Best Distribution ERP Software

Distribution ERP software integrates core business functions such as inventory, order, and warehouse management in one platform. We tested various solutions to deliver the best for each sector, from wholesalers to food and beverage distribution.

- Combined ERP and CRM

- Similar interface to MS Word and Outlook

- Integrations with Microsoft applications

- Infinite serialization levels for diverse requirements

- Integrated QC tests throughout product lifecycle

- Seamless regulatory compliance with ERP foundation

- Open architecture for rapid integrations

- Multi-entity support

- Mobile accessibility

We ranked the top systems based on their support for specific distribution industries, including wholesalers, food distributors, 3PL providers, and pharmaceutical distributors.

Follow this guide to discover which distribution ERP system is the best in your industry:

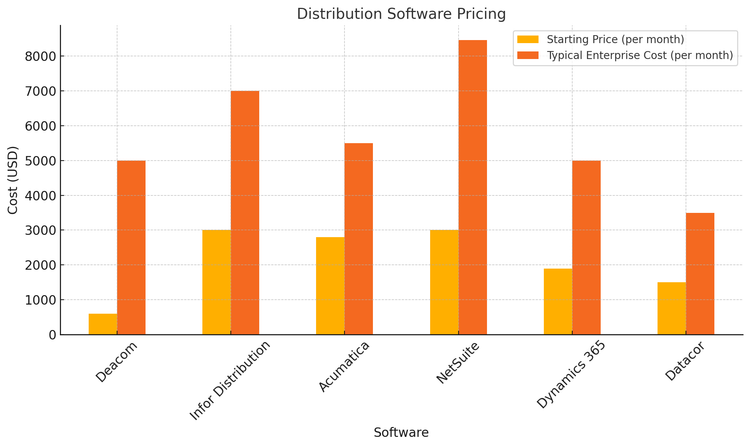

| Software | Best For | Deployment Options | Package Pricing Per Month |

|---|---|---|---|

| Dynamics 365 Business Central | Wholesalers | Cloud, On-Premise | $1,000 - $3,000 |

| Deacom | Food Distribution | Cloud, On-Premise | $500 - $5,000 |

| Acumatica | 3PLs | Cloud, On-Premise | $2,800 - $5,500 |

| NetSuite | Pharmaceuticals | Cloud | $3,000 - $8,500 |

| Epicor Prophet 21 | Building Materials | Cloud, On-Premise | N/A |

| Encompass Distribution Cloud | Beverage Distribution | Cloud | N/A |

| Infor Cloudsuite | Consumer Goods | Cloud, On-Premise | $3,000 - $7,000 |

| Datacor ERP | Chemicals | Cloud, On-Premise | $1,500 - $3,500 |

- Dynamics 365 Business Central: Best for Wholesale

- Deacom: Best for Food Distribution

- Acumatica: Best for 3PLs

- NetSuite: Best for Pharmaceuticals

- Epicor Prophet 21: Best for Building Materials

- Encompass Distribution Cloud: Best for Beverage Distribution

- Infor Cloudsuite: Best for Consumer Goods

- Datacor: Best for Chemicals

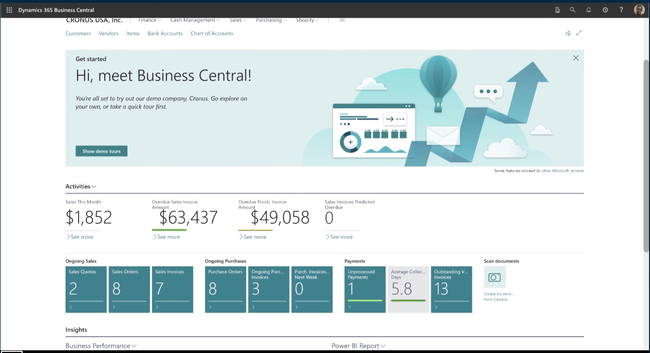

Dynamics 365 Business Central - Best for Wholesale

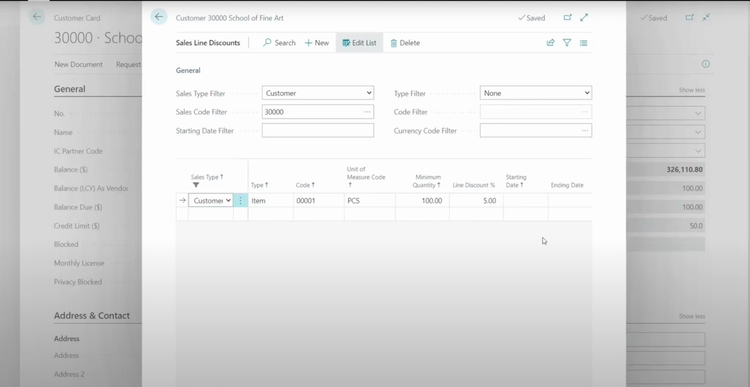

Wholesalers often need an ERP to manage many simultaneous pricing strategies designed to encourage larger bulk orders and repeat customers. Microsoft Dynamics 365 Business Central offers advanced pricing and discount management capabilities. The system features flexible pricing structures, including:

- Customer-Specific Pricing: Prices can be set at the item level for specific customers or customer groups, allowing you to tailor pricing for large retail chains versus smaller, independent stores more effectively.

- Quantity Break Pricing: Specify different unit prices based on order quantities. For example, set a lower price when ordering 20+ items versus 1-19 to incentivize bulk purchases and move larger inventory quantities.

- Date Sensitive Pricing: Set seasonal or time-limited promotional prices to help run time-bound sales. Standard pricing will be automatically reverted after the end date passes.

- Currency-Specific Pricing: Set prices in different currencies if operating internationally. You can define prices in multiple currencies for each item, which will automatically apply the correct price based on the customer’s currency.

It also offers discount capabilities, such as:

- Line Discounts: Apply discounts to individual products or services, such as an overstock item or seasonal clothing.

- Customer Discount Groups: Set a specific discount to a certain group of customers, such as a 10% discount to wholesale buyers on purchases between 2,000 - 4,000 units.

- Best Price Calculation: When multiple discounts are applied to one order and can be combined, Dynamics 365 will stack them to provide the best price. It will also give the client the best discount presented when discounts cannot be stacked.

- Invoice Discounts: If a customer pays an invoice within a certain time period, they may receive a small discount. For example, a 2% discount may apply if the invoice total exceeds a certain amount, such as $1,500, and is paid within 12 days.

By leveraging these pricing and discount capabilities, you can create sophisticated pricing strategies and maintain competitive pricing while protecting profitability.

Read more about Dynamics 365 in our full review.

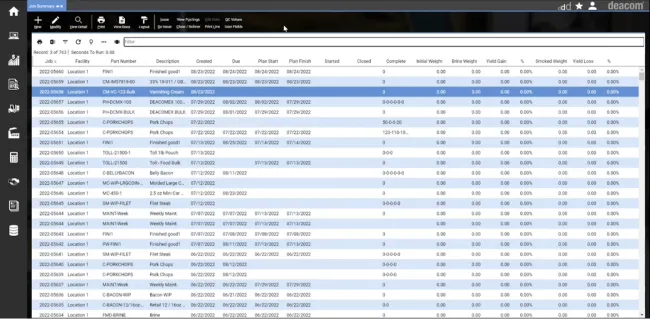

Deacom - Best for Food Distribution

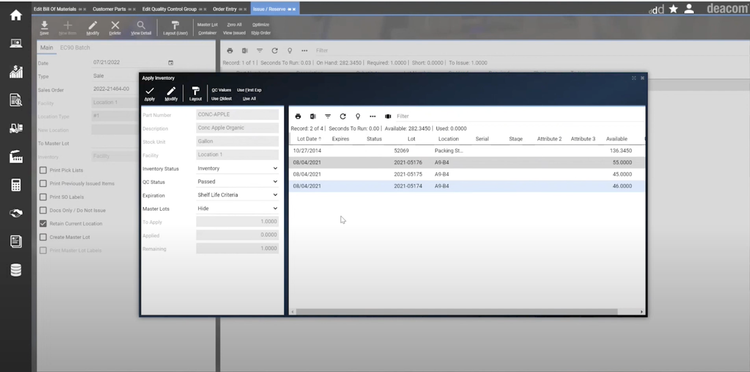

Deacom offers strong lot tracking and traceability functionalities for various food distributors, including meat, dairy, candy, snacks, and consumer packaged goods. The system allows you to track individual lots, showing where and when each was used and who received them. You can find details on everything from raw materials to customer delivery.

With the lot traceability tool, you can drill down into a specific order and receive its entire audit trail. This level of transparency helps you comply with USDA and FDA regulations, like FSMA Section 204, which requires detailed records within 24 hours of a recall. You can also view finished goods shipped, see any adjustments made, and see what inventory is left on hand.

Deacom can track granular attributes for each lot, including quality specifications, supplier information, and expiration dates. Its First Expired, First Out (FEFO) inventory management feature builds on lot traceability by automatically prioritizing lots nearing expiration. This feature helps ensure that ingredients and finished goods closest to expiring are used or shipped first.

While the software offers industry-specific functionalities that can significantly benefit the food industry, some customer reviews report issues with complex menu navigation and a cumbersome user interface.

Read our full review of Deacom to learn more.

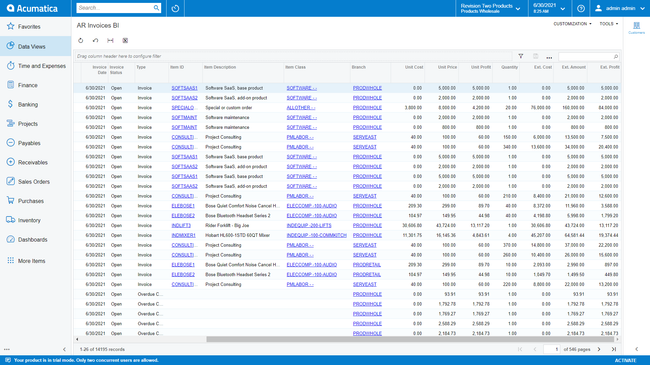

Acumatica - Best for 3PLs

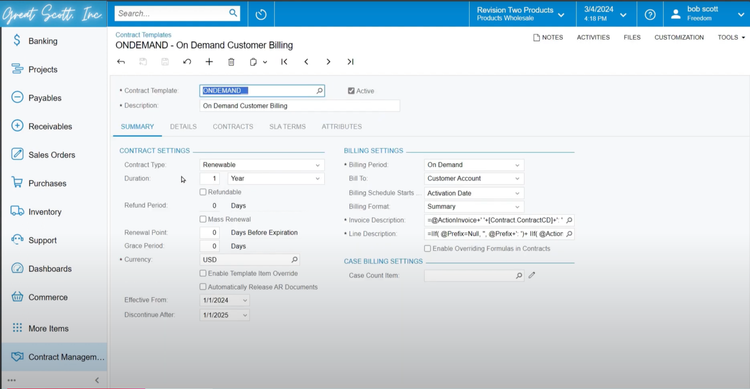

Acumatica’s contract management module can automate client-specific billing scenarios and help you manage complex service agreements. This module features an on-demand customer billing template that supports dynamic contract settings like renewable, expiring, and unlimited agreements, making it easy to set customized service terms for each client.

The system also offers advanced customer billing scenarios, including:

- Fixed Price: A predetermined fee is charged for services, such as $5,000 per month for warehousing and order fulfillment, regardless of the volume of goods stored.

- Cost-Plus: Clients are billed based on actual costs and an agreed-upon markup. This could include labor costs billed plus 20%.

- Time and Materials: Billing is calculated based on specific work performed or resources used. For example, billing $2 per box at 50 boxes would make the total bill $100.

- Milestone: Invoices are based on reaching predetermined project milestones, such as billing a project in three stages. 30% when receiving goods, 30% after storing, and 40% upon completion.

Acumatica can also automate billing based on handling, transportation, storage, and special services provided to clients. The software calculates these fees automatically, reducing manual errors and ensuring accuracy.

The system then allows 3PL customers to view their billing status, inventory, and orders in real time through client-specific dashboards and portals. However, the initial distribution package does not include shipping carrier integration and warehouse management. Adding these functionalities will cost roughly:

- Shipping Carrier Integration:$4,500 - $5,500 license fee, $2,000 - $2,500 annual fee.

- Warehouse Management: $6,000 - $7,000 license fee, $2,500 - $3,000 annual fee.

These advanced features come at a higher price, which may be expensive for small 3PLs. If so, you may want to look into Infoplus WMS.

Learn more about pricing in our full review of Acumatica.

NetSuite - Best for Pharmaceuticals

NetSuite offers a Life Sciences Edition with a more advanced inventory module specifically tuned for pharmaceutical distributors. This helps you manage product lifecycles effectively and minimize issues with expired or soon-to-expire products.

A core feature is its ability to track granular details for every lot, including:

- expiration date

- quantity on hand

- location

- full transaction history

This enables proactive inventory management. For example, this module can automatically generate notifications when inventory lots are approaching expiration dates. This allows you to sell, transfer, or dispose of at-risk stock.

NetSuite’s inventory management module also supports strategies like FEFO to ensure proper stock rotation based on expiration dates. This can help minimize waste and maintain quality and regulatory compliance.

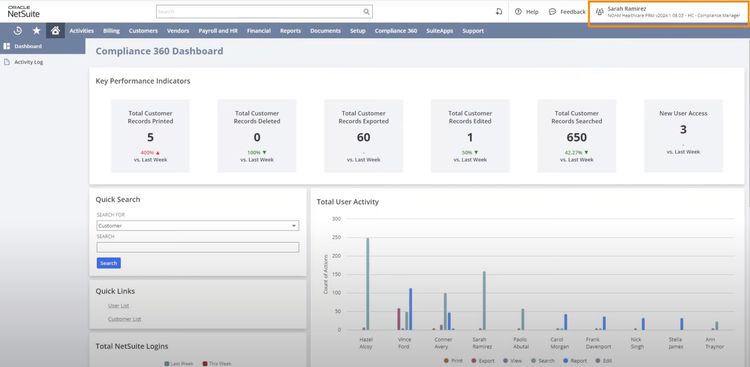

The same detailed tracking functionalities that power inventory management also help you meet regulatory standards. Since compliance starts with accurate inventory data, NetSuite’s full audit trails and traceability tools for every stock-related action help maintain compliance with FDA regulations, including DSCSA requirements. For added support, the Compliance 360 SuiteApp builds on these inventory management foundations by providing tools to monitor data activity, user interactions, and changes to records, ensuring your operations align with industry standards.

NetSuite isn’t the only option for pharmaceuticals. See our sub-vertical guide for more pharmaceutical systems like Blue Link ERP and SYSPRO.

Read more about NetSuite in our full review.

Epicor Prophet 21 - Best for Building Materials

Epicor Prophet 21’s bulk inventory management functionality is designed to manage large, high-volume materials like lumber, steel, and cement. The system integrates real-time data from sales, shipping, and purchasing modules to maintain accurate stock levels.

If a shipment comes in with 500 tons of concrete, you can utilize Epicor’s mobile scanning feature to log the batch into the system, including details like its weight and lot number. The software automatically assigns it to an optimal storage area based on the current inventory layout. For example, a contractor needs 50 tons of concrete and 100 sheets of drywall. Epicor Prophet 21 will automatically calculate your available stock, reserve the requested quantity, and generate a pick list for the warehouse team.

During the loading process, the software can confirm the correct weight and dimensions of the outgoing shipment, ensuring compliance with transportation regulations. A barcode scanner will confirm the lot numbers, and the system will update your inventory. Epicor Prophet 21 is best suited for mid-size to large distributors that handle complex supply chains and high-volume transactions. The system offers cloud-based and on-premise solutions for distributors.

For more details on Epicor Prophet 21, visit our full product review.

Encompass Distribution Cloud - Best for Beverage Distribution

Encompass Distribution Cloud offers a strong route optimization feature to ensure timely deliveries while reducing fuel consumption and travel time.

The system’s route optimization feature assigns a route based on pre-set rules. These factors determine the routes:

- Distance from Distribution Centers: Prioritizes routes based on the proximity to the delivery point, reducing travel time when delivering perishable products.

- Vehicle Capacity: Considers the weight, volume, and types of goods to ensure that the vehicle’s capacity is maximally utilized.

- Delivery Time Windows: Takes into account specific time windows when deliveries are preferred for each customer.

- Driver Availability: Routes are planned based on driver availability, ensuring compliance with labor laws.

- Traffic Patterns: Integrates real-time traffic data to adjust routes and avoid congested areas.

- Delivery Priorities: Prioritizes certain deliveries based on customer needs, service level agreements, or product types, ensuring that the highest-priority deliveries are made first.

Improving route efficiency helps industries like beverages or food maintain product freshness and ensure timely deliveries, upholding your brand’s reputation.

In addition to route optimization, Encompass Distribution Cloud integrates inventory control and warehouse management. These functions directly support route optimization, ensuring products are picked, packed, and ready for dispatch. Orchestra Cloud by Encompass provides an integrated ERP solution specifically designed for the beverage industry, offering tools geared toward breweries and distilleries.

Infor Cloudsuite - Best for Consumer Goods

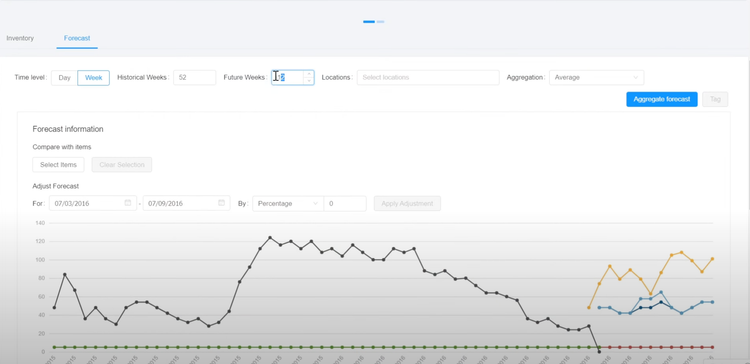

Infor Cloudsuite Distribution’s demand planning feature can automatically process large volumes of data from various sources to create accurate forecasts. Some common sources include:

- Historical Sales Data: The system leverages historical data from transaction records, sales order history, point-of-sale data, and past demand statistics. This data is then used to segment demand into categories based on factors like product type or sales channel to create accurate forecasts.

- Market Trends: Infor uses probabilistic forecasting methods, machine learning algorithms to predict demand based on real-time data, and predictive analytics to deliver accurate forecasts.

- Economic Shifts: The software includes built-in scenario modeling functionality to evaluate different economic scenarios and their potential impact on demand, test different strategies to respond to economic shifts, and revise plans based on economic projections.

- Customer Behavior: The system processes large volumes of customer data in real-time, including point-of-sale transaction data, online browsing and purchase history, and customer demographics.

With this data, you can conduct ‘what-if’ scenario modeling and uncover trends and patterns, helping you optimize inventory and increase efficiency. You can adapt to potential disruptions by getting full visibility into your supply chain; Distribution Cloud consolidates data from suppliers, distribution channels, and warehouses to give you a complete picture of product flows.

Learn more about Infor Cloudsuite in our full review.

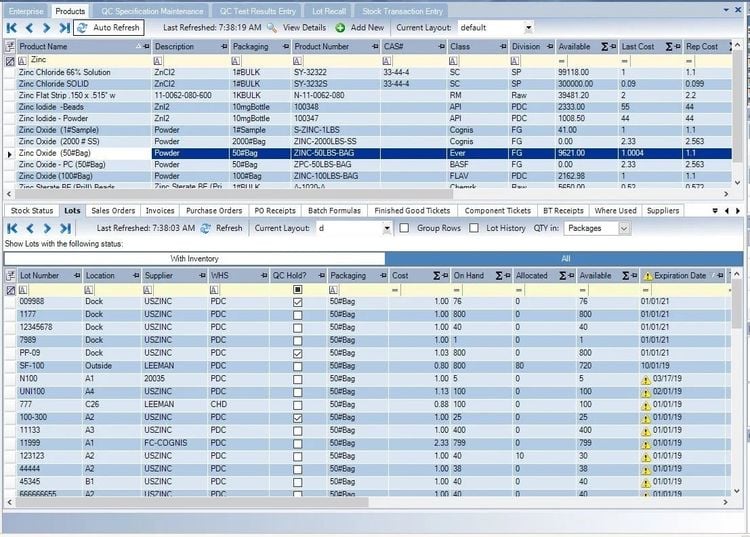

Datacor - Best for Chemicals

Datacor ERP, formerly Chempax, offers specialized tools for the chemical distribution industry, such as hazardous materials management. The ERP integrates government reporting requirements with business operations, allowing you to automatically collect and disperse relevant information, including Department of Transportation (DOT) codes, hazard classifications, and material properties.

With the hazardous materials management functionality, the software can create compliant shipping documents for each order, adhering to OSHA and DOT regulations. It can also create Safety Data Sheets (SDS) for each chemical product. These sheets detail hazard classifications, handling procedures, and emergency measures, which can help reduce compliance risks and ensure safe communication.

Datacor’s hazardous materials management features extend beyond compliance documentation. The software includes tools for tracking quarantined chemicals to verify that off-spec materials are tested before they enter the supply chain. This helps maintain quality and reduces the risk of distributing non-compliant products. The system also allows you to manage rework and off-spec materials efficiently, ensuring that these hazardous products are safely disposed of or reprocessed according to regulatory requirements, which could prevent expensive mistakes.

With the numerous functionalities geared toward chemical distributors, the system can be a bit expensive for smaller companies. If this is the case, you may want to consider a more affordable option, like Accolent ERP by ADS.

Discover more key features in our full review of Datacor.

Other Systems We Like

- SAP Business One: SAP is a good option for online wholesalers, offering integrated eCommerce and omni-channel sales management. The platform can integrate with third-party platforms like Magento, WooCommerce, Shopify, Amazon, and eBay.

- Sage Intacct: Sage recently released a distribution version for small and midsize wholesale distributors. Its key features include real-time inventory tracking, streamlined order management, procurement automation, and financial management.

What is Distribution ERP Software?

Distribution ERP software is a business management system that streamlines the distribution of goods and manages inventory, orders, logistics, and finances. It provides several functionalities to manage the day-to-day operations of wholesale trade and distribution. These end-to-end tools primarily include order management, inventory control, purchasing, accounting, and overall supply chain management. Larger distributors at an enterprise level may need advanced features such as electronic data interchange (EDI) and warehouse management.

Some distributors also install and service the products they sell, like dock-and-door suppliers that manage on-site installation and ongoing maintenance. These hybrid wholesalers need a field-service module to schedule installations, dispatch technicians, and capture service labor and parts. Some distribution ERP supports bolt-on field-service functionality or a built-in module to run accounting, inventory, projects, and service calls all on the same database.

How to Choose the Best Distribution Software

Here’s how to choose the best distribution ERP software for your business:

- Distribution-Specific Features: Prioritize tools like order management, route optimization, multi-location inventory management, demand forecasting, and SKU tracking.

- Inventory Visibility: Distribution often involves managing extensive inventories. Ensure that the software provides real-time visibility into inventory levels across multiple locations and helps prevent overstocking or stockouts.

- EDI (Electronic Data Interchange) Support: If your business relies on EDI for communication with customers and suppliers, confirm that the software supports EDI integration and can handle the necessary transaction types.

- Compliance and Regulatory Support: Depending on your industry, you may need to adhere to specific regulations and compliance standards. Verify that the software can assist you in meeting these requirements.

- Cross-Docking and Transshipment: If you engage in cross-docking or transshipment operations, check if the software supports these advanced distribution strategies.

- Performance Analytics for Distribution: Look for analytics and reporting features that specifically address distribution metrics, such as order fill rates, on-time deliveries, inventory turnover, and warehouse efficiency.

- Multi-Channel Sales Support: If your distribution involves selling through multiple channels (e.g., online, B2B, B2C), ensure the software can effectively manage orders and inventory across these channels.

- Scalability for Distribution Growth: Distribution software should be capable of scaling as your distribution network and operations expand. Confirm that it can accommodate future growth without significant disruptions.

- Field-Service Add-On Module: If you install or maintain the products you distribute, verify the ERP offers an integrated field-service module (like NetSuite or Acumatica) so projects, service billing, and dispatching all live in one system.

Key Features and Benefits

- Order Management: Capture, track, and fulfill orders across your sales channels. This will improve sales visibility and increase the efficiency of your order processing. This includes order entry and fulfillment of sales orders.

- Warehouse Management: Optimize space utilization, pick/pack/ship operations, warehouse processes, and RFID tracking.

- Supply Chain Management: Manage the flow of goods between locations by planning, controlling, and executing the supply chain processes.

- Customer Relationship Management (CRM): Manage customer information, service interactions, and sales processes.

- Compliance: Ensure data protection and adherence to industry standards.

- Improved Inventory Management: Provide real-time visibility into inventory stock levels, track products nearing expiration, and receive alerts when items are low in stock. This allows you to minimize stockouts, reduce waste, and optimize inventory levels.

- Strong Demand Forecasting: Leverage advanced analytics to more accurately predict customer demand by analyzing historical sales data, seasonal trends, and market fluctuations.

- Increased Customer Satisfaction: Ensure accurate inventory counts and fast order fulfillment to increase customer satisfaction by reducing delays and backorders.

- Streamlined Operations: Centralize data and automate workflows across all departments, improving efficiency and reducing manual errors.

Read more about the Benefits of ERP for Logistics and Distribution Industries.

Challenges Distribution ERP Helps Solve

- Inventory Management Issues: Automating reordering processes provides visibility into inventory levels, accurate stock tracking, and avoiding stockouts or overstocking.

- Inefficient Warehouse Operations: Optimizing picking routes and automating receiving, picking, packing, and shipping tasks streamlines warehouse efficiency.

- Supply Chain Visibility: Tracking orders and shipments in real-time provides end-to-end visibility across the supply chain.

- Demand Planning Inconsistencies: Utilizing historical data and predictive analytics to forecast demand reduces the risk of stock shortages or overstock.

- Complex Order Fulfillment: Manging multi-channel sales, drop shipments, and backorders to ensure accurate timeline deliveries while balancing fulfillment methods.

- Compliance and Reporting Challenges: Automating compliance documentation and generating real-time reports to reduce audit risks and comply with industry standards.

Trends in Distribution ERP Software

- AI and Machine Learning: ERP developers are embedding AI functionalities into their solutions that can help you improve demand forecasting accuracy and inventory levels. This integration can provide actionable insights based on historical sales data, such as product suggestions.

- Omnichannel Retail Capabilities: ERP systems can now support sales across multiple online or offline channels. Integrations with eCommerce platforms like Amazon, Shopify, and WooCommerce ensure accurate stock updates across all channels.

- Cloud-Based Applications: Cloud ERP solutions are becoming increasingly popular due to their lower IT costs and frequent updates. These systems can also grow with your business and allow you to access your database anywhere.

Pricing

Distribution ERP software pricing can vary depending on several factors. Netsuite, for example, costs around $2,999 base price plus $99/user/month for up to 30 users on their Distribution Standard plan. However, depending on your company’s needs, you may find a higher or lower price range.

The biggest cost variables of distribution ERP software will be the:

- Number of users

- Module additions

- Required integrations

- Ongoing support and maintenance

- Cloud-based or on-premise deployment