FactoryTalk Review: Features, Pros, Cons

We like FactoryTalk for its IoT integrations and in-depth data analytics. Additionally, we found the suite’s AR support vital for large-scale maintenance and operations. The modular approach is great for companies targeting specific aspects of industrial automation, and you can add more as you need.

However, FactoryTalk isn’t viable for companies below the enterprise level. The MES suite requires heavy implementation support and incurs a high total cost of ownership.

- Includes Internet of Things (IoT) support

- Offers global, multi-site customer deployment

- On-premise and cloud-based scalability

- Suited for process, batch, discrete applications

- Pricing requires consultation call

- Steep learning curve

- May require advanced coding knowledge

- Traditional architecture

- Developer Rockwell Automation

- Client OS Windows, Web

- Deployment Cloud Hosted

What Is FactoryTalk?

FactoryTalk is an MES that supports an ecosystem of advanced applications for industrial processes and roles, from system architects to plant operators and maintenance personnel.

-

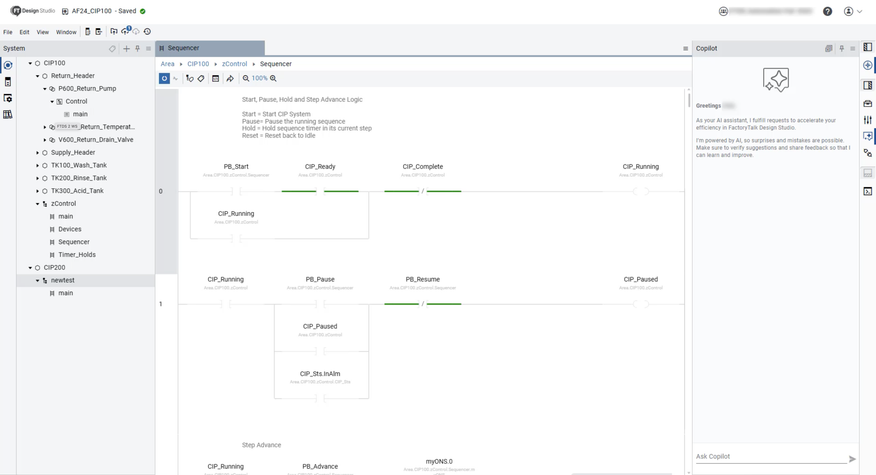

FactoryTalk DesignSuite: Delivers instant value to architects who can use the same language, tools, and resources to build or modify a system.

-

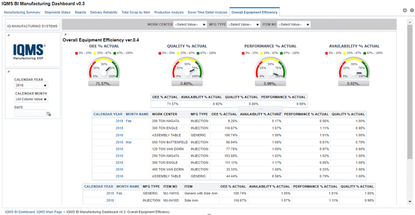

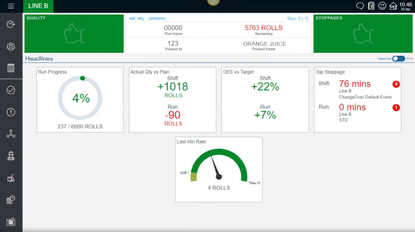

FactoryTalk OperationSuite: Software provides operators with immediate data and role-based information in context.

-

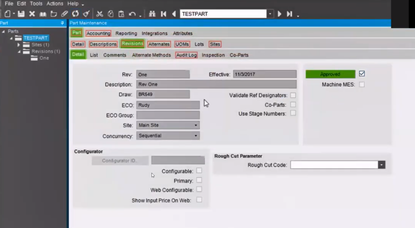

FactoryTalk MaintenanceSuite: Provides users with immediate access to a tool for securing, managing, versioning, tracking, and reporting automation-related asset information across your entire facility.

-

FactoryTalk InnovationSuite: Provides IIoT, data analytics, AR, and machine learning in one comprehensive solution.

Rockwell Automation provides cloud-based solutions through FactoryTalk Cloud. It also offers traditional on-premises solutions, allowing companies to deploy and manage the software within their infrastructure.

Our Ratings

| Usability - 6.8 | While architecture appears traditional, navigation is reasonably user-friendly; utilizing some deeper processes may require advanced coding knowledge or familiarity with internal manufacturing processes. |

| Support - 7.7 | May require TechConnect contract for some online features and phone support.; users can also submit product questions and call engineers for personal remote support; provides extensive online knowledge base, documentation, and industrial training. |

| Scalability - 7.5 | Not compatible with every ERP application, but offers various FactoryTalk suites to meet high-level automation and process control; supports a range of industrial communication protocols; offers mobile and tablet solutions. |

| Security - 10 | Provides features for user authentication and authorization; enables configurable permissions so that users can only access certain areas; provides audit trails for compliance tracking. |

| Value - 7 | High project, training, and annual maintenance costs, but provides an extensive feature set and suite of applications and modules; may be cost-prohibitive for smaller companies but is designed to scale with company growth. |

| Performance - 10 | Enables fast and responsive communication of machines, devices, and systems with technicians and operators; provides real-time data acquisition and processing capabilities. |

| Key Features - 10 | Integrates with PLCs, sensors, and actuators to monitor and control manufacturing operations; includes features such as batch and recipe management, scheduling, and production tracking; also provides asset tracking, maintenance planning, condition monitoring, and predictive maintenance capabilities. |

Who Uses FactoryTalk?

FactoryTalk supports large manufacturing enterprises using discrete, batch, and process operations. It is particularly relevant to sectors that require high-level automation and process control. The food and beverage industry uses FactoryTalk to maintain strict quality controls, ensure product consistency, and manage intricate packaging processes. Additionally, the pharmaceutical sector leverages FactoryTalk for compliance with regulations, traceability, and accuracy in production.

What Features Are Missing?

- Straightforward implementation and adoption: FactoryTalk requires significant training, which can be time-consuming and costly. It might not be intuitive for non-technical users, which could lead to a steeper learning curve and slower adoption of the platform. Additionally, some businesses might find FactoryTalk’s features and capabilities more advanced than their current needs, leading to under-utilization.

- Affordability: FactoryTalk’s initial investment and maintenance fees can be quite high, making it less accessible for smaller enterprises. The cost of implementation could pose challenges for organizations with limited budgets. Finally, the platform may require a degree of customization for specific industries, which could lead to extra costs and time-consuming efforts.

FactoryTalk Pricing

Rockwell Automation does not publicly list FactoryTalk pricing or offer a free trial of its applications. Pricing for FactoryTalk can vary depending on selected products and modules, project scale, number of licenses required, and additional services like support or training.

FactoryTalk is sold modularly, so you can choose which functionalities you need a la carte. This way, you can target specific operational goals without buying tools you don’t need. Alternatively, you can purchase entire suites in one go. Either way, clients will need to contact FactoryTalk directly for a pricing consultation.

Who makes FactoryTalk?

FactoryTalk is made by Rockwell Automation, a prominent company specializing in industrial automation and information technology. Rockwell Automation is known for its wide range of products and services aimed at helping industrial companies and manufacturers improve their efficiency and performance through automation and information solutions.

FactoryTalk is one of Rockwell Automation’s flagship software suites designed to optimize manufacturing operations through visualization, information, and process control applications.

Alternatives

Summary

We recommend FactoryTalk for enterprise-scale manufacturers in various industries, from automotive to pharmaceuticals. The system offers a scalable family of human-machine interface applications, including FactoryTalk View, FactoryTalk Linx, FactoryTalk TeamONE, and FactoryTalk AssetCentre. It’s best for companies that have the technical expertise and budget required to maintain a complex network of applications.

However, we don’t recommend FactoryTalk for businesses outside the industrial automation, manufacturing, or maintenance management fields. Smaller companies will likely under-utilize its vast feature set and find implementation, training, and maintenance fees far too steep.

Overall, FactoryTalk’s data integration capabilities and advanced analytics make it an attractive choice for companies looking to optimize their manufacturing processes and stay competitive in today’s dynamic industrial landscape.

User Reviews of FactoryTalk

No reviews have been submitted. Do you use FactoryTalk? Have you considered it as part of your software evaluation process? Share your perspective by writing a review, and help other organizations like yours make smarter, more informed software selection decisions!