The Best Food Manufacturing ERP Software

Food ERP software makes it easier to ensure quality and safety and track ingredients during a recall. We assessed various platforms based on their industry fit, from dairy to beverage processors.

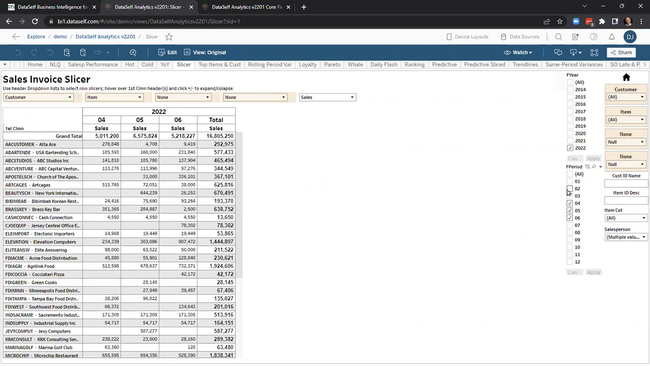

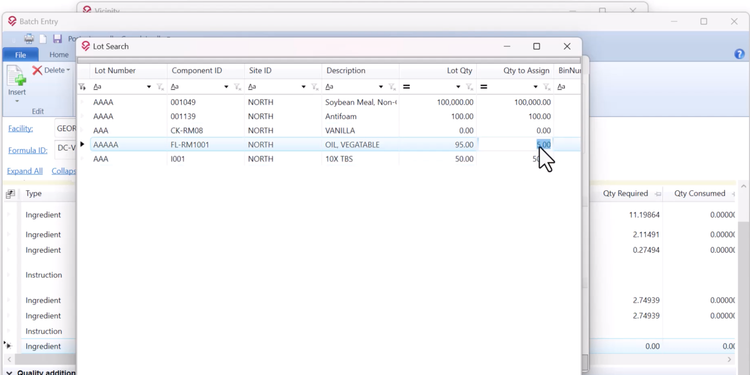

- Includes Code 128 barcodes for catch weight or fixed weight items and serial numbers

- Supports standard, customer-specific, markup, and promotional pricing with volume discounts

- Supports live plant floor weighing and labeling

- Infinite serialization levels for diverse requirements

- Integrated QC tests throughout product lifecycle

- Seamless regulatory compliance with ERP foundation

- Compiles data in real-time for better decision-making

- Covers finance, sales, customer service, manufacturing, and more

- Supports multiple languages and currencies

In this guide, we’ve evaluated the top food manufacturing ERP platforms for the mid- and downstream agrifood supply chain. We considered each system’s feature set, including specialized capabilities like label generation and rework support.

| Challenge | Tool & Feature | Pricing |

|---|---|---|

| Meat/poultry tracking | CAI Minotaur – touchscreen recognition | $1,800 /user /year |

| Bakery cost tracking | Deacom – ingredient cost module | Full ERP: $5,000; Essentials: $500 / mo |

| Seafood compliance | Sage X3 – document storage | $4,500 /user (perpetual license) |

| Dairy quality management | Aptean – quality tool | Requires custom quote |

| Beverage lot selection | Vicinity – lot selection tool | Requires custom quote |

| Frozen food traceability | BatchMaster – traceability & lot control | $2,000 /user (perpetual license) |

| Inventory & lot tracking | Food Connex – inventory + lot tracking module | Requires custom quote |

| Recipe & batch management | iNECTA Food ERP – recipe & batch tools | ≈ $150,000 first year |

These starting prices are approximate; actual costs may vary based on user count, setup, and customization needs. Implementation fees and larger configurations can increase costs beyond the listed price.

- CAI Minotaur: Best for Meat and Poultry

- Deacom: Best for Bakery & Confectionary

- Sage X3: Best for Seafood

- Food Connex: Best Lot Tracking Module

- Aptean: Best for Dairy

- Vicinity: Best for Beverage

- BatchMaster: Best for Frozen Foods

- iNECTA Food ERP: Best for Microsoft Users

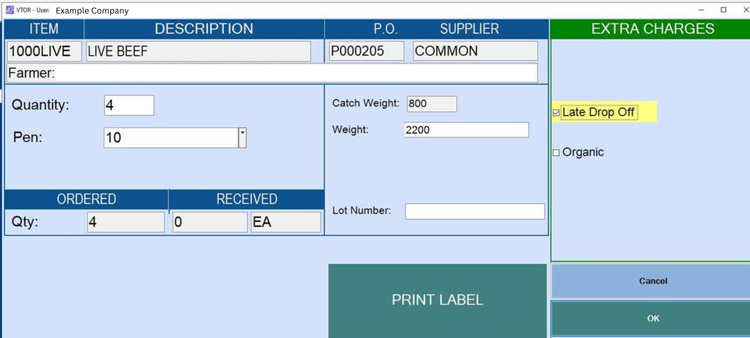

CAI Minotaur - Best for Meat and Poultry

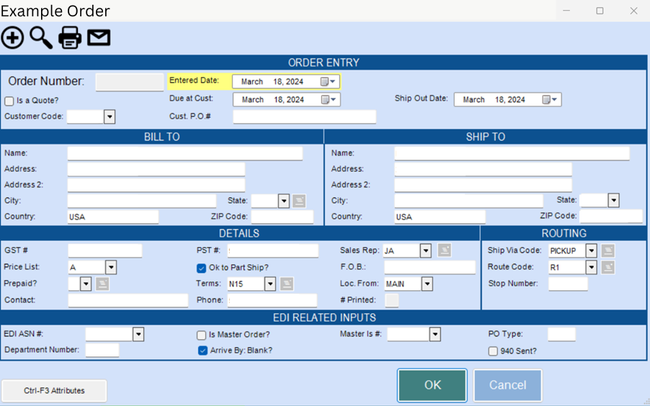

CAI Minotaur includes touchscreen product recognition to help streamline weighing, labeling, and tracking meat and poultry products in real time. The interface is intuitive and easy to use directly on the production floor; employees can enter data, print labels, and select options like product type or SKU for accurate tracking. If multiple production zones are in use, employees can select the zones they’re working in, so only products assigned to their areas appear on the interface.

This food ERP software includes a touchscreen system that connects to a scale for random-weight products. Users can select preset weights for fixed-weight items without manually entering each one. Your team can then select active sales orders from a list and assign each product to a specific order. This directly connects your production with customer orders for organized staging and shipping.

From there, employees can select the type of container or indicate which products must be added to a pallet. This includes options to batch products under a single container label, like a box label or pallet license plate. Depending on the order or product, your employees can choose between different label formats and customize details like lot numbers, serial numbers, or expiration dates. The system then generates and prints the label.

In meat processing facilities, Minotaur’s touchscreen system makes cleaning areas with strict hygiene requirements easier. We recommend this system for food and meat manufacturers, abattoirs, and processors with more than 15 employees. However, small businesses with fewer than 15 employees will likely find the system cost-prohibitive and too complex for their needs. At that point, CAI recommends Food Connex, often the first ERP for many companies graduating from spreadsheets or QuickBooks.

Learn more about CAI Minotaur’s key features.

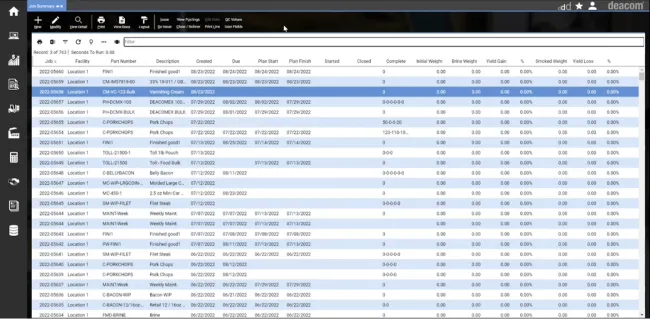

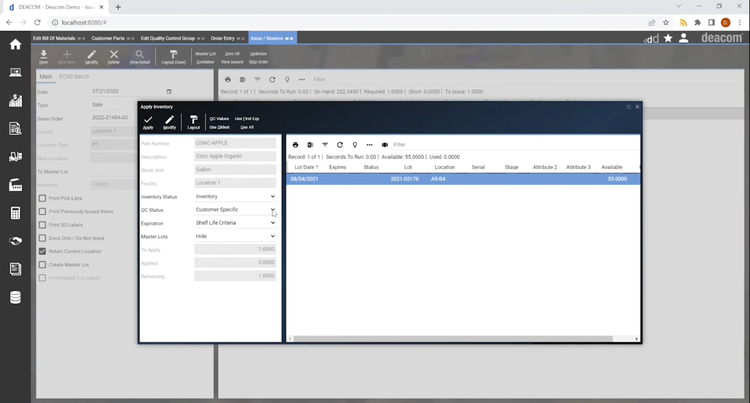

Deacom - Best for Bakery & Confectionary

Deacom helps you assess how each ingredient contributes to your final product’s cost. Its ingredient cost tracking module provides options for:

- Average Cost: Calculates a rolling average of ingredient costs over time, like fluctuating prices for cocoa or sugar, to even out short-term price spikes. This promotes stable product pricing.

- Standard Cost: Provides standard ingredient costs to better forecast expenses for new products or high-demand periods like holidays.

- Actual Cost: Reflects true costs to help respond to margin shifts from premium items like fresh dairy or seasonal fruit; helps determine whether to adjust pricing, alter recipes, or negotiate with suppliers.

This food and beverage ERP also rolls up labor and material expenses into the final product cost, giving you a full overview of your total production expenses. Its routing features allow you to set machine and labor costs based on standard production metrics, like units produced per hour, to visualize how operations affect your product costs.

By combining ingredient, labor, and operational costs, Deacom helps bakeries set prices that maintain profitability, even when ingredient costs fluctuate over time. This means live cost tracking and proactive margin control to manage your production costs tightly, ensuring each batch stays on target.

If you want comprehensive functionalities like lot tracking and compliance features, Deacom starts at $5,000 for the full-scale ERP. However, smaller batch and process manufacturers can turn to Deacom Essentials starting at $500/month.

Read more about Deacom ERP on our product page.

Sage X3 - Best for Seafood

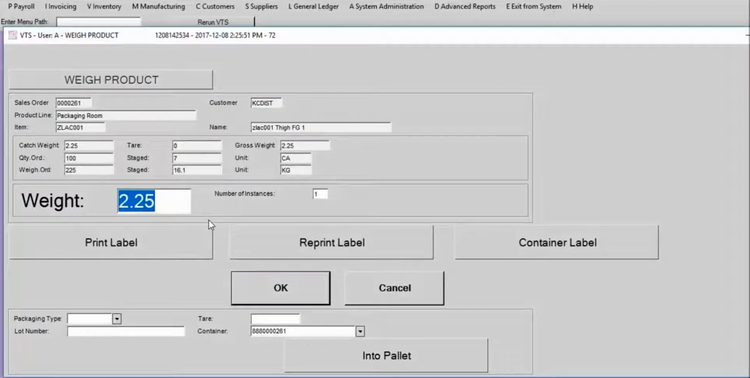

Sage X3 offers seafood processors strong document storage and compliance management capabilities to meet regulatory standards like Hazard Analysis and Critical Control Points (HACCP) and the Food Safety Modernization Act (FSMA). It gives you a centralized location for storing all compliance documents, like temperature logs and batch test results, organized by customer and product.

With Sage X3, you can easily attach documents like certificates of analysis directly to specific product entries. For seafood, this ensures you have immediate access to test results for contaminants, microbiological testing, or any other quality metrics. During audits, inspections, or recalls, you can quickly retrieve these documents. You can even print or email them directly within the system, keeping retail partners and distributors informed.

Additionally, this food manufacturing ERP includes multi-company and multi-site functionality. You can customize compliance requirements for each site and even set up user permissions and access controls based on location or role.

If you’re managing stock across locations, Sage X3 also supports inter-site transfers and batch tracking. It maintains a detailed record of each batch’s history, from harvest date to storage conditions. Having a documented chain of custody means you can prove you handled each batch according to industry and safety standards throughout its lifecycle.

Get pricing details on Sage X3 and more on key features.

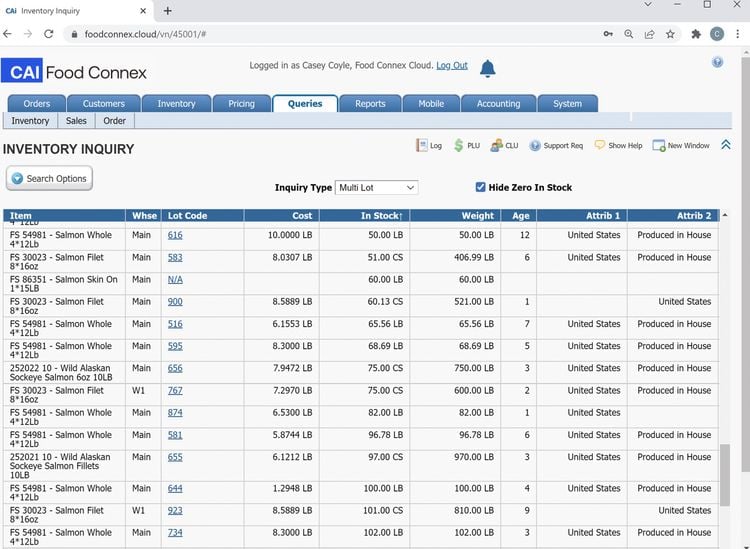

Food Connex - Best Lot Tracking Module

Food Connex includes a dynamic inventory management and lot tracking module. As shipments arrive at your plant, this food ERP software allows you to instantly assign a unique lot number and batch code to each delivery. From there, it’s easy to trace all products, from raw materials through processing to the final packaged food items. This makes it much simpler to catch any problematic batches and isolate them.

This inventory control module captures all product details in real time, so it’s easy to customize downloadable reports in Excel and CSV. These reports can give you detailed insights into product movement, order history, and stock levels, helping your managers make better decisions about replenishment and pricing adjustments.

Overall, it’s a solid pick for food manufacturers graduating from spreadsheets or QuickBooks. It’s best for small to mid-sized companies with straightforward warehouse configurations, as Food Connex does not support multi-slot capabilities.

Aptean - Best for Dairy

Aptean Food and Beverage offers a strong quality management tool that lets you set specific QC triggers for inbound ingredients, like cream and cultures, and outbound finished goods, like cheese or yogurt. You can define custom thresholds for factors such as moisture content and temperature to ensure quality standards are met as goods move through production.

This system also prompts your team to complete required checks at each phase, helping them stay on top of quality. Operators receive prompts based on predefined instructions for each production stage. Your team can check humidity and seal integrity with guided inspection statuses and checklists. This inspection interface is fairly easy to use and even enables photo uploads to document visual quality indicators like texture and color.

In the event of a recall, Aptean’s lot tracking streamlines the process. The system documents lot numbers for all batches, so you can quickly initiate recalls and alert affected distributors and customers. Finally, you can leverage built-in templates for recall communications to help minimize liability and maintain trust with your buyers.

Vicinity - Best for Beverage

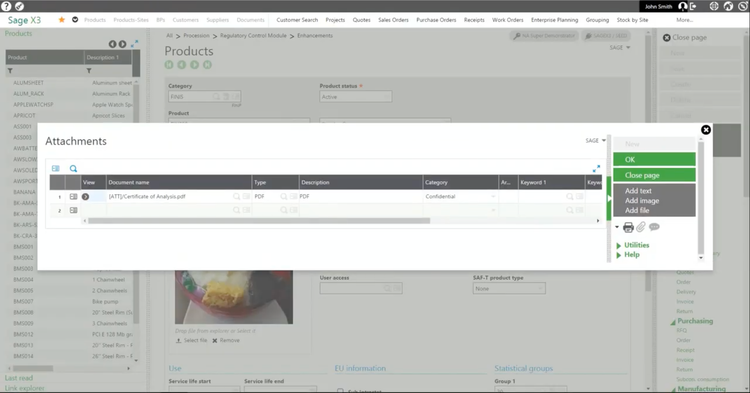

Vicinity Software offers a lot selection tool for more accurate inventory management. This is useful when handling precise ingredients or rework processes. The platform includes a powerful search functionality, allowing you to pull up relevant lots based on specific attributes, like site ID or description. This makes it simpler to handle mid-batch updates or last-minute changes without delay.

Lot selection in Vicinity is cursor-driven. Once you click on the lot in the lot selection screen, you can assign the needed quantity without extra steps or pop-ups to navigate. This is particularly useful if you only need a portion of the lot, like five pounds of fruit concentrate, for a new beverage batch. It’s easy to input this amount directly, leaving the rest available for other batches.

The lot selection tool even supports adding ingredients to batches that weren’t a part of the original formula. If you require a preservative or sweetener that wasn’t initially planned mid-production, you can add it without modifying the existing recipe. This is critical when responding to unexpected ingredient adjustments, like balancing flavors or production variations. It’s also useful for rework, letting you recycle any leftover inventory into new products or reallocate surplus to different batches.

After assigning an ingredient, the tool tracks each lot’s remaining quantity and auto-updates documentation. This keeps records up-to-date for compliance and traceability, helping you meet beverage quality standards while keeping everything organized.

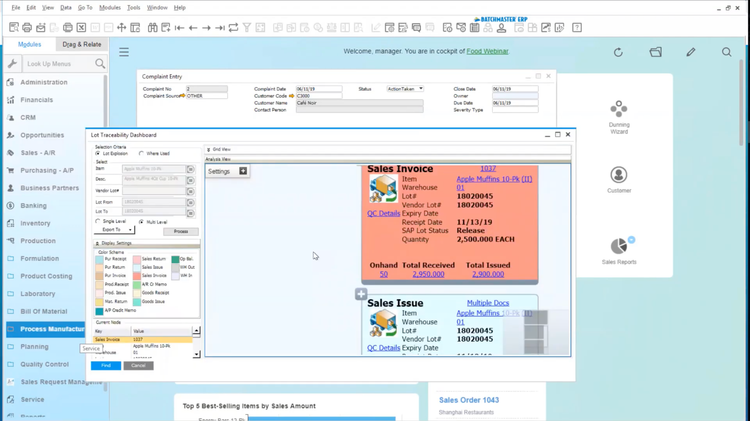

BatchMaster - Best for Frozen Foods

BatchMaster’s bi-directional traceability and lot control features initiate tracking as soon as raw materials arrive at your plant. BatchMaster captures your vendor’s lot number upon receipt and then cross-references this with your internal lot number for tracking. That way, you have a clear audit trail for each ingredient, a must when you deal with perishable frozen goods.

The food ERP software’s lot tracking continues into the WIP stages, where it assigns lot numbers for intermediate products like vegetable blends or cooked meats. It associates each lot number with detailed data like expiration dates and QC statuses, like “on hold” or “approved” based on test results. In this way, BatchMaster supports inventory validation, so no expired or compromised materials enter your production line. Instead, you can continuously verify each lot for a lower turnover rate of raw ingredients.

In the event of a recall, BatchMaster supports backward tracing by linking sales orders or lot numbers back to their production sources. If a compromised ingredient is found, you can use the traceability tool to identify which supplier batches it came from so you can isolate affected products. This can prevent recalls from escalating further and supports proactive rather than reactive quality management.

Additionally, BatchMaster includes built-in root cause analysis, linking non-conformances directly to CAPA records. It then provides a graphical tool to view batch paths, so you can trace the entire production and distribution path of a lot, both backward and forward. Plus, the system even captures and links customer complaints to batch records, making any issues over spoilage or contamination immediately traceable.

That said, the user interface could be more streamlined. It’s designed using Microsoft’s .NET framework, bringing traditional buttons and navigational panes. However, it also integrates with Microsoft products like Excel or Dynamics 365 CRM, making it familiar and easy for teams already using that product ecosystem.

Check out pros, cons, and pricing on our BatchMaster product page.

iNECTA Food ERP - Best for Microsoft Users

iNECTA Food ERP is the natural upgrade path if you’re already using Microsoft Business Central or Office 365. Because iNECTA is built directly on top of Business Central, it extends the ERP’s native capabilities. That way, your team can stick with Microsoft’s familiar interface and layer on recipe and batch management capabilities.

Start by opening a standard production BOM, tagging allergens, and setting a target yield percentage; this lets you create a single recipe master that never drifts into Excel spreadsheets. From there, enter the desired finished-goods weight; this food and beverage ERP resizes every ingredient by applying Business Central’s “quantity-per calculations.” With one click, you can pull live material prices and labor rates into the recipe header, so your team can see the margin impact before releasing the batch.

Your scheduler can drag the batch onto the calendar when it’s time to start production. Or, they can ask Copilot to group orders by allergen class to keep changeovers to a minimum. On the shop floor, operators can scan ingredients into the “production-in” bin, and iNECTA logs each lot on the spot.

Once the run is done, they can scan the finished cases, and the system records the actual weights automatically. WIP, yield, and accounting figures all update simultaneously, so nobody wastes time reconciling spreadsheets.

Though iNECTA requires a consultation call for pricing, first-year budgets can be around $150,000. This includes implementation costs, making this food ERP best suited for mid-sized to enterprise-level manufacturers.

Learn more about iNECTA Food ERP.

What is Food Manufacturing Software?

Food manufacturing software is an ERP system supporting production, processing, and distribution operations in the agrifood value chain, where perishable goods move from the plant floor to the plate. These platforms include quality control, inventory management, and compliance tools to adhere to food safety regulations. Federal and state regulatory agencies establish these:

- U.S. Food and Drug Administration (FDA)

- United States Department of Agriculture (USDA)

- Environmental Protection Agency (EPA)

These regulations can include:

- Food Safety Modernization Act (FSMA): The FDA Food Safety Modernization Act (FSMA) was signed into law to shift focus to preventing foodborne illnesses instead of just responding to incidents. The FSMA addresses food safety at different points along the global supply chain. For more information on compliance dates, visit fda.gov.

- Hazard Analysis Critical Control Points (HACCP) - Track and monitor food storage, handling, and preparation processes to reduce hazard risks and take corrective action as needed.

- 2002 Bioterrorism Act - Tracking every product batch and matching ingredients with their individual batch number.

- Current Good Manufacturing Processes (cGMP) - Keep thorough records of sanitation, staff qualifications, and equipment verification to minimize contamination or errors in the manufacturing process.

- FDA 21 CFR Part 11 - Ensure electronic records are authentic and secure with digital electronic signatures, validation scripts, audit trails, and additional security features.

What is Food Traceability Software?

Food traceability software lets you track products or ingredients throughout the production cycle. It assigns barcodes or QR codes to every ingredient batch, recording its origin, handling stages, and destination as it moves through processing to distribution. This allows you to respond quickly to safety incidents and manage recalls for affected inventory.

If you only want to track and trace, check out our list of the top food traceability software.

Challenges

Food and beverage processors face a number of challenges related to labor, consumer demand, and compliance.

Conforming to Safety Regulations

Ensuring food safety is a top priority since violations can lead to costly recalls and loss of trust in your brand. Many companies pursue advanced food safety certification to help meet strict regulatory compliance standards and reassure consumers about product quality. These certifications require thorough record-keeping and quality and compliance monitoring to adhere to requirements set by agencies like the FDA and USDA.

Labor Shortages

According to AIB International’s article, “How to Improve Food Manufacturing Recruitment Amid the Labor Shortage”, as many as 73% of food and beverage manufacturers are having difficulty finding talent. More baby boomers are retiring, and hiring qualified workers to operate the equipment is becoming more difficult as automation grows.

Fluctuating Consumer Demand

Seasonal trends, health and wellness movements, and economic factors cause consumer purchasing patterns to fluctuate. This results in unpredictable demand cycles affecting your production planning and stock management. For example, health-conscious consumers who want to know where their food comes from may prefer organic produce and alternatives like using spices to color food instead of dyes. There has also been a shift from fat-free foods to high-saturated fats like natural oils, full-fat dairy products, and grass-fed meat.

This unpredictability makes it difficult to manage optimal inventory levels, which can cause stockouts or overproduction that hurts your bottom line. To keep up, you’ll need demand forecasting capabilities to stay agile and respond to rapid changes in consumer tastes.

Regulatory Pressures

Agencies like the FDA and USDA establish strict regulations that can vary by product type and market. To avoid steep penalties and costly recalls, you’ll need to log meticulous records and have thorough quality control processes in place. Failure to comply can damage your brand’s reputation and lead to a loss of consumer confidence.

Increasingly, manufacturers are turning to software to address these challenges. Aptean’s Food and Beverage 2024 Trends and Outlook Report showed that, for those choosing to automate, the average rate of growth was 20% higher than those relying on manual processes.

Key Features & Benefits

Food processing software can help

| Feature | Description | Benefits |

|---|---|---|

| CRM System | Manages interactions with end consumers, retailers, and distributors for feedback on product quality and preferences. | Enhances distributor relationships and helps identify consumer trends. |

| Accounting and Financials | Tracks ingredient costs, reports batch profitability, and manages financial aspects of food manufacturing. | Supports financial planning and accurate profitability analysis on profit margins per batch; informs pricing strategies. |

| Purchasing | Organizes ingredient procurement from certified vendors, adjusting based on demand. | Streamlines procurement to improve efficiency, ensure quality, and reduce delays. |

| Distribution | Manages store and distributor replenishments, inbound/outbound activities, and inter-warehouse transfers. | Optimizes distribution channels to keep products fresh and reduce spoilage with quicker delivery times. |

| Product Development Tools | Uses advanced programming to introduce new products meeting nutritional and financial specs. | Speeds up product development to meet consumer demand and market trends. |

| Quality and Compliance | Ensures compliance with industry standards on labeling, allergen declarations, lot traceability, and recalls. | Simplifies compliance tracking and supports effective recall management if needed. |

| Sales | Manages distributor quotes, tracks campaigns, oversees discounts and promotions for high-demand or seasonal periods. | Improves sales effectiveness and optimizes promotional impact. |

| Inventory Control | Provides demand planning and production scheduling to optimize material procurement and production. | Reduces waste and overstocking, minimizes waste of perishable ingredients. |

How to Choose Software

By identifying your needs based on your industry, you can choose an ERP system that aligns with your production goals:

| Sector | Estimated US Market ($M) | Example Products | Recommended Software Platforms |

|---|---|---|---|

| Meat & Poultry Processing | 200 | Beef, Chicken, Pork Products | CAI Minotaur |

| Dairy Processing | 150 | Milk, Cheese, Yogurt | Aptean Food and Beverage |

| Beverage Manufacturing | 100 | Soft Drinks, Alcohol, Juices | Vicinity Software |

| Bakery Product Manufacturing | 80 | Bread, Pastries, Cakes | Deacom |

| Fruit & Vegetable Processing | 70 | Canned Vegetables, Dried Fruits | Food Connex |

| Snack Food Manufacturing | 60 | Chips, Nuts, Granola Bars | JustFood |

| Seafood Processing | 50 | Shrimp, Crab, Fish Products | Sage x3 |

| Frozen & Prepared Food Manufacturing | 45 | Frozen Meat, Poultry, Vegetables | BatchMaster ERP |

You should also base your ERP decision around your company size:

Small to Mid-Size Businesses

SMBs should look for the following features in an ERP system:

- Compliance Management: Without extensive compliance teams found in larger companies, small businesses need to rely on software to help adhere to local and federal regulations.

- Accounting Integration: Small companies should look for platforms that integrate with their current accounting systems, like QuickBooks Online to simplify their financial reporting.

- Recipe Management: Build a strong brand reputation in an increasingly competitive market through tight recipe management, ensuring standardized production and consistent food quality.

- Cost-Effective Options: Consider a cloud-based, SaaS solution with low upfront costs and predictable monthly sees to fit your smaller budget.

Enterprises

On the other hand, large companies should look for more advanced functionalities:

- Demand Forecasting: Project product demand to minimize waste and better manage your inventory for optimized production.

- QC Testing: Implement quality control tools to help maintain food safety and meet industry standards, building consumer trust.

- Ingredient Control: Manage bulk ingredients and track their usage to help balance stock levels, avoiding overstock and shortages.

- Advanced Compliance Management: Go for more sophisticated compliance functionality to adhere to multi-level regulatory requirements across regions.

- Traceability Tools: Track ingredients from origin to the finished product in case of recalls and to increase transparency with consumers.

Pricing

Food processing ERP can cost anywhere from $15,000 to over $150,000 per year, depending on your company’s size and operational needs.

Basic ERP Systems ($15,000 - $40,000 per year)

These systems provide core functionalities for smaller food manufacturing businesses. They include basic inventory management, production planning, and order tracking without the extensive customization options found in higher tiers. Although these systems may lack industry-specific tools, they’re affordable for businesses in the early stages of growth or those with simpler workflows.

Mid-Tier ERP Systems ($40,000 - $110,000 per year)

Mid-tier ERPs support a broader range of functionalities, such as demand forecasting and a higher degree of flexibility and customization. This means you can tailor the ERP software to meet your unique needs in food processing, distribution, and quality management.

Enterprise-Level ERP Systems ($150,000+ per year)

These platforms cater to large, multi-facility food manufacturing companies with complex operational demands and regulatory requirements. Enterprise-level ERP includes real-time production monitoring, multi-level lot traceability, and detailed reporting to meet food safety standards.

For each of the tiers above, implementation often involves a substantial upfront cost, commonly around twice the annual license fee. This cost includes setup, customization, and training to integrate the ERP into your manufacturing operations.