The Best Chemical Manufacturing Software

In this guide, we reviewed the top chemical manufacturing ERP software for different production workflows. Whether you’re in oil and gas, pharmaceuticals, cleaning compounds, or agricultural chemicals, you’ll find a solution built for your industry’s demands.

- Recalls and mock recalls are easy to perform

- Greatly increases the ability to fill orders

- Wide variety of reports

- Infinite serialization levels for diverse requirements

- Integrated QC tests throughout product lifecycle

- Seamless regulatory compliance with ERP foundation

- Enhanced regulatory compliance

- Optimized supply chain management

- Offers tailored features like recipe and lab management

Using our advanced review methodology, we’ve identified the top ERP for chemical manufacturing. These platforms can handle the intricacies of your sector, from managing formulations to ensuring compliance with strict regulations.

- Mar-Kov: Best Overall

- Deacom ERP: Best for Oil & Gas

- Datacor: Best for Pharmaceuticals

- Sage X3: Best for Cleaning Compounds

- Vicinity Software: Best for Agricultural Chemicals

- DELMIAWorks: Best Process Monitoring

- BatchMaster: Best Traceability Tools

- SAP S/4HANA: Best Product Compliance Module

- Acumatica: Best Formulation Management Module

- SYSPRO: Best Quality Management Module

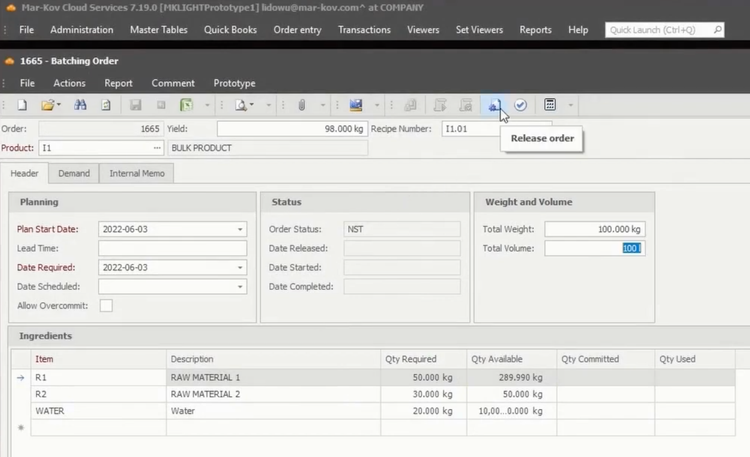

Mar-Kov - Best Overall

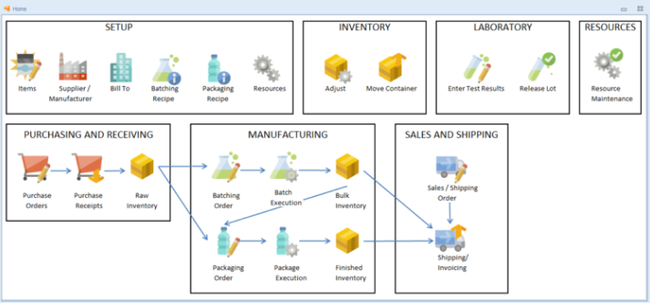

Mar-Kov includes a highly detailed packaging and batching module for managing precise formulations across specialty chemicals, adhesives, and pharmaceuticals. Start with a published recipe listing process steps, exact materials, and safety protocols. When creating a new batch order, Mar-Kov auto-calculates ingredient quantities and yield based on your recipe. If you need to scale production, this manufacturing ERP dynamically recalculates materials while ensuring compliance with regulatory limits, like REACH or OSHA thresholds.

This chemical software seamlessly integrates quality control into its batching workflows. For example, when handling chemicals with critical testing needs, like volatile solvents, you can generate sample sets. The system requires you to record results and approve batches prior to any further processing. This means every product you release meets safety standards before moving on to packaging.

Like the batching process, published packaging recipes include granular instructions for dividing bulk products into containers with precision. This ensures accurate measurements, proper labeling, and compliant transport and storage processes. Finally, Mar-Kov’s batching module offers full traceability, capturing everything from Certificates of Analysis (CofAs) to testing results and expiry dates.

Learn more about Mar-Kov on our product page.

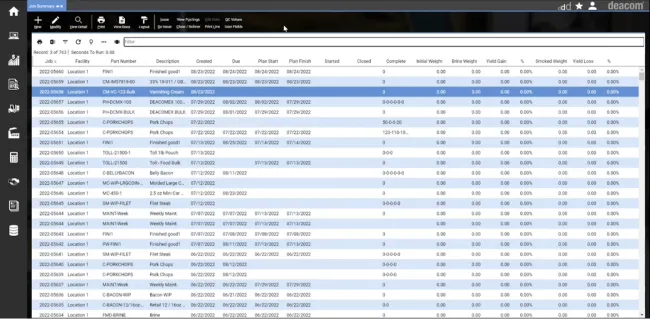

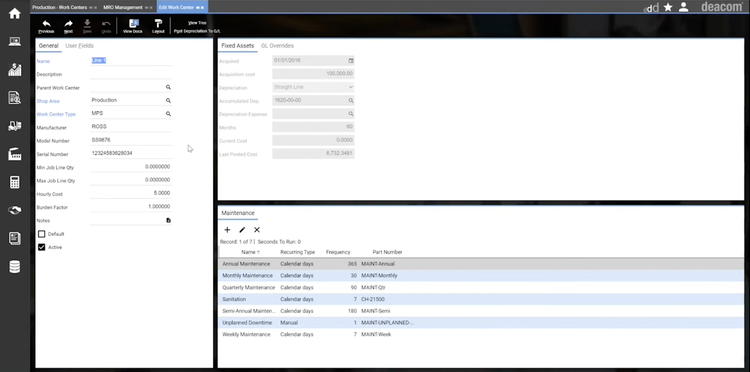

Deacom ERP - Best for Oil & Gas

Deacom helps you integrate preventive maintenance with your workflow schedule through its maintenance, repair, and operations (MRO) module. With the master production calendar, you can plan upkeep during slower periods or scheduled shutdowns.

This module goes beyond basic tracking, offering detailed insights into your equipment and its components. Whether it’s a drilling rig or a pipeline system, Deacom lets you map every asset down to its parts, like joints and fittings. When breakdowns occur, you can create work orders in a few clicks, providing you with a clear picture of all pending activities so they’re aligned with your production timelines.

For larger projects like overhauls, the platform supports maintenance workflows with predefined bills of materials (BOMs). This ensures you have the parts and supplies you need without manual input, keeping your operations efficient and cost-effective. Plus, Deacom’s pricing is quite flexible for businesses of different sizes. Smaller companies can opt for Deacom Essentials at $500 per month. The full-featured version starts at $5,000 per month for more advanced tools.

Learn more about Deacom’s pros, cons, and key features.

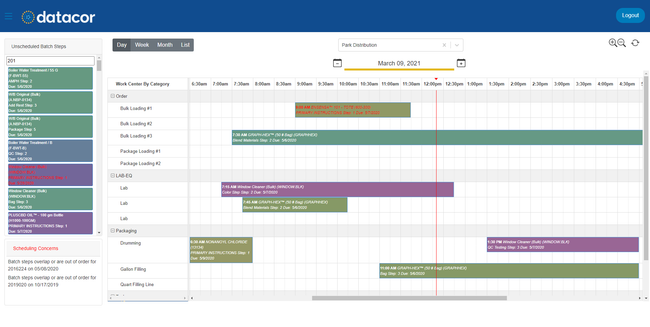

Datacor - Best for Pharmaceuticals

Datacor includes a comprehensive lot tracking and traceability tool that assigns unique identification labels, or lots, to production runs. These can include raw materials, intermediates, or finished goods.

For example, a pharmaceutical manufacturer producing cold medicine can assign each batch a lot number. When you scan the medicine bottles, the system automatically logs details like warehouse location, receipt date, and supplier information. This provides you with full “cradle-to-grave” tracking, critical for meeting Good Manufacturing Practices (GMP) and swift recall management.

Moreover, Datacor’s ERP lot tracking integrates with its quality management module. This attaches essential documents–like Certificates of Analysis (COAs)–to raw materials at the lot level. This can help confirm that active pharmaceutical ingredients (APIs) meet regulatory requirements for potency and purity. This integration supports inbound and outbound quality testing, ensuring every product meets strict FDA specifications before manufacturing or shipping ever begins.

Plus, you can use the system’s bin location functionality for precise barcoding and labeling of every spot in the warehouse. This can help you avoid issues like mixing up lots of the same drug with different shelf lives, which could mean shipping expired medications to pharmacies. By minimizing these risks, Datacor can help you ensure product safety. This chemical ERP starts at $1,500 monthly, though exact pricing requires a consultation call.

See our profile on Datacor for more details.

Sage X3 - Best for Cleaning Compounds

The formula management module in Sage X3 includes strong R&D capabilities, with a built-in environment for developing, revising, and managing formulations. You can store all details here, including proprietary formulations and process instructions, to safeguard your intellectual property.

The R&D sandbox lets you experiment with formula variations without influencing your production data. Test cost-effective ingredient substitutes and adjust concentrations in your cleaning products to meet performance and quality requirements while cutting costs. Real-time costing factors in yield adjustments and inventory costs so you can calculate exact costs for different batch sizes.

Once you approve a formula, the “Publish to BOM” feature smoothly transitions it into production. This results in accurate batch processing and inventory pulls while maintaining a full revision history to maintain an audit trail.

Sage X3 also embeds regulatory standards directly into the formulation process. It tracks CAS numbers and generates safety data sheets (SDS) for strong compliance with REACH, GHS, or OSHA. This is vital when you’re managing hazardous chemicals that are also present in cleaning compounds. You can define quality control specifications as needed. If one of your compound’s performance specs changes, like a higher degreasing power, Sage X3 logs and tracks these updates automatically.

Read about the key features and benefits of Sage X3.

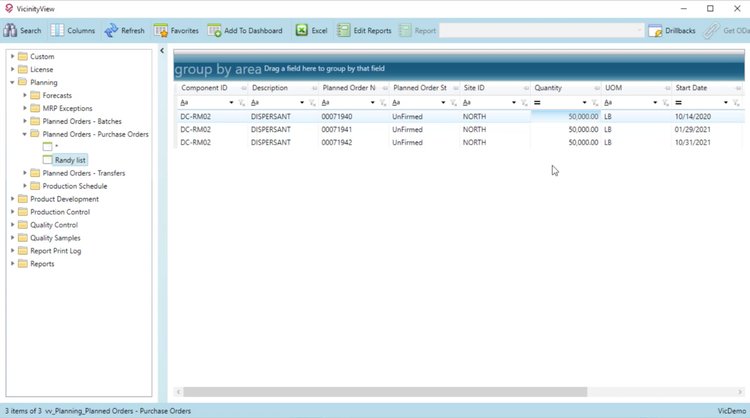

Vicinity Software - Best for Agricultural Chemicals

Vicinity Software’s minimum order quantity (MOQ) and incremental order sizing are game-changers if your plant produces pesticides or fertilizers. You can set a minimum purchase or production quantity for raw materials or finished products, and you can define increments for orders above that threshold.

For example, a fertilizer manufacturer can set an MOQ of 50,000 for a raw material like urea. If demand increases, they can add increments of 10,000 pounds. This allows the material requirements planning (MRP) module to consolidate smaller, fragmented orders into efficient batches, better aligning you with supplier terms.

You can link the MOQ settings to specific vendors and customize requirements based on their terms, helping you meet volume discounts. Additionally, the system reduces unnecessary purchase orders, lowering administrative burden and costs. These are all vital to boosting your margins in high-volume sectors like agricultural chemicals.

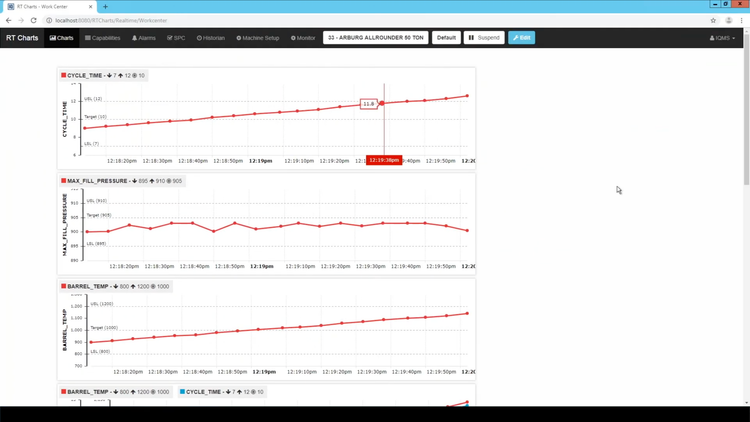

DELMIAWorks - Best Process Monitoring

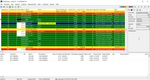

DELMIAWorks’s Real-Time Process Monitoring module makes it easy to track variables like temperature, fill levels, pressure, and cycle timing across your mixers and ovens. It can process data from both modern and legacy equipment via OPC connections, DELMIAWorks’ own device drivers, or a dedicated PLC for older systems. This allows you to get a comprehensive view of how every chemical batch is actually being produced.

Once connected, you can configure each machine and production job with specific thresholds for temperature, pack time, and cycle count. DELMIAWorks sends an alert via email, text message, or plant-wide notifications; a live plant-floor layout shows the affected equipment and its location.

Your team can also compare and correlate variables, such as how a temperature change impacts pressure or cycle time during a batch. This is vital in chemical environments where unstable or unsafe conditions can lead to quality failures or safety risks, allowing you to surface issues long before a batch is completed.

A built-in historian captures all your process data, and you can access it through DELMIAWork’s statistical process control tool. This lets you view performance over time through X-bar and R charts and histograms. Simply filter by production date, work order, lot number, or tooling to get a better view of plant activity. Unfortunately, DELMIAWorks does not publicly disclose pricing, so you’ll need a custom quote.

See our full profile on DELMIAWorks for more details.

BatchMaster - Best Traceability Tools

BatchMaster offers complete traceability of solvents, catalysts, and stabilizers from procurement to final use. This chemical ERP assigns a system-generated lot number to every delivery, which links back to the vendor’s own lot ID. If anything questionable arises, you can divert it straight to QC. The system preserves that linkage through batching, WIP, and shipments, so you can run a bi-directional search in seconds: forward from a suspect raw to every shipment it touched, or backward from a customer complaint to the exact batch and vendor delivery.

The system’s inventory management leverages first expired, first out (FEFO) methodology to reduce waste and keep unsafe materials from reaching production. This chemical industry software automatically flags expired lots for disposal, and operators can’t allocate them to new batches. On the shop floor, workers scan barcodes with mobile devices during receiving, put-away, picking, and production, so the system always knows who handled what and when.

Plus, BatchMaster integrates with SDS authoring tools like Lisam Systems’ ExESS, ensuring Safety Data Sheets are always accurate and attached to the right materials. Built-in quality checks let you track specific parameters like VOC content, viscosity, and density to meet your performance and safety targets. This level of detail means every batch you produce stays consistent and compliant, no matter how complex your formulations are, with a clear audit trail.

Learn more about BatchMaster on our product page.

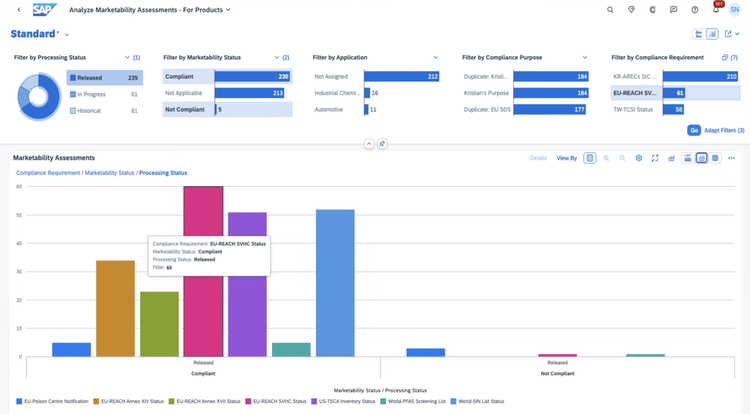

SAP S/4HANA - Best Product Compliance Module

The product compliance module in SAP S/4HANA helps you adhere to regional and global regulations. With embedded data for regulations like EU REACH and TSCA, this platform minimizes manual data entry. It also includes marketability assessments that check whether your chemical products meet regional legal requirements before entering new markets.

SAP S/4HANA includes automated SDS generation and distribution, so your workers and customers always have access to safety documentation during sales and delivery processes. Plus, it validates transportation and packaging to comply with hazardous material handling regulations. This proactively reduces your risk of fines or accidents by verifying allowable shipping methods and routes.

SAP S/4HANA is geared toward large enterprises with 500 to over 10,000 employees, and its pricing reflects its capabilities. Hosted subscriptions start at roughly $20,000 per month and can exceed $100,000, depending on your specific needs. For on-premise perpetual licenses, costs range from $200,000 to over $2 million. For businesses seeking a more budget-friendly alternative, SYSPRO may be a better fit.

Read about key features and ratings of SAP S/4HANA in our full review.

Acumatica - Best Formulation Management Module

Acumatica’s centralized formula database allows you to create, store, and manage formulations. You can even include fine details like raw material types, quantities, unit conversions, and instructions. This ERP tracks any changes made to formulations for a clear audit trail. This supports innovation and reformulation efforts; you can compare versions and analyze ingredient impacts without losing visibility into historical changes.

Because the formulation module syncs with Acumatica’s BOM functionality, you can tie formulations directly to production workflows. This extends even to discrete components like packaging materials, where you can create composite BOMs for both your products and their containers. Additionally, the system can handle complex units of measurement when working with raw materials in various states–whether liquid, solid, or gaseous.

If a batch fails quality control, you can tweak the formulations in real time. You can modify ingredient proportions or add processes like impurity removal to correct any deviations. Unlike many chemical ERP systems, Acumatica doesn’t charge per user. Instead, its pricing depends on your transaction volume and the modules you use. For basic setups, pricing ranges from $1,000 to $1,500 monthly, with most companies spending between $3,000 and $5,000 as their operations grow.

Learn more about Acumatica on our review page.

SYSPRO - Best Quality Management Module

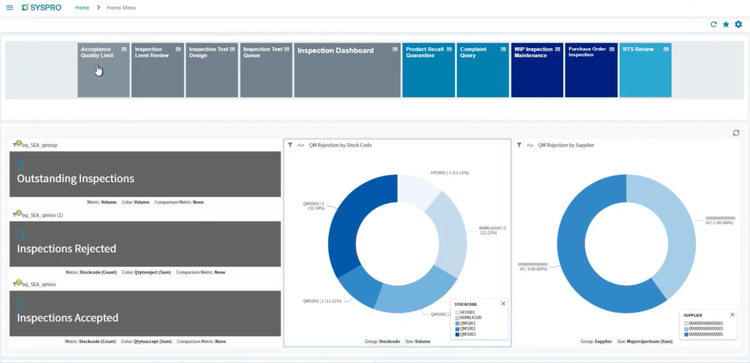

SYSPRO integrates quality management processes directly into its ERP for stronger compliance and traceability. The system allows you to define quality plans for raw materials and finished goods. These plans include acceptable quality limits (AQL) tailored by suppliers, stock codes, and production requirements, helping you meet stringent industry standards.

The system allows you to create and automate specific quality tests for chemical properties like pH levels, viscosity, and density. For example, you can specify tolerances for each property and set test frequencies, such as for every batch or at random intervals. SYSPRO even calculates sample sizes and pass-fail criteria according to ISO standards, which streamlines your compliance processes even further.

Each quality test links directly to SYSPRO’s lot traceability module. So, if a product batch fails, you can trace defects back to specific suppliers or forward to customers so you can notify them. Built-in dashboards showing inspection metrics and trends can help you analyze long-term trends; this makes it easier to identify recurring quality issues and adopt a more proactive approach to process improvement.

SYSPRO’s pricing typically starts at $1,000 to $2,500 per month for smaller setups. However, costs can vary widely depending on factors like your number of users, selected modules, and transaction volumes; this makes it adaptable to different operational needs, whether you’re a smaller company with 10 employees or a mid-sized business with 500.

See our full review of SYSPRO to learn more details.

Other Systems We Like

Aptean Process Manufacturing ERP Ross Edition offers advanced tools to monitor hazardous materials. This includes a graphical lot trace viewer and Google Maps integration for tracking shipments, providing better recall management and quality control.

What is Chemical Manufacturing Software?

Chemical software will centralize formulation, inventory management, order tracking, batching, and quality control for your business and simplify compliance auditing. The goal of this software is to address the challenges faced by chemical manufacturers in all markets, from industrial to consumer goods to life science:

- Accurately plan and budget for consistent order fulfillment

- Manage formulation for a product catalog that could be changing or expanding

- Reduce waste by analyzing resource intake and product output

Chemical manufacturing software can handle all those needs and ensure strict adherence to a litany of changing rules from multiple regulatory agencies.

Key Features

| Feature | Description |

|---|---|

| Formula Management | Track ingredients used in the formula, batch scaling calculations, and encode parts of the formula to keep it secret. |

| Compliance Management | Manage compliance from various regulatory agencies. See detailed information on regulatory compliances that chemical software helps manage. |

| Quality Control/Quality Assurance | Assists in testing product samples throughout the manufacturing process against the normal values to track variations |

| Document Management | Store and retrieve important documents in a variety of file formats. Document management software will help you stay within regulatory compliance requirements. |

| Chemical Inventory Management | Keep track of your current stock levels and purchased materials. Chemical manufacturing software maintains inventory records in accordance with regulatory compliance standards. |

| Tracking Yield Variances | Chemistry software monitors your predicted yield vs. actual yield for every batch you manufacture. This helps you take corrective action if the yield is too low or too high. Depending on the type of chemical you manufacture, regulatory agencies need to be notified if the batch yield is large. |

| Storage Planning | Chemicals you manufacture or ingredients you use often need to meet specific storage requirements. Chemical software will ensure your products and materials are stored at the correct temperature, humidity level, or other pre-defined specifications by notifying you when there is a variance. |

| Shipping Requirements Management | Chemical manufacturing software tracks shipping requirements and creates special shipping labels when needed. |

| Material Requirements Planning (MRP) | Advanced chemical manufacturing software features MRP functionality which includes shop floor control, purchase planning, demand forecasting, and equipment maintenance scheduling. |

Regulations that Chemical Software Helps Manage:

- Environmental Protection Agency (EPA) - The Toxic Substance Control Act (TSCA) regulated chemicals manufactured, processed, or imported. Chemical software helps ensure your records are compliant and can help with creating pre-manufacture notice (PMN) documents as needed.

- Food and Drug Administration (FDA) - If you manufacture chemicals for food & beverage or pharmaceutical industries, you might need to comply with FDA regulations like the 2002 Bioterrorism Act. Chemical manufacturing software will help you track ingredients in accordance with FDA regulations.

- Occupational Safety and Health Administration (OSHA) - Safety Data Sheets (SDS), formerly known as Material Safety Data Sheets (MSDS), need to be in compliance with OSHA’s Hazard Communication Standard (HCS). Chemistry software will ensure your SDS is in the correct format and display the necessary information, including hazard identification, first-aid measures, chemical composition, accidental release measures, handling & storage, personal protective equipment (PPE), reactivity, and toxicological info.

- Hazard Analysis Critical Control Points (HACCP) - Chemical software helps keep records and documentation in accordance with HACCP Principle 7. If you manufacture chemical products for agricultural industries, you likely need to be in compliance with Food Safety Inspection Service (FSIS) HACCP sections 326.6(b) or 381.606(b), as well as section 417.5 for record-keeping compliance.

- Bureau of Alcohol, Tobacco, Firearms, and Explosives (ATF) - If you manufacture explosives or products used in explosives, you need to have reporting in place that is compliant with ATF regulations. Your reports also need to include information about theft or loss of the product.

- Drug Enforcement Administration (DEA) - If you make or use ingredients in the manufacturing process that are regulated by the DEA under the Controlled Substances Act (CSA), chemical software will ensure you meet reporting and documentation compliance.

- Current Good Manufacturing Practice (cGMP) - Chemical software helps create reports in compliance with cGMP.

Benefits

- Manage regulatory compliance - Chemical software helps you maintain regulatory compliance by storing and organizing product and manufacturing process data and can automate reporting.

- Real-time sensors keep products stored properly - Some chemical products must be stored within certain parameters. Sensors monitor humidity, temperature, and lighting, alerting you in real time when they are outside the threshold.

- Automated adjustments - Some chemical software systems can automate small adjustments to temperature or dosage or even stir as needed. This allows you to focus on other tasks instead of continually monitoring and tweaking throughout the manufacturing process.

- Improved supply chain efficiency - A chemical manufacturing ERP solution can handle supply and demand planning, allowing you to save money by purchasing and manufacturing only what you need.

Software by Business Size

-

Small and medium-sized businesses: Small and medium businesses should find chemical software with formula management, so you can scale batch sizes and keep your products consistent. Compliance management is also useful to ensure you adhere to government and state regulations. Consider a chemical software solution that integrates with QuickBooks or another accounting software system you have in place.

-

Large businesses: Manufacturing facilities that are part of a large organization need chemical software that integrates well with the company’s ERP application or other systems that are currently in place. Some manufacturers should look for chemical manufacturing ERP software that features material requirements planning (MRP), chemical inventory management, yield variance tracking, shipping requirements management, storage planning, formula management, and compliance management.

What Are the Risks of Chemical Manufacturing?

- Volatile commodity pricing - The pricing volatility of materials and commodities used in chemical manufacturing makes it difficult to plan the costs of future manufactured products. For example, natural gas is used by many chemical manufacturers, and prices fluctuate regularly. Chemical software can help you plan product quantities based on supply and demand as prices fluctuate.

- Recalls & quality audits - Chemical manufacturers need to be able to act fast in the event of recall as well as maintain strict quality compliance regulations. Chemical software will help you manage regulatory compliance and provide batch traceability to quickly identify contaminated or recalled batches.

- Raw material availability - Depending on seasonality and cost, raw materials needed for manufacturing can be harder to come by. Chemical software can include seasonal demand planning functionalities, so you know when to manufacture certain products.

- Reworking or reblending products - If your product batch doesn’t meet specific quality control standards or the customer’s requirements, your products might need to be reworked, reblended, or completely scrapped and remade. A chemical manufacturing ERP solution can help with costing and inventory management as you correct the error.

Pricing

Pricing for chemical ERP varies, from products like xTuple, which starts at $175/user/month to SAP S/4HANA, ranging from $20,000 per month to over $100,000. Final costs depend on your user count, required modules, and other factors like:

- Setup fees

- Training requirements

- Support and ongoing maintenance

- Deployment method

| Tier | Annual License Cost | Example ERP | Implementation Cost | Company Size Fit |

|---|---|---|---|---|

| Low | $10k – $30k | xTuple, MRPeasy, Katana, Odoo, Striven, JobBOSS² | ~2× yearly license | Small businesses |

| Mid | $40k – $110k | Mar-Kov, Deacom, Datacor, BatchMaster, Sage X3, Vicinity Software | ~2× yearly license | Mid-market companies |

| High | $150k+ | SAP S/4HANA, Oracle Fusion Cloud, Microsoft Dynamics 365 Finance & Supply Chain | ~2× yearly license | Large enterprises |

Cloud solutions usually have lower upfront costs since you pay for the software over time, with $5,000 to $20,000 in the first year of ownership for setup, configuration, and training. Ongoing subscription fees typically range from $1,000 to $30,000 a year.

On-premise software requires a significant initial investment, including licensing, implementation, and training costs. Prices can range from $10,000 to over $100,000. Setup and training can cost between $20,000 and $50,000 and support can range from $1,500 to $20,000.

How to Choose

User-Friendly Interface

- Ease of Use: Prioritize chemical manufacturing software that is intuitive and easy to navigate, with cloud-based options for easier access and maintenance.

- Scalability and Updates: Ensure the software can adapt to the chemical industry’s evolving needs, including handling complex chemical processes and accommodating regulatory changes.

Comprehensive Features and Integrations

- Core Functionalities: Look for software with modules essential for chemical manufacturing, like formula management, batch and lot tracking, hazardous materials handling, inventory management, and quality control.

- Integration Options: Choose software that integrates well with ERP systems and supports industry-specific functionalities like waste management and safety data sheet management.

Industry-Specific Specializations

- Regulatory Compliance: Select software specifically designed to meet the chemical industry’s stringent regulatory requirements, such as REACH, OSHA, and EPA regulations.

- Customizations: Ensure the software can be tailored for the specific chemical manufacturing processes, including custom reactions, blending, and compounding requirements.

Cost-Effective Solutions

- Flexible Pricing Models: Consider software with pricing plans that cater to chemical manufacturers of different scales, from small labs to large industrial plants.

- Transparent Pricing: Opt for products with clear, upfront pricing, which is crucial for budgeting in the chemical manufacturing sector.

Accessible Customer Support

- Support Availability: Ensure the software provider offers strong customer support, preferably with expertise in chemical manufacturing.

- Multiple Support Channels: Look for vendors with a range of support options, including phone, email, live chat, training resources, and knowledge bases.

- Dedicated Assistance: Seek software providers that include dedicated account managers familiar with the chemical industry’s complexities.

Evaluation and Trials:

- Software Demos: Request demos tailored to chemical manufacturing scenarios to assess the software’s capabilities in handling complex chemical processes and compliance management.

- Hands-On Trials: Utilize trial periods to test the software’s practical application in your chemical manufacturing environment, focusing on aspects like formula management, regulatory compliance, and safety.

What Is the Future of the Chemical Industry?

- Circular economy & sustainability - More chemical manufacturers are considering supply levels of non-renewable resources and the environmental impact of the manufacturing process. This focus on sustainability and a circular economy has chemical manufacturers looking into renewable energy, reducing waste, and minimizing emissions. A study by Deloitte predicts three key drivers for chemical industry sustainability in 2025: affordable clean energy, evolving policies, and companies’ ability to create value across interconnected ecosystems.

- 3D Printing - Large chemical manufacturing companies are beginning to use 3D printing for molecular modeling, creating expensive or complex laboratory equipment for a lower cost and creating replacement parts for plant assets to reduce maintenance costs. One of the largest chemical producers, BASF, invested $25 million in 3D printing software.