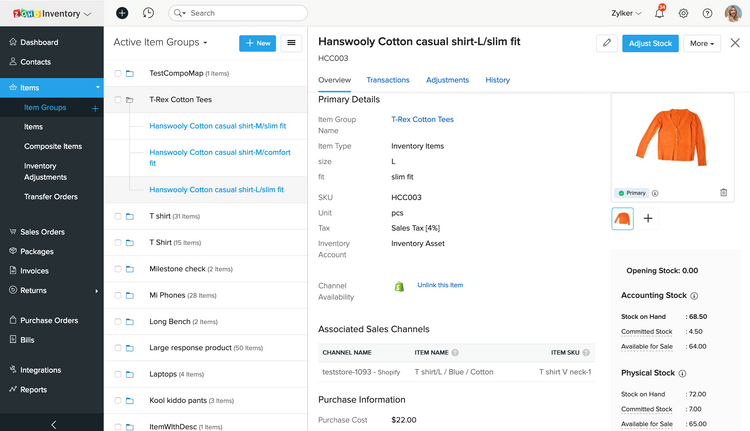

Zoho Inventory - Best for Small Online Retailers

Zoho Inventory is a strong choice for businesses seeking manufacturing inventory software, particularly for small to midsize enterprises focusing on online retail. This cloud-based solution makes it easy to maintain stock across inter-warehouse transfers. Expiration dates, serial numbers, or batches can track individual units.

Zoho Inventory is more aimed at managing inventory in the eCommerce sector. However, those tools are still valuable for manufacturers looking to bundle products, manage warehouses, merge orders, and efficiently track inventory using features like RFID and barcode scanning. It’s worth noting that users may require additional add-ons to meet all specific manufacturing needs.

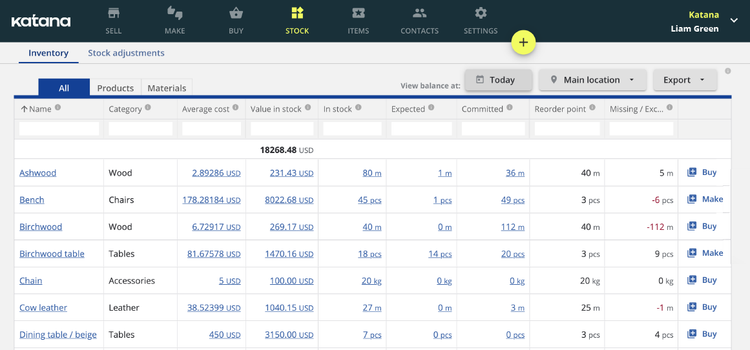

Katana MRP - Best for Batch-Based Manufacturing

Katana MRP is a good option for industries like food and beverage, cosmetics, and pharmaceuticals. Its batch management tool helps you keep track of on-hand inventory levels by assigning unique batch numbers to raw materials and finished goods. These follow products through every stage, from production to sale, to help you meet quality and safety standards.

You can log details like supplier information, compliance notes, and batch expiration dates. This creates a clear digital audit trail that streamlines regulatory checks. In the event of a recall, Katana’s traceability feature even lets you pinpoint affected batches down to their raw materials and manufacturing timeline.

Finally, Katana’s batch management includes FIFO functionality for managing materials with short shelf lives. This ensures that the oldest stock is used first, reducing waste and optimizing inventory turnover.

Though Katana’s Starter plan is affordable at $179/month, it only supports one inventory location. You’ll need to upgrade to the Standard plan at $358/month for three inventory locations and the Professional plan at $799/month for up to 10.

Prodsmart - Best for Data Analytics

Prodsmart is an MES aimed at SMB manufacturers. A suite of features that cover a wide spectrum of production-related functions, including:

- MRP and ERP

- Production scheduling

- Quality management

- Inventory management

- Bills of materials

The support for tracking associated operations and raw materials, along with lot traceability, adds value to inventory management. Prodsmart uses a data-driven approach to allow businesses to make informed decisions and adapt swiftly to changes in the manufacturing landscape.

MRPEasy - Best for Production Planning

MRPeasy is a cloud-based MRP designed for small manufacturers. One notable feature of MRPEasy is its flexibility, allowing users to select the features that align with their specific requirements, thus catering to both smaller and growing enterprises.

However, it’s important to note that MRPEasy is primarily a manufacturing resource planning software and requires integration with a separate accounting system for best functionality, but it excels in handling stock, BOM, and inventory management while simplifying production and assembly orders.

MISys Manufacturing - Most Scalable Option

MISys Manufacturing is the best fit for small to mid-sized manufacturers looking for scalable inventory management. The software is designed to grow with businesses, offering modules that can be added as manufacturing requirements expand. It provides detailed tracking of inventory levels, costs, and manufacturing orders, making it easier for companies to manage their resources effectively.

MISys is particularly beneficial for sectors like electronics, machinery, and fabricated metals, offering features like serial and lot tracking, multi-level BOM, and bin tracking. Its ability to integrate with popular accounting systems such as QuickBooks and Sage 50 enhances its utility for managing financials alongside manufacturing operations.

What is Manufacturing Inventory Software?

Manufacturing inventory software keeps track of the on-hand physical inventory levels of raw materials and finished goods for manufacturing production orders. Manufacturing businesses need a system that accurately tracks inventory to reorder supplies as needed to keep up with demand.

The inventory management system will automate purchase orders once your supplies drop below a certain threshold, ensuring you don’t run out.

Manufacturing inventory management software allows you to track the cost of each item in your inventory. Knowing the cost of your manufactured goods helps with budgeting and financial planning, ensuring you receive ROI on your finished products.

Improving inventory traceability is a substantial benefit of manufacturing inventory systems. Inventory software for manufacturing is generally compatible with RFID and barcode scanners that allow you to gather information about a product quickly.

Some of this information can include pricing, physical location, and vendor info. Having the location and vendor information on hand lets you quickly identify any recalled products from which vendor the materials came from, to where the product is stored.

Key Features

| Feature | Description |

|---|---|

| Bill of Materials (BOM) | List of raw materials and assemblies needed to manufacture a product. |

| Inventory Costing | Establish a cost value of the inventory items to improve profitability tracking and manage tax accounting. |

| Purchase Order Management | Reorder raw materials and supplies before running out. Purchase orders will automatically be sent to the appropriate vendor. |

| Inventory Tracking | Track inventory item quantities, pricing, and physical location. Uses barcoding, serial number and lot number tracking, and RFID tracking. |

| Inventory Matrix | Track product combinations by color, size, or another dimension. |

Benefits

Some of the benefits of manufacturing inventory software include:

1 Improved Traceability

- Batch Tracking: Essential for process manufacturers, batch tracking ensures product quality and safety. In case of a recall, manufacturers can quickly identify and isolate affected products, reducing risk and maintaining consumer trust.

2 Integration with eCommerce Channels and Point of Sale

- Real-time Stock Updates: Inventory software that is integrated with eCommerce and POS systems ensures stock levels are updated in real time. This synchronization prevents overselling and enhances customer satisfaction.

3 Time Savings

- Automated Processes: By automating inventory management tasks, manufacturers save considerable time, allowing staff to focus on strategic tasks instead of manual inventory processing.

4 Improved Accuracy

- Error Reduction: Automated systems significantly reduce manual data entry errors, improving inventory accuracy and preventing costly mistakes like duplicate entries.

5 Enhanced Visibility

- Real-time Monitoring: Inventory software provides a comprehensive view of inventory levels, stock movements, and sales margins, aiding in quick decision-making and response to market changes.

6 Optimized Supply Chain

- Efficient Inventory Levels: Manufacturers can streamline their supply chain by effectively managing inventory levels, improving cash flow, reducing excess stock, and lowering carrying costs.

7 Cost Savings

- Reduced Wastage and Excess Inventory: Inventory software helps avoid over-purchasing and holding excess inventory, thereby saving money and reducing wastage.

8 Data Analytics

- Sales and Wastage Tracking: Software systems offer valuable insights into sales trends and wastage, enabling strategic decision-making and process optimization.

9 Customer Satisfaction

- Quality Control and On-time Delivery: Inventory management software enhances customer satisfaction by ensuring quality products are delivered on time and providing transparency in order tracking.

10 Production Efficiency

- Lean Manufacturing Principles: Inventory software aligns with lean manufacturing principles, optimizing the flow of parts and materials to enhance overall production rates.

11 Reduced Risk of Out-of-Stock Situations

- Accurate Stock Information: Systems using perpetual counting provide current stock numbers, reducing the risk of out-of-stock situations and associated customer dissatisfaction.

12 Accurate Sales Forecasting

- Informed Production Decisions: The inventory management systems data help accurately forecast future sales, enabling manufacturers to adjust production accordingly and avoid over- or underproduction.

These benefits, ranging from time savings and improved accuracy to cost savings and enhanced customer satisfaction, illustrate the significant impact that manufacturing inventory software can have on a manufacturing operation’s efficiency, profitability, and customer relations.

13 Simplification of Inventory Management

- Ease of Tracking Orders and Products: Inventory management systems simplify tracking orders, production, and stored products, allowing managers to focus on core business operations.

Pricing

The cost of manufacturing inventory software varies widely based on features, deployment options (cloud-based or on-premise), and the scale of the manufacturing operation.

Here are some specific examples to illustrate the range of pricing:

1 Perpetual License Pricing Plan

For a manufacturing perpetual license, the cost starts at a minimum of $8,895 for two users. These plans with higher upfront costs are more common with on-premise systems that you purchase outright compared to subscribing to (like a cloud option).

The per-user cost decreases with the addition of more users. Such plans are suitable for businesses looking for a long-term investment with a one-time payment, often chosen by larger companies or those requiring extensive customization.

2 Monthly Subscription Models

- Some basic software options start at $39/month, and they may include essential features suitable for smaller or less complex operations.

- Mid-tier options are closer to $99/month, likely offering more advanced features or catering to larger manufacturing operations.

- Higher-end solutions can cost around $600/month, indicating a more comprehensive feature set for large-scale manufacturing needs.

- There are also user-based pricing models, such as $49/user/month, which can be scalable based on the number of users or employees who need access to the software. These pricing models typically require a minimum number of users.

When evaluating the cost of manufacturing inventory software, consider your operation’s specific needs, including the scale of your manufacturing, the complexity of your inventory processes, and the level of integration required with other systems.

Keep in mind that while some software options might appear expensive, they could offer a higher return on investment due to their comprehensive features and efficiencies. On the other hand, more affordable options could be sufficient for less complex needs and offer an economical solution without compromising on essential features.

How to Choose Software

When choosing the best manufacturing inventory software, consider the following key aspects, integrating real-world examples and specific factors:

- Assess Business Needs and Existing Processes: Analyze warehouse procedures to identify inefficiencies in inventory turnover, stock control, demand forecasting, reorder points, safety stock, and customer demand.

- Key Software Features: Look for features like real-time inventory updates, barcode scanning for data accuracy, enterprise mobility, purchase order management, advanced inventory tracking (batch traceability, bulk moves), optimal replenishment automation, and integration capabilities with systems like MES and WMS.

- Deployment Options: Decide between on-premises and cloud-based solutions. While cloud-based (SaaS) solutions are popular for their scalability and reduced IT burden, some organizations may prefer on-premises deployments for specific needs. Hybrid solutions that offer flexibility between these two models are also available.

- Evaluating Software Providers: Research providers with a proven history in your industry. For instance, food and beverage companies may need software that automates traceability, while industrial manufacturers might focus on shop floor data collection. It’s crucial to read reviews, request demos, and consider the provider’s track record in implementing similar solutions effectively.

- Cost and ROI Considerations: Analyze the cost and potential return on investment (ROI). More complex solutions may have higher upfront costs and longer implementation times, affecting the ROI timeline. Compare pricing plans, considering one-time purchases versus subscription models, and factor in additional costs like support, upgrades, and customization.

- The Cost of Waiting: Ineffective tracking and manual processes can be costly, leading to significant operational efficiency and accuracy losses. Modern inventory software can address these issues through automation, potentially reducing material handling costs and increasing data accuracy, thereby saving companies significant amounts annually.

- Benefits and Challenges: Manufacturing inventory software offers time savings, improved accuracy, enhanced visibility, optimized supply chain, and integration with other business applications. However, challenges include implementation difficulties, training and adoption, cost considerations, and data security.

- Current Market Trends: Stay informed about smart inventory tracking (RFID, barcoding), cloud-based solutions, business intelligence and analytics, mobile applications, and IoT advancements. These technologies enhance inventory tracking, decision-making, and operational efficiency and facilitate remote work capabilities.

- Implementation Steps: Evaluate your inventory management requirements, research software options, define essential features, and request demos or trials. Assess user-friendliness, integration capabilities, customization options, and the level of support and training the software provider offers. Analyze scalability and seek references or case studies before planning the implementation.

What Systems Provide Functionality Beyond Inventory?

You may be looking for a dedicated inventory program because you are at peace with your existing systems and don’t want to go through the ordeal of implementing a manufacturing ERP software. This may lead to

Depending on your business needs, you may want to consider another solution that includes or integrates with inventory systems. Some examples include:

Manufacturing ERP Software

Inventory control is an important part of general manufacturing software. These systems are ideal for businesses looking to improve product quality and efficiency during the manufacturing process.

Manufacturing software generally includes additional functionality like:

- Supply Chain Management

- Work Order Management

- Production Planning and Scheduling

- Demand Forecasting

- Shop Floor Control

- Quality Control

- Bills of Material

Manufacturing software solutions can be designed for a specific industry or type of manufacturer. Solutions are available for discrete or process manufacturers and can be broken down further into specific industries, including:

- Apparel Manufacturers

- Food and Beverage Manufacturers

- Medical Device Manufacturers

- Pharmaceutical Manufacturers

- Chemical Manufacturers

Finding the right solution for your industry ensures that your manufacturing processes and finished products comply with specific regulatory industries.

Warehouse Management Software

Warehouse management solutions coordinate and manage inventory and actions in a warehouse. The system tracks where inventory items are located and allows managers to optimize warehouse picking methods.

Small businesses often use warehouse software to track inventory and speed up the shipping process. Larger enterprises use warehouse management systems to manage the inventory of multiple warehouses, track serial numbers, and manage retail compliance laboring.

Material Resource Planning (MRP) Software

Manufacturing resource planning (MRP) helps streamline the manufacturing process through production planning, scheduling, and inventory control. Known as a leading type of manufacturing software, MRP systems allow manufacturers to plan and calculate material requirements, coordinate personnel and machine workloads, and optimally plan purchasing to meet customer demands.

MRP also aids in inventory and production schedules to produce products and complete manufacturing jobs. An MRP system determines which assemblies must be built, what materials must be purchased, and the order in which to build products to meet customer due dates.