Eyelit MES-M

3 Reviews 5/5 ★ ★ ★ ★ ★A cloud based MES software to enhance factory and manufacturing performance.

Product Overview

EYELIT MES-M (formerly MESTEC) is a 100% cloud-based manufacturing execution system designed for mid-sized and fast-scaling manufacturers. With rapid deployment timelines and low IT demands, it helps teams digitize shop floor operations, track labor in real time, and maintain high compliance standards. Its no-code configurability and out-of-the-box functionality deliver value in weeks–not months.Pros

- Advanced, low-code implementation option

- Cloud-based, multi-tenant solution

- Leverages AI, ML, and optimization to deliver solutions to clients

- Strong out-of-the-box capabilities

Cons

- Functionality is limited to certain manufacturing sectors

- Complex solution requires in-depth training

- Pricing details not provided by the developer

Target Market

Manufacturers that are scaling operations and need a fast, cloud-based solution for their manufacturing processes. It’s particularly well suited for companies in the electronics, aerospace and defense, and medical device sectors that need a quick deployment.Eyelit MES-M Features

Eyelit MES-M (MESTEC) has features that are best for mid-market or fast-scaling manufacturers looking for complete MES capabilities with fast cloud-deployment. For enterprises or organizations requiring on-premise deployment we recommend checking out Eyelit MES.

Core MES Functionality

- Real-time shop floor data capture (touchscreen + barcode)

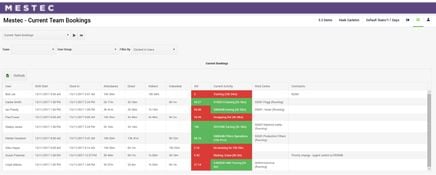

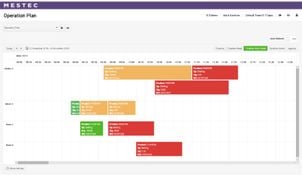

- Dynamic production scheduling with Gantt views

- Finite capacity planning and what-if analysis

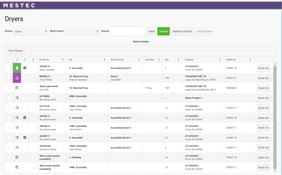

- Live WIP tracking and job progress visibility

- Paperless factory with digital work orders

Inventory & Asset Tracking

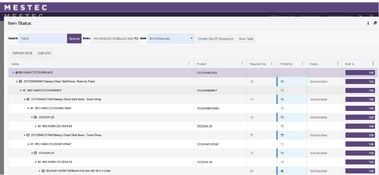

- Material, sub-assembly, and ingredient traceability

- Receipt/dispatch logging and label printing

- Real-time OEE and downtime monitoring of machines

- Tool management and IIoT connectivity

Quality and Compliance Management

- Quality checks

- Electronic device history records (eDHR)

- Non-conformance and issue management

- Detailed manufacturing workflow definition and enforcement

- Document links

- Rework routings and recording

- Monitoring of process parameters

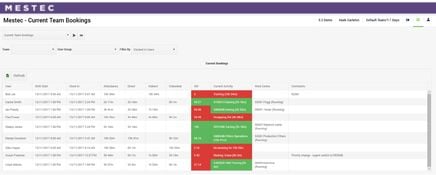

Labor Management

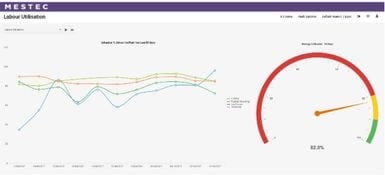

- Live labor tracking and productivity reporting

- Digital timecards, time & attendance

- Skill-based resource allocation

- Live activity views

Dashboards & Analytics

- 130+ pre-built KPIs and real-time dashboards

- Metrics for cost, throughput, downtime, scrap, utilization, and more

- Supports continuous improvement and lean initiatives

Industries Supported

- Aerospace and Defense

- Industrial

- Automotive

- Medical Devices

- Electronics

- Project Engineering

- Food

MESTEC Integrations

- Microsoft

- Oracle NetSuite

- Sage

- Infor

- Epicor

- SAP

- QuickBooks

- and more.

Product Overview

Developer Overview

Related Products

User Reviews of Eyelit MES-M

Write a Review- Manufacturing

Increased Efficiencies

Using MESTEC, our team has significantly increased efficiencies from the office to the field through automation and real-time analytics. Traceability and quality control have improved with comprehensive data tracking, enhancing product deconstruction and sustainability efforts. Full visibility into labor utilization and supply chain operations has reduced costs and improved on-time deliveries. The platform offers rapid reporting, cloud security, customizable dashboards, and regular upgrades, driving continuous innovation and supporting progress toward net-zero goals.

Each month, we get back twenty times the cost

Prior to installing the MESTEC factory management system, we reckoned that unrecovered labour costs amounted to £10-15,000 per month and was a problem that had been growing progressively as the business grew. Today GTK is entirely free of the unrecovered labour burden and, as we continue to gain efficiencies using the data MESTEC provides, we’re targeting a third year of real term cost reductions to drive our competitiveness in the market.

Each month, we get back twenty times the cost of our monthly MESTEC subscription in tangible financial value–which is impressive, and significantly exceeded our expectations.

Without doubt, we can demonstrate very real savings

MESTEC gave us the ability to link people to work centres. Which not only gave us the ability to ensure that the people performing tasks were appropriately qualified and ‘current’, but also gave us log-on and log-off times, from which we could capture manufacturing cost and efficiency metrics.

Without doubt, we can demonstrate very real savings. From capturing and reporting ‘as-built’ data, to faster cycle times and improved material flow, we’re a business today that runs far more efficiently, thanks to MESTEC.