IoT and ERP Integration: Benefits and Challenges

Integrating IoT with ERP means connecting smart devices and their real-time data with ERP software to enhance automation, decision-making, and business processes.

IoT and ERP integration benefits include:

- Enhanced forecasting

- Improved operational efficiency

- Deeper business intelligence (BI)

- Optimized asset management

- Improved data integrity.

What Is IoT and ERP Integration?

The Internet of Things (IoT) equips physical objects with the capability to transmit data over the Internet. On the other hand, ERP software centralizes and coordinates core business operations. When integrated, these systems meld real-world data capture with digital process management.

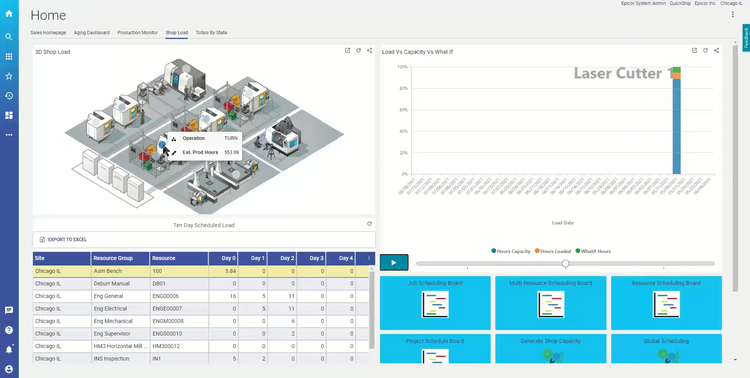

For example, IoT sensors can monitor machine performance, temperature, and production output in a manufacturing plant. The ERP system captures this data to automatically adjust production schedules, order replacement parts, or alert maintenance teams. Some examples of IoT devices used with ERP include:

- Sensors on monitoring equipment

- Asset tracking devices: RFID tags, GPS-enabled devices

- Communication protocols

Integrating ERP with IoT ensures minimal downtime, efficient resource utilization, and timely product deliveries. Some examples of notable ERP systems that support IoT integration include:

What Are the Benefits of Integrating ERP with IoT?

IoT in ERP impacts numerous business dimensions, changing how firms operate, driving them toward automation, and increasing real-time responsiveness.

Forecasting: Companies enhance their forecasting by merging real-time data from IoT devices with historical trends. This continuous info stream helps identify patterns, like factory sensors detecting a gradual decline in machine performance. These insights feed into the ERP’s predictive models, anticipating maintenance needs or potential downtimes.

Operational efficiency: IoT and ERP integration streamlines core processes. For instance, if IoT sensors detect a dip in the quality of raw materials, the ERP system logs this anomaly. This allows plant supervisors to spot potential bottlenecks and reconsider supplier relationships, leading to cost savings and ensuring the delivery of quality goods to customers.

BI: ERP and IoT come together to provide rich, real-time analytics. Companies gain clearer insights into market conditions by continuously analyzing data from various sources. For instance, if IoT machinery tracks an item’s production rate and ERP systems monitor its sales, a sudden sales drop with steady production might signal a shift in market demand or consumer preference.

Asset management: Merging IoT with ERP enhances asset tracking and monitoring. Using smart shelves with weight sensors and RFID tags, warehouses can detect when inventory falls below a certain threshold. Upon notification, the ERP system automatically reorders items, maintaining optimal stock levels to satisfy customer demand.

Data integrity: When systems coordinate seamlessly, they capture and resolve data entry mistakes in real time. This means stakeholders can trust the information, driving informed decision-making and solidifying confidence in your ERP software as a source of truth.

For instance, RFID readers or IoT sensors can automatically record details of raw materials in the ERP system, capturing quantities, material type, supplier information, arrival timing, and storage location. This eliminates human error in data entry and allows staff to focus on more complex tasks.

What Are the Challenges of Integrating IoT with ERP?

Understanding the potential pitfalls of IoT integrations helps companies take a proactive approach, preventing costly setbacks.

Cost: Some organizations find initial setup and ongoing maintenance cost-prohibitive. Fees can quickly add up, from procuring the right devices to updating software. For small companies, these upfront expenses may challenge their ROI prospects.

Legacy equipment: Companies with outdated machinery face hurdles when introducing IoT. They could incur additional costs for necessary upgrades or grapple with compatibility issues, potentially disrupting their workflow.

Connectivity issues: IoT depends heavily on constant connectivity. Areas with weak or inconsistent Internet compromise the benefits of real-time information. Interruptions in data flow could disrupt operations or result in misguided decision-making.

Weak security: The more devices connected, the greater the potential risk of cyberattacks. Integrating IoT expands the attack surface for potential threats. Firms must invest in strong security measures to safeguard their data and operations.

Is Integrating IoT with ERP Worth It?

Syncing IoT and ERP improves decision-making, operational efficiency, and proactive asset management. However, like any significant investment, it comes with its risks. Organizations can reap strategic benefits after tackling initial costs and potential hiccups. Companies without the necessary resources or those operating with extensive legacy equipment should carefully weigh the pros and cons before deploying AI-integrated ERP.