aPriori Software

2 Reviews 5/5 ★ ★ ★ ★ ★A digital manufacturing simulation and cost estimating software for mid-sized to large companies.

Product Overview

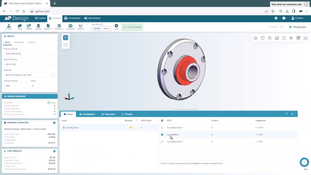

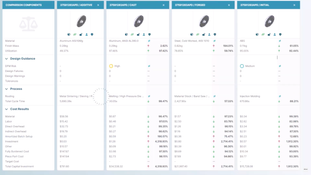

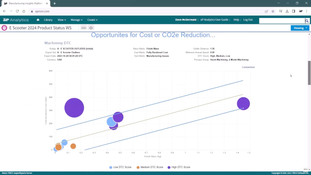

aPriori is a digital manufacturing simulation software used in the manufacturing industry. It can evaluate costs for both CAD models and physical parts, offering user-guided costing function modules that are highly customizable. Additionally, its bulk costing function supports efficient batch part costing analysis. aPriori integrates with CAD tools, enhancing the design-to-cost process.Pros

- Efficient scenario running and analysis

- Offers physical parts cost analysis & bulk costing

- Responsive customer support

Cons

- Some discrepancies in actual cost versus software-estimated cost

- Occasional UI quirks

- Complex troubleshooting for cost variances

Target Market

Medium to large-sized organizations in the manufacturing industry, particularly those in aerospace, defense, and consumer electronics.With aPriori, professionals in design, engineering, sourcing, manufacturing, and cost engineering can analyze cost quickly and accurately in real-time for components and complete product assemblies based on:

- What’s being manufactured: Using intelligent cost modeling, aPriori can create highly detailed part and product cost assessments. It can also import complex engineering bills of materials from ERP, PLM, MRP, and other enterprise applications.

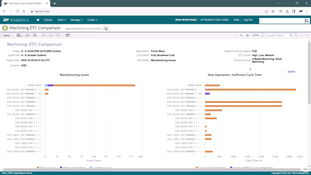

- How it’s being manufactured: aPriori has deep domain expertise in the manufacturing processes, operation sequences, and the cost drivers that most impact product cost.

- Where it’s being manufactured: aPriori Virtual Production Environments allow users to estimate the cost of manufacturing products at specific facilities or buying products from a regional supplier.

aPriori Key Features

aPriori has introduced several highly innovative technologies as part of its product cost management platform:

- Geometric Cost Drivers: A capability within the software that automatically extracts manufacturing process-specific information directly from any 3D CAD model and creates the inputs for cost models that reside in Virtual Production Environments.

- Intelligent Routing Engine: aPriori embeds intelligence within its cost models and manufacturing feasibility rules that help automate selecting the most appropriate manufacturing route within the selected factory. For example, if a user increases the thickness of a part, aPriori may look at the change and instantly understand that a new laser with a higher wattage would be required to cut out the form of the part efficiently.

- Virtual Production Environments: A digital copy of a physical manufacturing plant that includes all of the data and logic about how that facility operates, including raw material data, machine data, labor costs, overhead costs, manufacturing process logic, etc.

Video Overview

Product Overview

Developer Overview

Related Products

User Reviews of aPriori Software

Write a ReviewWe went from eight in-house hours per quote to one hour

With aPriori we make better use of our resources by often shortening our time to market and reducing the time in which we can provide our customers an RFQ answer. In real numbers, with the application of aPriori, we went from eight in-house hours per quote to one hour, freeing up seven hours of our time per quote. That means aPriori can save Soucy up to 3150 hours this year alone.

Adopting a powerful piece of software like aPriori can be a big change

We are a small team and one of our biggest challenges was trying to control and reduce costs, so we adopted aPriori, a product costing software. We were actually a beta test for them, as they typically work with much higher volume companies. Adopting a powerful piece of software like aPriori can be a big change for any company, especially for a small team. Admittedly, it took some time to set the software up properly and learn how to use it to its maximum potential. We’ve been using aPriori for about four years and the platform has overhauled my position as a cost engineer.