Worximity

3 Reviews 5/5 ★ ★ ★ ★ ★A cloud-based factory automation system for large manufacturers with real-time analytics and overall equipment effectiveness (OEE) monitoring.

Product Overview

Worximity is a manufacturing software known for its real-time factory analytics and performance optimization capabilities. It stands out for its ability to integrate easily with other systems such as ERP and MES. The software is geared towards improving operational efficiencies in manufacturing environments, with features like OEE monitoring, data visualization, and AI-driven manufacturing analytics.Pros

- Has a quick implementation process

- Provides a full overview of business operations

- Uses sensors to measure production speed

Cons

- Lacks some more advanced features

- Pricing details not provided by the manufacturer

Target Market

Medium to large-sized manufacturing companies, particularly in industries like food & beverages, pharmaceuticals, consumer goods, and machining centers.Worximity includes:

- TileConnect: Technology that can be connected to any type of production equipment for wireless automatic data collection–allowing you to monitor events or production counts in real-time.

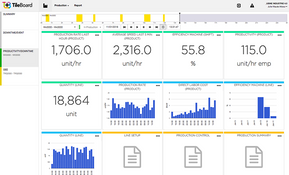

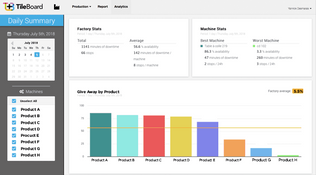

- TileBoard: A real-time dashboard with multi-device access and continuous improvement.

- Smart Factory Analytics: Provides trends on the main causes of downtime, reports on the least profitable products, and reports on the most effective shifts.

Video Overview

Worximity Features

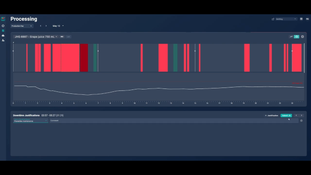

- Quick performance report: Access equipment’s past performance

- Line or equipment timeline of events: View production status and alerts on a timeline

- Real-time email notifications: React quickly to production gap

- Shift performance comparison: Compare teams’ productivity between shifts

- Downtime monitoring: Measure equipment status on a real-time dashboard

- Downtime justification: Use the smart form to discover the reasons for downtime

- Pareto chart reasons: Categorize gap causes in order of importance

- Centralized continuous improvement plan: Share a smart corrective action plan for increased productivity

- Shop floor dashboard: Display factory lines’ performance compared to their objectives

- Throughput monitoring: Monitor the output on production lines in real-time

- Performance by product/job: Visualize the productivity of production lines by product type

- Throughput gap justification: Use the smart form to discover the causes of speed gaps

- Quality monitoring: Measure the number of rejected items on production lines

- OEE monitoring: Monitor production lines’ overall performance

- Non-quality justification: Add causes to explain non-quality

- Yield monitoring: Monitor production lines’ yield to reduce waste

- Giveaway monitoring: Monitor production lines’ giveaway to reduce overproduction

Pricing Packages

Worximity offers 3 packages, all with quote-based pricing:

- Monitoring: Real-time production monitoring to track processes. Key features include OEE and thoughtput monitoring, shift management, and manual data export.

- Analytics: This package includes everything in the monitoring package and offers analytics, ERP API, and multifactory viewing.

- Enterprise: For companies with more than 2 plants.

Product Overview

Developer Overview

Related Products

User Reviews of Worximity

Write a ReviewThe overall picture of our production

The overall picture of our production obtained through TileBoard® allowed us to understand where our main downtimes were and to understand what might be beneficial to us. That is why we want to invest more energy and resources in this technology in order to use the tool to its full potential.

The use of sensors and TileBoard has a real impact

The use of sensors and TileBoard has a real impact on our production speed. These technologies allow us to know what is going on in the factory at any time and from anywhere in the world. With the email alerts, our response time is better and the corrective actions are quickly taken. We can do more in the same period of time.

Downtime has been reduced without additional measures

Because employees are made aware of their impact on production, downtime has been reduced without having to implement additional improvement measures. Employees were diligent in reducing setup times and in reacting more quickly when problems occurred on the line. The more I will use the application over time the more I will be able to identify new opportunities for improvement and reap the benefits from using TileBoard