ProShop ERP

6 Reviews 5/5 ★ ★ ★ ★ ★A cloud-based manufacturing ERP for small to midsized manufacturers that includes ERP, MES, and QMS modules.

Product Overview

ProShop ERP is a software designed to enhance manufacturing efficiency, particularly in aerospace contract manufacturing. It offers a comprehensive suite of modules, including audit reports, inventory management, job costing, quality management, scheduling, and more.Pros

- Stores historical data on run descriptions, process dev, BOMs, etc.

- Supports cross-module and multi-level reports

Cons

- Limited customization in areas like part labels

- Pricing quote requires consultation

Target Market

Small to midsize manufacturing companies in oil & energy, aviation & aerospace, defense & space, and machinery.ProShop ERP includes functions for office management, QMS functions for AS9100 systems, and MES functions for shop floor efficiency. It’s specifically designed for aerospace contract manufacturers in the Pacific Northwest.

ProShop ERP Key Features

ERP

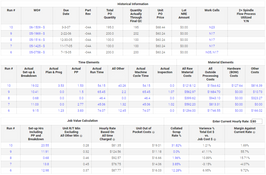

- Job Costing: Accurately tracks costs associated with each job to enhance project profitability analysis.

- Inventory Management: Offers real-time control over stock levels, reducing carrying costs and stockouts.

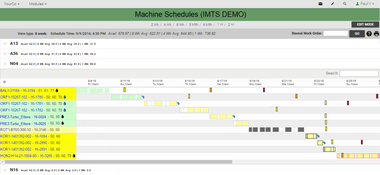

- Scheduling: Efficiently plans and manages production schedules to minimize downtime.

- Track Time: Allows employees to log work hours, aiding labor cost monitoring and payroll accuracy.

- Create Quotes: Generates accurate customer quotes, ensuring competitive and profitable pricing.

- Streamline Purchasing: Simplifies the purchasing process, from requisition to order, for timely procurement.

- Manage Customer Purchase Orders: Supports the accurate and timely fulfillment of customer orders.

- Estimating: Assists in creating accurate job estimates to win contracts and plan resources effectively.

MES

- Manage Tooling: Ensures availability of required tools for manufacturing processes.

- User Access: Allows user role management for data security and access control.

- Generate Work Orders: Streamlines production workflows and provides clear guidance for shop floor operations.

- Process Return Material Authorizations (RMA): Simplifies handling RMAs for returning and replacing defective products.

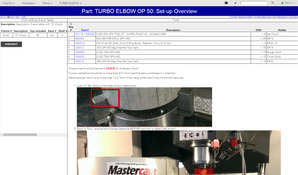

- Visual Work Instructions Ties photos, videos, and PDFs to part numbers, with revision-tracking and sign-offs.

- BOM Traceability: Links every component to specific work orders and assemblies.

QMS

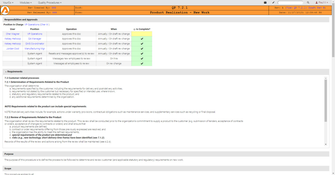

- Quality Manual: Ensures adherence to quality standards and processes throughout manufacturing.

- Non-Conformance Reports (NCR): Facilitate identifying and resolving quality issues.

- Preventative Action: Implements proactive quality management plans to prevent potential issues.

- Audit Reports: Support tracking and documenting changes in the system for transparency and compliance.

- Compliance Tools: Supports adherence to industry standards in manufacturing processes.

- Corrective and Preventive Actions Module: Sends real-time notifications and task queues; fully links work orders, POs, audits, NCRs, and customer complaints.

ProShop ERP Pricing

Businesses must contact ProShop directly to receive a custom price quote, as prices are not disclosed publicly.

Pricing is based on the number of total employees in your shop, with user seats for different roles and access levels:

- Shop users

- Office users

- Admin/executive users

Product Overview

Developer Overview

Related Products

User Reviews of ProShop ERP

Write a ReviewProShop ERP Review

The scheduling in our old ERP system didn’t work as advertised. With our old ERP we were about 75% on-time. Since using Proshop, we’ve maintained over 95% on-time delivery since we started over a year ago.

ProShop ERP Review

ProShop was one of the best business decisions we’ve ever made. We’ve seen huge improvements in places we never expected. It’s been a total game changer for us.

ProShop keeps quality at the heart of everything

ProShop keeps quality at the heart of everything it does. It’s helped us dramatically reduce the time we spend on quality functions such as getting ready for audits, preparing document packages for final inspection, and helped us improve part quality by monitoring in-process inspection in real time.

ProShop ERP Review

Everything is under one roof. It’s not 5-6 different systems anymore. Now the shop crew has a full feedback loop. They can give us information, we can give them information. It’s all real-time…we can’t imagine living without it.

"I cannot even access information this quickly"

I was giving tour of our shop last week to aerospace client and had to take opportunity to be a bit of a fan boy and show off proshop (I consider it my baby giving the implementation responsibilities I had). No joke they were in awe and I quote “I cannot even access information this quickly with our system!”. He was so impressed he had to take a picture of one of his work orders we happen to be running at time.

Our experience with ProShop has been very positive

Our experience with ProShop has been very positive! It has been shown to be a very powerful tool. We have tried other tools in the past to keep track of jobs, work orders, due dates, etc. but nothing came close to the full package that ProShop provides. My favorite feature, as an offsite programmer, would be the ability to store and capture tribal knowledge and information within ProShop, whether it be in the run description, process dev, BOM, cots, etc. Having somewhere to store information is so important not only for me, but for the rest of the team. There is less back and forth and less confusion on due dates, machines, availability, you name it.