BatchMaster ERP

5 Reviews 4/5 ★ ★ ★ ★ ★An end-to-end process and formula-based manufacturing ERP software.

Product Overview

BatchMaster ERP is a process manufacturing ERP designed for formula-based industries such as food and beverage, chemical, and pharmaceutical manufacturing. Instead of forcing manufacturers to adapt to a generic manufacturing system, BatchMaster is built around the complexities of batch production.

It supports product R&D, recipe and formula tracking, packaging, BOM management, job costing, production planning, scheduling, traceability, and inventory control. The system includes SDS/FDA compliance, BRC/SQF lot traceability, quality management, and warehouse management capabilities. An optional mobile app supports production and warehouse workflows using a smart device.

Businesses can run BatchMaster alongside accounting systems like QuickBooks, Sage Products, Microsoft 365, and SAP Business One. Or users can upgrade to the complete ERP that supports process manufacturing, financials, supply chain management, and CRM all in one, with options for on-premise and cloud demployment.

Pros

- Comprehensive formula and recipe management

- Seamless integration with leading financial systems

- Includes quality control and compliance features

Cons

- Pricing requires consultation call

- Steep learning curve

Target Market

Small to medium-sized businesses in process manufacturing industries like food and beverage, chemical, nutraceutical, life sciences, hemp and CBD, cosmetics and beauty, and pharmaceuticals.BatchMaster ERP is an industry-specific manufacturing ERP that offers two solutions: BatchMaster SME Edition & BatchMaster Enterprise Edition.

-

The SME Edition is natively built for the cloud, combining BatchMaster’s advanced process manufacturing add-on with existing accounting or financial management software. This version is best for growing businesses that have outgrown basic accounting functionality and need tools specific to process and batch production.

-

The Enterprise Edition is built on the SAP Business One platform and offers both on-premises or cloud deployment options. This edition for established process manufacturers looking for an all-in-one solution to replace silod systems.

Video Overview

Features

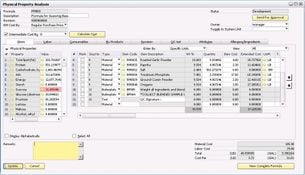

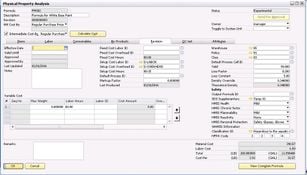

- Product Development: Supports the creation of formulas and packaging specifications, allowing dynamic adjustment of ingredients to meet various targets. It includes multi-level workflow approvals for specification management.

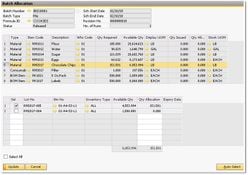

- Production: Facilitates scaling up production, including co-products and by-products, with dynamic job scheduling and auto inventory allocation.

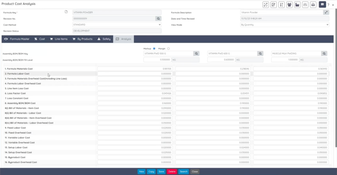

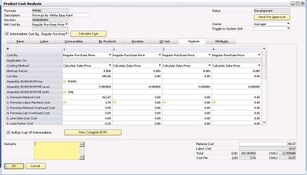

- Costing: Accounts for various costs (raw materials, consumables, labor, etc.) in product development, enabling accurate cost estimation and comparison of actuals to estimates.

- Quality Control: Employs inspection plans, checklists, and QC tests to reduce rework and scrap, and supports continuous improvement through adverse event tracking and compliance capabilities.

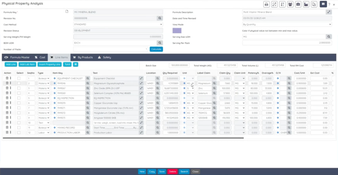

- Inventory Management: Offers comprehensive management of inventory characteristics and real-time visibility across different units of measure.

- Compliance: Generates compliant labels and documents for various standards (e.g., FDA, GHS/SDS) and audit reports to ensure regulatory adherence.

- Traceability: Tracks and traces materials throughout the supply chain for compliance with traceability and recall mandates.

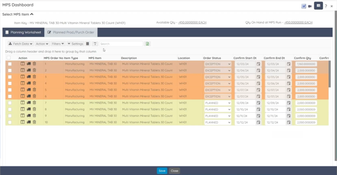

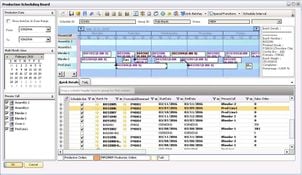

- Master Production Scheduling: Utilizes “what-if” analysis and graphical tools to optimize batch job scheduling based on current and forecasted demand.

- Materials Requirements Planning: Includes dashboards for scheduling purchase orders to maintain optimal inventory levels and prevent production shortages.

- Warehousing: Supports warehouse operations across multiple locations with mobile capabilities for tasks like receiving, order fulfillment, and batch job management.

- Reporting: Provides prebuilt reports and dashboards for trend analysis and business intelligence to inform decision-making.

- Bills of Material: Offers flexibility in combining, mixing, and preparing raw materials, especially for consumer products where packaging is crucial.

- Capacity Planning: Features rough-cut capacity planning to balance resource utilization against production line throughput rates and planned downtime.

- Compliance Reporting: Automatically generates compliance documents like Material Safety Data Sheets in line with various government reporting requirements.

- Formulas: Supports the creation and management of multi-level formulas with audit trails for experimentation and material substitutions.

- Laboratory: Brings computerized formulation to the lab, reducing manual calculations and providing user-definable raw material specifications and formula properties.

- Purchasing: Enhances purchasing operations with sophisticated management tools, integrating seamlessly with accounting software.

- Quality Control: Offers versatile quality control throughout operations, ensuring consistent quality from raw material receipt to finished goods shipment.

- Sales Order Entry: Provides control over sales and order entry with customizable pricing strategies and versatile sales order processing capabilities.

Pricing

Pricing for BatchMaster starts at $1,250/user/month for cloud-based plans. For detailed pricing figures and quotes on on-premise plans, BatchMaster requires a custom quote. Costs typically scale with user count, feature scope, and customization complexity. BatchMaster often bundles user licenses, implementation, and support costs into monthly subscription packages.

There is no free trial or free plan available. BatchMaster offers Free Demos to explore the system.

Product Overview

Developer Overview

Related Products

User Reviews of BatchMaster ERP

Write a ReviewBatchMaster ERP Review

Absolutely terrible. Run from this system at all costs. The company puts all its money into writing contracts and no money into coding a usable software.

Pros

In 2005, it was groundbreaking for process manufacturing. Unfortunately, in 2025, it isn't.

Cons

Poorly functioning, terrible support/implementation staff. Ineffective code. Difficult user interface.

Hair Product Manufacturing Program

I was looking for a manufacturing software for one of my hair product clients. We ended up going with the BatchMaster ERP system as it was made for and fit our industry really well.

We looked at a few other systems but BatchMaster and their robust compliance management, batch tracking, and quality control features stood out to us.

BatchMaster was the clearly best fit especially with all the compliance regulations being imposed recently.

Ability to support our extensive MRP needs

One of the critical pieces of BatchMaster ERP with SAP Business One was its ability to support our extensive MRP needs. If we don’t have excellent control on nutraceutical production and order demand, we could have back-orders that aren’t meeting our customer ship dates and this is unacceptable.

The most comprehensive food manufacturing solution

We reviewed nearly 10 ERP solutions and found BatchMaster ERP with SAP Business One to be the most comprehensive food manufacturing solution that would also be easy to learn and use for our staff and that could address the added complexities and regulations in food manufacturing.

Exciting to find a solution built upon the SAP Business One platform

After stacking up process-manufacturing ERP solutions side-by-side after soliciting responses from nearly 30 ERP vendors, it was very exciting to find a solution built upon the SAP Business One platform that was designed for the chemical industry, meeting most of our requirements right out of the box.