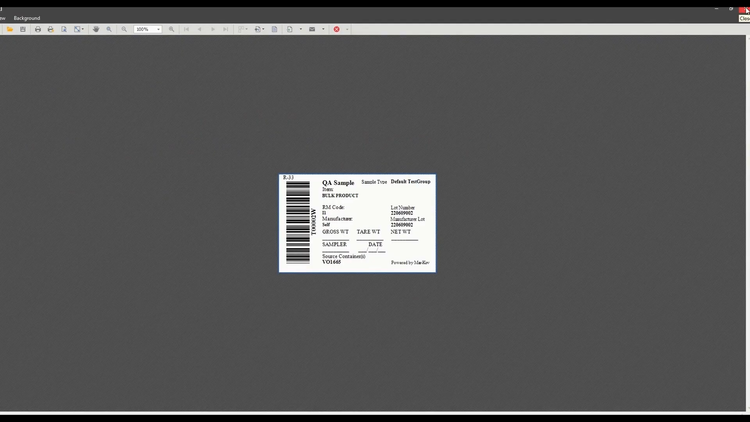

The Best Process Manufacturing Software

Process manufacturing software helps batch manufacturers keep track of recipes, control costs, and comply with regulations. We’ve evaluated and ranked the top solutions based on the best industry fit, company size, and core functionalities.

- Infinite serialization levels for diverse requirements

- Integrated QC tests throughout product lifecycle

- Seamless regulatory compliance with ERP foundation

- Comprehensive formula and recipe management

- Seamless integration with leading financial systems

- Includes quality control and compliance features

- Recalls and mock recalls are easy to perform

- Greatly increases the ability to fill orders

- Wide variety of reports

We reviewed ERP for process manufacturing, covering continuous and batch production processes, from petroleum refining to food and beverage. Our selection criteria considered value for money, industry specialization, ease of use, and support for various compliance requirements.

| Software | Best for | Starting Price |

|---|---|---|

| Deacom | Petroleum Refining | $500 for Essentials Plan, $5,000 for ERP |

| BatchMaster | Food and Beverage | $2,000/user, perpetual license |

| Mar-Kov | Inventory Management | $159/month |

| Datacor | Chemicals | Custom Quote |

| Cometri Product Manager | Cosmetics | Custom Quote |

| QAD ERP O3 | Pharmaceuticals | Custom Quote |

| MRPEasy | Textiles | $49/user/month |

| xTuple | Paints & Coatings | $175/user/month |

| Vicinity | Breweries | Custom Quote |

| Aptean Process Manufacturing ERP | Batch Tracking and Traceability | Custom Quote |

- Deacom: Best for Petroleum Refining

- BatchMaster ERP: Best for Food & Beverage

- Mar-Kov: Best Inventory Management

- Datacor: Best for Chemicals

- Cosmetri Product Manager: Best for Cosmetics

- QAD ERP O³: Best for Pharmaceuticals

- MRPEasy: Best for Textiles

- xTuple: Best for Paints & Coatings

- Vicinity Software: Best for Breweries

- Aptean Process Manufacturing ERP: Best Batch Tracking and Traceability

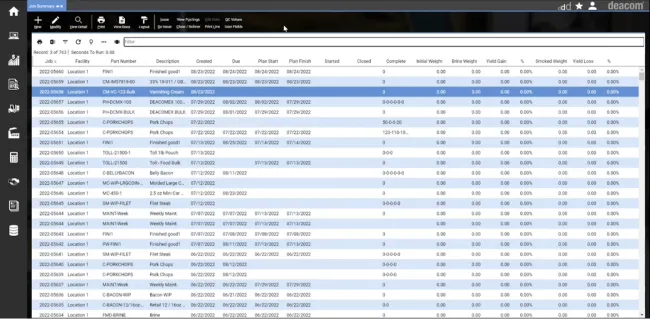

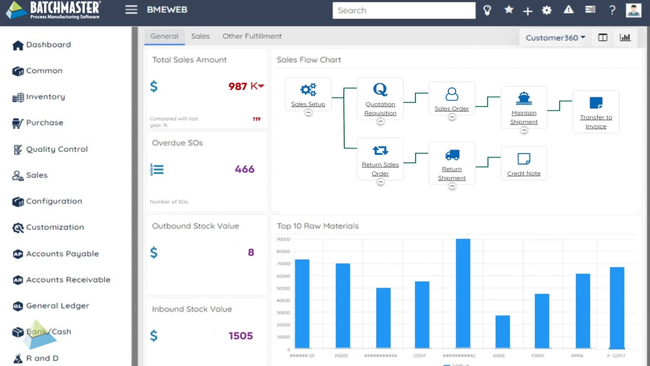

Deacom - Best for Petroleum Refining

Deacom’s maintenance, repair, and operations (MRO) module integrates directly with production schedules, making it easy for petroleum refiners to manage preventive maintenance alongside production. The master production calendar allows you to minimize downtime by scheduling maintenance during low-production times or planned shutdowns, minimizing downtime.

This module also streamlines equipment tracking down to individual components like compressors, motors, and pumps. You can map each work center or machine within a larger hierarchy, with every component thoroughly tracked and documented. Each equipment entry includes specific info such as location, manufacturer details, and even serial numbers for easier identification. For example, a distillation unit might contain several machines like compressors and pumps, each with unique parts; you can track these down to the smallest components, like valves and seals, for more precise maintenance planning.

Additionally, refiners can set preventive maintenance based on flexible triggers, including:

- Calendar Days: Set specific days for regular tasks.

- Production Volume: Trigger maintenance for critical equipment after processing a set amount of raw materials.

- Hours of Operation: Schedule maintenance intervals based on cumulative machine runtime.

The MRO module integrates with Deacom’s MRP and accounting tools, helping manage requisitions for maintenance supplies. All maintenance-related orders flow directly into accounting for more accurate budget tracking and cost management.

For smaller operations, Deacom Essentials starts at $500 per month, while the full version with advanced features is available from $5,000 per month. This pricing structure makes the software accessible to both smaller operations and growing businesses.

Learn more about Deacom on our product page.

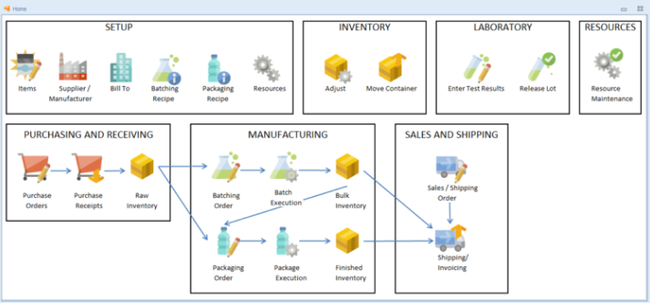

BatchMaster ERP - Best for Food & Beverage

BatchMaster ERP’s recipe management functionality allows you to make dynamic adjustments like scaling batch sizes up or down depending on demand. Additionally, if the cost of core ingredients like oils or produce spikes, you can easily substitute ingredients based on cost changes or seasonal availability. This keeps your operations flexible and cost-effective.

This ERP syncs recipe management with cost analysis, so you can roll up both actual and estimated costs for ingredients, batches, and finished goods. You can factor in variable costs for perishables, high-cost spices, and even packaging materials. Plus, you can run “what-if” costing analyses during product development so you can manage margins across fluctuating market conditions and ingredient prices.

Additionally, BatchMaster’s recipe management integrates with its QMS module to provide strict quality controls for each batch. You can set specific quality control parameters directly in the recipe and generate automated QC plans for HACCP compliance, allergen testing, and expiration tracking. You can even make real-time formula adjustments based on test results, meaning each batch that leaves your facility meets safety and quality standards.

The interface can take some time to figure out, as the layout of modules isn’t always intuitive. Users will likely need a little extra time to grow proficient with the platform. That said, it uses Microsoft’s .NET framework, so this might be less of a hurdle for those already familiar with that product ecosystem.

Review pros, cons, and pricing on our BatchMaster product page.

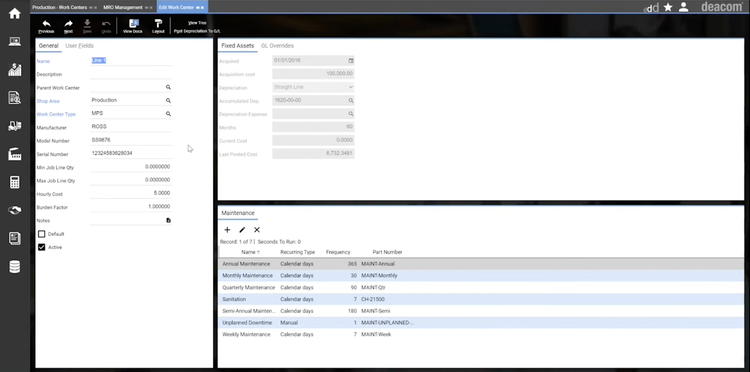

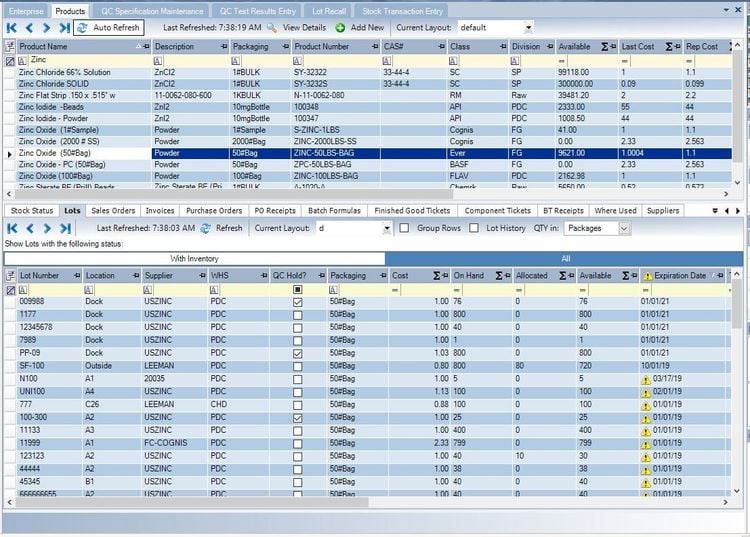

Mar-Kov - Best Inventory Management

Mar-Kov’s extensive inventory management module is great for process manufacturers of all types, whether you’re in chemicals, food and beverage, or cosmetics. The system lets you track container-level stock of all ingredients, components, and finished goods to maintain accuracy for all production levels. When your team receives goods, they can generate internal barcodes for simple labeling, and the system even reminds them to take a test sample to manage quarantine. This is crucial for quality assurance and compliance.

The system also lets you warehouse your inventory effectively. Track every time by location and configure unique storage rules so you always know where stock is. Mar-Kov supports FEFO and FIFO methods, so expiring batches are always moved first to avoid spoilage. And when they are moved, it generates electronic signatures automatically to comply with FDA 21 CFR Part 11 regulations.

Unlike many of the systems on the list, Mar-Kov is an MRP system, not a full ERP system. It’s a great option for small and midsize companies looking to integrate with QuickBooks Online or their current ERP system. Pricing starts at $159/month, though you’ll need a custom quote for exact figures.

See user reviews and more key features on our Mar-Kov product page.

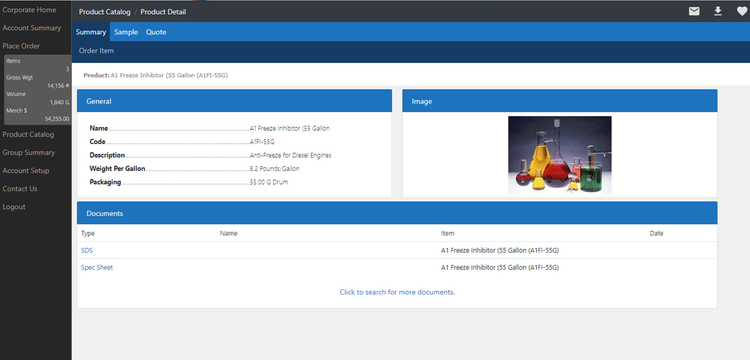

Datacor - Best for Chemicals

Datacor ERP’s hazardous materials management tool helps your plant meet strict regulations, including those set by the EPA. The system helps you adhere to safety and environmental standards for flammable liquids, corrosive substances, and toxic materials. Its cradle-to-grave lot traceability makes it easy to track materials from procurement to disposal for safer storage and fewer spills or accidents.

Additionally, the system documents every production stage, capturing details like batch numbers, quantities, and handling procedures. Automated documentation streamlines your compliance reporting and provides an accurate log of your operations, which prepares you for potential audits.

Datacor’s built-in label generation tools support compliance with the Globally Harmonized System of Classification and Labeling of Chemicals (GHS). These labels include essential elements like pictograms, signal words, and hazard statements, everything you need for total compliance. Additionally, this ERP can generate and maintain safety data sheets (SDS) to meet GHS requirements. These SDS provide critical details on the properties, hazards, and safe handling of chemicals, ensuring your safety info is always up-to-date and readily accessible.

Learn more about Datacor’s key features on our product page.

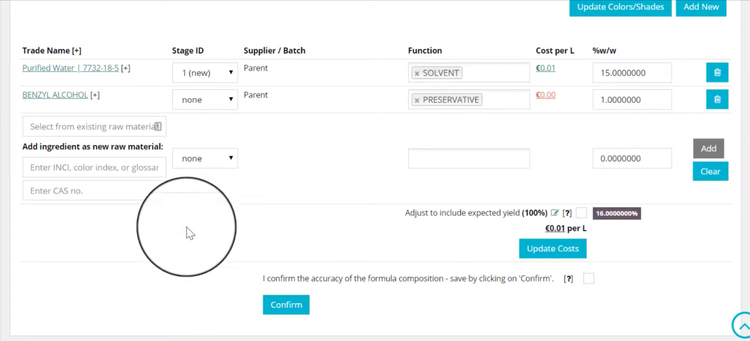

Cosmetri Product Manager - Best for Cosmetics

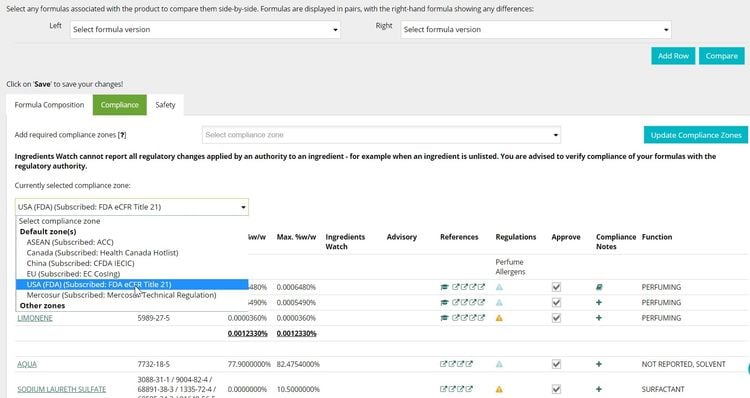

Cosmetri Product Manager includes powerful formulation management and regulatory compliance tools. These streamline product development from initial concept to market approval. They also ensure that formulations for fragrances, makeup, and skincare meet strict regulatory requirements and safety standards.

Cosmetri has a database of over 27,000 cosmetic ingredients. You can select raw materials by the International Nomenclature of Cosmetic Ingredients (INCI) or Chemical Abstracts Service (CAS) number. This makes it easier to source ingredients and ensure consistency across your formulas. You can even import your own raw material data to integrate existing suppliers or specialized ingredients into your projects. By providing access to a wide range of verified ingredients, Cosmetri accelerates the R&D process.

Additionally, the software lets you calculate formula costs by factoring in raw materials, packaging, and labor. You can manage these in any currency, with real-time exchange rates ensuring accurate pricing for international markets. Plus, the system supports cloning and comparison, so you can quickly test multiple formula versions to find the best balance of cost and performance without sacrificing quality.

As for regulatory compliance, Cosmetic has built-in regulatory data for different global markets. You can create custom ingredient blacklists based on regional bans. You can also assign ingredients to set compliance zones, ensuring your products are always in line with FDA guidelines or the EU Cosmetics Regulation. This greatly reduces your risk of non-compliance during approval or market entry.

Cosmetic offers three different plans, including the Essentials Plan, which includes up to five users and 100 products. You’ll need to upgrade to the Standard Plan for unlimited products and the Professional Plan if you need to include over ten users.

Learn more about Cosmetri Product Manager.

QAD ERP O³ - Best for Pharmaceuticals

QAD ERP O³ offers extensive quality management through its lot control and serialization features. It can help manage materials like active pharmaceutical ingredients, excipients, and solvents. As these materials move through different production stages, from compounding to formulation, the system captures each step. Serialization adds deeper traceability, allowing you to track individual units for accurate regulatory reporting. This helps you adhere to the Drug Supply Chain Security Act (DSCSA), letting you quickly retrieve details of a product’s complete history.

The ERP system integrates with QAD’s enterprise quality management system (EQMS). It automates quality checks and records the results for better regulatory compliance. In this way, the tool helps meet the FDA’s Good Manufacturing Practices (GMP) through in-process quality checks and non-conformance management. When an issue arises, QAD automatically flags it and triggers the corrective and preventive action (CAPA) process to address it right away.

This system even auto-generates Certificates of Analysis (COAs) and other compliance documents for regulatory submissions and inspections. These records validate your production processes and quality control steps, helping your team demonstrate full GMP adherence with ease.

QAD ERP O³ is well-suited for mid-sized to enterprise-level healthcare and pharmaceutical companies. However, its complex functionality and higher starting costs may be more than smaller companies can handle. For a lower-cost option with a compact feature set, xTuple also supports the biomedical and pharmaceutical industries.

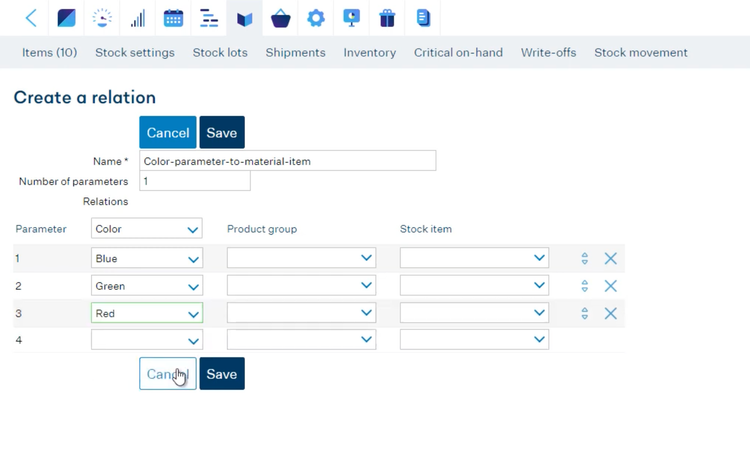

MRPEasy - Best for Textiles

MRPEasy uses flexible, parameterized structures to help you better manage your bills of materials (BOMs). This allows you to dynamically adjust components and quantities based on fabric types, colors, and sizes.

For example, if you have fabrics with the same thread count in different colors or fibers, you can group them together in the system based on that shared parameter. For example, you may have a red cotton and blue polyester fabric, both with a 200 thread count. When you switch from one material to the other in the BOM, MRPEasy automatically updates the required quantities and adjusts related aspects like cost and weight. This reflects across the entire BOM hierarchy, keeping your production aligned with your latest specs.

The system also provides strong inventory tracking for different BOM variations. It automatically updates inventory levels as BOMs change and monitors available stock for each material variant. This is useful when you’re managing small textile runs or custom orders with slight variations. Even with frequent design changes, your production process will stay on track, all while avoiding material shortages.

MRPEasy starts at $49/user/month, making it one of the more affordable platforms for process manufacturing. The matrix BOM and product with parameters features are available in the Professional Plan at $69/user/month, still positioning MRPEasy on the lower end of the pricing spectrum for such solutions.

Get details on pros, cons, and pricing on our MRPEasy product page.

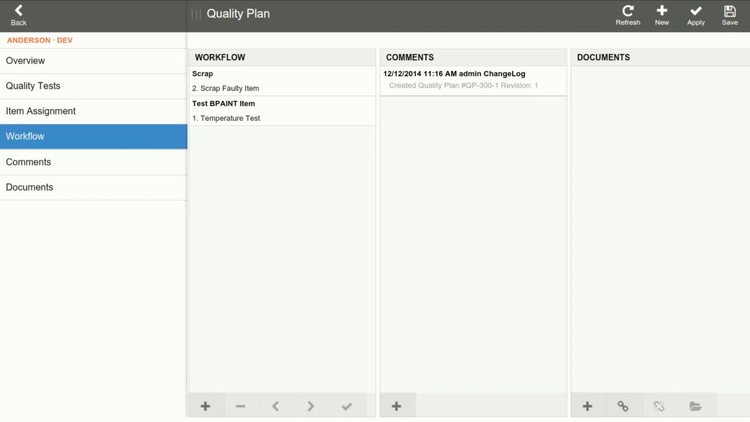

xTuple - Best for Paints & Coatings

In xTuple, the quality workflow tool allows you to define and automate quality testing processes through custom workflows. Each includes test steps, pass/fail criteria, and follow-up actions based on results. When the system triggers a quality test, the workflow automatically assigns it to a relevant team member and flags items based on test results.

Start by setting up workflows aligned with your quality standards for attributes like color, viscosity, and dry time. When you establish these parameters upfront, you can ensure each batch meets these benchmarks before moving forward. You can initiate quality tests at specific production stages, like after mixing or packaging. If the batch meets the initial quality checks, the workflow proceeds to the next stage. If it fails, the tool launches predefined corrective actions, like adding corrective ingredients to fine-tune the batch. This keeps your processes efficient and minimizes delays.

When an item doesn’t meet quality standards, xTuple flags it for different types of handling. This is critical for paints and coatings, where even slight variances can impact performance and safety. These can include:

- Rework: Sending items back for adjustments, like adding pigments or ingredients to achieve the right consistency; reduces waste and helps bring items back into compliance without added production cycles.

- Quarantine: Isolating potentially defective batches for further review; this is useful for items awaiting lab testing for safety and performance.

- Scrap: Disposing of items that don’t meet quality or compliance standards to prevent defective products from reaching consumers.

xTuple is a cost-effective option starting at around $175 per user per month. Pricing can vary depending on whether you choose cloud or on-premise hosting and any additional support packages. With a five-user minimum for the manufacturing edition, pricing is based on named users–meaning only the specific users who need access at any one time.

Read our full review of xTuple to learn more.

Vicinity Software - Best for Breweries

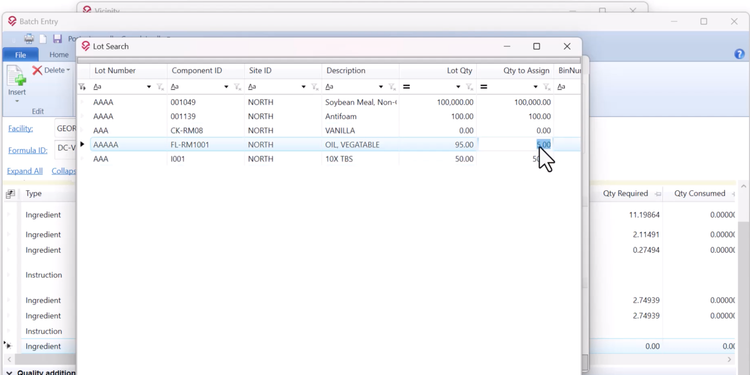

Vicinity Software gives breweries a precise lot tracking tool that streamlines inventory adjustments and ingredient tracking. You can quickly pinpoint hops or malt in the system by searching lots using attributes like site ID or description. This is handy when need to make last-minute recipe changes.

The lot selection screen allows you to assign exact ingredient quantities to batches, all in a single view. For example, if you only want to use a part of a malt lot, you can input the precise amount and leave the remainder for future brews–all without navigating additional popups or screens.

Plus, you can make mid-brew adjustments even during production. Vicinity allows you to tweak batch tickets in real time without modifying the master recipe in the system. For example, if you want to incorporate a clarifying agent mid-brew, just include it in the ingredient list with the desired quality. Then, save the batch ticket to update your production records.

Vicinity’s lot selection capabilities extend to rework as well. You can combine remaining ingredients from numerous lots to create a new product, like a seasonal brew from excess hops. The rework functionality tracks each lot and its usage, providing traceable records on origin, quantity, and use in new batches. That way, every batch adheres to your quality standards, even when you’re repurposing ingredients.

Aptean Process Manufacturing ERP - Best Batch Tracking and Traceability

Aptean Process Manufacturing ERP can help you monitor, manage, and trace batches throughout the production cycle, from raw materials to finished goods.

The system creates batches and assigns raw materials lot numbers that link to the finished product, such as pineapple pulp and sugar for tropical juice. During production, the ERP captures and records any data related to the batch, such as the temperature maintained during pasteurization or production date. The system creates a network of connections between raw materials and final goods, enabling end-to-end traceability.

After production, the juice is packed into bottles containing a label with a batch number for traceability. If a supplier reports a contaminant in your pineapple pulp, you can quickly and easily identify all affected batches using Aptean.

The batch traceability functionality lets you pinpoint stores and distributors that received the affected batches. This allows you to initiate targeted recalls, minimizing brand damage. Regulatory bodies will receive detailed records of the recall, ensuring compliance and avoiding any penalties.

Aptean Process Manufacturing ERP specializes in process manufacturing, offering full visibility into sales, inventory, purchasing, and manufacturing operations. It’s tailored to industries like food and beverage, chemicals, and pharmaceuticals.

What is Process Manufacturing Software?

Process manufacturing software helps optimize production operations that transform raw materials into final products—liquids, powders, or compounds—through processes like mixing or chemical reactions. Unlike discrete manufacturing, which builds distinct, countable items from separate parts, process manufacturing focuses on continuous or batch-based production.

Process manufacturing ERP encompasses the entire workflow, from sourcing ingredients or raw materials to producing finished goods. Modules often include inventory control, recipe management, production planning, quality assurance, and tools for regulatory compliance.

Continuous vs. Batch Production

- Continuous: Operates non-stop, continuously feeding materials to produce high-demand, high-volume products. Used in industries like petrochemicals, cement, and certain food production like flour milling.

- Batch: Processes materials in specific, fixed quantities, where manufacturers can tweak quantities, recipes, or ingredients between batches. Common in pharmaceuticals and food and beverage, where formulas vary slightly per batch.

Types

| Category | Description |

|---|---|

| Chemical manufacturing software | Tracks compliance (FDA, EPA, DEA, ATF, FSIS) with recipe management, quality assurance, traceability, and waste control for sectors like industrial chemicals, fertilizers, and plastics. |

| Cosmetic manufacturing software | Manages quality, ingredient tracking, and FDCA compliance, ideal for skincare, makeup, and hair care products. |

| Food manufacturing ERP software | Supports batch tracking, traceability, and food safety compliance with FDA, USDA, HACCP standards, suited for packaged foods, dairy, and frozen products. |

| Pharmaceutical manufacturing software | Ensures compliance (GMP, FDA) with recipe management, batch tracking, and serialization, tailored for manufacturers of prescription drugs, over-the-counter medications, and supplements. |

| Oil and Gas Software | Manages blending, quality control, and adherence to EPA and OSHA standards for gasoline, diesel, and lubricant production. |

Common Challenges

While process manufacturing plays a pivotal role in various industries, it also poses several challenges. These challenges include:

- Cost Control: Manufacturing processes can be expensive, and effective cost control is essential for profitability. Process manufacturing software assists in optimizing production, managing inventory levels, reducing waste, and enhancing operational efficiency.

- Increased Competition: The manufacturing landscape is highly competitive, and staying ahead requires continuous improvement. Process manufacturing software provides valuable insights and data analytics to help organizations identify opportunities for optimization and innovation.

- Streamlined Quality Assurance: Maintaining high-quality standards is crucial, especially in industries such as pharmaceuticals and food and beverages. Process manufacturing software enables companies to establish robust quality assurance systems, track product quality at every stage, and quickly address any quality issues.

- Regulatory Compliance: Industries involved in process manufacturing are subject to stringent regulatory requirements. Compliance with safety, environmental, and quality standards is critical. Process manufacturing software helps organizations ensure adherence to these regulations by providing traceability, documentation, and real-time monitoring capabilities.

Key Features and Benefits

Continuous and batch manufacturing software includes functionalities to handle a variety of production environments and challenges:

| Feature | Description | Benefit |

|---|---|---|

| Lot Control and Batch Tracking | Monitors and records each batch, enabling detailed tracking of production batches for compliance and recalls. | Ensures traceability for regulatory compliance and simplifies recall processes if necessary. |

| Recipe and Formula Management | Manages recipes and formulas for batch production, allowing adjustments for consistency and quality. | Maintains product quality by ensuring consistency across production batches. |

| Inventory Management | Tracks stock levels, reorder points, and usage rates for raw materials, WIP, and finished goods. | Optimizes stock levels to reduce waste, minimize stockouts, and manage costs effectively. |

| Quality Control | Implements real-time quality checks at each production stage to ensure standards are met. | Helps avoid defects, ensures compliance with safety standards, and improves customer trust. |

| Compliance Management | Maintains records for FDA, EPA, and other regulatory bodies, including reporting and documentation. | Reduces risk of non-compliance and simplifies audits by maintaining thorough documentation. |

| Expiration Tracking | Monitors shelf life and expiration dates for raw materials and finished products. | Reduces waste by preventing the use of expired materials, enhancing product safety. |

| Recall Management | Facilitates quick and efficient recalls by tracking affected batches and locations. | Minimizes disruption, protects brand reputation, and ensures swift corrective actions. |

| Production Scheduling | Plans and schedules production runs based on demand forecasts, resource availability, and lead times. | Enhances productivity, reduces downtime, and aligns production with demand. |

How to Choose Software

Choosing the right process manufacturing ERP depends on whether it can handle the operations unique to your sector. Here are our ERP recommendations based on the best industry fit.

| Industry | Estimated U.S. Market Size | Recommended ERP | Example Products |

|---|---|---|---|

| Chemical Manufacturing | $800 billion | Datacor ERP | Industrial chemicals, fertilizers, plastics |

| Food and Beverage Production | $760 billion | BatchMaster ERP | Packaged foods, beverages, dairy products |

| Pharmaceuticals | $550 billion | QAD ERP O³ | Prescription drugs, over-the-counter medications |

| Petroleum Refining | $500 billion | Deacom | Gasoline, diesel, jet fuel |

| Pulp and Paper Manufacturing | $200 billion | MRPEasy | Paper products, packaging materials |

| Textile Production | $100 billion | MRPEasy | Fabrics, apparel, home textiles |

| Paints and Coatings | $50 billion | xTuple | Industrial coatings, consumer paints, varnishes |

| Cosmetics and Personal Care | $40 billion | Cosmetri Product Manager | Skincare products, makeup, hair care products |

Technological Integrations

- Cloud computing transforms process manufacturing processes by offering enhanced accessibility and flexibility. This integration stores all your production data, such as formulas, recipes, and batch records, into one centralized system.

- Mobile applications can help you better track your production process and manage your inventory. You can even set role-based access to ensure secure remote control of your ERP system.

- IoT connects production and storage equipment and devices to your ERP, allowing you to effectively track machine performance, production quality, and environmental conditions continuously. It can also provide alerts for deviations, such as equipment overheating or batch inconsistencies.

Pricing

Pricing for process manufacturing ERP can vary depending on your business’s size and complexity and any specific modules or features required.

- Entry-level software: MRPEasy starts at $49/user/month; xTuple starts at $175/user/month

- Premium options: Deacom costs $500-$5,000, depending on whether you choose the Deacom Essentials or full ERP suite.

- On-premise software: Its initial cost ranges from $10,000 to $100,000 or more, with setup and training costing between $20,000 and $50,000. Annual support fees may vary from $1,500 to $20,000.

- Cloud-based options (SaaS): Ongoing subscription fees range from $1,000 to $30,000 annually, with lower upfront costs of $5,000 to $20,000. Costs for extra storage or premium support range between $1,000 and $5,000 annually.

In most cases, you’ll need to request a pricing quote directly from the ERP provider. Key factors influencing ERP costs include:

- Add-on modules: Adding specialized modules like product lifecycle management can significantly increase the overall cost.

- Training: Expenses can vary widely based on system complexity and user count.

- Implementation: Setup costs often depend on integration needs and the time required to tailor the system to your unique manufacturing processes.

- User Count: Costs typically scale with the number of users, as many ERP systems utilize a per-user pricing model.

- Support and Maintenance: Includes technical support and regular updates, with fees varying based on service levels.